American Laser Cutter: Your Precision Cutting Partner in Los Angeles

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

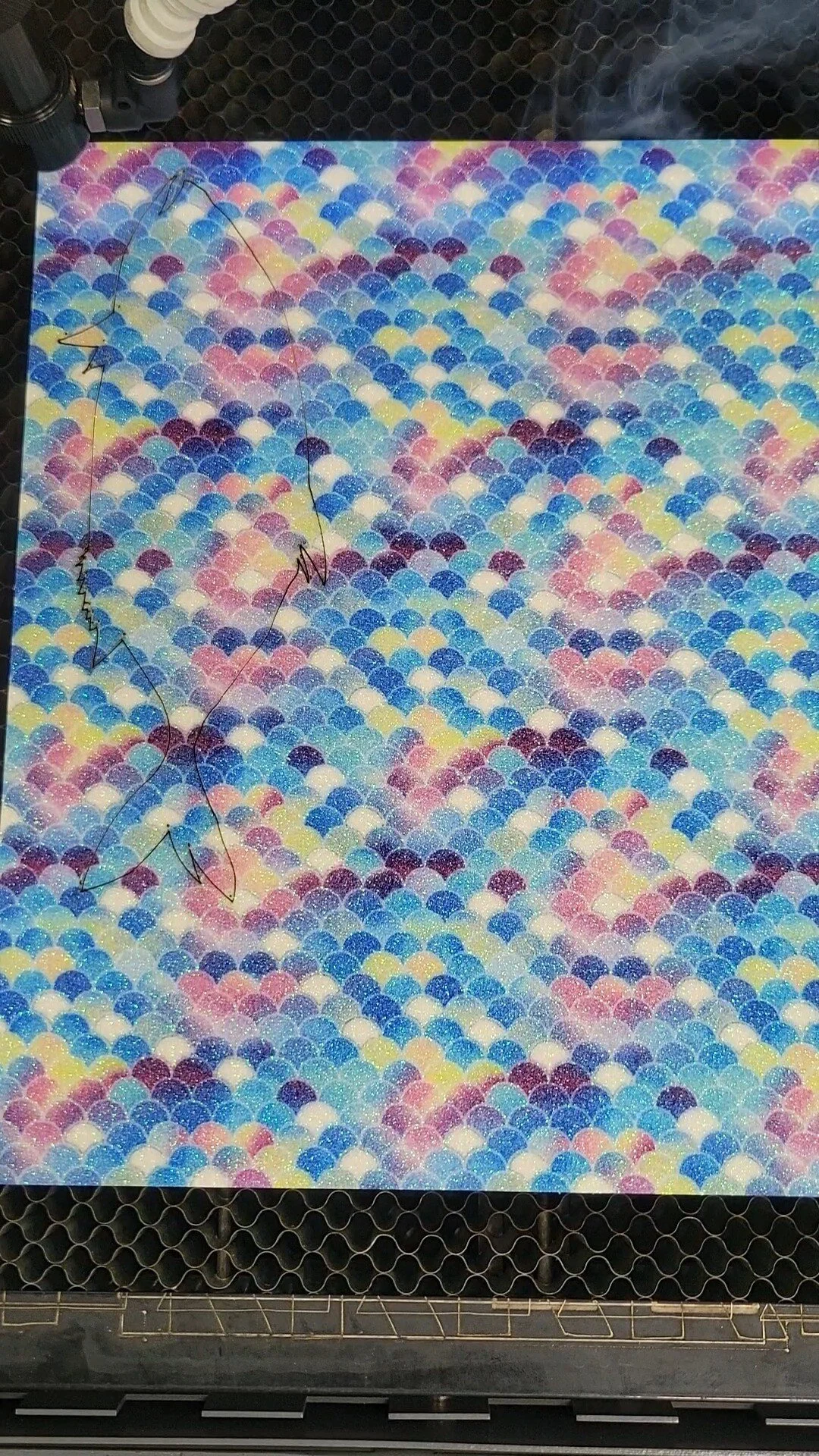

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

repairing a laser cutter

When it comes to repairing a laser cutter, having the right tools can make all the difference. Here are some of the best tools we recommend using when repairing a laser cutter:

1. Multimeter: A multimeter is an essential tool for any laser cutter technician. It can help you determine if there are any electrical issues with the cutter, such as a blown fuse or a faulty wire.

2. Allen Wrench Set: Most of the screws and bolts on a laser cutter are likely to be hexagonal in shape. That's why having an Allen wrench set of various sizes is crucial to effectively loosen or tighten screws and bolts.

3. Needle-nose Pliers: These come in handy when you need to reach into tight spaces to grab a wire or hold onto a screw while you're tightening it.

4. Screwdriver Set: A screwdriver set, particularly one with both Phillips and flat-head screwdrivers, is essential for any laser cutter repair.

5. Lubricant: A good lubricant will help keep the moving parts of your laser cutter running smoothly.

Whether you're a professional technician or a DIY enthusiast, having these tools on hand will help you effectively repair your laser cutter. But remember, safety should always come first, so be sure to wear the appropriate protective gear and follow all safety protocols when dealing with a laser cutter.

Laser cutters are becoming more and more popular, and for good reason.

Laser cutters are becoming more and more popular, and for good reason. They are versatile, fast, and can produce incredibly precise cuts. If you're wondering whether or not you should invest in a laser cutter, here are 5 reasons why you should consider doing so:

1. It's versatile: Whether you're a DIY enthusiast, artist, or small business owner, a laser cutter can be used for a wide range of applications. From creating custom signage and jewelry, to prototyping mechanical parts and cutting fabric, a laser cutter can handle it all.

2. It's fast: Unlike traditional cutting methods, a laser cutter is incredibly fast. It can cut through materials like wood and acrylic in a matter of seconds, making it ideal for projects with tight deadlines.

3. It's precise: Accuracy is key in many projects, and a laser cutter is capable of producing incredibly precise cuts. This means you can create intricate designs and patterns with ease, and it's less likely that you'll need to fix mistakes or re-cut materials.

4. It's cost-effective: While the initial investment in purchasing a laser cutter can be high, the cost savings over time can be substantial. You'll no longer need to pay for outsourcing or expensive equipment rentals, and you can easily create your own products and designs.

5. It's fun: Let's face it, working with a laser cutter can be incredibly fun and rewarding. You'll get to watch your designs come to life in a matter of minutes, and the possibilities for creativity are endless!

Overall, a laser cutter is a great investment for anyone looking to expand their creative or entrepreneurial pursuits. With the right investment and a little bit of practice, a laser cutter can open up a world of possibilities for your projects and designs.

Choosing the right laser cutting supplier

Laser cutting is an important process in many industries, from automotive to electronics. Choosing the right laser cutting supplier can be the difference between a successful project and a costly failure. Here are 5 key factors to consider when selecting a laser cutting supplier:

1. Experience and Reputation: Look for a supplier with extensive experience in laser cutting, and a strong reputation for quality work and customer satisfaction.

2. Equipment and Capabilities: Make sure the supplier has the right equipment and capabilities to handle your specific project requirements. Look for suppliers with a range of laser cutting machines that can handle a variety of materials and thicknesses.

3. Quality Control and Certifications: Quality control is crucial in laser cutting. Look for a supplier with robust quality control processes. This ensures that your parts are manufactured to the highest standards.

4. Turnaround Time: Ask about the supplier's turnaround time and make sure it aligns with your project schedule. A reliable supplier should be able to provide fast turnaround times without sacrificing quality.

5. Customer Service: Finally, make sure the supplier provides excellent customer service. Look for a supplier that is responsive, communicates clearly and is committed to meeting your needs.

Choosing the right laser cutting supplier is key to the success of your project. By carefully considering these factors, you can find a supplier that meets your needs, delivers high-quality work, and helps you achieve your project goals.

Professional laser cutting

Laser cutting and engraving have rapidly become some of the most popular forms of industrial cutting and printing techniques over the last few years, largely thanks to the seamless results they can achieve. But, what is professional laser cutting and engraving, and how do you know the right service for your needs?

Professional laser cutting and engraving services offer precise and efficient cutting and engraving solutions for a wide range of materials. The services are performed with the use of high-precision and highly advanced laser technology.

Laser cutting works by directing a laser beam onto the targeted material, which vaporizes or melts the material, creating the required shape. This technique is ideal for materials such as wood, acrylic, glass, metal, and plastics. Engraving, on the other hand, utilizes a similar laser beam to etch or engrave a design or text onto the material's surface.

Professional laser cutting and engraving services offer precision laser cutting services that are ideal for intricate designs, patterns, or shapes. You can also have your materials cut to measure or engraved according to specific designs that meet and exceed your expectations.

When selecting a professional laser cutting and engraving service, it is essential to consider experts who can offer you a personalized service from the design phase right up to the delivery of your finished product. Choose a service provider that has an excellent track record, with top-notch customer service and a friendly team that can guide you through the process of creating your desired laser cutting and engraving projects.

Ultimately, professional laser cutting and engraving services can transform the way you approach your projects. With high-precision, detailed designs, and seamless finishes, you can achieve top-quality results for all your cutting and engraving needs. Contact a reputable laser service provider today to unlock the true potential of laser technology.

Laser cutting and engraving have rapidly become some of the most popular forms of industrial cutting and printing techniques over the last few years

Laser cutting and engraving have rapidly become some of the most popular forms of industrial cutting and printing techniques over the last few years, largely thanks to the seamless results they can achieve. But, what is professional laser cutting and engraving, and how do you know the right service for your needs?

Professional laser cutting and engraving services offer precise and efficient cutting and engraving solutions for a wide range of materials. The services are performed with the use of high-precision and highly advanced laser technology.

Laser cutting works by directing a laser beam onto the targeted material, which vaporizes or melts the material, creating the required shape. This technique is ideal for materials such as wood, acrylic, glass, metal, and plastics. Engraving, on the other hand, utilizes a similar laser beam to etch or engrave a design or text onto the material's surface.

Professional laser cutting and engraving services offer precision laser cutting services that are ideal for intricate designs, patterns, or shapes. You can also have your materials cut to measure or engraved according to specific designs that meet and exceed your expectations.

When selecting a professional laser cutting and engraving service, it is essential to consider experts who can offer you a personalized service from the design phase right up to the delivery of your finished product. Choose a service provider that has an excellent track record, with top-notch customer service and a friendly team that can guide you through the process of creating your desired laser cutting and engraving projects.

Ultimately, professional laser cutting and engraving services can transform the way you approach your projects. With high-precision, detailed designs, and seamless finishes, you can achieve top-quality results for all your cutting and engraving needs. Contact a reputable laser service provider today to unlock the true potential of laser technology.

Art is amazing, and so are artists

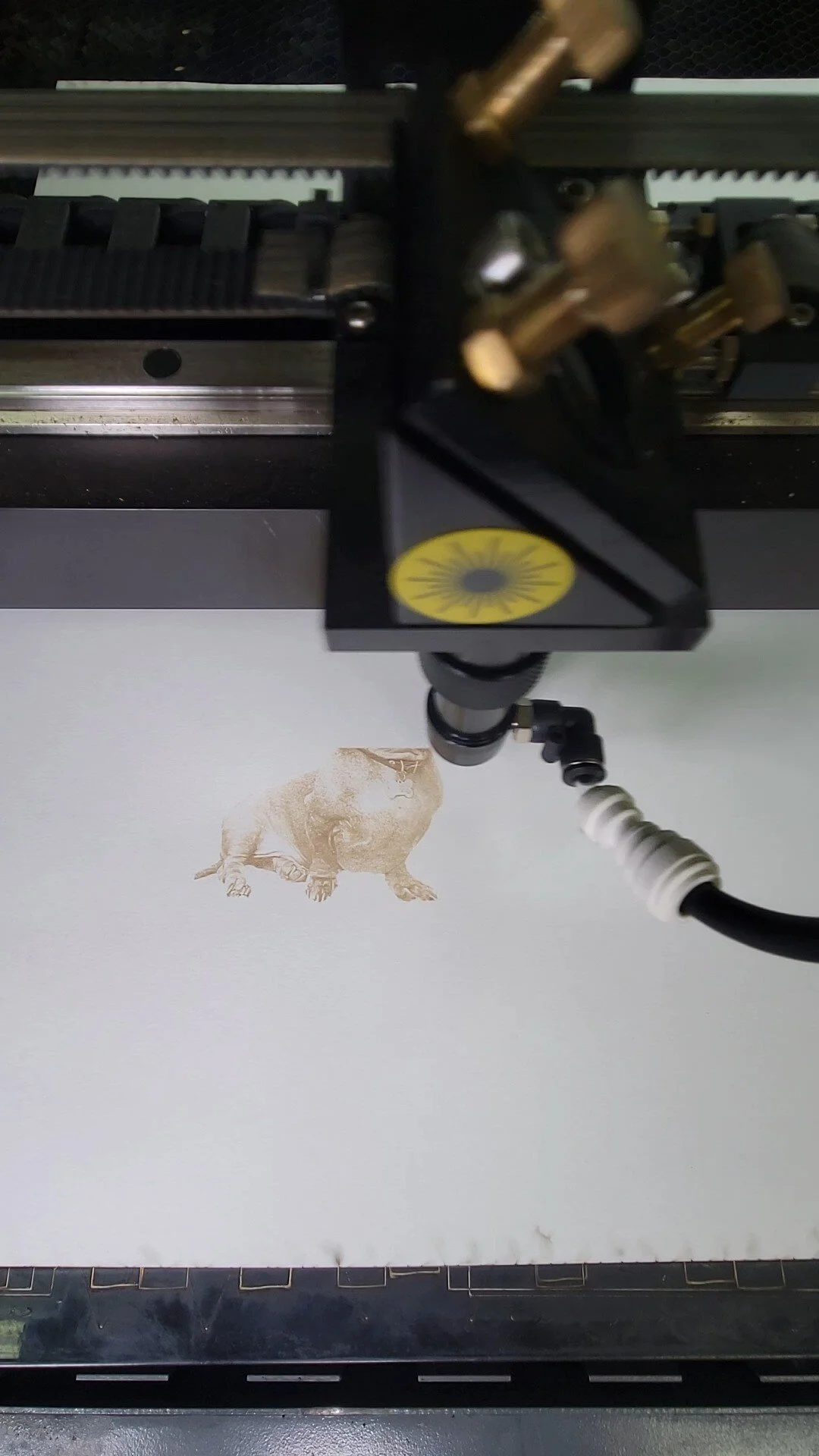

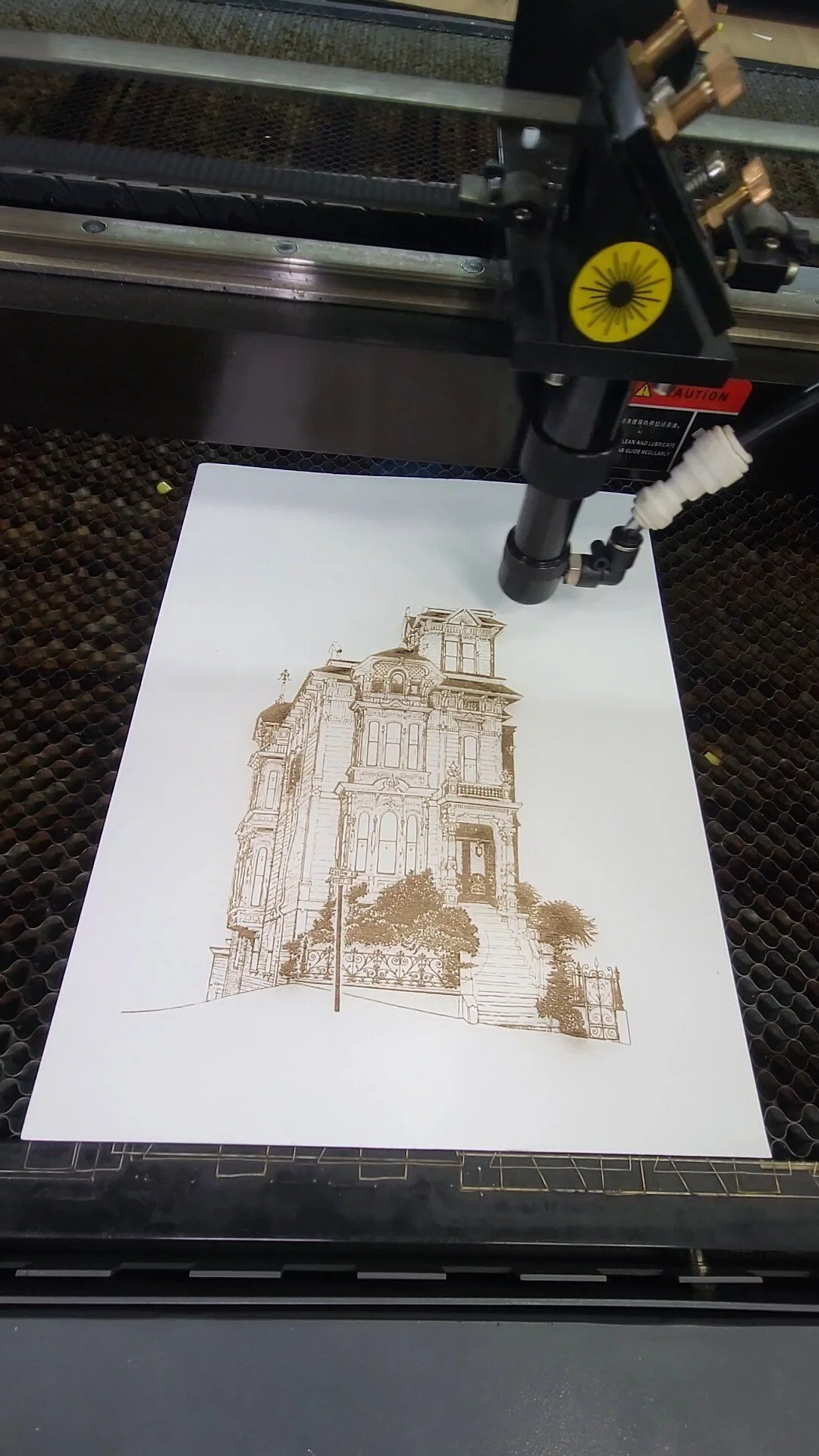

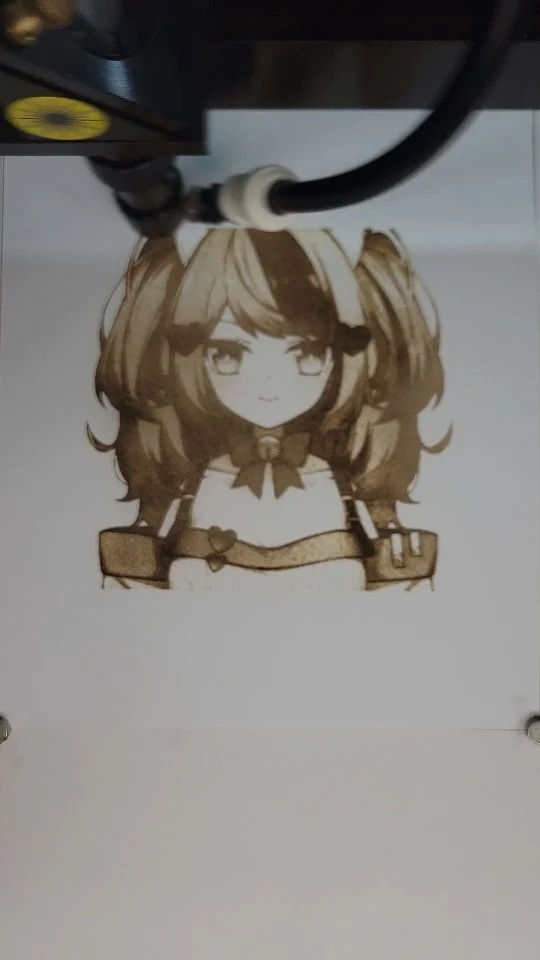

Art is amazing, and so are artists. Their unique perspective and talent allow them to create something awe-inspiring and thought-provoking. One such artist, who has recently caught our attention, is [Name]. What's unique about their art is that they use a laser cutter to create their masterpieces.

The precision and control of the laser allowed the artist to create intricate designs, impossible to make by hand. Their use of a laser cutter makes the artwork elusive, intriguing, and gives it a modern edge. It's not only the result that's impressive, but the process behind it. Watching the artist work and seeing the laser cutter transform the material into art is a mesmerizing experience.

The inspiration for their artwork is derived from elements found in nature and science-fiction themes. Looking closely at the art, you can see how the artist used lines, texture, and layers to add depth and meaning. Their work is something you will want to explore slowly, to appreciate the details and the emotions behind them.

In conclusion, the laser cutter is an innovative tool that pushes the boundaries of art. It allows for a new level of creativity and precision. [Artist's name] has shown us how masterfully they have used this tool to create something beautiful while challenging the viewer's imagination. If you have the opportunity to see their art in person, don't miss it. You never know, it could inspire you to create your own masterpiece!

Starting and running a business can be tough

Starting and running a business can be tough, but with the right tools and strategies, you can take your venture to the next level. One such tool is a laser cutter - a machine that uses a high-powered laser beam to cut, etch, and engrave various materials, such as wood, plastic, acrylic, leather, and fabric. But how exactly can a laser cutter help your business grow?

First and foremost, a laser cutter can increase your production rate and efficiency. With its precise and fast cutting capabilities, you can create high-quality and intricate designs in less time than it would take with traditional methods. This means you can fulfill more orders, meet tight deadlines, and take on larger projects.

On top of that, a laser cutter allows for customization and personalization. You can offer your clients unique and personalized products, such as engraved names, logos, or designs. This sets you apart from your competitors and lets you tap into niche markets and customer segments that value bespoke items.

Moreover, a laser cutter can help you reduce waste, costs, and resources. Unlike other cutting methods that generate a lot of scrap materials, a laser cutter produces minimal waste and uses less raw materials. Plus, you can use it to recycle and repurpose materials, such as scrap wood or acrylic, for other projects.

Beyond its practical benefits, a laser cutter also opens up new creative possibilities for your business. You can experiment with different materials, colors, and shapes to create unique and innovative products that capture your brand identity and values. You can also collaborate with designers, artists, or makers to bring your ideas to life and showcase your vision.

In conclusion, a laser cutter is a powerful tool for any business that wants to grow and thrive. From increasing productivity and customization to reducing waste and fostering creativity, a laser cutter offers a range of benefits that can give you a competitive edge in the market. So why not consider investing in one today and unlock your business's potential?

Do I need a file for laser cutting?

Laser cutting technology has gained significant popularity in recent times. It is commonly used in various industries to create precise cuts on different materials. However, many people who are new to laser cutting may be unsure whether they need to prepare a file before starting a laser cutting project.

The answer to this question is yes, you need to prepare a file for laser cutting. A file is essential in laser cutting as it provides the instructions that the laser cutting machine uses to cut through the material. The file includes the design for the object you want to create and instructions for the laser cutter to follow. Without a file, the laser cutter cannot begin the cutting process.

In preparing a file for laser cutting, there are some important considerations to keep in mind. First, you need to choose the right file format. The most commonly used file formats for laser cutting include SVG, DXF, and AI. Ensure to check with your laser cutting service provider to determine the file format they prefer.

Another crucial consideration is the design itself. The design should be in line with the cutting requirements, such as the thickness of the material and the precision required for the cuts. You should ensure that the lines in your design are continuous, and there are no overlaps or gaps that could result in a distorted cutting pattern.

Lastly, ensure that your file's dimensions match those of the material you intend to cut. A mismatch in dimensions can lead to unusable or distorted cuts. It is also essential to consult with your laser cutting service provider on their material size specifications.

In conclusion, to have a successful laser cutting project, you need to prepare a file that includes the design and cutting instructions. The file should be in the correct format, have an appropriate design, and match the material's dimensions. By following these simple guidelines, you will enjoy the benefits of laser cutting technology to create precise and intricate designs on a wide variety of materials.

laser cutter problem

If you own a laser cutter, you know how beneficial it can be for your projects. However, like any other machine, it can encounter some problems from time to time. Here are the top 5 problems you may encounter with your laser cutter:

1. Alignment issues: Improper alignment of the laser can affect the quality of your cuts. Make sure to check the alignment of the laser on a regular basis.

2. Poor cutting results: If you are experiencing poor cutting results, it could be due to a variety of factors, including improper settings or a dull laser. Check your settings and make sure your laser is clean and sharp.

3. Material not cutting all the way through: If your material isn't cutting all the way through, it could be due to the speed, power, or focus of the laser. Adjust these settings accordingly.

4. Flames and smoke: Laser cutters can create flames and smoke, which can pose a safety hazard. Make sure your workspace is well-ventilated and monitor your machine to prevent any potential hazards.

5. Malfunctions or errors: If your laser cutter is malfunctioning or displaying any error messages, consult your user manual or reach out to a professional for assistance.

With proper maintenance and troubleshooting, you can keep your laser cutter running smoothly and minimize any potential problems. Happy cutting!

laser cutting suppliers

Laser cutting is an important process in many industries, from automotive to electronics. Choosing the right laser cutting supplier can be the difference between a successful project and a costly failure. Here are 5 key factors to consider when selecting a laser cutting supplier:

1. Experience and Reputation: Look for a supplier with extensive experience in laser cutting, and a strong reputation for quality work and customer satisfaction.

2. Equipment and Capabilities: Make sure the supplier has the right equipment and capabilities to handle your specific project requirements. Look for suppliers with a range of laser cutting machines that can handle a variety of materials and thicknesses.

3. Quality Control and Certifications: Quality control is crucial in laser cutting. Look for a supplier with robust quality control processes. This ensures that your parts are manufactured to the highest standards.

4. Turnaround Time: Ask about the supplier's turnaround time and make sure it aligns with your project schedule. A reliable supplier should be able to provide fast turnaround times without sacrificing quality.

5. Customer Service: Finally, make sure the supplier provides excellent customer service. Look for a supplier that is responsive, communicates clearly and is committed to meeting your needs.

Choosing the right laser cutting supplier is key to the success of your project. By carefully considering these factors, you can find a supplier that meets your needs, delivers high-quality work, and helps you achieve your project goals.

WHAT IS A DIODE LASER CUTTER?

If you're in the market for a diode laser cutter, you've come to the right place. In this comprehensive guide, we'll cover everything you need to know about diode laser cutters, including how they work, what to look for when shopping for one, and tips for using them. We'll start by discussing how diode laser cutters work. Then, we'll move on to talking about what to look for when you're shopping for one of these machines. After that, we'll share some tips for using your diode laser cutter once you have it. So without further ado, let's get started! How do diode laser cutters work? A diode laser cutter is a machine that uses a laser to cut materials. The laser is directed through a lens, which focuses the light into a small beam. This beam is then directed at the material that you want to cut. The material is usually placed on a table that can move back and forth so that the beam can cut it into any shape that you desire. What should you look for when shopping for a diode laser cutter? There are several things that you should keep in mind when you're shopping for a diode laser cutter. First, consider the power of the laser. You'll want to make sure that the laser is powerful enough to cut through the materials that you want to use it on. Second, take into account the size of the machine. You'll need to make sure that it's large enough to accommodate the materials that you want to cut, but not so large that it's cumbersome to use. Finally, consider the price of the machine. Diode laser cutters can range in price from a few hundred dollars to several thousand dollars. Tips for using your diode laser utterance you have your diode laser cutter, there are a few things that you should keep in mind when using it. First, always wear safety goggles when operating the machine. The laser beam can be harmful to your eyes if you're not careful. Second, make sure that the area around the machine is clear before you start cutting. You don't want anything to catch on fire while you're working. Finally, take your time when cutting. If you rush, you might make a mistake that could ruin your project. Now that you know all about diode laser cutters, you're ready to start shopping for one. Keep the tips that we've shared in mind, and you'll be sure to find the perfect machine for your needs. And once you have your diode laser cutter, be sure to follow the tips that we've shared for using it safely and effectively.

FIVE THINGS TO CONSIDER WHEN BUYING A LASER CUTTER

When it comes to choosing a laser cutter, there are a few things you need to take into account in order to make sure you're making the best decision for your needs. Here are 5 of the most important factors to consider:1. What will you be using it for?The first thing you need to think about is what exactly you'll be using the laser cutter for. Different machines are better suited for different tasks, so if you know what you need it for then that will help narrow down your choices.2. What is your budget?Laser cutters can range in price from a few hundred dollars to tens of thousands, so it's important to have a budget in mind before you start shopping.3. What is the size of the material you'll be cutting?This is an important consideration because some laser cutters are only able to handle smaller pieces of material, while others are built for larger projects.4. What is the power output of the laser cutter?The power output will determine how quickly the machine can cut through materials and how thick of materials it can handle.5. What features do you need?Some laser cutters come with additional features like engraving or etching, so if you think you might need those capabilities then make sure to look for a machine that offers them.By keeping these factors in mind, you'll be well on your way to choosing the best laser cutter for your needs.

THE ULTIMATE GUIDE FOR CHOOSING PLYWOOD FOR LASER CUTTING

When it comes to laser cutting, plywood is often the material of choice. It is strong, durable and easy to work with. However, not all plywood is created equal. There are many different types and grades of plywood, and each has its own advantages and disadvantages. In this guide, we will break down everything you need to know about choosing the right plywood for your next laser cutting project. Plywood comes in a variety of thicknesses, from 1/8" to 1". The thicker the plywood, the more sturdy and resistant it will be to warping. However, thicker plywood can also be more difficult to cut through with a laser cutter. If you are working with a thinner piece of plywood, you may need to use a lower power setting on your laser cutter to avoid burning through the material. When it comes to choosing plywood for laser cutting, it is important to consider the grain of the wood. The grain will affect how the plywood cuts and engraves. For example, if you are looking for a clean and precise cut, you will want to choose plywood with a straight grain. If you are looking for a more rustic look, you can choose a plywood with a wavy grain. The type of grain you choose should be based on the overall look you are going for with your project.There are three main types of plywood: hardwood, softwood and composite. Hardwood plywood is made from hardwoods, such as maple or oak. It is denser and more durable than softwood plywood, making it a good choice for projects that require a sturdy material. However, hardwood plywood can be more difficult to cut through with a laser cutter. Softwood plywood is made from softer woods, such as pine or fir. It is not as strong as hardwood plywood, but it is much easier to cut. Composite plywood is made from a combination of hardwoods and softwoods. It offers the best of both worlds – the strength of hardwood plywood and the ease of cutting of softwood plywood.Plywood comes in a variety of grades, from A to D. Grade A plywood is the highest quality and is typically used for cabinets, furniture and other high-end projects. Grade B plywood is a lower quality, but it is still suitable for most projects. Grade C plywood is of lower quality and is not recommended for projects that require a sturdy material. Grade D plywood is the lowest quality and should only be used for very low-end projects. Try to go in the store and pick it out in person so you can get the flattest piece possible. Usually you need to put it on the floor to see. Now that you know all about choosing plywood for laser cutting, it’s time to get started on your next project! Remember to take into consideration the thickness, grain and type of plywood you need before making your final decision. With a little bit of planning, you can create beautiful and professional looking laser cut projects using plywood.

BEST LASER CUTTER ACCESSORIES

There are many different types of accessories available for laser cutters, and the best accessory for your machine will depend on what you plan to use it for. If you're looking for general-purpose accessories that will help you get the most out of your machine, we recommend investing in a few basics like a workbench, fume extractor, and safety glasses. Here are some other great accessories to consider:

- A rotary attachment: This is a must-have if you want to be able to cut intricate designs into metal or glass.

- A laser engraving kit: This can be used to add personalization or branding to products made with your laser cutter.

- A cutting mat: This will protect your work surface from scratches and debris.- A set of replacement lenses: These are important to have on hand in case your original lens gets damaged.- A laser pointer: This can be used for alignment and positioning when setting up your cuts.

With so many different types of accessories available, it's easy to get overwhelmed. But don't worry - our experts can help you choose the best accessories for your specific needs. Contact us today to get started.

WHAT SHOULD I DO TO KEEP MY LASER CUTTER LENS AND MIRRORS CLEAN?

If your laser cutter lens and mirrors become dirty, it can negatively impact the quality of your cuts. In some cases, it can even cause the machine to malfunction. That's why it's essential to keep these components clean. But what's the best way to do that? There are a few options for cleaning your laser cutter lens and mirrors. One is to use a lens cleaning solution specifically designed for this purpose. You can also use a soft, lint-free cloth dampened with alcohol. Just be sure not to use harsh chemicals or abrasive materials, as they could damage the surfaces. Whichever method you choose, be sure to follow the manufacturer's instructions carefully. With a bit of care and attention, you can keep your laser cutter working its best.

Laser cutter mirrors are made out of a variety of materials, depending on the intended use of the mirror. For example, some mirrors are made out of glass, while others are made out of metal. The material that a mirror is made of will affect its properties, such as its reflectivity and durability.

You might not know this, but mirrors can be made out of some pretty dangerous chemicals. In fact, you should never touch them with your bare hands. You might not realize that it can cause a chemical reaction that can be dangerous to your health. So next time you go to clean your mirror, be sure to use gloves so you don't accidentally come into contact with the chemicals. And if you do happen to touch the mirror, be sure to wash your hands immediately afterward.

If you're looking for a way to clean your mirrors and lens, you may want to use a sterilized Q-tip. The highest grade alcohol you can purchase will work the best. Be sure to use as little pressure as possible when cleaning. This will help prevent any damage to your equipment.

If you're in need of sterilized Q-tips (the ones for medical purposes), Amazon is a great place to look. You can find a variety of options from different sellers, so you're sure to find the perfect product for your needs. Plus, with Prime shipping, you can get your Q-tips delivered right to your door in no time. So if you're in need of sterilized Q-tips, be sure to check out Amazon. Also if you ever drop the Q-tip or get it dirty make sure not to use it and get a fresh one. Also, don't touch the tip your finger oils are very bad for your optics.

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)