Laser 101: f.a.q and tips about Laser cutting

New to laser cutting? Start here. We explain the basics—how CO₂ lasers cut and engrave, which materials are safe, and how to set up your file. You’ll learn the difference between cutting and engraving, why vector files matter, and simple ways to avoid burn marks or rough edges. We also cover safety, ventilation, and tips for better results. Whether you plan to rent a laser or have us do the work, this quick guide will help you make confident choices and get cleaner parts.

FAQs

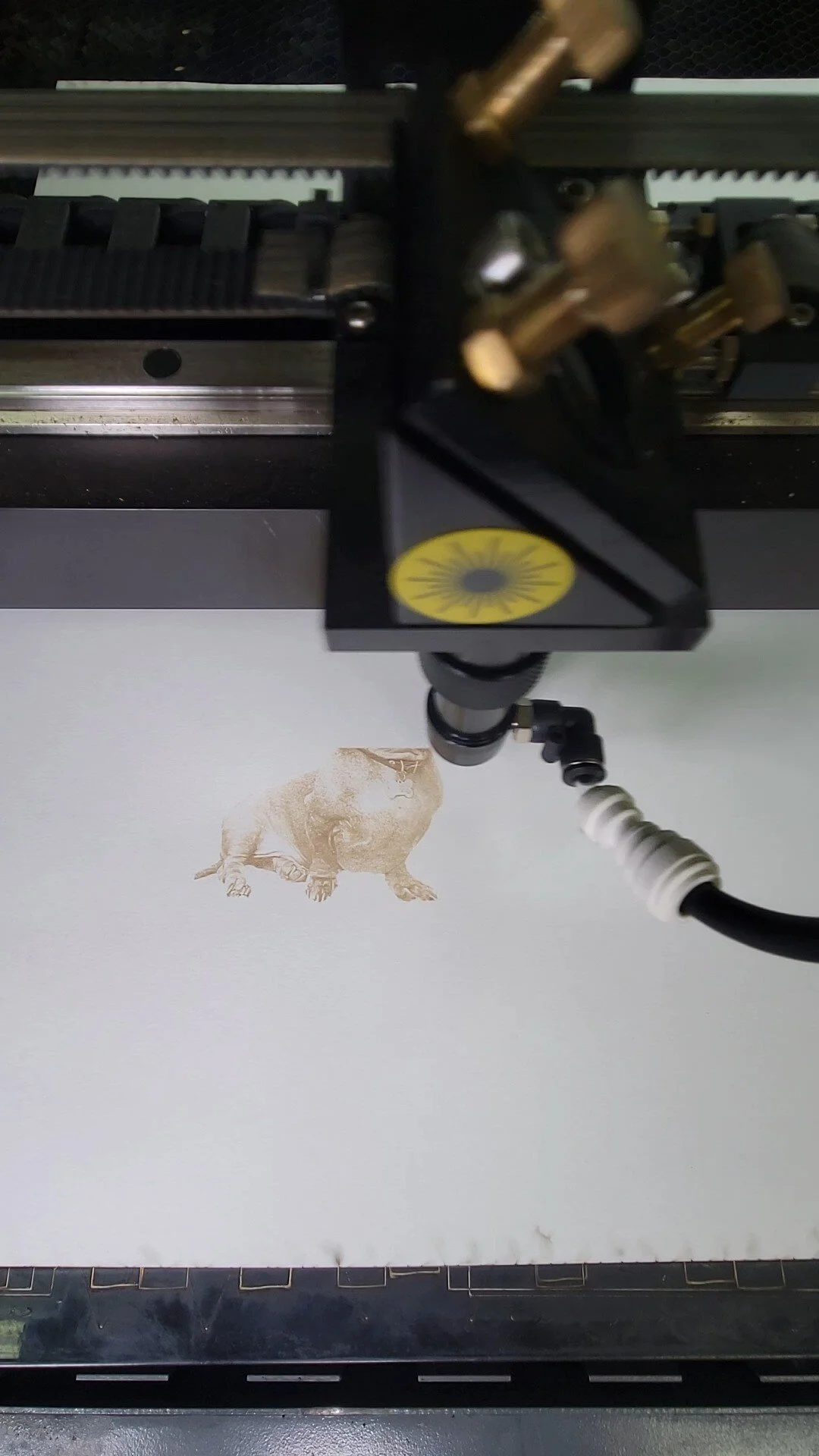

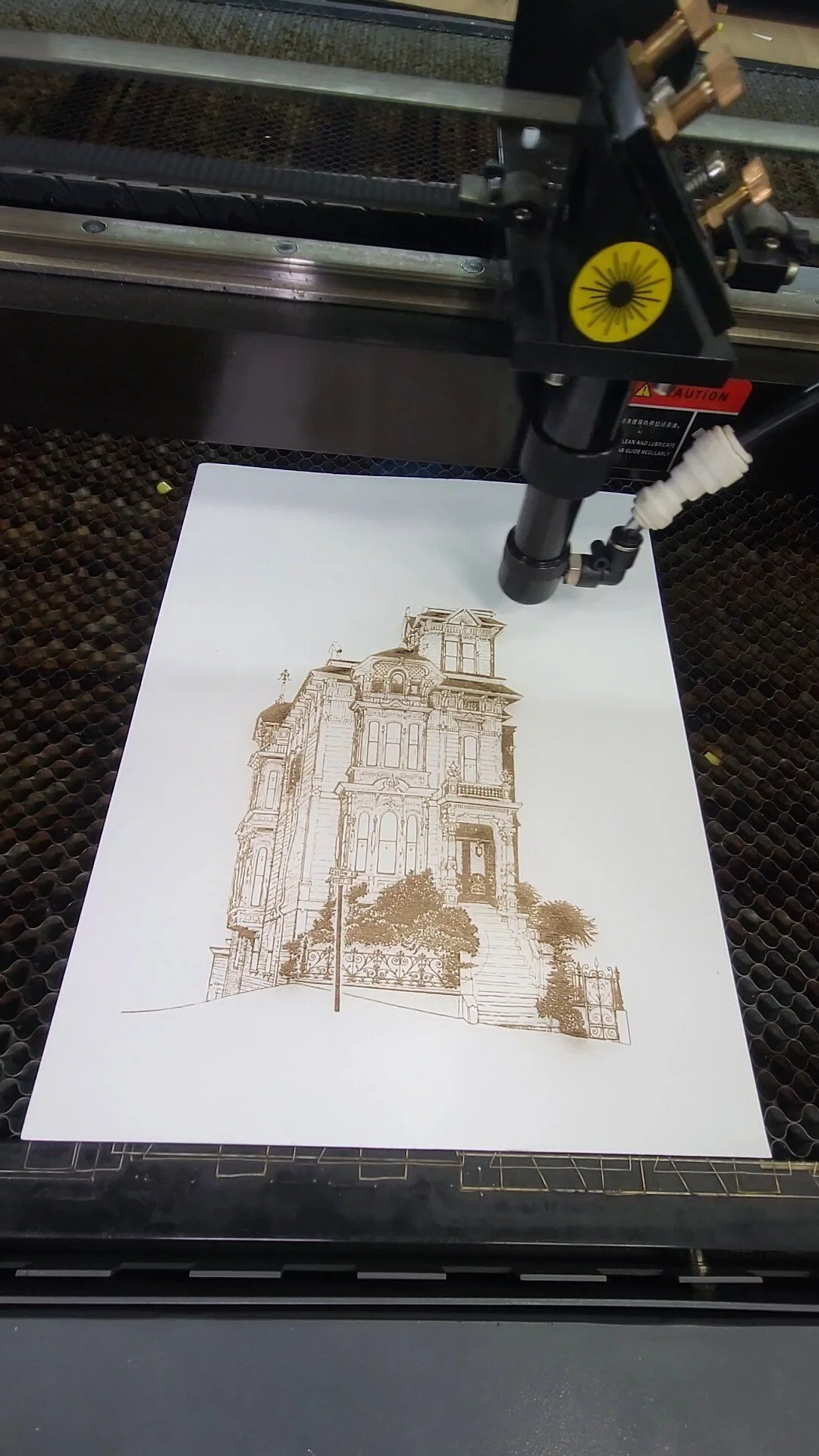

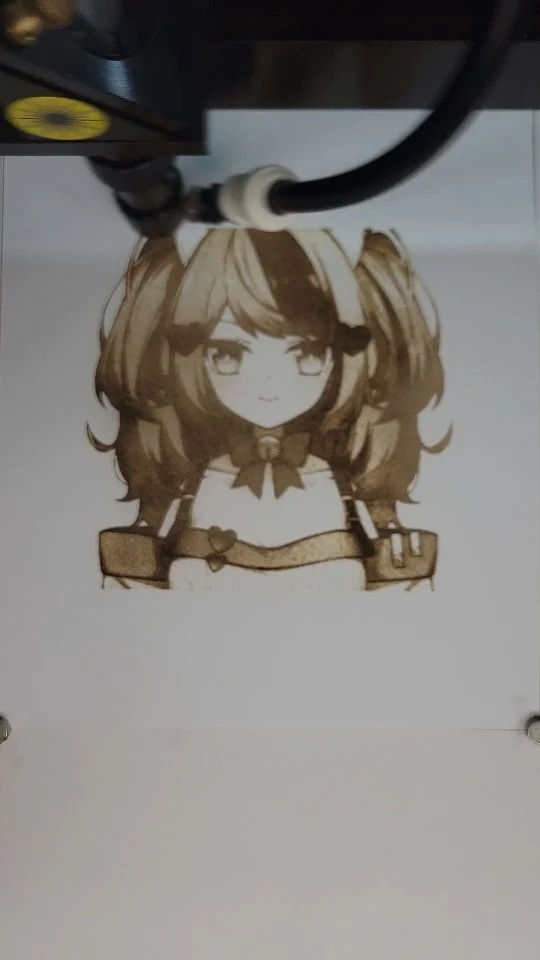

- Cutting vs. engraving—what’s the difference?

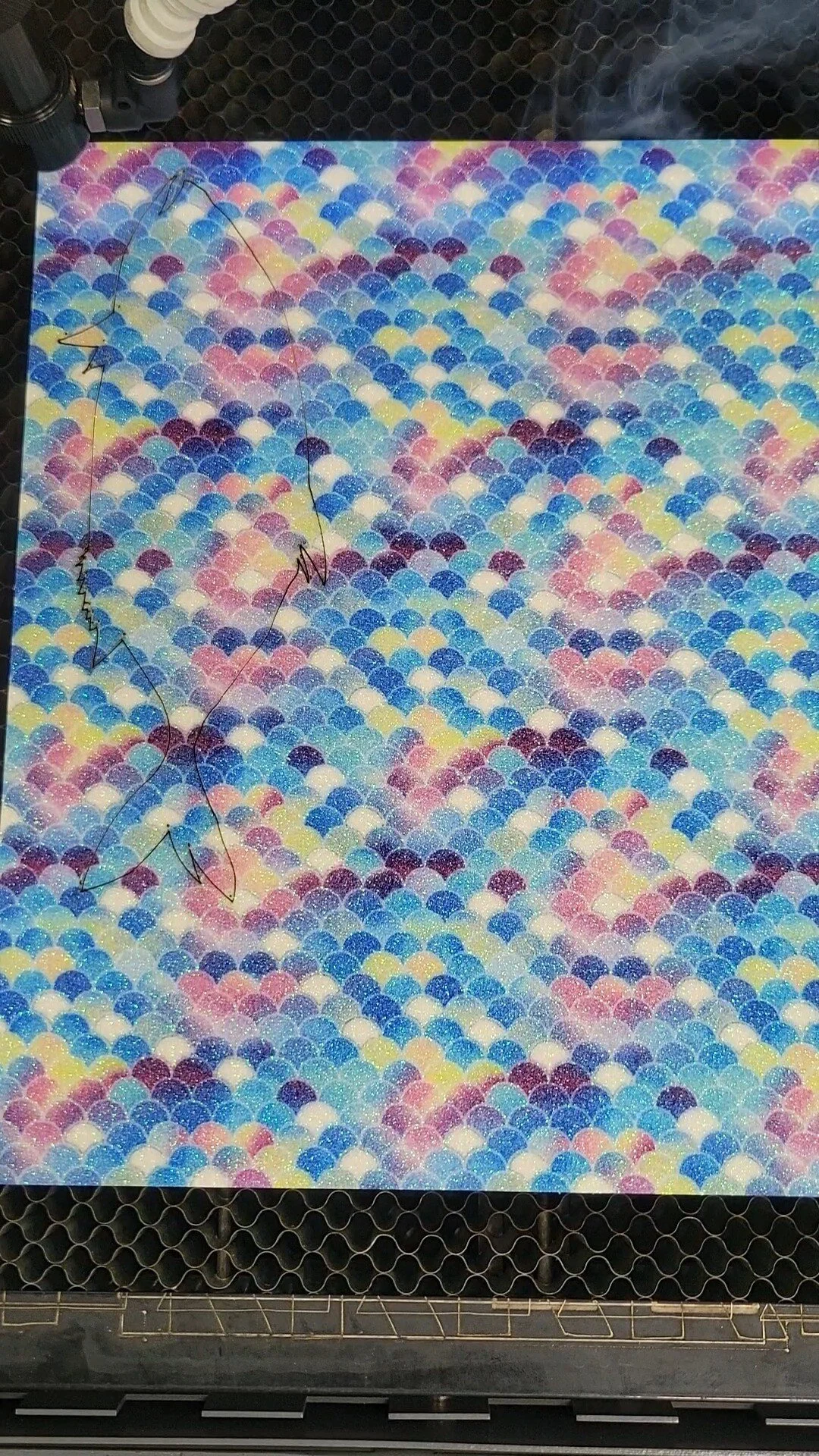

Cutting goes through the material; engraving marks the surface. - Which materials are safe to cut?

Common options include acrylic, wood, cardboard, some fabrics, and other laser-safe materials. Avoid PVC and unknown plastics. - Why won’t JPEG or PNG work for cutting?

They don’t contain paths. Laser cutters need vector files like AI, DXF, or PDF. - What software should I use?

Illustrator or LightBurn are common choices. Export clean vectors at the correct scale. - Any quick tips for cleaner results?

Use the right material, nest parts to save stock, keep optics clean, and choose sensible power/speed settings.

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)