full-service CO2 laser cutting services!

FOR A FAST RESPONSE, EMAIL YOUR FILES TO americanlaserco@gmail.com

or call us at 213-866-4738 for questions. please note we cannot provide quotes over the phone. A vector file is required for the quoting process. If you do not have a vector file feel free to reach out to us and we can discuss your options.

We offer fast and free email quotes, and our average production turnaround time is 3 to 5 business days to make high-quality laser parts.

Rush projects are available in 1 to 2 days.

We now offer cuts on acrylic up to 1/2 inch

American Laser Cutter: Your Partner in Precision and Innovation

American Laser Cutter is a leading provider of professional laser cutting and engraving services in Los Angeles. With our state-of-the-art equipment and team of skilled technicians, we offer a wide range of laser cutting solutions to meet the needs of businesses and individuals alike.

Our Services:

Custom Laser Cutting: Our team can create custom laser-cut pieces to your exact specifications. Whether you need intricate signage, personalized products, or architectural models, we can bring your vision to life.

Professional laser cutting services offer precise and efficient cutting solutions for a wide range of materials, including wood, acrylic, fabric, and more. These services are ideal for businesses and individuals who need high-quality custom parts, prototypes, or products. Professional laser cutting often involves advanced equipment and skilled technicians who can handle complex designs and large-scale production.

Prototyping: Need to quickly and efficiently create prototypes for your new product? Our laser cutting services can help you turn your ideas into tangible objects.

Production: For larger-scale production runs, we can handle the entire process from design to manufacturing.

LASER CUTTER EXPORT SETTINGS for files

DXF, PDF, or AI only - AutoCAD 08 - 2013 - Export in millimeters - send as a cut-ready file, not a blueprint

Export text as curves (not font) Export bitmap as PNG - Unfilled (just the outline) - .001 or hairline in Corel

Red For Cut - Blue For Etch - Green For Score Line

include a 25 mm square on your page for size referencing or give us the file dimensions please make sure you do

not have multiple pages layered on top of each other or artwork doubling on itself. They will all export together on a single page. Everything must be on one page no hidden pages. if your file is exporting in an incorrect size please make sure that all of your measurements are set to millimeters before exporting. We need a min of .25 in bleed room from the edge of the material. If you Don’t have bleed room please tell us and we will see if it can be jigged.

The big bed is 4 x 5 feet max the max cut is 46 x 58. Our standard beds are 3' x 4' with a max cut of 34 x 46 in. For larger projects, it is best to try to design to the smaller machine size. Otherwise, if we can only use one machine on your project, it may increase the cost.

LASER CUTTING MATERIALS WE STOCK

1/4 Wood

1/4 Acrylic (clear, black, white. Other colors can be ordered)

1/8 wood

1/8 Acrylic (clear, black, white. Other colors can be ordered)

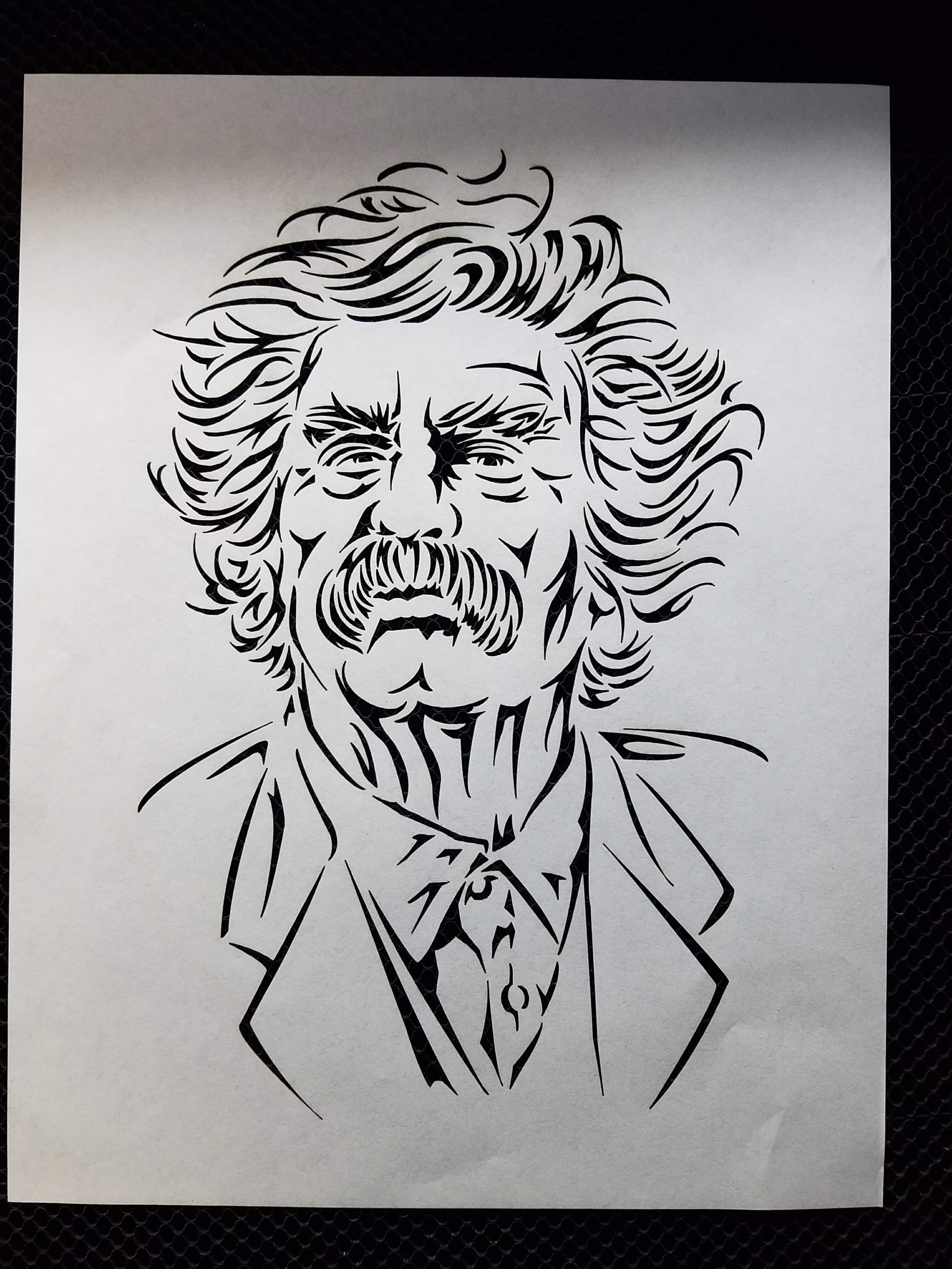

Stencil material (oil board)

OTHER COLORS, MATERIALS, AND THICKNESSES CAN BE ORDERED. There are some random colors and thicknesses in the shop.

Feel free to bring in your own materials. If they are not on the safety list, please email us at americanlaserco@gmail.com with a manufacturer's safety data sheet.

Please note that if it is on the never cut list, we absolutely cannot cut it for our own safety, which includes any PVC product.

HOW IS LASER CUTTING PRICED?

Laser cutting is typically priced by the hour, with the cost depending on the power of the laser cutter and the complexity of the design. Higher-powered laser cutters can cut through thicker materials faster, so they are generally less expensive to use.

Laser cutting services also charge differently for simple and complex designs. Simple designs can be cut quickly and easily, while complex designs may take longer to cut and may require additional time. We use a quoting program, which is why a vector file is required for the quote.

“All we do is Laser cutting and these guys are professionals. We have been working together for a little bit now and they are pretty much my main supplier at this point.*****”

— L

WHAT MATERIALS CAN BE LASER CUT?

SAFE MATERIALS

Professional laser cutting services can cut or etch a variety of materials, including wood, paper, cork, and some plastics. Etching can be done on almost any safe surface, making it a versatile tool for a variety of applications.

Material

Many kinds of wood

Plywood/Composite woods

MDF/Engineered woods

Paper, card stock

Cardboard, carton

Cork

Acrylic/Plexiglas/PMMA

Mylar

Solid Styrene

Depron foam

Gator foam

Cloth/felt/hemp/cotton

Leather/Suede

Magnetic Sheet

NON-CHLORINE-containing rubber

Coroplast ('corrugated plastic')

NEVER CUT THESE MATERIALS

Material

PVC (Poly Vinyl Chloride)/vinyl/pleather/artificial leather/chemically tanned and colored leather

Polycarbonate/Lexan

ABS

HDPE/milk bottle plastic

Polystyrene Foam

Polypropylene Foam

Epoxy

Fiberglass

Coated Carbon Fiber

Any foodstuff ( such as meat, seaweed 'nori' sheets, cookie dough, bread, tortillas... )

Material with Sticky Glue Backing (glue dependent)

“Jonathan did a nice job cutting for me on several work and personal projects in plastic. They have a large machine with large capacity.*****”

— Dev

WE DON'T JUST LASER CUT WE ALSO LASER ENGRAVE

We don't just laser cut, we also offer laser engraving services. We can engrave on a variety of materials. Engraving is a great way to add a personal touch to your projects.

THE PROS OF LASER CUTTING

One of the biggest advantages of using a laser engraving machine is that it allows you to make custom products with unique designs. You can even add text to your product so that it looks professional. Another advantage is that laser engravers are very fast. It takes less than an hour to complete one project.

LASER CUTTING RESOURCES

recommended designer - https://www.fiverr.com/calondesainer

recommended courier - https://www.roadie.com

*Please note we are not responsible for defective cuts due to file errors or for material defects if you provide your own material.

American Laser Cutter, based in Los Angeles, offers a comprehensive suite of laser cutting solutions tailored for both individuals and businesses. We distinguish ourselves through a unique blend of accessibility, expertise, and advanced technology. Our core offerings include DIY (Do-It-Yourself) laser cutting services, where clients can rent and operate industrial-grade CO2 laser cutters, including unique large-format machines (3'x4' and 4'x5') unparalleled for self-service in LA. Complementing this, we provide professional laser cutting, engraving, etching, and scoring services for those preferring a hands-off approach or requiring large-scale production, guaranteeing fast turnaround times. We specialize in a wide array of materials such as wood, acrylic (including 1/2 inch thick acrylic), fabric, leather, paper, cardboard, and foam, and even stock common plexiglass and plywood for client convenience. Beyond direct cutting, American Laser Cutter is a true laser hub, offering expert training, including an "Intro to LightBurn" course available remotely or on-site, to empower users with software mastery and material knowledge. We also provide laser cutter repair and maintenance services, leveraging over a decade of experience to support clients with our machines, ensuring consistent operation and offering valuable technical support during all DIY sessions.