American Laser Cutter: Your Precision Cutting Partner in Los Angeles

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

How Wood Hardness Affects Your Laser Cutting Project: A Guide for Crisp Cuts

How Wood Hardness Affects Your Laser Cutting Project: A Guide for Crisp Cuts

The magic of laser cutting lies in its ability to transform wood into intricate shapes and designs with precise control. But have you ever wondered how the type of wood you choose impacts the final outcome? One crucial factor is wood hardness. This article explores how wood hardness affects laser cutting and equips you with the knowledge to achieve crisp, clean cuts on your projects.

Understanding Wood Hardness:

Wood hardness refers to its resistance to indentation or deformation. Hardwoods, like oak or maple, are denser and more challenging to cut compared to softwoods, like pine or balsa. Here's how hardness influences laser cutting:

Cutting Speed and Power: Harder woods require slower cutting speeds and higher laser power settings to achieve a clean cut through the entire thickness of the material. Conversely, softer woods can be cut with faster speeds and lower power settings.

Charring and Burning: Excessive laser power or slow cutting speeds on hardwoods can lead to charring or burning of the edges. Softer woods are generally less susceptible to burning but can still experience some scorching at high power settings.

Edge Quality: Hardwoods, with their denser structure, tend to produce cleaner and sharper edges after laser cutting compared to softer woods, which might have slightly ragged or frayed edges.

Choosing the Right Wood for Your Laser Cutting Project:

Keeping wood hardness in mind, here are some tips for selecting the perfect wood for your laser cutting project:

Detailed Designs: For projects with intricate details and sharp corners, hardwoods like birch or cherrywood are ideal due to their ability to hold a clean edge.

Thicker Cuts: If your project involves cutting through thicker pieces of wood, opting for a hardwood like maple or oak is recommended as it can withstand the higher laser power needed.

Faster Cutting and Reduced Power Needs: For projects where speed is a priority or delicate materials are involved, softer woods like pine or basswood might be suitable. These woods can be cut with faster speeds and lower power settings, minimizing the risk of charring.

Optimizing Your Laser Cutting Settings for Wood Hardness:

Consult Your Laser Cutter's Manual: Most laser cutters come with recommended settings for different materials and thicknesses. Use these as a starting point and adjust based on your specific wood type and desired results.

Experimentation is Key: Don't be afraid to experiment with different cutting speeds and power settings on scrap wood pieces before tackling your final project. This allows you to fine-tune the settings for optimal results with your chosen wood type.

Additional Tips for Laser Cutting Wood:

Moisture Content: Wood that is too moist can be challenging to cut cleanly. Ensure your wood is properly dried for best results.

Grain Direction: The direction of the wood grain can slightly affect the cutting process. Experiment to see if cutting with or against the grain yields a cleaner edge for your project.

Ventilation is Crucial: Laser cutting wood generates smoke and fumes. Proper ventilation is essential to ensure a safe and healthy work environment.

Conclusion:

Wood hardness is a crucial factor to consider when laser cutting. By understanding how hardness impacts the cutting process and selecting the appropriate wood type and settings, you can achieve stunning results with crisp, clean cuts, transforming your vision into a beautiful laser-cut creation. So, grab your favorite wood, fire up your laser cutter, and get ready to experience the magic of laser cutting!

Laser Cutting: A Precision Tool for Cell Phone Company Testing Equipment

Laser Cutting: A Precision Tool for Cell Phone Company Testing Equipment

Laser cutting technology has revolutionized the manufacturing process across various industries, including the tech sector. Its precision, efficiency, and versatility make it an ideal tool for producing custom testing equipment tailored to the specific needs of cell phone companies.

The Role of Testing Equipment in the Cell Phone Industry

Testing equipment plays a critical role in ensuring the quality, reliability, and performance of cell phones. From hardware components to software applications, rigorous testing is essential to identify and address potential issues before products are released to the market. Laser cutting technology offers a powerful solution for producing custom testing equipment that meets the unique requirements of the cell phone industry.

Benefits of Using Laser Cutting for Testing Equipment

1. Precision and Accuracy: Laser cutting ensures precise dimensions and cuts, guaranteeing that testing equipment functions as intended. This precision is crucial for obtaining accurate and reliable test results.2. Customization: Laser cutting allows for a high degree of customization, enabling cell phone companies to create testing equipment that is tailored to their specific needs. This flexibility is essential for meeting the unique requirements of different cell phone models and applications.3. Efficiency and Speed: Laser cutting is a fast and efficient process, reducing production time and costs. This is particularly beneficial for cell phone companies that need to quickly develop and test new products.4. Intricate Designs: Laser cutting can create intricate designs and patterns, enabling the production of complex testing equipment. This is essential for testing features such as antennas, cameras, and displays.5. Versatility: Laser cutting can be used to cut through various materials, including metals, plastics, and composites. This versatility allows for the creation of testing equipment that is suitable for different types of cell phones and tests.

Applications of Laser Cutting in Cell Phone Testing Equipment Production

Laser cutting can be used to produce a wide range of testing equipment, including:

Antenna testing chambers: Laser cutting can be used to create custom chambers for testing the performance of cell phone antennas in different environments.Durability testing fixtures: Laser cutting can be used to produce fixtures for testing the durability of cell phones under various conditions, such as drops, shocks, and temperature extremes.Battery testing equipment: Laser cutting can be used to create components for battery testing equipment, such as holders and probes.Camera testing equipment: Laser cutting can be used to produce precise components for camera testing, such as targets and calibration tools.Display testing equipment: Laser cutting can be used to create fixtures for testing the performance of cell phone displays, including brightness, color accuracy, and touch sensitivity.

The Laser Cutting Process for Testing Equipment

6. Design: The initial step involves creating a detailed design for the testing equipment, considering factors such as functionality, precision requirements, and material selection.7. Material Selection: The appropriate material is chosen based on the specific requirements of the testing equipment.8. Laser Cutting: The design is transferred to the laser cutting machine, which uses a focused laser beam to cut the material into the desired shape.9. Assembly: The cut components are assembled to form the complete testing equipment.10. Testing: The finished testing equipment is thoroughly tested to ensure that it meets the specified requirements.

Advantages of Using Laser Cutting for Testing Equipment Over Traditional Methods

Reduced Lead Times: Laser cutting allows for faster production times compared to traditional manufacturing methods, enabling cell phone companies to bring new products to market more quickly.Improved Accuracy: Laser cutting ensures greater precision and accuracy, leading to more reliable test results.Reduced Costs: Laser cutting can reduce costs by minimizing waste and improving efficiency.Increased Customization: Laser cutting allows for greater customization, enabling cell phone companies to create testing equipment that is tailored to their specific needs.Improved Product Quality: By using laser cutting to produce high-quality testing equipment, cell phone companies can ensure that their products meet the highest standards of quality.

In conclusion, laser cutting technology offers numerous benefits for the cell phone industry when it comes to producing custom testing equipment. Its precision, efficiency, versatility, and ability to create complex designs make it an invaluable tool for ensuring the quality and reliability of cell phones. By leveraging laser cutting, cell phone companies can streamline their development processes, reduce costs, and bring innovative products to market more quickly.

A Beginner's Guide to Laser Cutting Manufacturing

A Beginner's Guide to Laser Cutting Manufacturing

Laser cutting technology has revolutionized manufacturing processes, offering precision, speed, and versatility. If you're considering starting a laser cutting business, this comprehensive guide will provide you with essential information to get started.

Understanding the Basics

Laser cutting uses a focused laser beam to cut through materials, creating intricate and precise shapes. The process involves a laser head that moves across the material, melting or vaporizing the material to create the desired cut.

Types of Lasers Used in Manufacturing

CO2 lasers: Ideal for cutting non-metals like wood, acrylic, and fabric.Fiber lasers: Suitable for cutting metals, especially stainless steel and aluminum.YAG lasers: Often used for marking and engraving on metals.

Essential Equipment

Laser cutting machine: The centerpiece of your business, a laser cutting machine can range from small desktop models to large industrial machines.Computer with design software: You'll need a computer with specialized design software to create the digital files that control the laser cutter.Material handling equipment: This includes tables, clamps, and other tools for safely handling and positioning materials.Safety equipment: Protective gear such as laser safety glasses, gloves, and a ventilated workspace are essential for safety.

Business Planning

1. Market Research: Analyze the demand for laser cutting services in your local area or target market. Identify your potential customers and competitors.2. Business Plan: Develop a comprehensive business plan outlining your goals, target market, financial projections, and marketing strategy.3. Legal and Regulatory Compliance: Ensure compliance with local business regulations, zoning laws, and safety standards.4. Financing: Secure funding for your business, whether through personal savings, loans, or investments.

Acquiring Necessary Skills

Laser Cutting Training: Consider attending training courses or workshops to learn the proper operation and maintenance of laser cutting machines.Design Skills: Develop proficiency in design software like AutoCAD or Adobe Illustrator to create accurate digital files.Business Management: Learn essential business skills such as marketing, sales, and financial management.

Setting Up Your Workspace

Location: Choose a suitable location for your laser cutting business, considering factors like accessibility, zoning, and rental costs.Workspace Setup: Create a well-organized and safe workspace, ensuring proper ventilation and adequate lighting.Equipment Installation: Install your laser cutting machine and other necessary equipment according to manufacturer's instructions.

Sourcing Materials and Supplies

Material Suppliers: Establish relationships with reliable suppliers of materials such as wood, metal, acrylic, and fabric.Inventory Management: Implement a system for managing your inventory and ensuring you have sufficient materials on hand.

Marketing and Sales

Online Presence: Create a professional website and utilize social media to showcase your services and reach potential customers.Networking: Attend industry events and network with potential clients and other businesses.Pricing Strategy: Develop a competitive pricing strategy based on your costs, market demand, and value proposition.

Building Customer Relationships

Customer Service: Provide excellent customer service to build strong relationships and encourage repeat business.Quality Control: Ensure the quality of your products and services to maintain customer satisfaction.Customization: Offer customization options to meet the specific needs of your customers.

Expanding Your Business

Diversify Services: Consider offering additional services like engraving, marking, or custom design.Invest in Technology: Stay updated with the latest laser cutting technology to improve efficiency and expand your capabilities.Partnerships and Collaborations: Explore partnerships with other businesses to expand your reach and customer base.

Starting a laser cutting business requires careful planning, investment, and dedication. By following these guidelines and continuously learning and adapting, you can successfully navigate the industry and build a thriving business.

A Glimpse into the Future: Laser Cutting in 2025

A Glimpse into the Future: Laser Cutting in 2025

Laser cutting technology has revolutionized various industries, from rapid prototyping to small-scale manufacturing. As we hurtle towards 2025, let's delve into the exciting advancements we can expect in the realm of laser cutting:

1. Enhanced Automation and Integration:

AI-powered Design Optimization: Artificial intelligence (AI) will play a more prominent role, analyzing designs and suggesting laser cutting parameters for optimal efficiency and material usage.

Seamless Workflow Integration: Expect smoother integration between design software, laser cutters, and other fabrication tools, creating a more streamlined workflow from concept to creation.

Automated Material Handling: Advances in robotics will likely lead to automated material loading and unloading systems, minimizing manual intervention and improving overall production speed.

2. A Material Metaverse:

Exotic Material Compatibility: Laser cutting technology is constantly evolving to handle new materials. Expect wider compatibility with exotic materials like advanced composites, high-performance polymers, and even some types of fabrics.

Multi-material Layering: The ability to precisely cut and layer different materials during the laser cutting process could open doors to creating objects with unique properties and functionalities.

3. The Rise of Micro-manufacturing:

Ultra-precise Micromachining: Laser cutting will likely achieve even higher precision levels, enabling the creation of intricate micro-components for various applications, like microfluidics and miniaturized electronics.

Desktop Laser Cutting Revolution: Advancements in laser technology could lead to the rise of more affordable and user-friendly desktop laser cutters, empowering makers and hobbyists to explore laser cutting at home.

4. Sustainability in Focus:

Eco-friendly Laser Sources: The development of more energy-efficient laser sources is on the horizon, minimizing the environmental impact of the laser cutting process.

Reduced Material Waste: Advancements in laser cutting software and automation could lead to significant reductions in material waste during the cutting process.

5. The Future of Customization:

On-Demand Laser Cutting Services: Expect a rise in on-demand laser cutting services, allowing businesses and individuals to easily access laser cutting capabilities for small batch production or personalized creations.

Laser Cutting Customization on the Rise: Laser cutting will likely play a more prominent role in mass customization, allowing for the creation of unique and personalized products at scale.

Conclusion:

The future of laser cutting is brimming with exciting possibilities. From enhanced automation and a wider material compatibility to a focus on sustainability and on-demand customization, laser cutting technology is poised to revolutionize various industries and empower creators to bring their ideas to life in even more innovative ways. As 2025 approaches, one thing is certain: the world of laser cutting is set to become even more remarkable.

pen_spark

tuneshare

more_vert

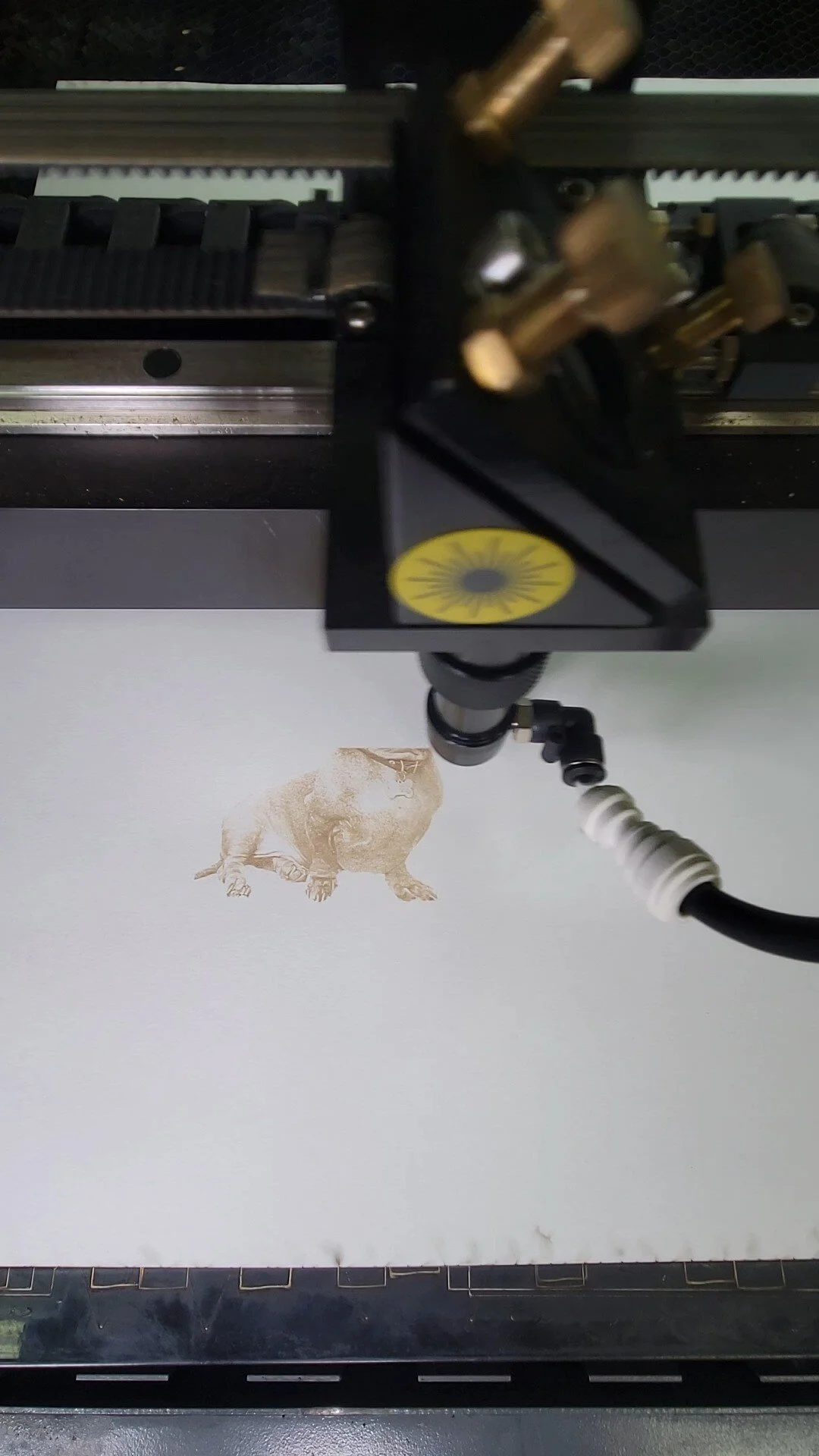

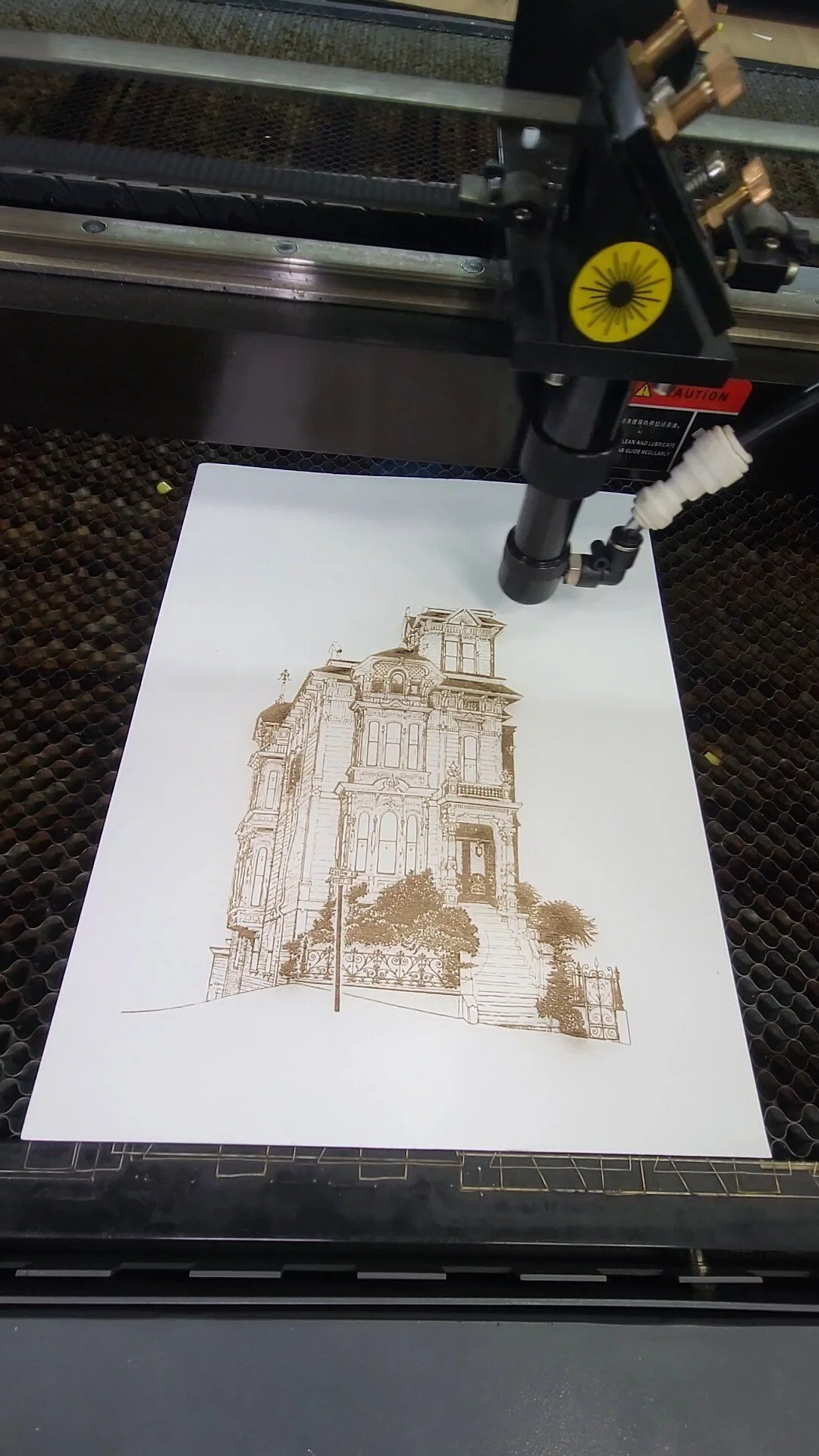

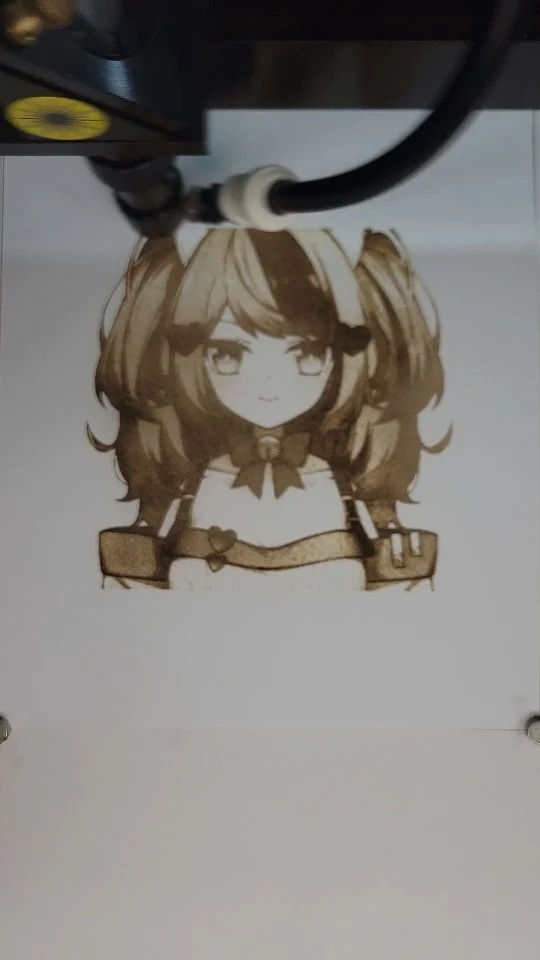

Laser Cutting: A Precision Tool for Artists

Laser Cutting: A Precision Tool for Artists

Laser cutting technology has revolutionized the manufacturing industry, offering precision, efficiency, and versatility in creating customized products. In the realm of art, laser cutting has emerged as a powerful tool for artists, enabling them to bring their creative visions to life with stunning precision and detail.

Benefits of Laser Cutting for Artists

1. Precision and Accuracy: Laser cutting ensures precise dimensions and cuts, allowing artists to create intricate and detailed artwork with exceptional accuracy. This precision is essential for achieving a high-quality finish and ensuring that pieces meet the artist's exact specifications.2. Customization: Laser cutting allows for a high degree of customization, enabling artists to create unique and personalized pieces. This flexibility is essential for expressing artistic vision and creating one-of-a-kind works of art.3. Efficiency and Speed: Laser cutting is a fast and efficient process, reducing production time and costs. This is particularly beneficial for artists who need to quickly create prototypes or meet tight deadlines for exhibitions or commissions.4. Intricate Designs: Laser cutting can create intricate designs and patterns that would be difficult or impossible to achieve using traditional methods. This opens up new possibilities for artists to explore complex and visually stunning concepts.5. Versatility: Laser cutting can be used to cut through a wide range of materials, including wood, acrylic, metal, and even paper. This versatility allows artists to experiment with different materials and create a variety of artistic expressions.

Applications of Laser Cutting in Art

6. Sculpture: Laser cutting can be used to create intricate sculptures, from abstract forms to realistic representations. The precision of laser cutting allows for the creation of delicate details and complex shapes.7. Wall Art: Laser cutting can be used to create unique wall art pieces, including decorative panels, murals, and mosaics. The ability to cut through various materials and create intricate designs makes laser cutting an ideal tool for this application.8. Jewelry: Laser cutting can be used to create custom jewelry pieces, including pendants, earrings, and rings. The precision of laser cutting allows for the creation of intricate designs and delicate details.9. Home Decor: Laser cutting can be used to create a variety of home decor items, such as lamps, clocks, and decorative objects. The ability to customize these items makes them unique and personalized gifts.10. Product Design: Laser cutting can be used to create prototypes and production models for product design, allowing artists to visualize and refine their ideas before committing to final production.

The Laser Cutting Process for Art

11. Design: The initial step involves creating a detailed design for the artwork, considering factors such as size, materials, and desired aesthetic.12. Material Selection: The appropriate material is chosen based on the specific requirements of the artwork, including durability, color, and texture.13. Laser Cutting: The design is transferred to the laser cutting machine, which uses a focused laser beam to cut the material into the desired shape.14. Finishing: Additional finishing touches, such as painting, engraving, or assembly, can be applied to complete the artwork.

Challenges and Considerations

While laser cutting offers numerous benefits for artists, there are some challenges to consider:

Material Thickness: Laser cutting may have limitations in terms of cutting thickness, especially for certain materials.Complexity: Highly complex designs may require multiple laser cutting operations or additional manufacturing processes.Cost: The initial investment in laser cutting equipment can be significant.Safety: Proper safety measures must be in place to prevent accidents and injuries during the laser cutting process.

The Future of Laser Cutting in Art

As laser cutting technology continues to evolve, it is likely to play an even more significant role in the art world. Advancements in materials science, optics, and software will enable artists to create even more innovative and complex works of art.

In conclusion, laser cutting is a powerful tool that has revolutionized the art industry. Its precision, efficiency, and versatility allow artists to bring their creative visions to life in a way that was previously unimaginable. As laser cutting technology continues to advance, we can expect to see even more groundbreaking and inspiring works of art created with this innovative tool.

Own or Outsource: The Laser Cutting Dilemma

Own or Outsource: The Laser Cutting Dilemma

Deciding whether to purchase your own laser cutter or outsource your projects to a professional service is a significant business decision. Let's weigh the pros and cons of each option.

Owning Your Laser Cutter

Pros:

Control: Complete autonomy over your production process.

Cost-Effective: Can be cost-efficient for high-volume production.

Flexibility: Ability to handle a wide range of materials and projects.

Rapid Prototyping: Quickly iterate on designs without external dependencies.

Cons:

High Initial Investment: Purchasing and maintaining a laser cutter is expensive.

Expertise Required: Operators need training and experience.

Space Requirements: Laser cutters can be bulky and require dedicated workspace.

Maintenance Costs: Regular upkeep and repairs are necessary.

Outsourcing Laser Cutting Services

Pros:

Lower Upfront Costs: No need to invest in equipment or hire staff.

Expertise: Benefit from the experience of professionals.

Scalability: Easily adjust production volume based on demand.

Focus on Core Business: Allows you to concentrate on your core competencies.

Cons:

Dependency on Third Party: Reliance on external services can impact production timelines.

Potential for Higher Costs: Can be more expensive for small-scale or one-off projects.

Intellectual Property Concerns: Sharing designs with external parties might pose risks.

Limited Control: Less control over the production process.

Making the Right Choice

The best option depends on factors such as production volume, budget, available space, and required expertise. If you have consistent, high-volume needs and the resources to invest in equipment and personnel, owning a laser cutter might be advantageous. However, for smaller projects or businesses without the necessary infrastructure, outsourcing can be a more practical solution.

Consider creating prototypes or small test runs before committing to a large investment in equipment. This can help you assess the potential return on investment and determine if owning a laser cutter aligns with your long-term goals.

By carefully evaluating your specific requirements, you can make an informed decision that best suits your business needs.

[Image: Comparing owning a laser cutter vs outsourcing laser cutting services]

Would you like to explore specific industries that benefit more from owning a laser cutter versus outsourcing?

Venting vs. Filtering: A Comprehensive Guide for CO2 Laser Cutters

Venting vs. Filtering: A Comprehensive Guide for CO2 Laser Cutters

CO2 laser cutters are powerful tools used in various industries, but they can also generate harmful fumes and particulates that can pose health risks if not properly managed. Venting and filtering are two primary methods used to mitigate these risks. This article will delve into the differences between venting and filtering, their respective advantages and disadvantages, and best practices for their implementation.

Venting

Venting involves the removal of airborne contaminants from the laser cutting area by drawing in fresh air and expelling the contaminated air outside. This is typically achieved using exhaust fans and ducts that connect to the laser cutter's enclosure.

Advantages of Venting:

Effective for Large Volumes of Fumes: Venting is particularly effective for removing large volumes of fumes and smoke generated during cutting operations.Cost-Effective: Venting systems can be relatively inexpensive to install and maintain compared to some filtering systems.Simple Installation: Venting systems are generally easier to install and require less complex design considerations.

Disadvantages of Venting:

Weather Dependence: Venting systems can be affected by external weather conditions, such as wind and temperature, which can influence the effectiveness of fume removal.Noise Pollution: Exhaust fans can generate noise, which may be a concern in certain environments.Limited Control: Venting systems may not provide precise control over the level of contaminant removal, especially in areas with high levels of fume generation.

Filtering

Filtering involves capturing and removing airborne contaminants from the laser cutting area using specialized filters. These filters can be either particulate filters or activated carbon filters, each with its own advantages and disadvantages.

Advantages of Filtering:

Precise Control: Filtering systems can provide precise control over the level of contaminant removal, ensuring that the air quality within the workspace meets specific standards.Reduced Noise: Filtering systems typically generate less noise than venting systems.Indoor Use: Filtering systems can be used in indoor environments where venting may not be feasible or desirable.

Disadvantages of Filtering:

Higher Initial Cost: Filtering systems can be more expensive to purchase and install than venting systems.Maintenance Costs: Filters require regular maintenance, including cleaning or replacement, which can add to operating costs.Limited Capacity: Filters have a limited capacity to capture contaminants. If the filter becomes saturated, it may no longer be effective.

Hybrid Systems

In some cases, a combination of venting and filtering can be used to achieve optimal air quality control. Hybrid systems can provide the benefits of both methods while minimizing their drawbacks.

Best Practices for Venting and Filtering

Ventilation System Design: Consult with a ventilation specialist to design a system that meets your specific needs and complies with local regulations.Filter Selection: Choose filters that are appropriate for the types of contaminants generated by your laser cutter.Regular Maintenance: Conduct regular maintenance on both venting and filtering systems to ensure their effectiveness.Air Quality Monitoring: Use air quality monitors to track the levels of contaminants in the workspace and adjust ventilation or filtering accordingly.Personal Protective Equipment (PPE): Even with proper ventilation and filtering, it is essential for operators to wear appropriate PPE, such as respiratory protection and safety glasses.

By understanding the differences between venting and filtering and implementing best practices, you can create a safe and healthy working environment for your laser cutting operations.

Top 10 Software for Laser Cutting Design

Top 10 Software for Laser Cutting Design

Laser cutting has revolutionized manufacturing and design, enabling the creation of intricate and precise components. To harness the full potential of laser cutting technology, it is essential to have the right software tools. This article will explore the top 10 software options commonly used for laser cutting design.

1. AutoCAD

AutoCAD, a widely used CAD software, offers robust features for laser cutting design. It provides precise drawing and drafting tools, along with compatibility with various laser cutting machines. AutoCAD's extensive libraries and customization options make it a versatile choice for professionals in various industries.

2. Adobe Illustrator

Adobe Illustrator, a vector graphics editor, is a popular tool for creating intricate designs and illustrations. It offers a wide range of features for designing laser cutting patterns, including pen tools, shape tools, and text tools. Illustrator's compatibility with various file formats ensures seamless integration with laser cutting software.

3. CorelDRAW

CorelDRAW is another vector graphics software that is well-suited for laser cutting design. It offers similar features to Illustrator, such as pen tools, shape tools, and text tools. CorelDRAW's user-friendly interface and affordable pricing make it a popular choice for both professionals and hobbyists.

4. Inkscape

Inkscape is a free and open-source vector graphics editor that is a viable alternative to commercial software like AutoCAD and Illustrator. It offers a wide range of features for laser cutting design, including drawing tools, text tools, and file format compatibility.

5. LaserCAD

LaserCAD is a specialized software designed specifically for laser cutting applications. It offers features like automatic nesting, toolpath optimization, and material databases, making it a valuable tool for laser cutting professionals.

6. Vectorworks

Vectorworks is a versatile CAD software that can be used for various design disciplines, including architecture, landscape design, and product design. It offers features for laser cutting design, such as drawing tools, dimensioning, and file export for laser cutting machines.

7. ArtCAM

ArtCAM is a specialized software for 3D carving and milling, but it also offers features for laser cutting design. It provides tools for creating complex 3D models and generating toolpaths for laser cutting machines.

8. Vcarve Pro

Vcarve Pro is another software specifically designed for 3D carving and milling, but it also has features for laser cutting. It offers tools for creating 2D and 3D designs, generating toolpaths, and simulating the cutting process.

9. Lasercut Studio

Lasercut Studio is a dedicated laser cutting software that offers a user-friendly interface and features specifically designed for laser cutting applications. It provides tools for creating designs, generating toolpaths, and simulating the cutting process.

10. LightBurn

LightBurn is a popular software for controlling laser cutters, especially those based on the Ruida controller. It offers features for creating designs, generating toolpaths, and monitoring the laser cutting process.

The choice of software for laser cutting design depends on various factors, including the complexity of your designs, the type of laser cutter you are using, and your budget. By exploring these top 10 options and considering your specific needs, you can select the ideal software to enhance your laser cutting workflow.

The Dynamic Duo: How Laser Cutters and 3D Printers Revolutionize Prototyping and Production

The Dynamic Duo: How Laser Cutters and 3D Printers Revolutionize Prototyping and Production

The world of making is undergoing a revolution, fueled by the dynamic duo of laser cutters and 3D printers. While each technology offers distinct advantages, their combined power unlocks a new level of creativity, efficiency, and possibility in prototyping and production. This article explores the magic that unfolds when laser cutting and 3D printing join forces.

Complementary Strengths:

Laser cutters and 3D printers excel in different areas, creating a synergy that benefits makers and businesses alike:

Laser Cutting: Precision reigns supreme! Laser cutters deliver clean cuts on a wide range of flat materials, ideal for creating intricate details, stencils, and custom shapes.

3D Printing: Building in layers! 3D printers bring designs to life in three dimensions, allowing for the creation of complex objects with moving parts or internal features.

The Power of Combining Forces:

When these two technologies work together, the possibilities are truly remarkable:

Enhanced Prototyping: Laser-cut parts can be incorporated into 3D printed prototypes, adding details, strengthening specific areas, or creating functional components that 3D printers struggle to produce.

Improved Functionality: Laser cutting allows for the creation of precise gears, hinges, or other mechanical elements that can be integrated into 3D printed objects, resulting in more functional prototypes.

Material Versatility: Laser cutting can handle a wider range of materials than 3D printers. Combine 3D printed parts with laser-cut wood, metal, or fabric elements for unique and functional creations.

Production Efficiency: Laser cutting can be used to create custom jigs or fixtures that hold 3D printed parts in place during assembly or post-processing, streamlining the production process.

Customization on Steroids: Laser cutting allows for the creation of personalized engravings, logos, or other decorative elements that can be applied to 3D printed objects, taking customization to a whole new level.

Examples in Action:

Here's a glimpse of how laser cutting and 3D printing collaborate in various scenarios:

Robotics: 3D printed robot bodies can be enhanced with laser-cut gears, sensors, and custom enclosures.

Wearable Tech: 3D printed smartwatches can be paired with laser-cut watch straps or decorative elements.

Architecture and Design: 3D printed architectural models can be complemented with laser-cut details like windows, doors, or intricate facades.

Art and Design: Laser-cut stencils can be used to create unique patterns on 3D printed sculptures, adding depth and complexity.

Getting Started with the Dynamic Duo:

To embark on your laser cutting and 3D printing journey together, consider these steps:

Design Integration: 3D design software often allows for incorporating laser-cut elements seamlessly into your 3D models.

Material Selection: Choose materials compatible with both technologies. Wood, acrylic, and some metals can be laser cut and integrated with 3D printed parts.

Experimentation is Key: Don't be afraid to experiment! The possibilities are endless, so embrace the learning process and explore different combinations.

Conclusion:

Laser cutters and 3D printers are no longer isolated technologies. When used together, they become a formidable force, empowering creators and businesses to bring their ideas to life with greater precision, functionality, and customization. So, unleash the power of the dynamic duo and embark on a journey of limitless creation!

Customer Service: The Unsung Hero of Laser Cutter Purchases

Customer Service: The Unsung Hero of Laser Cutter Purchases

While the laser cutter itself is undoubtedly a crucial component of any laser cutting operation, the quality of customer service provided by the manufacturer or supplier can significantly impact your overall experience and satisfaction. In fact, in many cases, exceptional customer service can be even more important than the laser cutter itself.

Pre-Purchase Support

Knowledge and Expertise: A reputable supplier should have knowledgeable staff who can guide you through the selection process, ensuring you choose the right laser cutter for your specific needs.Personalized Recommendations: Good customer service involves tailoring recommendations to your individual requirements, considering factors such as budget, workspace, and desired applications.Demo Opportunities: A reputable supplier should offer the opportunity to see the laser cutter in action and experience its capabilities firsthand.

Post-Purchase Support

Training and Education: Comprehensive training on how to operate and maintain your laser cutter is essential for maximizing its efficiency and longevity.Technical Support: Timely and effective technical support is crucial for addressing any issues that may arise. A responsive and knowledgeable support team can help you resolve problems quickly and minimize downtime.Maintenance and Repairs: A reliable supplier should offer maintenance and repair services to keep your laser cutter running smoothly.

The Importance of Customer Relationships

Building a strong relationship with your laser cutter supplier is essential for long-term success. A reputable supplier will value your business and strive to provide exceptional service throughout the entire customer lifecycle.

Trust and Reliability: A supplier with a strong reputation for customer satisfaction is more likely to be trustworthy and reliable.Ongoing Support: A good relationship with your supplier ensures that you have access to ongoing support and resources, even after the initial purchase.Future Upgrades: As your business grows and your needs evolve, a trusted supplier can help you upgrade your laser cutter or explore new technologies.

Case Study: A Laser Cutter Purchase Gone Wrong

Imagine purchasing a laser cutter from a supplier that provides minimal training and support. When you encounter technical difficulties, you find it difficult to get in touch with the support team, and when you do, they are unable to resolve your issue. This experience can lead to frustration, downtime, and potentially even financial loss.

In contrast, a supplier that provides excellent customer service will proactively reach out to ensure you are satisfied with your purchase and offer ongoing support to help you succeed.

Conclusion

While the laser cutter itself is an important investment, the quality of customer service provided by the manufacturer or supplier should not be overlooked. By choosing a supplier with a strong reputation for customer satisfaction, you can ensure a positive and successful experience with your laser cutter purchase.

Essential Tools for Laser Cutting: A Comprehensive Guide

Essential Tools for Laser Cutting: A Comprehensive Guide

While a laser cutter is the centerpiece of any laser cutting operation, a range of additional tools can significantly enhance your productivity, safety, and project outcomes. Here's a breakdown of essential power and hand tools to complement your laser cutter:

Power Tools

Air Compressor: Provides compressed air for air assist, crucial for removing molten material during the cutting process.

Vacuum System: Efficiently removes dust and fumes generated by the laser cutter, maintaining a clean workspace.

Dust Collector: Captures fine particles, protecting your workspace and equipment.

Table Saw: For cutting large sheets of material to size before laser cutting.

Drill Press: Used for creating holes or pilot holes for assembly.

Sander: For finishing and smoothing cut edges.

Hand Tools

Calipers: Essential for precise measurements and ensuring accurate design transfer.

Push Sticks: Used to safely feed material into the laser cutter.

Tweezers: For handling small parts and removing debris.

Utility Knife: For cutting and trimming materials.

Safety Glasses: Protect your eyes from laser light and debris.

Gloves: Protect your hands from sharp edges and hot materials.

Additional Tools and Accessories

Material Clamps: Hold materials securely in place during the cutting process.

Focus Lens Cleaning Kit: Maintains the cleanliness of your laser cutter's optics.

Air Compressor Accessories: Includes hoses, fittings, and quick-connect couplers.

Safety Equipment: Fire extinguisher, first aid kit, and emergency shutdown devices.

By investing in the right tools, you can optimize your laser cutting workflow, improve safety, and achieve better results.

Laser-Assisted Anodization: A New Frontier in Surface Treatment

Laser-Assisted Anodization: A New Frontier in Surface Treatment

Anodization is a widely used electrochemical process to create a durable, protective oxide layer on the surface of metals, primarily aluminum. Traditionally, anodization involves immersing the metal in an electrolytic solution and applying a direct current. However, recent advancements in laser technology have opened up new possibilities for anodization, enabling precise control over the oxide layer and its properties.

The Role of Laser Technology in Anodization

Laser technology offers several advantages over traditional anodization methods:

Precision and Control: Lasers can be used to create highly localized and controlled anodization patterns, allowing for intricate designs and functional features.Flexibility: Laser-assisted anodization can be applied to a variety of shapes and sizes, making it suitable for complex components and intricate designs.Efficiency: Laser-based methods can often be more efficient than traditional anodization, reducing processing time and energy consumption.New Materials: Laser-assisted anodization can be used to anodize a wider range of materials, including alloys and composites.

Laser-Assisted Anodization Techniques

1. Laser-Induced Breakdown Anodization (LIBA): This technique involves focusing a high-energy laser beam onto the metal surface, creating a localized breakdown of the electrolyte. This breakdown leads to the formation of an oxide layer in the affected area.2. Laser-Assisted Micro-Anodization: This technique uses a pulsed laser beam to create micro-structured patterns on the metal surface before anodization. This allows for precise control over the oxide layer's morphology and properties.3. Laser-Assisted Color Anodization: By varying the laser parameters and electrolyte composition, it is possible to create a wide range of colors and finishes on anodized surfaces.

Applications of Laser-Assisted Anodization

Laser-assisted anodization has numerous applications in various industries, including:

Aerospace: Creating corrosion-resistant and wear-resistant coatings for aircraft components.Automotive: Producing decorative finishes for automotive parts, such as trim pieces and wheels.Electronics: Creating protective and functional coatings for electronic components, such as heat sinks and connectors.Medical Devices: Producing biocompatible and corrosion-resistant coatings for medical implants and instruments.Art and Design: Creating unique and artistic effects on metal surfaces.

Challenges and Future Directions

While laser-assisted anodization offers significant advantages, there are still challenges to be addressed:

Equipment Cost: The specialized equipment required for laser-assisted anodization can be expensive.Process Optimization: Optimizing laser parameters and electrolyte composition for specific applications can be complex.Scalability: Scaling up laser-assisted anodization processes for large-scale production can be challenging.

Despite these challenges, the future of laser-assisted anodization looks promising. Continued research and development will likely lead to further advancements in this technology, expanding its applications and improving its efficiency.

Conclusion

Laser-assisted anodization is a rapidly evolving field with the potential to revolutionize surface treatment processes. By offering precise control, flexibility, and efficiency, laser-based methods can create unique and functional anodized coatings for a wide range of applications. As technology advances, we can expect to see even more innovative and exciting developments in this area.

Laser Cutting: A Catalyst for Rapid Prototyping and Development

Laser Cutting: A Catalyst for Rapid Prototyping and Development

Laser cutting technology has revolutionized the prototyping and development process across various industries. Its precision, speed, and versatility have made it an invaluable tool for bringing ideas to life quickly and efficiently. This article will explore the advantages of laser cutting for rapid prototyping and development, along with its applications in different sectors.

Precision and Accuracy

One of the most significant advantages of laser cutting is its exceptional precision and accuracy. Laser cutters can create intricate and complex designs with minimal tolerances, ensuring that prototypes closely resemble the final product. This precision is crucial for ensuring functionality and aesthetics, especially in industries like aerospace, automotive, and consumer electronics.

Versatility and Material Compatibility

Laser cutting can be used to process a wide range of materials, including metals, plastics, wood, and composites. This versatility allows designers and engineers to experiment with different materials and explore various design possibilities. Whether you need a prototype made from a durable metal or a lightweight plastic, laser cutting can accommodate your needs.

Speed and Efficiency

Laser cutting is a highly efficient process, capable of producing prototypes in a fraction of the time required by traditional manufacturing methods. This speed is essential for rapid prototyping, where time-to-market is often critical. By reducing the time spent on prototyping, businesses can accelerate product development and bring new innovations to market more quickly.

Cost-Effectiveness

While laser cutting equipment can be a significant investment, the long-term cost benefits can be substantial. By reducing the time and resources required for prototyping, laser cutting can help businesses save money and improve their bottom line. Additionally, the ability to create functional prototypes early in the development process can help to identify and address potential issues before investing heavily in production.

Applications of Laser Cutting in Rapid Prototyping

Product Design: Laser cutting is used to create physical models of new products, allowing designers to visualize and test their concepts before committing to production.Functional Prototypes: Laser cutting can be used to create functional prototypes that can be tested for performance, durability, and usability.Customization and Personalization: Laser cutting enables the creation of customized and personalized prototypes, allowing businesses to offer unique and tailored products.Industrial Design: Laser cutting is used in industrial design to create prototypes of new products, such as automotive components, consumer electronics, and medical devices.Architectural Modeling: Laser cutting can be used to create highly detailed architectural models, helping architects and designers visualize their designs and make informed decisions.

Future Trends in Laser Cutting for Rapid Prototyping

As laser cutting technology continues to evolve, we can expect to see even more innovative applications in the field of rapid prototyping. Some potential future trends include:

Integration with 3D Printing: Laser cutting can be used to create support structures for 3D printing, enabling the production of complex and intricate prototypes.Advancements in Materials: Laser cutting technology is constantly expanding to accommodate new materials, such as advanced composites and biomaterials.Increased Automation: Automation and robotics are being integrated into laser cutting systems, further streamlining the prototyping process.Cloud-Based Services: Cloud-based laser cutting services are becoming more accessible, allowing businesses to access prototyping capabilities without the need for significant upfront investment.

In conclusion, laser cutting has become an indispensable tool for rapid prototyping and development. Its precision, versatility, speed, and cost-effectiveness make it a valuable asset for businesses across various industries. As laser cutting technology continues to advance, we can expect to see even more innovative applications in the future.

10 Laser Cut Delights: Crafting a Merry and Bright Christmas with Laser Magic

10 Laser Cut Delights: Crafting a Merry and Bright Christmas with Laser Magic

The holiday season is upon us, and with it comes the delightful task of decking the halls and spreading Christmas cheer. Laser cutting technology can elevate your holiday decorating and gift-giving to a whole new level! This article explores ten fantastic laser cut ideas to infuse your Christmas with a touch of personalized magic.

1. Ornament Extravaganza: Laser cutting allows you to create unique and personalized Christmas ornaments unlike any store-bought variety. Design snowflakes with intricate details, whimsical characters from your favorite holiday stories, or ornaments featuring family names or monograms.

2. Tree Topper Triumph: Ditch the ordinary star and craft a stunning laser-cut tree topper. Design a majestic reindeer silhouette, a delicate snowflake masterpiece, or even a personalized topper that incorporates your family's name.

3. Festive Placemats and Coasters: Laser cut placemats and coasters featuring Christmas motifs like snowflakes, reindeer, or even custom messages for each guest will add a touch of holiday cheer to your Christmas dinner table.

4. Advent Calendar Countdown: Laser cutting allows you to create a one-of-a-kind advent calendar. Design a box with numbered compartments that open to reveal small treats or festive messages, making the wait for Christmas even more exciting.

5. Stocking Stuffers with Flair: Laser cut wooden snowflakes, miniature Christmas trees, or personalized gift tags – small laser-cut tokens add a special touch to even the simplest stocking stuffers.

6. Gift Box Bonanza: Ditch the wrapping paper and create beautiful laser-cut gift boxes in various sizes. Personalize them with names, festive designs, or even season's greetings for a truly unique gift presentation.

7. Lights Aglow: Laser cut intricate snowflake or star designs from thin wood or acrylic and string them together with fairy lights to create a magical and personalized Christmas light display.

8. The Gift of Words: Laser cut inspirational Christmas quotes, poems, or song lyrics onto wood or acrylic for a heartwarming and decorative wall hanging or shelf display.

9. Cookie Cutters with Character: Laser cut custom cookie cutters in fun shapes like snowmen, reindeer, or candy canes to elevate your Christmas cookie decorating game.

10. Snowflake Extravaganza: Laser cut snowflakes in various sizes and materials like wood, felt, or even glitter acrylic to create a winter wonderland display on your windows, walls, or even as table confetti.

Conclusion:

Laser cutting isn't just about precision cuts; it's about unleashing your creativity and adding a personalized touch to your holiday season. So embrace the laser magic, create unique decorations and gifts, and make this Christmas a season to remember! With a laser cutter and a dash of holiday spirit, the possibilities are endless.

Top 10 Artists Utilizing Laser Cutters for Stencils

Top 10 Artists Utilizing Laser Cutters for Stencils

Laser cutting technology has revolutionized the art world, empowering artists to create intricate and precise stencils with unprecedented ease. Here are 10 prominent artists who have harnessed the power of laser cutters to push the boundaries of their craft:

1. Gabriel Schama

Renowned for his layered, 3D laser-cut artworks, Gabriel Schama's pieces are a testament to the versatility of laser cutting. His intricate designs, often inspired by nature and architecture, showcase the precision and detail that can be achieved with this technology.

2. Anila Quayyum Agha

Anila Quayyum Agha's mesmerizing light installations use laser-cut metal screens to cast intricate shadows onto walls and ceilings. Her work explores themes of culture, identity, and the interplay between light and shadow, demonstrating the transformative power of laser-cut stencils.

3. Tord Boontje

Tord Boontje is a Dutch designer known for his whimsical and organic creations. He frequently incorporates laser cutting into his work, using the technology to create delicate and intricate patterns in materials like wood, paper, and metal.

4. Erin Hanson

Erin Hanson, a renowned landscape painter, uses laser-cut stencils as a starting point for her vibrant and detailed paintings. The precision of laser cutting allows her to create intricate patterns and textures that serve as a foundation for her expressive brushwork.

5. Eric Jacobson

Eric Jacobson is a sculptor who specializes in creating intricate, lifelike sculptures using laser-cut materials. His work often involves layering multiple laser-cut pieces to create complex and dynamic compositions.

6. Martin Tomsky

Martin Tomsky's intricate papercut art is made possible by the precision of laser cutting. His intricate designs, often inspired by nature and architecture, showcase the delicate beauty that can be achieved with this technology.

7. Joshua Abarbanel

Joshua Abarbanel is a contemporary artist who uses laser cutting to create intricate and thought-provoking sculptures. His work often explores themes of memory, history, and the passage of time.

8. Treeline & Tide

Treeline & Tide is a collaborative art duo that uses laser cutting to create stunning botanical-inspired sculptures. Their work celebrates the beauty and complexity of nature, showcasing the intricate details that can be achieved with this technology.

9. John Edmark

John Edmark is a kinetic artist who uses laser cutting to create intricate, moving sculptures. His work explores the intersection of art, science, and technology, demonstrating the potential of laser cutting to create dynamic and interactive pieces.

10. Martijn van Strien

Martijn van Strien is a Dutch designer who uses laser cutting to create functional and aesthetically pleasing objects. His work often incorporates playful and unexpected elements, showcasing the versatility of laser cutting as a design tool.

These are just a few examples of the many talented artists who are using laser cutting to push the boundaries of their craft. As laser cutting technology continues to evolve, we can expect to see even more innovative and inspiring works from artists around the world.

Outsourcing Laser Cutting: Weighing the Pros and Cons

Outsourcing Laser Cutting: Weighing the Pros and Cons

The decision to invest in your own laser cutter or outsource your cutting needs is a significant one. While owning a machine offers control and potential cost savings, outsourcing can provide several advantages.

1. Should I Pay For Laser-Cutting Services Or Invest In A Machine? - Esprit Automation

Benefits of Outsourcing Laser Cutting

Cost-Effectiveness: For low to medium volume production, outsourcing can be more economical due to the elimination of equipment, maintenance, and labor costs.

Expertise: Professional laser cutting services often have highly skilled operators and advanced machinery, ensuring high-quality results.

Time Efficiency: Outsourcing frees up your time and resources to focus on other aspects of your business.

1. Why Your Business Should Outsource Its Laser Cutting - Coruzant

Scalability: You can easily adjust production volume based on demand without investing in additional equipment.

1. Why Should You Outsource Your Laser Cutting? | Wrekin Sheetmetal

Access to a Wider Range of Materials and Finishes: Many laser cutting services offer a variety of materials and finishing options.

When to Consider Outsourcing

Low to Medium Production Volumes: If you don't have consistent, high-volume needs, outsourcing might be more cost-effective.

Lack of Expertise: If you don't have in-house laser cutting expertise, outsourcing can ensure quality results.

Limited Space: Laser cutters can be bulky, so if space is limited, outsourcing is a practical option.

Rapid Prototyping: Outsourcing can be a quick and efficient way to test new product designs.

Factors to Consider When Choosing a Laser Cutting Service

Equipment Capabilities: Ensure the service provider has the necessary machinery for your project.

Material Options: Verify that the service offers the materials you need.

Turnaround Time: Consider the service provider's ability to meet your project deadlines.

1. Discover the Best Laser Cutting Services in the North West - Etch and Cut

Cost: Compare prices and services offered by different providers.

Quality Control: Review customer reviews and request samples to assess the quality of work.

Ultimately, the decision to outsource or invest in your own laser cutter depends on your specific needs, budget, and long-term goals. Carefully evaluating the pros and cons of each option will help you make an informed choice.

Samsung's Laser Cutting Innovations: A Cutting-Edge Perspective

Samsung's Laser Cutting Innovations: A Cutting-Edge Perspective

Samsung, a global leader in electronics and technology, has embraced laser cutting as a vital tool in its manufacturing processes. From smartphones and tablets to home appliances and industrial equipment, laser cutting technology plays a crucial role in ensuring precision, efficiency, and quality in Samsung's products.

Precision and Detail in Electronics

One of the most prominent applications of laser cutting at Samsung is in the production of electronic components. Laser cutters are used to create intricate patterns and precise cuts on materials such as metal, plastic, and glass, ensuring the accuracy and functionality of components.

Printed Circuit Boards (PCBs): Laser cutting is used to create precise circuit patterns on PCBs, which are essential for the operation of electronic devices.Metal Components: Laser cutting is employed to fabricate metal components, such as brackets, connectors, and enclosures, for various electronic products.Glass Components: Laser cutting can be used to create precise apertures and patterns on glass components, such as touchscreens and display panels.

Customization and Personalization

Laser cutting technology enables Samsung to offer customized and personalized products to its customers. By using laser cutting, Samsung can create unique designs and patterns on various products, adding a personal touch to the customer experience.

Smartphone Cases: Laser cutting is used to create intricate designs and patterns on smartphone cases, allowing customers to personalize their devices.Home Appliances: Laser cutting can be used to create custom engravings or designs on home appliances, such as refrigerators and washing machines.Wearable Technology: Laser cutting is used to create precise components and designs for wearable devices, such as smartwatches and fitness trackers.

Efficiency and Productivity

Laser cutting has significantly improved the efficiency and productivity of Samsung's manufacturing processes. By automating tasks and reducing waste, laser cutting technology has helped Samsung to meet the demands of the fast-paced consumer electronics market.

Rapid Prototyping: Laser cutting allows Samsung to quickly create prototypes of new products, accelerating the development process and reducing time-to-market.Reduced Waste: Laser cutting minimizes material waste by allowing for precise cutting and eliminating the need for manual trimming or finishing.Automation: Laser cutting machines can be integrated into automated production lines, increasing efficiency and reducing labor costs.

Quality and Reliability

Laser cutting ensures high-quality and reliable products by providing precise and consistent cuts. This is particularly important for electronic components, where even slight variations in dimensions can affect performance.

Improved Product Quality: Laser cutting helps to eliminate defects and inconsistencies in products, resulting in higher quality and reliability.Enhanced Durability: Laser-cut components are often more durable and resistant to damage due to the precision of the cutting process.

Future Applications of Laser Cutting at Samsung

As laser cutting technology continues to evolve, Samsung is likely to explore new and innovative applications. Some potential future uses include:

3D Printing: Laser cutting can be used to create support structures for 3D printing, enabling the production of complex and customized products.Materials Science: Laser cutting can be used to analyze and test materials, aiding in the development of new and improved materials for use in Samsung's products.Sustainable Manufacturing: Laser cutting can be used to reduce waste and improve energy efficiency, contributing to Samsung's sustainability goals.

In conclusion, laser cutting has become an indispensable tool for Samsung, enabling the company to produce high-quality, innovative, and personalized products. As laser technology continues to advance, we can expect to see even more exciting applications from Samsung in the future.

A Comprehensive Guide to Laser Cutter and Engraver Types

A Comprehensive Guide to Laser Cutter and Engraver Types

Laser cutting and engraving machines have revolutionized various industries, from manufacturing to art and design. Understanding the different types of laser cutters and engravers available is essential for selecting the right machine to meet your specific needs. This article will delve into the key characteristics and applications of the most common types.

CO2 Laser Cutters and Engravers

CO2 lasers are the most versatile and widely used type of laser for cutting and engraving. They are suitable for a broad range of materials, including wood, acrylic, plastics, and certain metals. CO2 lasers emit infrared radiation, which is highly efficient for cutting and engraving non-metals.

Advantages:

Versatile for cutting and engraving various materialsHigh power output for efficient cuttingRelatively affordable compared to other laser typesDisadvantages:

Less efficient for cutting metals, especially reflective ones

Fiber Lasers

Fiber lasers are becoming increasingly popular due to their efficiency and ability to cut metals with precision. They use a fiber optic cable to deliver the laser beam, which is generated by a rare-earth-doped fiber.

Advantages:

Excellent for cutting metals, especially stainless steel and aluminumHigh beam quality for precise cutsEnergy-efficientDisadvantages:

Generally more expensive than CO2 lasersLimited to cutting metals and certain non-metals

YAG Lasers

YAG (yttrium aluminum garnet) lasers are solid-state lasers that emit near-infrared radiation. They are often used for marking and engraving applications, but can also be used for cutting certain materials.

Advantages:

Versatile for marking and engraving applicationsCan be used for cutting some metals and non-metalsDisadvantages:

Lower power output compared to CO2 and fiber lasersCan be less efficient for cutting thicker materials

Excimer Lasers

Excimer lasers are pulsed lasers that use a mixture of gases to generate ultraviolet radiation. They are primarily used for micromachining applications, such as cutting thin films and creating microstructures.

Advantages:

Extremely precise for micromachining applicationsCan cut a wide range of materials, including metals and ceramicsDisadvantages:

High maintenance requirementsLimited power output compared to other laser types

Ultrafast Lasers

Ultrafast lasers generate extremely short pulses of laser radiation, measured in femtoseconds or picoseconds. They are used for micromachining applications that require precision and minimal heat-affected zones.

Advantages:

Extremely precise for micromachining applicationsMinimal heat-affected zonesCan cut a wide range of materials, including metals and ceramicsDisadvantages:

High cost and complex operation

Choosing the Right Laser

The best laser type for your needs depends on several factors, including:

Materials to be cut or engraved: Consider the type of materials you will be working with.Cutting or engraving depth: Determine the thickness of the materials you need to cut or engrave.Desired precision and accuracy: Evaluate the level of detail and precision required for your applications.Budget: Consider your budget, as different laser types vary in cost.Maintenance requirements: Evaluate the maintenance needs and costs associated with each laser type.

By carefully considering these factors, you can select the most suitable laser cutter or engraver for your specific requirements.

Laser Sharp: Why Laser Cutting Should Be Your Go-To for Product Manufacturing

Laser Sharp: Why Laser Cutting Should Be Your Go-To for Product Manufacturing

In today's competitive manufacturing landscape, efficiency, precision, and versatility are king. Enter laser cutting technology, a game-changer that offers a multitude of advantages for product creation. Whether you're a seasoned manufacturer or a budding entrepreneur, this article delves into the compelling reasons why laser cutting should be your go-to method for product manufacturing.

Revolutionizing Production: Laser cutting offers a distinct edge over traditional manufacturing methods:

Unmatched Precision: Laser cutters deliver incredibly clean and precise cuts, ensuring consistent quality and eliminating human error in the cutting process. This is crucial for products requiring intricate details or tight tolerances.

Material Versatility: Laser cutters can handle a wide range of materials, from wood and acrylic to metals and even fabrics. This opens doors to a vast array of product possibilities and caters to diverse design needs.

Speed and Efficiency: Laser cutting offers rapid turnaround times compared to traditional methods. This translates to faster production cycles, quicker product launches, and the ability to meet tight deadlines.

Minimal Waste Generation: Laser cutting utilizes a focused laser beam, minimizing material waste during the cutting process. This translates to cost savings and a more environmentally friendly production approach.

Design Freedom: Laser cutting technology allows for complex designs to be incorporated into products. This empowers manufacturers to create unique and innovative products that stand out from the competition.

Scalability: Laser cutting can be readily scaled to accommodate low-volume production runs for prototypes or high-volume manufacturing for established products.

Reduced Labor Costs: Laser cutting automates the cutting process, reducing reliance on manual labor. This can translate to lower production costs and improved overall efficiency.

Beyond the Basics: Additional Advantages for Manufacturers:

Improved Product Quality: The precise cuts and minimal material handling associated with laser cutting lead to a higher overall product quality.

Enhanced Design Flexibility: Laser cutting allows for intricate details and design elements to be incorporated, leading to more visually appealing and functional products.

Prototyping Efficiency: Laser cutting is ideal for creating prototypes quickly and efficiently, enabling rapid design iteration and product development.

Customization Potential: Laser cutting allows for easy product customization, catering to individual customer needs or creating limited-edition product lines.

Laser Cutting: Ideal for a Range of Products:

The applications of laser cutting in product manufacturing are vast:

Electronics: Laser cutting is used to create precise circuit board outlines and component stencils.

Consumer Goods: From crafting wooden toys to cutting intricate jewelry pieces, laser cutting empowers creativity in consumer product design.

Wearables: Laser cutting allows for the creation of customized watch bands, intricate details on clothing, or personalized accessories.

Prototyping: Laser cutting is instrumental in creating precise and functional prototypes for various industries.

Signage and Displays: Laser cutting allows for the creation of high-quality signage, promotional displays, and custom packaging solutions.

Conclusion:

Laser cutting technology is no longer a futuristic vision; it's a manufacturing reality. By embracing laser cutting, you gain a competitive edge through its precision, speed, versatility, and ability to produce high-quality products. So, rethink your manufacturing approach – with laser cutting, the possibilities are as sharp as the cuts themselves.

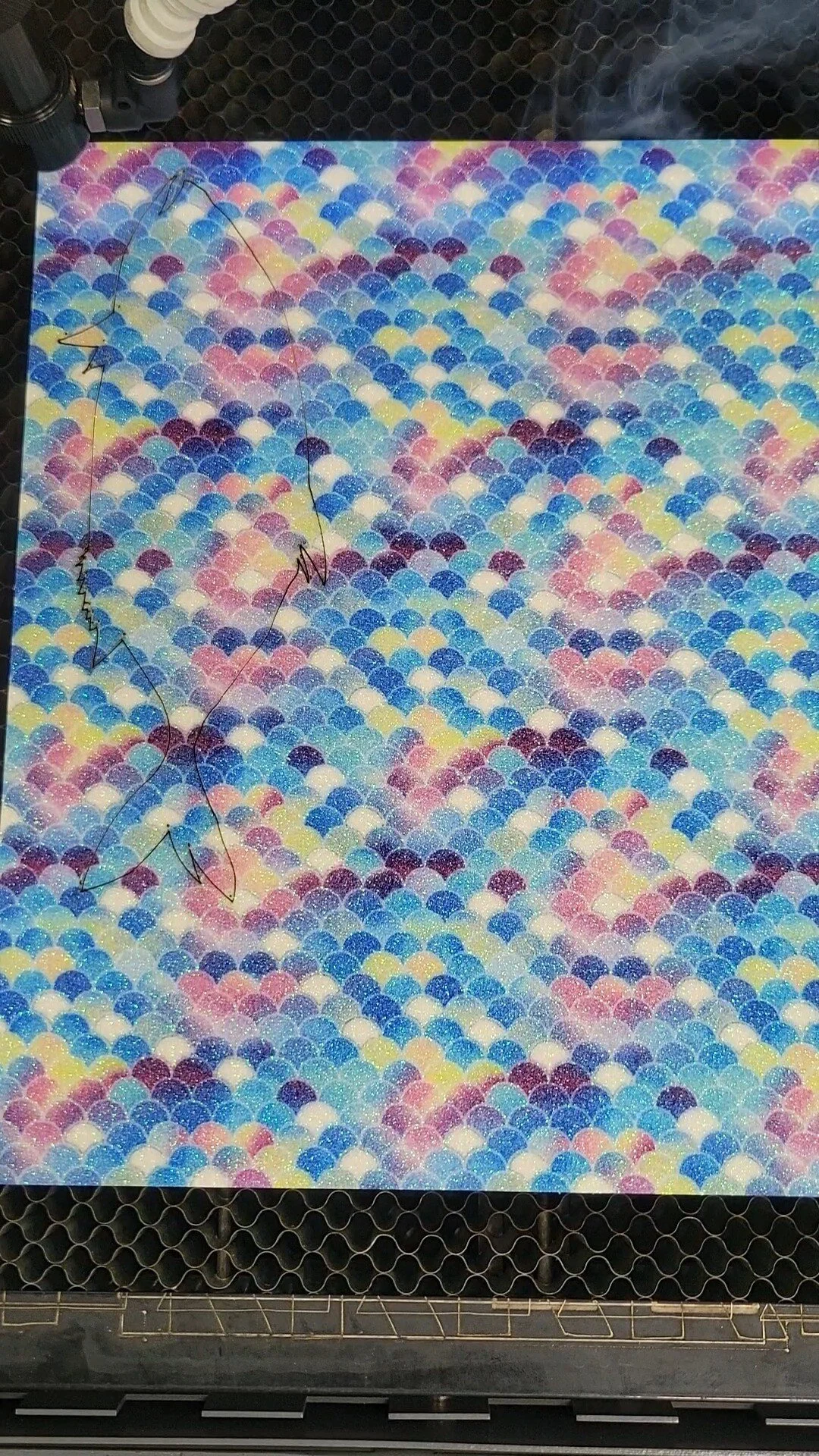

Laser Cutting Stencils: Precision and Versatility

Laser Cutting Stencils: Precision and Versatility

Laser cutting technology has revolutionized the stencil-making process, offering unparalleled precision, speed, and customization options. Stencils are widely used in various applications, from art and crafts to industrial manufacturing, and laser cutting has become the preferred method for creating them.

Advantages of Laser Cutting Stencils

1. Precision and Accuracy: Laser cutters can create stencils with exceptional precision, ensuring clean edges and intricate details. This is crucial for applications where accuracy is critical, such as fine art and industrial processes.2. Versatility: Laser cutting can be used to create stencils from a wide range of materials, including metal, plastic, wood, and cardboard. This versatility allows for the creation of stencils for various applications, from painting and spray-painting to sandblasting and etching.3. Speed and Efficiency: Laser cutting is a highly efficient process, capable of producing stencils quickly and accurately. This is particularly beneficial for large-scale production or projects with tight deadlines.4. Customization: Laser cutting allows for a high degree of customization, enabling the creation of stencils with unique shapes, sizes, and patterns. This is ideal for artists, designers, and manufacturers who require tailored stencils for their specific needs.5. Durability: Stencils created with laser cutting are often more durable than those made using traditional methods, as the cutting process can create clean edges that are less prone to wear and tear.

Types of Stencils Made with Laser Cutting

6. Painting Stencils: These stencils are used to create patterns or designs on surfaces using paint, spray paint, or other coatings. They can be made from a variety of materials, including metal, plastic, and cardboard.7. Etching Stencils: These stencils are used to create etched patterns on surfaces using chemicals or abrasive materials. Etching stencils are often made from metal or a durable plastic.8. Sandblasting Stencils: These stencils are used to create textured surfaces using sand or other abrasive materials. Sandblasting stencils are typically made from metal or a thick plastic.9. Industrial Stencils: These stencils are used in industrial applications, such as marking products or creating patterns on large surfaces. Industrial stencils are often made from durable materials like metal or high-density polyethylene (HDPE).

Laser Cutting Stencils for Artists and Designers

Laser cutting has become a popular tool for artists and designers who want to create unique and intricate stencils. By using laser cutting, artists can easily create custom stencils for their projects, allowing them to experiment with different designs and materials.

Custom Stencils: Artists can create custom stencils with complex patterns and designs that would be difficult or impossible to achieve using traditional methods.Mixed Media: Laser cutting can be used to create stencils for mixed media projects, combining different materials and techniques.Limited Edition Prints: Artists can use laser cutting to create limited edition prints, adding a unique and personalized touch to their work.

Laser Cutting Stencils for Industrial Applications

Laser cutting stencils are widely used in industrial applications, such as manufacturing, construction, and product labeling. By using laser cutting, manufacturers can create high-quality stencils that improve efficiency and accuracy.

Product Marking: Laser cutting can be used to create stencils for marking products with logos, serial numbers, or other information.Industrial Decoration: Laser cutting can be used to create decorative patterns or designs on industrial products, such as machinery or equipment.Manufacturing Processes: Laser cutting stencils can be used in various manufacturing processes, such as etching, engraving, and sandblasting.

Choosing the Right Laser Cutter for Stencil Making

The choice of laser cutter for stencil making depends on several factors, including the materials to be cut, the desired level of precision, and the volume of production. Some of the most common laser cutter types used for stencil making include:

CO2 Laser Cutters: These are versatile machines that can cut a wide range of materials, including wood, acrylic, and cardboard.Fiber Lasers: Fiber lasers are ideal for cutting metals and other materials with high melting points.YAG Lasers: YAG lasers are often used for marking and engraving applications, but can also be used for cutting certain materials.

In conclusion, laser cutting has revolutionized the stencil-making process, offering unparalleled precision, versatility, and efficiency. By understanding the different types of stencils and laser cutters available, you can select the right tools for your specific needs and create high-quality stencils for a wide range of applications.

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)