Laser 101: f.a.q and tips about Laser cutting

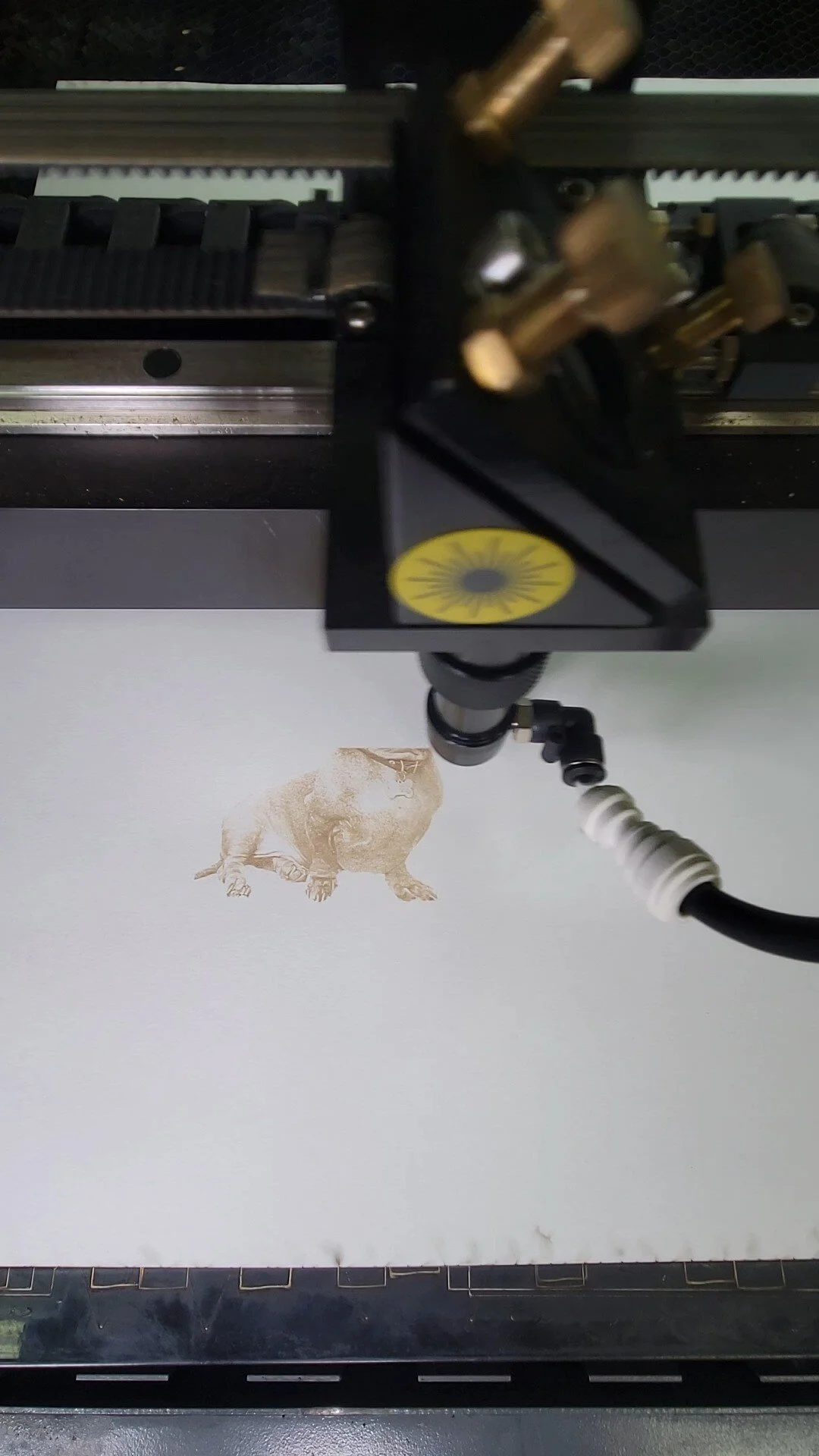

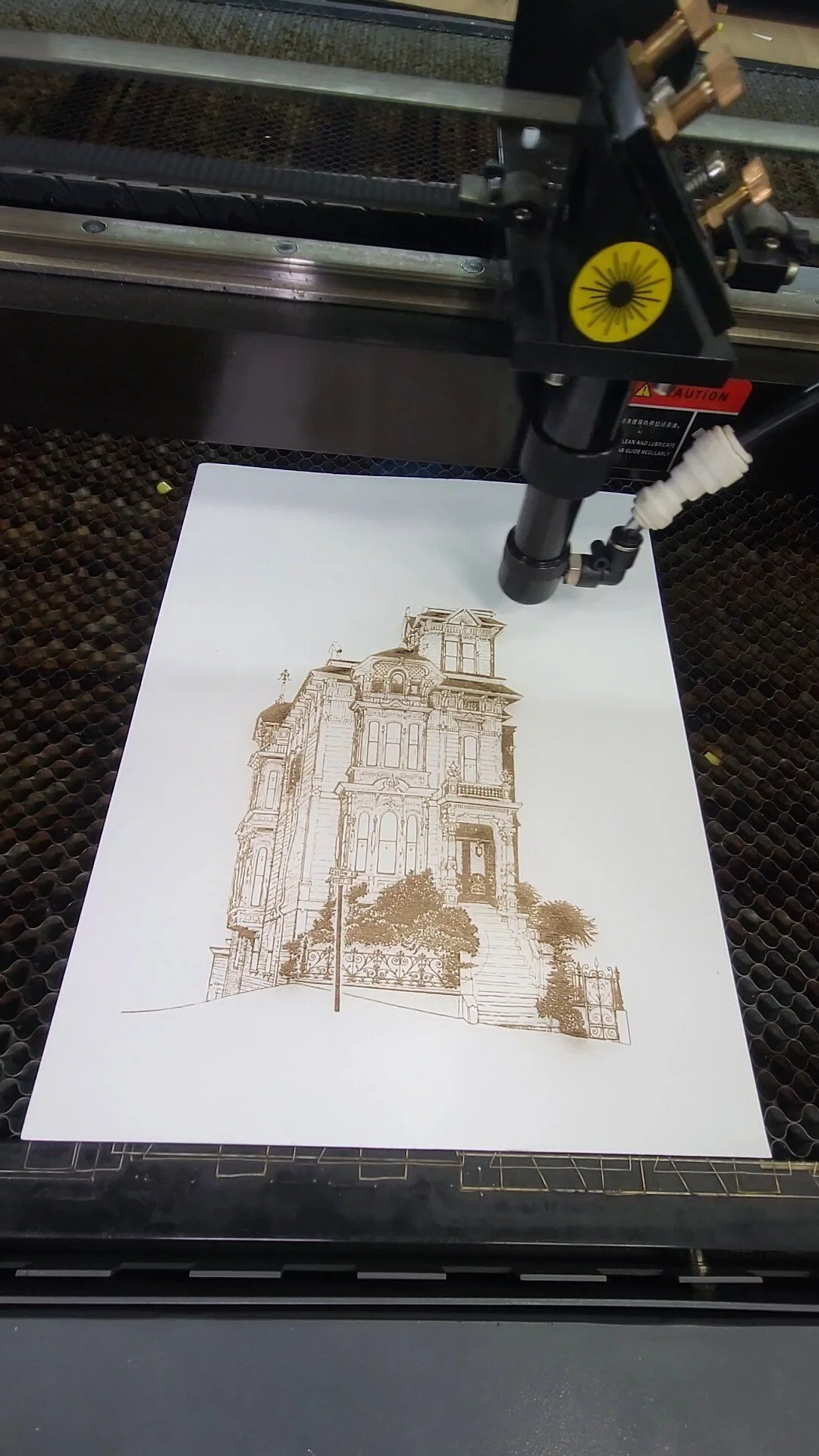

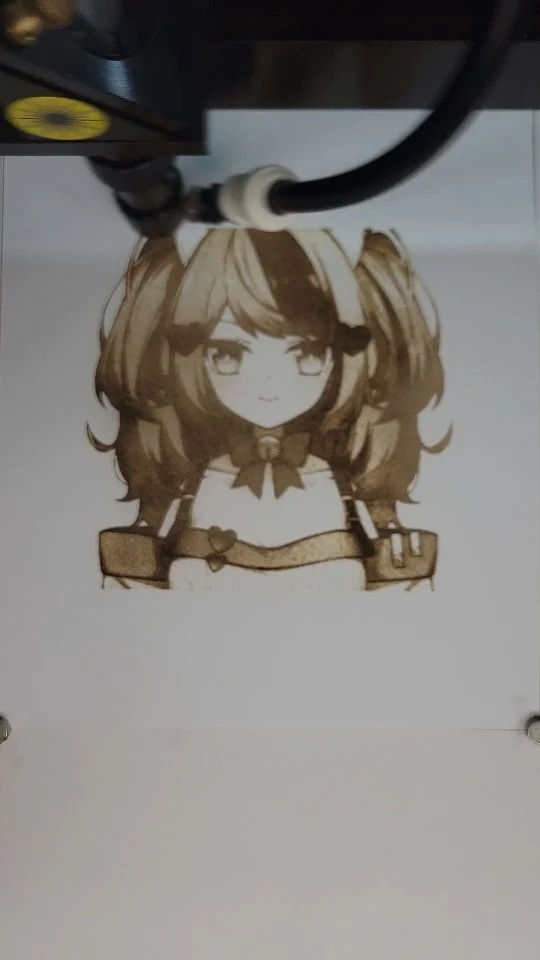

New to laser cutting? Start here. We explain the basics—how CO₂ lasers cut and engrave, which materials are safe, and how to set up your file. You’ll learn the difference between cutting and engraving, why vector files matter, and simple ways to avoid burn marks or rough edges. We also cover safety, ventilation, and tips for better results. Whether you plan to rent a laser or have us do the work, this quick guide will help you make confident choices and get cleaner parts.

FAQs

- Cutting vs. engraving—what’s the difference?

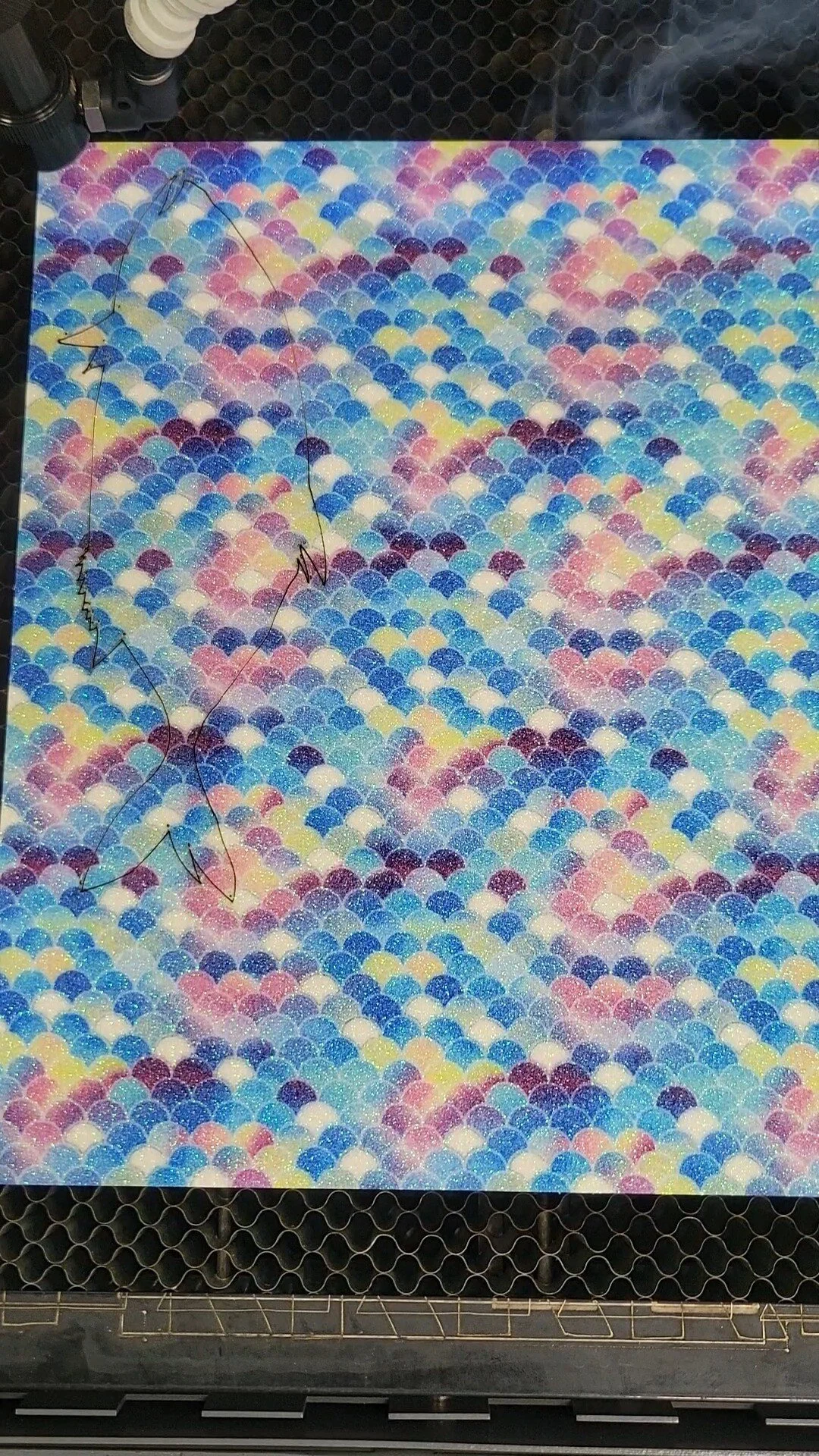

Cutting goes through the material; engraving marks the surface. - Which materials are safe to cut?

Common options include acrylic, wood, cardboard, some fabrics, and other laser-safe materials. Avoid PVC and unknown plastics. - Why won’t JPEG or PNG work for cutting?

They don’t contain paths. Laser cutters need vector files like AI, DXF, or PDF. - What software should I use?

Illustrator or LightBurn are common choices. Export clean vectors at the correct scale. - Any quick tips for cleaner results?

Use the right material, nest parts to save stock, keep optics clean, and choose sensible power/speed settings.

Top Laser Cutting Shops in Los Angeles

Top Laser Cutting Shops in Los Angeles

Los Angeles is a hub for creativity and innovation, and laser cutting is no exception. With a burgeoning maker culture and a demand for precise, customized products, the city boasts a variety of laser cutting shops to cater to different needs.

American Laser Cutter

Location: 1319 S Los Angeles St, Los Angeles, CA 90015

Services: Laser cutting, engraving, acrylic store, repair service, sign shop, trophy shop

Known for: Wide range of services, customer-centric approach

Factors to Consider When Choosing a Shop

Equipment: Ensure the shop has the right laser cutter for your materials and project requirements.

Expertise: Look for shops with experienced operators who can provide guidance and recommendations.

Turnaround Time: Consider the shop's capacity to meet your project deadlines.

Pricing: Compare prices and services offered by different shops.

Customer Reviews: Read reviews to get a sense of the shop's reputation and customer satisfaction.

By carefully considering these factors, you can find the perfect laser cutting shop to bring your ideas to life.

Note: It's essential to contact the shops directly to inquire about their specific services, pricing, and availability.

Would you like to know more about specific types of projects that these shops might specialize in?

Rent or Own? Unveiling the Advantages of Renting a Laser Cutter for DIY Projects

Rent or Own? Unveiling the Advantages of Renting a Laser Cutter for DIY Projects

The world of DIY has expanded dramatically with the advent of laser cutting technology. This powerful tool allows for precise cuts on a vast array of materials, opening doors to endless creative possibilities. But when embarking on your DIY journey, a crucial decision arises: should you rent or own a laser cutter? This article explores the advantages of renting a laser cutter, highlighting the reasons why it might be the perfect solution for your project needs.

The Case for Renting a Laser Cutter:

While owning a laser cutter offers a sense of autonomy, renting presents several compelling advantages, particularly for DIY enthusiasts:

Cost-Effectiveness: Laser cutters represent a significant investment. Renting eliminates the upfront cost, making laser cutting technology accessible for smaller projects or those on a budget.

Project-Specific Needs: Do you only need a laser cutter for a single project or a limited time? Renting allows for flexible use without the long-term commitment of ownership.

No Maintenance Hassles: Laser cutters require regular maintenance and calibration. Renting eliminates the burden of maintenance and ensures you have a machine in top working condition.

Learning Before Investing: Renting allows you to experiment with laser cutting and gain practical experience before committing to purchasing your own machine. This can help you determine if laser cutting aligns with your long-term DIY goals.

Trying Before You Buy: With various laser cutter models available, renting allows you to try different machines and discover which one best suits your needs in terms of power, bed size, and material compatibility.

Space Considerations: Laser cutters can have a significant footprint. Renting eliminates the need to dedicate permanent space in your home or workshop for the machine.

Renting Doesn't Mean Missing Out:

Many rental facilities offer additional benefits to enhance your DIY experience:

Training and Support: Some rental facilities provide basic training or instructional resources to get you started with laser cutting safely and effectively.

Material Selection: Certain rental facilities offer a selection of laser-cuttable materials you can purchase for your project alongside renting the machine.

Cutting Time Flexibility: Rental options can vary, from hourly rates to daily or weekly rentals, allowing you to choose a timeframe that best suits your project needs.

Is Renting Right for You?

Here are some factors to consider when deciding between renting and owning a laser cutter for your DIY projects:

Project Scope and Frequency: For one-off projects or infrequent use, renting is likely more cost-effective. For frequent use or ongoing projects, owning might be more economical in the long run.

Budgetary Constraints: If upfront costs are a concern, renting allows you to access laser cutting technology without a significant financial investment.

Available Space: If space is limited in your home or workshop, renting eliminates the need for dedicated storage for the machine.

Comfort Level: If you're new to laser cutting, renting allows you to gain experience and build confidence before making a significant purchase.

Conclusion:

Renting a laser cutter is a fantastic option for DIY enthusiasts to explore the potential of this technology without a major financial commitment. With its cost-effectiveness, project-specific flexibility, and learning opportunities, renting empowers you to bring your creative visions to life. So, weigh your options, consider your project needs, and embrace the exciting world of laser cutting – rented or owned, the possibilities are endless!

Intro to LightBurn class

Unlock Your Creative Potential with American Laser Cutter's Intro to LightBurn

American Laser Cutter is excited to announce the launch of our Intro to LightBurn course, now available remotely for just $120 per hour. This comprehensive training program is designed to empower you with the skills and knowledge needed to master the art of laser cutting and engraving.

Why Choose Our Intro to LightBurn Course?

Expert Instruction: Our experienced instructors will guide you through the intricacies of LightBurn software, ensuring you gain a solid understanding of its features and capabilities.

Personalized Learning: Our remote learning format allows for personalized attention and tailored instruction to meet your specific needs.

Hands-On Experience: Learn by doing with practical exercises and real-world project examples.

Flexible Scheduling: Our flexible scheduling options make it easy to fit training into your busy schedule.

Affordable Pricing: Invest in your skills with our competitive pricing.

What You'll Learn:

LightBurn Basics: Learn the fundamentals of LightBurn software, including the user interface, toolbars, and basic operations.

Design and Preparation: Discover how to create and prepare your designs for laser cutting, from importing images to vectorizing artwork.

Material Selection and Settings: Learn about different materials suitable for laser cutting and how to optimize settings for optimal results.

Laser Cutting Techniques: Explore various laser cutting techniques, such as engraving, cutting, and marking.

Troubleshooting Tips: Learn how to troubleshoot common issues and optimize your laser cutting process.

Take the Next Step in Your Creative Journey

Whether you're a hobbyist, artist, or business owner, our Intro to LightBurn course is the perfect way to unlock the full potential of laser cutting technology. Don't miss this opportunity to learn from industry experts and elevate your projects to new heights.

Enroll in our Intro to LightBurn course today and start your laser cutting journey!

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)