American Laser Cutter: Your Precision Cutting Partner in Los Angeles

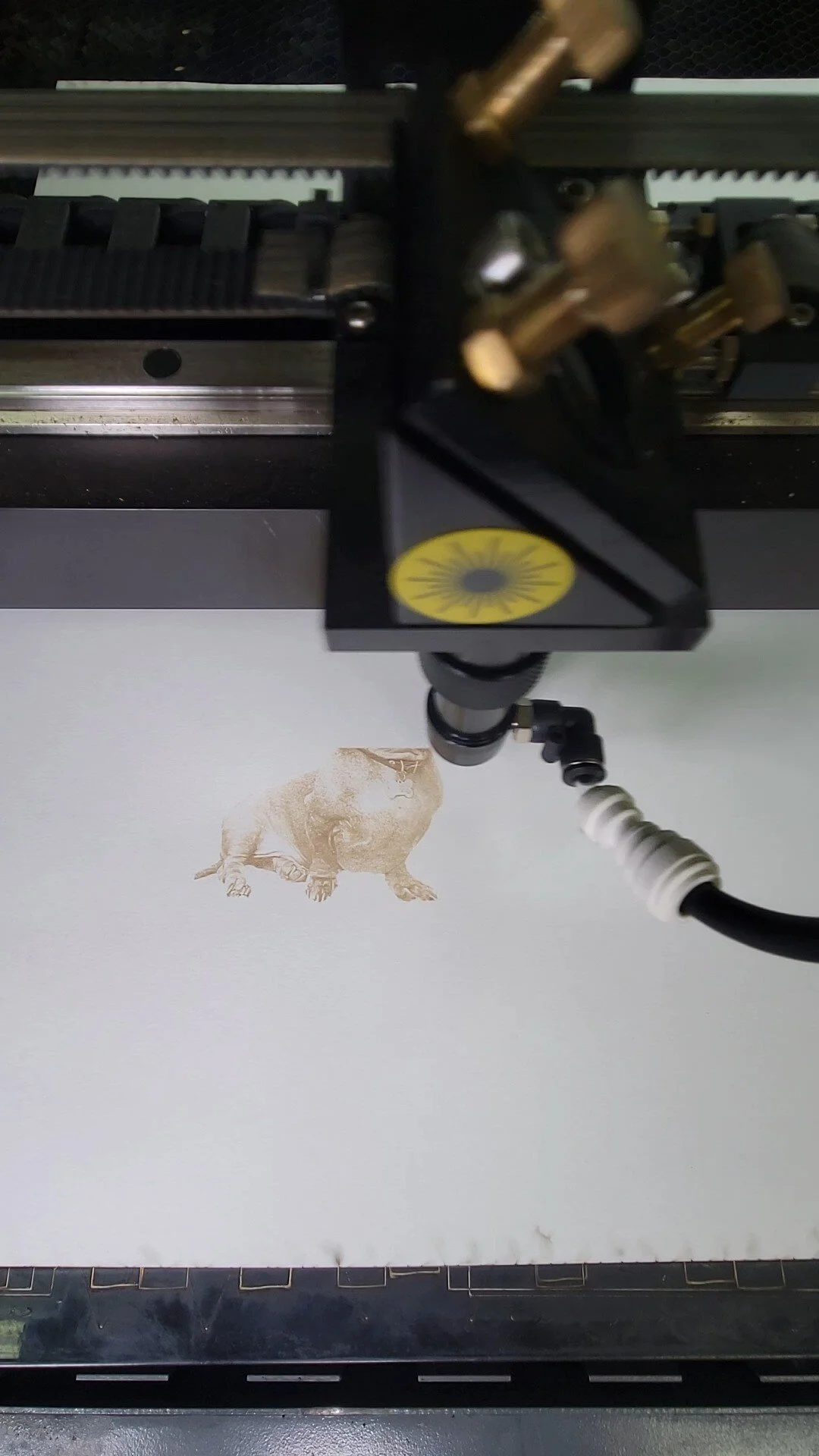

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

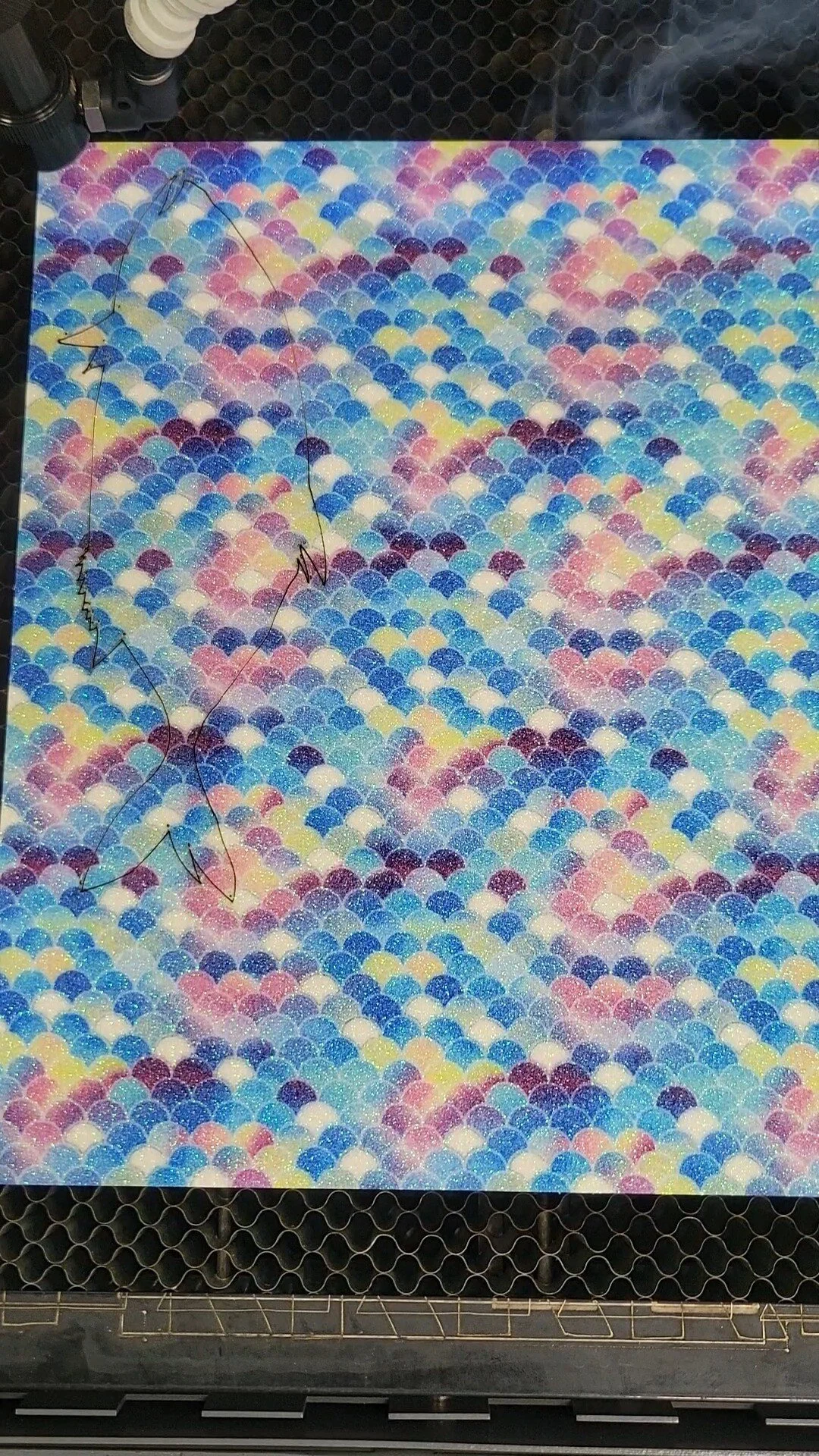

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

When to Use Which Laser Cutter: CO2, Fiber, or Diode

When to Use Which Laser Cutter: CO2, Fiber, or Diode

Choosing the right laser cutter for a specific task is crucial for efficiency, precision, and cost-effectiveness.

Each type of laser cutter has its strengths and weaknesses, making them ideal for different applications.

1. From Precision to Power: How to Choose the Perfect Laser Cutter for Your Industry - Medium

2. Fiber vs. CO2 vs. Diode Laser: The Ultimate Guide - xTool Europe Store

CO2 Laser Cutters

Best for: Non-metallic materials like wood, acrylic, paper, fabric, and leather.

When to use:

Cutting and engraving intricate designs on wood or acrylic for crafts, signage, or interior decor.

Processing textiles and fabrics for fashion or home decor.

Creating prototypes or small-scale production runs of non-metallic components.

Fiber Laser Cutters

Best for: Metals, especially stainless steel, aluminum, and carbon steel.

1. Laser Engravers for Metal Guide (CO2 vs. Fiber vs. Diode) - Laserax

When to use:

Cutting thick metal sheets for industrial applications, such as automotive or aerospace.

1. How Accurate is Laser Cutting: Standard Laser Cutting Tolerances - ACCURL

Producing metal components with high precision and speed.

Engraving or marking metals for identification or aesthetic purposes.

Diode Laser Cutters

Best for: Thin materials like acrylic, wood, and some plastics.

When to use:

Cutting or engraving delicate materials without causing damage.

Creating small, intricate designs or patterns.

Prototyping or hobbyist projects with limited material thickness.

Comparison Summary

Laser TypeBest forIdeal ApplicationsCO2Non-metalsWoodworking, acrylic fabrication, textile cuttingFiberMetalsMetal fabrication, industrial productionDiodeThin materialsHobbyist projects, small-scale cutting

Export to Sheets

Factors to Consider

Material thickness: The thickness of the material will determine which laser cutter is suitable.

Desired cut quality: The required precision and finish will influence the choice of laser.

Speed: High-volume production may necessitate a faster laser cutter like fiber.

1. The Advantages of Fiber Laser Cutting - McKiney Manufacturing

Budget: CO2 lasers are generally more affordable, while fiber lasers tend to be more expensive.

1. CO2 Laser Vs Fiber Laser: Differences in Laser Cutting | Xometry

By understanding the strengths and weaknesses of each laser type, you can make informed decisions about which one to use for your specific project or application.

CO2, Fiber, and Diode Laser Cutters: A Comparison

CO2, Fiber, and Diode Laser Cutters: A Comparison

Laser cutters have become indispensable tools in various industries, from manufacturing to crafting. But with different types available, choosing the right one can be daunting. Let's delve into the key differences between CO2, fiber, and diode laser cutters.

1. How Laser Cutting Is Used in Different Industries | Xometry

CO2 Laser Cutters

How it works: Uses carbon dioxide as a lasing medium.

1. Understanding CO2 Lasers and the Advantages of Use - Tusco Manufacturing

Material compatibility: Excellent for cutting and engraving non-metals like wood, acrylic, paper, and fabric.

Pros: Versatile, affordable, and can handle a wide range of materials.

Cons: Slower cutting speeds compared to fiber lasers, requires a gas assist for certain materials.

1. CO2 vs. Fiber Laser: Choosing the Right Tool for Your Cutting Needs

Fiber Laser Cutters

How it works: Uses a rare earth-doped fiber as a lasing medium.

1. Laser Engravers for Metal Guide (CO2 vs. Fiber vs. Diode) - Laserax

Material compatibility: Primarily used for cutting metals, but can also process some non-metals.

1. Fiber vs. CO2 vs. Diode Laser: The Ultimate Guide - xTool Europe Store

Pros: High cutting speeds, precision, and efficiency.

1. Laser Engravers for Metal Guide (CO2 vs. Fiber vs. Diode) - Laserax

Cons: Higher initial cost compared to CO2 lasers, limited to certain materials.

Diode Laser Cutters

How it works: Uses a semiconductor diode as a lasing medium.

1. Diode Lasers: Definition, How They Work, Types, Applications, and How to Use | Xometry

Material compatibility: Best suited for thinner materials like acrylic, wood, and some plastics.

Pros: Compact, affordable, and low maintenance.

Cons: Lower power output compared to CO2 and fiber lasers, limited cutting depth.

Choosing the Right Laser Cutter

The best laser cutter for you depends on your specific needs. Consider the following factors:

Materials you'll be cutting: What type of materials will you be working with most frequently?

Cutting thickness: How thick are the materials you need to cut?

Desired speed and precision: Do you prioritize speed or accuracy?

Budget: What is your budget for the laser cutter and ongoing operating costs?

By carefully evaluating these factors, you can select the laser cutter that best suits your requirements and delivers optimal performance.

Would you like to explore specific applications for these laser cutters or discuss potential use cases?

New Kids on the Block: Emerging Laser Cutter Brands in America

New Kids on the Block: Emerging Laser Cutter Brands in America

The laser cutter market is heating up, with new and innovative brands constantly pushing the boundaries of technology and affordability. While established players like Glowforge and Epilog have dominated the scene for years, a crop of fresh contenders is challenging the status quo. Let's explore some of the newest laser cutter brands making waves in the American market.

xTool: Precision Meets Affordability

Hailing from China but gaining significant traction in the US, xTool has rapidly become a household name among hobbyists and small businesses. Their focus on user-friendly interfaces, powerful software, and competitive pricing has made them a strong contender. With models ranging from entry-level to professional, xTool offers something for everyone.

WeCreat: Smart and Safe Laser Cutting

WeCreat has entered the market with a strong emphasis on safety and user experience. Their laser cutters feature advanced safety features like automatic fire detection and a full enclosure, making them ideal for both beginners and experienced users. Additionally, their focus on smart technology, such as camera-based alignment, sets them apart from the competition.

Other Notable Mentions

While xTool and WeCreat are making significant strides, several other brands are also worth mentioning:

Ortur: Known for its budget-friendly options, Ortur has gained a loyal following among DIY enthusiasts and makers.

Atomstack: Offering a balance of affordability and performance, Atomstack has carved a niche for itself in the market.

Snapmaker: While primarily known for 3D printing, Snapmaker also offers laser cutting modules, providing a versatile all-in-one solution.

What to Look for in a New Laser Cutter Brand

When considering a laser cutter from a new brand, keep the following factors in mind:

Build quality and durability: Ensure the machine is built to last.

Cutting and engraving capabilities: Consider the materials you'll be working with and the machine's compatibility.

Software and user interface: A user-friendly experience can significantly impact your workflow.

Safety features: Prioritize safety features to protect yourself and your workspace.

Customer support: Reliable customer support is crucial when dealing with new technology.

Price and value: Compare features and pricing to determine the best value for your needs.

As the laser cutter market continues to evolve, we can expect even more exciting innovations and competitive offerings. By carefully considering your needs and researching the latest brands, you can find the perfect laser cutter to bring your creative visions to life.

Have you tried any of these new laser cutter brands? Share your experiences in the comments below!

xTool Laser Cutters: Precision and Versatility Redefined

xTool Laser Cutters: Precision and Versatility Redefined

xTool has rapidly emerged as a leading player in the desktop laser cutter market, offering a range of innovative and user-friendly machines. Their focus on precision, versatility, and safety has made them a popular choice for hobbyists, small businesses, and even educational institutions.

1. xTool Laser | Smart Desktop Laser Cutter and Engraver

2. 5 Reasons Why the xTool P2 Laser Cutter is the Best Option for Your Small Business

Core Features and Benefits

Precision Cutting and Engraving: xTool laser cutters deliver exceptional accuracy and detail, making them ideal for intricate designs and delicate materials.

Wide Material Compatibility: From wood and acrylic to leather and even some metals, xTool machines can handle a variety of materials, expanding creative possibilities.

User-Friendly Software: Intuitive software makes it easy to design, prepare, and execute cutting or engraving projects, even for beginners.

Safety First: xTool prioritizes user safety with features like automatic air assist, emergency stop buttons, and eye protection.

Compact Design: These machines fit comfortably on desktops, saving space and making them portable.

Community and Support: xTool has a thriving online community, providing users with valuable resources, tutorials, and support.

Popular xTool Laser Cutter Models

xTool D1 Pro: A versatile entry-level model suitable for a wide range of applications.

1. xTool D1 Pro Laser Cutter and Engraver Review - Top 3D Shop

xTool S1: Designed for larger cutting areas and thicker materials, ideal for hobbyists and small businesses.

xTool M1: A multi-functional machine offering cutting, engraving, marking, and even 3D carving capabilities.

Applications of xTool Laser Cutters

The applications for xTool laser cutters are vast and varied:

Hobbyists and Makers: Create custom crafts, home decor items, and personalized gifts.

Small Businesses: Produce custom products, prototypes, and small-scale production runs.

Education: Teach students about laser technology, engineering, and design.

Industrial Prototyping: Rapidly create prototypes for product development.

The Future of xTool

As laser technology continues to advance, xTool is likely to introduce even more innovative and powerful machines. Their commitment to user experience and product development positions them well to remain a leader in the desktop laser cutter market.

Have you used an xTool laser cutter? Share your experiences and projects in the comments below!

Opens in a new window amazon.com

xTool laser cutter

Laser Cut Wedding Invitations: A Cut Above the Rest

Laser Cut Wedding Invitations: A Cut Above the Rest

Laser cutting has revolutionized the wedding invitation industry, offering couples a unique and personalized way to announce their special day.

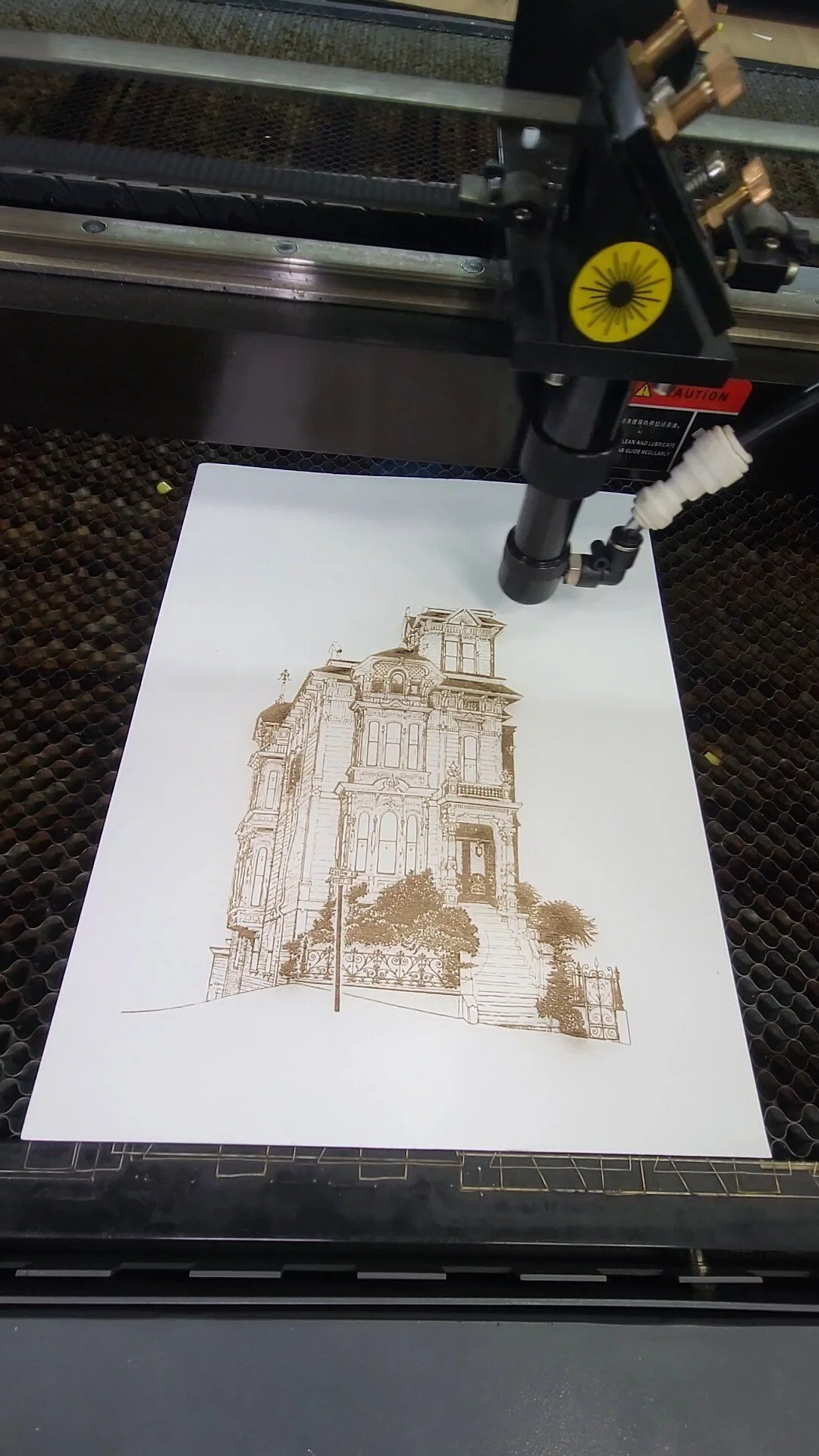

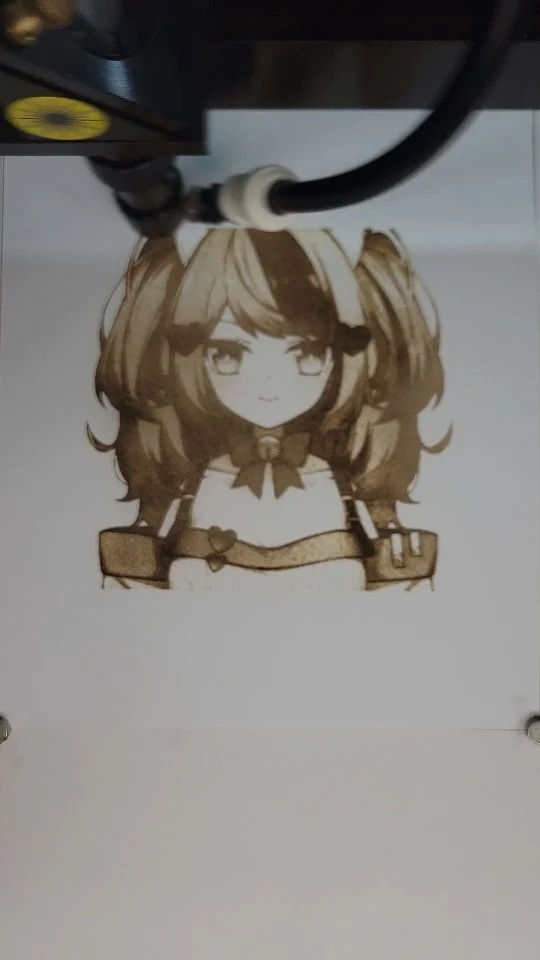

With its precision and intricate detailing capabilities, laser cutting transforms ordinary paper into stunning works of art.

1. Laser Cut Wedding Invitations: Great Picks For Your Laser Business - xTool

2. Laser Cutting and Art: An artistic revolution

The Magic of Laser Cut Invitations

Unparalleled Detail: Laser cutting allows for incredibly intricate designs, from delicate floral patterns to geometric shapes. This attention to detail elevates the invitation to a luxurious level.

Customization: Couples can personalize their invitations to match their wedding theme, color palette, or personal style. Whether it's a classic, modern, or rustic affair, there's a laser cut design to complement it.

Variety of Materials: From elegant paper stocks to shimmering metallic cardstock, laser cutting can be applied to a wide range of materials, offering endless possibilities for creativity.

1. What Materials Are Suitable for Laser Cutting? | Fractory

Eco-Friendly Options: Many laser cutting companies offer eco-friendly options, such as recycled paper or plant-based materials, allowing couples to incorporate sustainability into their wedding planning.

Design Ideas for Laser Cut Invitations

Floral Delights: Intricate floral patterns can create a romantic and ethereal atmosphere.

Geometric Chic: Modern couples may opt for clean lines and geometric shapes for a contemporary look.

Vintage Charm: Laser cutting can recreate the elegance of vintage designs, adding a touch of nostalgia.

Custom Monograms: Personalized monograms add a touch of sophistication and elegance to the invitation.

Layered Effects: Multiple layers of laser-cut paper can create a dimensional and eye-catching effect.

Tips for Choosing Laser Cut Invitations

Set a Budget: Laser cut invitations can range in price, so it's important to establish a budget before starting your search.

Consider Your Theme: Choose a design that complements your overall wedding theme.

Request Samples: Many stationery companies offer samples, allowing you to see the quality of the paper and the intricacy of the laser cutting.

Order Early: To avoid last-minute stress, order your invitations well in advance of your wedding date.

By selecting laser cut wedding invitations, couples can make a lasting first impression on their guests and set the tone for a truly unforgettable celebration.

Top 10 Laser Cutting Videos on YouTube

Top 10 Laser Cutting Videos on YouTube

Laser cutting is a fascinating process that has captured the attention of many on YouTube. Here are 10 of the most popular videos that showcase the power and precision of this technology:

"Laser Cutting a Giant Wooden Puzzle"

This video features a talented craftsman using a laser cutter to create an intricate wooden puzzle. The intricate details and smooth cuts are a testament to the power of laser cutting.

"Laser Cutting a Custom Guitar Body"

Watch as a skilled luthier uses a laser cutter to create a custom guitar body from scratch. The precision and speed of the laser cutter are impressive.

"Laser Cutting a Metal Sculpture"

This video showcases the artistry of laser cutting as a sculptor creates a stunning metal sculpture. The intricate details and clean lines are a testament to the versatility of laser cutting.

"Laser Cutting a Model Car"

This video features a hobbyist using a laser cutter to create a detailed model car. The precision and accuracy of the cuts are impressive.

"Laser Cutting a Custom Phone Case"

This video showcases the creative possibilities of laser cutting as a designer creates a custom phone case with a unique design.

"Laser Cutting a Wooden Sign"

This video features a DIY enthusiast using a laser cutter to create a custom wooden sign for their home. The process is simple and the results are impressive.

"Laser Cutting a Leather Wallet"

This video showcases the versatility of laser cutting as a craftsman creates a custom leather wallet with intricate details.

"Laser Cutting a Custom Keychain"

This video features a small business owner using a laser cutter to create custom keychains for their customers. The process is quick and efficient.

"Laser Cutting a Custom Jewelry Piece"

This video showcases the precision of laser cutting as a jeweler creates a custom piece of jewelry with intricate details.

"Laser Cutting a Custom Cutting Board"

This video features a home cook using a laser cutter to create a custom cutting board with a unique design. The process is simple and the results are impressive.

These are just a few of the many amazing laser cutting videos on YouTube. Be sure to check out these videos and others to see the incredible potential of this technology.

Diode Tabletop Laser Cutters: A Cutting-Edge Revolution

Diode Tabletop Laser Cutters: A Cutting-Edge Revolution

Diode tabletop laser cutters, compact and efficient machines, have rapidly gained popularity across various industries. With continuous advancements in laser technology, these cutters are becoming increasingly powerful and versatile, offering new possibilities for precision cutting, engraving, and marking.

The Rise of Diode Tabletop Laser Cutters

Unlike their larger CO2 and fiber counterparts, diode laser cutters are characterized by their smaller size, lower power consumption, and affordability. This makes them ideal for a wide range of applications, including:

Prototyping and rapid manufacturing:

Quickly creating prototypes and small production runs.

Hobbyists and makers: Enabling creative projects and personalized items.

Education and research: Supporting hands-on learning and experimentation.

Small-scale industrial production: Handling intricate cutting and engraving tasks.

Latest Advancements in Diode Tabletop Laser Cutters

Increased Power and Cutting Depth: Newer models boast higher wattage outputs, allowing for deeper cuts into various materials, including thicker acrylics and woods.

Enhanced Cutting Speed: Advancements in laser optics and control systems have led to significantly improved cutting speeds, boosting productivity.

Improved Beam Quality: Higher-quality laser beams result in cleaner cuts, finer details, and reduced heat-affected zones.

Advanced Motion Control: Precise motion control systems ensure accurate and repeatable cuts, even for complex designs.

User-Friendly Software: Intuitive software packages simplify the design and cutting process, making the machines accessible to users of all skill levels.

Expanded Material Compatibility: Diode laser cutters can now cut a wider range of materials, including some metals and engineered materials.

1. What You Need to Know about Direct Diode Laser Cutters - Westway Machinery

Integration of Automation: Some models offer automation features, such as automatic material feeding and removal, increasing efficiency.

Applications of Diode Tabletop Laser Cutters

The versatility of diode tabletop laser cutters has expanded their application range:

Acrylic and plastic cutting: Creating custom signs, awards, and decorative items.

Woodworking: Cutting intricate designs, engraving, and marking on wood products.

Leather and fabric cutting: Producing fashion accessories, home decor items, and industrial components.

Paper and cardboard cutting: Creating prototypes, packaging materials, and paper crafts.

Electronic component manufacturing: Cutting and marking circuit boards and other electronic components.

Medical device manufacturing: Producing small-scale medical components and prototypes.

As technology continues to evolve, diode tabletop laser cutters are poised to become even more powerful and versatile tools, offering endless possibilities for innovation and creativity.

Laser Cutting: A Versatile Tool Across Industries

Laser Cutting: A Versatile Tool Across Industries

Laser cutting, a process that uses a high-powered laser beam to cut through materials, has revolutionized manufacturing and production across a wide range of industries.

Its precision, speed, and versatility have made it an indispensable tool for businesses seeking efficiency and quality.

1. What is Laser Cutting: Process, Advantages, Materials and Costs - 3ERP

2. What Industries Use Laser Cutting? - G.E. Mathis Company

Key Industries Benefiting from Laser Cutting

Automotive Industry:

Precision cutting of complex metal components for car bodies, chassis, and interiors.

1. Laser-Cut Metal: Elevating Metalworking Precision and Efficiency | IMS

Creation of prototypes and tooling for rapid development.

Production of lightweight and high-strength components.

Aerospace and Defense:

Manufacturing of intricate parts for aircraft and spacecraft.

Cutting of composite materials used in aerospace applications.

Production of military equipment and components with stringent quality standards.

1. Laser Cutting Applications: 27 Industry Uses with Examples - ACCURL

Electronics and Technology:

Precision cutting of printed circuit boards (PCBs).

Manufacturing of electronic components with intricate designs.

Production of metal enclosures for electronic devices.

1. STAINLESS STEEL ENCLOSURE LASER CUTTING - TAKACHI ENCLOSURE - YouTube

Medical Device Manufacturing:

Creation of precise and sterile medical implants and instruments.

1. The Importance of Laser Metal Cutting In The Medical Industry

Cutting of delicate materials used in medical devices.

Production of dental and orthodontic appliances.

Metal Fabrication:

Cutting of various metal sheets and plates with complex shapes.

Production of metal components for construction, machinery, and other industries.

Prototyping and small-scale production of metal parts.

1. The Science Behind Precision Sheet Metal Laser Cutting - eMachineShop

Furniture and Interior Design:

Cutting of wood, acrylic, and other materials for furniture components.

Creation of intricate designs and patterns for decorative pieces.

Production of customized furniture and interior decor elements.

Jewelry and Fashion:

Cutting of precious metals and gemstones for jewelry making.

Creation of intricate designs and patterns for jewelry and accessories.

1. Laser Cutting in Jewelry & Metal Art: Precision & Creativity - HeatSign

Production of fashion accessories and components.

1. The use of laser in garment manufacturing: an overview | Fashion and Textiles | Full Text

Sign Making and Advertising:

Cutting of acrylic, metal, and other materials for signs and displays.

Production of high-quality and visually appealing signage.

Creation of custom-made promotional materials.

Construction and Architecture:

Cutting of metal components for building structures.

1. How Laser Cutting Is Used in Different Industries | Xometry

Creation of architectural models and prototypes.

Production of custom-designed metal elements for buildings.

Food and Beverage Industry:

Cutting of food packaging materials with precision.

1. The Science Of Laser Cutting In Packaging Design - CarePac

Production of food processing equipment components.

1. Application of Laser Cutting in Food Manufacturing Equipment | - HGSTAR

Creation of custom-shaped food products.

This is just a glimpse into the vast array of industries that benefit from laser cutting technology. As technology continues to advance, we can expect even more innovative applications to emerge in the years to come.

Let's Dive Deeper into Chinese Laser Cutter Manufacturers

Let's Dive Deeper into Chinese Laser Cutter Manufacturers

Understanding Your Specific Needs

When deciding the manufacturer for your future machine, there are a few things consider.

Industry or application: What industry are you in (e.g., metal fabrication, woodworking, jewelry)? What specific products or parts will you be cutting?

Material types: What materials will you primarily be cutting (e.g., metal, acrylic, wood, fabric)?

Cutting thickness: What is the maximum thickness of materials you need to cut?

Desired cutting speed and precision: What level of speed and accuracy is required for your application?

Budget: What is your approximate budget for the laser cutter?

Automation requirements: Do you need a fully automated system or a manual one?

Laser Cutter Types: A Brief Overview

While we delve into specific manufacturers, it's helpful to understand the primary types of laser cutters:

CO2 Laser Cutters: Best suited for non-metals like wood, acrylic, and fabric.

Fiber Laser Cutters: Ideal for metal cutting, offering high speed and precision.

Solid-State Laser Cutters: Versatile for both metals and non-metals, but often more expensive.

Beyond the Top 10

While the aforementioned manufacturers are reputable, the Chinese laser cutter market is vast. There are numerous other companies producing high-quality machines.

Top 10 Chinese Laser Cutter Manufacturers: A Cutting Edge Industry

Top 10 Chinese Laser Cutter Manufacturers: A Cutting Edge Industry

China has emerged as a global powerhouse in laser cutter manufacturing, producing a wide range of machines for diverse applications. From small-scale businesses to large-scale industrial operations, Chinese manufacturers offer a variety of options to suit different needs and budgets.

While the laser cutter market is highly competitive, certain manufacturers have distinguished themselves through innovation, quality, and customer satisfaction. Here's a look at ten of the leading Chinese laser cutter manufacturers:

Top 10 Chinese Laser Cutter Manufacturers

Raytu Laser: Known for its high-quality fiber laser cutting machines, Raytu Laser offers advanced technology and reliable performance.

G.WEIKE Laser: A prominent player in the industry, G.WEIKE provides a comprehensive range of laser cutters, from CO2 to fiber laser models.

HSG Laser: Specializing in fiber laser cutting machines, HSG Laser focuses on precision and efficiency.

ACME: Offering a wide range of laser cutting solutions, ACME caters to various industries with its customizable machines.

Senfeng: A reputable manufacturer of laser cutting equipment, Senfeng prioritizes innovation and customer support.

GYC Laser: Known for its expertise in fiber laser technology, GYC Laser produces high-performance cutting machines.

Han's Yueming: Offering a combination of affordability and quality, Han's Yueming has a strong presence in the market.

Raymond Laser: Specializing in fiber laser cutting machines for sheet metal processing, Raymond Laser delivers reliable performance.

DXTECH: A versatile manufacturer producing various laser machines, including cutting, engraving, and marking models.

Han's Laser: As a pioneer in the Chinese laser industry, Han's Laser offers a wide range of laser equipment and solutions.

Factors to Consider When Choosing a Laser Cutter

When selecting a laser cutter, several factors should be considered:

Type of laser: CO2 lasers are suitable for non-metals, while fiber lasers excel in metal cutting.

Cutting thickness: The machine's capacity to cut different material thicknesses.

Cutting speed and accuracy: The desired speed and precision for specific applications.

Automation level: Consider the level of automation required for production efficiency.

Budget: Determine the available budget for the laser cutter and associated costs.

After-sales support: Reliable customer support and service are essential for long-term satisfaction.

By carefully evaluating these factors and considering the specific needs of your application, you can choose the most suitable laser cutter from the wide range of options available from Chinese manufacturers.

Disclaimer: This list is not exhaustive and represents a selection of well-known manufacturers. It's essential to conduct thorough research and compare different options before making a purchasing decision.

Remote Laser Repair: A New Era of Maintenance

Remote Laser Repair: A New Era of Maintenance

Remote laser repair is a cutting-edge service that leverages advanced technologies to diagnose, troubleshoot, and resolve issues with laser cutting equipment without the need for on-site technicians. This innovative approach has revolutionized the maintenance and support industry, offering numerous benefits to laser cutting businesses.

How Does Remote Laser Repair Work?

Remote laser repair typically involves a combination of:

Real-time monitoring: Advanced sensors and software collect data on the laser cutting machine's performance, including temperature, vibration, and power consumption.

Remote diagnostics: Expert technicians analyze the collected data to identify potential issues or malfunctions.

Virtual support: Technicians provide guidance and troubleshooting steps to on-site operators through video conferencing, phone calls, or remote access to the machine's control system.

Software updates and adjustments: In many cases, issues can be resolved by updating software or adjusting machine parameters remotely.

Benefits of Remote Laser Repair

Reduced downtime: Issues can be identified and resolved quickly, minimizing production interruptions.

Cost savings: Eliminates the need for on-site visits, reducing travel expenses and labor costs.

Improved efficiency: Remote technicians can access a wealth of data and expertise, leading to faster and more accurate diagnoses.

Access to global expertise: Businesses can tap into the knowledge of specialists located anywhere in the world.

The Future of Remote Laser Repair

As technology continues to evolve, remote laser repair is expected to become even more sophisticated. Advancements in artificial intelligence and machine learning will enable predictive maintenance, allowing potential issues to be identified before they occur. Additionally, the integration of augmented reality and virtual reality will provide even more immersive and interactive support experiences.

In conclusion, remote laser repair is a game-changer for the laser cutting industry. By offering rapid response times, cost savings, and improved efficiency, it is transforming the way businesses maintain and optimize their laser cutting equipment.

OMTech: Powering Creativity with Laser Technology

OMTech: Powering Creativity with Laser Technology

OMTech Laser has carved a niche for itself in the realm of laser cutting and engraving technology. Catering to both hobbyists and professionals, the company offers a range of laser machines capable of transforming materials into intricate designs.

1. Home Laser Cutter: Making Laser Cutting Easy at Home in 2024 - OMTech Laser

A Versatile Tool for Diverse Applications

OMTech lasers have found their way into a myriad of industries and creative pursuits. From small-scale home businesses to large-scale manufacturing operations, the versatility of these machines is undeniable.

Hobbyists and Makers: Enthusiasts are utilizing OMTech lasers to create personalized gifts, home decor, and prototypes. The ability to work with a variety of materials, from wood and acrylic to leather and fabric, has expanded the creative possibilities for DIYers.

1. 5 Recommended DIY Laser Engraving Projects to Try Today - OMTech UK

Small Businesses: Entrepreneurs are leveraging OMTech lasers to produce custom products, from engraved jewelry and keychains to etched glassware and signage. The machines offer a cost-effective way to create unique items with high-quality finishes.

Manufacturing and Industry: Industrial applications of OMTech lasers include prototyping, rapid manufacturing, and precision cutting. The machines' speed and accuracy make them suitable for tasks ranging from cutting sheet metal to engraving complex patterns on industrial components.

Key Features and Benefits

OMTech lasers are renowned for their:

Affordability: The company offers a range of machines to suit various budgets, making laser technology accessible to a wider audience.

Reliability: Built with durability in mind, OMTech lasers are designed for long-lasting performance.

Ease of Use: User-friendly software and intuitive controls make it relatively simple to operate these machines, even for beginners.

Versatility: The ability to cut and engrave a wide range of materials opens up endless possibilities for creative projects.

The Future of Laser Technology with OMTech

As technology continues to advance, OMTech is likely to introduce even more innovative laser solutions to the market. With a focus on user experience and performance, the company is well-positioned to remain a leader in the industry.

Unleashing Creativity: Top Free Software Options for Laser Cutting Design

Unleashing Creativity: Top Free Software Options for Laser Cutting Design

The world of laser cutting is a playground for innovation, transforming digital designs into tangible objects with a burst of light. But before that first cut, you need the software to bring your ideas to life. While premium design software exists, a plethora of free options cater to various skill levels and project needs. This article explores the top free software choices for laser cutting design, empowering you to embark on your creative journey without breaking the bank.

1. Inkscape: The Open-Source Powerhouse for Vector Design

Inkscape https://inkscape.org/ stands as a free and open-source alternative to industry-standard vector design software like Adobe Illustrator. It boasts a user-friendly interface and a comprehensive set of tools for creating and editing vector graphics ideal for laser cutting.

Here's what makes Inkscape a great choice for laser cutting design:

Intuitive Interface: The interface is well-organized and easy to learn, even for beginners with no prior design experience.

Extensive Toolset: Inkscape offers a robust set of tools for drawing shapes, manipulating paths, and adding text.

Path Operations: The software excels in path operations like combining shapes, creating boolean unions and differences, and performing complex path editing, all crucial for laser cutting design.

Object Manipulation: Precise object positioning, scaling, and rotation allow for meticulous design control before sending your project to the laser cutter.

Node Editing: For intricate designs, Inkscape provides advanced node editing capabilities, allowing you to fine-tune the shape and curvature of your vector paths.

Active Community: A vibrant online community provides tutorials, resources, and user-created extensions that further enhance Inkscape's functionality.

Things to Consider with Inkscape:

Learning Curve: While user-friendly, Inkscape does have a learning curve compared to some basic design software.

Limited Raster Editing: While Inkscape allows basic image editing, more advanced raster manipulation might require additional software.

File Compatibility: Ensure your laser cutting software supports SVG (Scalable Vector Graphics) files, the primary format exported from Inkscape.

2. Tinkercad: A Gateway to 3D Design and Laser Cutting

Tinkercad https://www.tinkercad.com/ is a web-based 3D design platform that doubles as a fantastic tool for creating laser-cut projects. Its intuitive interface and block-based design approach make it perfect for beginners or those new to 3D design concepts.

Here's why Tinkercad is a great choice for laser cutting projects:

Web-Based Convenience: Access Tinkercad from any device with a web browser, eliminating the need for software downloads or installations.

Block-Based Design: The intuitive block system makes design creation as easy as dragging and dropping pre-designed shapes.

2D Design Mode: Tinkercad offers a dedicated 2D design mode perfect for laser cutting projects. Create flat shapes, text elements, and intricate designs for laser cutting.

Shape Export: Export your creations in SVG format, ensuring compatibility with most laser cutting software.

3D Printing Connection: While primarily a 2D design tool, Tinkercad seamlessly integrates with 3D printing if you ever venture into that realm.

Things to Consider with Tinkercad:

Limited Design Complexity: Tinkercad's block-based design approach might not be ideal for highly intricate or organic shapes.

Limited Editing Tools: The software offers basic editing tools, but for complex modifications, you might need to switch to a more advanced vector design program.

Internet Connection Required: As a web-based platform, Tinkercad requires an internet connection to function.

3. FreeCAD: Open-Source Powerhouse for 3D Modeling and Laser Cutting

For users comfortable with more advanced design concepts, FreeCAD https://www.freecad.org/ is a free and open-source alternative to professional 3D modeling software. While primarily a 3D modeling tool, FreeCAD offers robust 2D design capabilities perfect for laser cutting projects.

Here's why FreeCAD is a great choice for experienced users:

Advanced 2D Design Tools: FreeCAD offers a comprehensive set of tools for creating complex 2D geometries, including splines, curves, and advanced path editing features.

3D Modeling Integration: For projects requiring both 3D printed and laser-cut components, FreeCAD allows seamless integration within the same software.

Open Source and Customizable: The open-source nature of FreeCAD allows for customization through plugins and extensions, further enhancing its capabilities.

Large Online Community: A vibrant online community provides tutorials, resources

Laser Cutting on a Budget: Unleashing Creativity with Affordable Materials

The allure of laser cutting is undeniable. Transforming digital designs into tangible objects with a burst of light is pure magic. But for budget-conscious crafters, the initial investment in a laser cutter and premium materials can seem daunting. Fear not, creative minds! This article equips you with the knowledge and inspiration to embark on your laser cutting adventure without breaking the bank.

We'll delve into readily available, affordable materials that work wonders with your laser cutter. We'll also explore a plethora of project ideas specifically designed to showcase the potential of these budget-friendly materials. So, fire up your laser cutter (or consider used machine options) and get ready to unleash your creativity!

The All-Star of Affordability: Cardboard – A Humble Material with Hidden Potential

Cardboard – the unsung hero of packaging – transforms into a versatile laser cutting material. It's readily available, often free for the taking from local businesses or recycling bins. Cardboard's inherent brown color lends a rustic charm to projects, and it can be painted or spray-painted for a pop of color. Here are some project ideas to spark your imagination:

Geometric Coasters: Laser cut intricate geometric patterns from cardboard to create a stunning and functional set of coasters. Line them with felt or cork for added protection and a touch of luxury.

Customizable Gift Boxes: Design and laser cut personalized gift boxes in various sizes. Embellish them with ribbons, twine, or laser-cut tags for a unique and thoughtful presentation.

Organizational Dividers: Bring order to your drawers and shelves with laser-cut cardboard dividers. Craft dividers in different heights and sizes to accommodate various storage needs.

Playful Wall Art: Cardboard's lightweight nature makes it perfect for wall art installations. Design layered or multi-dimensional wall art pieces to add a touch of whimsy to your décor.

Beyond the Box: Rethinking Cardboard with Creative Techniques

Cardboard Stencils: Laser cut intricate stencils from cardboard for creative endeavors like fabric painting, airbrushing, or even cake decorating.

Faux Leather Effect with Paint: Apply a coat of black acrylic paint to cardboard and let it dry completely. Buff the surface with a soft cloth to reveal a subtle sheen, creating a convincing faux leather effect for budget-friendly jewelry or decorative accents.

Layered Cardboard Creations: Don't be afraid to layer multiple cardboard pieces for added thickness and dimension. This technique can be used for sturdy gift boxes or even 3D wall art sculptures.

The Colorful Allure: Exploring the World of Acrylic Scraps

Acrylic scraps, remnants from larger projects in fabrication shops or signage companies, can be a treasure trove for budget-conscious laser cutters. Often available at a discount or even for free, acrylic scraps come in a vibrant array of colors and thicknesses. Here's how to breathe new life into these colorful offcuts:

Personalized Keychains: Laser cut custom shapes or letterforms from acrylic scraps to create unique and colorful keychains. Add key rings and jump rings for a practical and stylish accessory.

Ornaments and Gift Tags: The festive nature of acrylic makes it perfect for holiday ornaments or gift tags. Laser cut snowflakes, stars, or other festive shapes and embellish them with paint, glitter, or permanent vinyl for a personalized touch.

Drink Coasters with Flair: Laser cut coasters from colorful acrylic scraps. You can even experiment with different shapes or layer multiple colors of acrylic for a unique and eye-catching design.

Modern Wall Art with Geometric Flair: Create a statement piece for your home with laser-cut geometric wall art from acrylic scraps. Play with negative space and overlapping shapes for a modern and dynamic aesthetic.

Transforming the Humble: Wood Veneer Sheets – Budget-Friendly Elegance

Wood veneer sheets offer the warmth and beauty of natural wood at a fraction of the cost of solid wood. Available in a variety of wood species and finishes, they're ideal for laser cutting projects that exude a touch of elegance. Here are some project ideas to elevate your home décor with wood veneer sheets:

Stylish Phone Stands: Laser cut a phone stand design from wood veneer and personalize it with a monogram or inspirational quote. This project is both functional and adds a touch of sophistication to your workspace.

Minimalist Coasters with Natural Beauty: Wood veneer's inherent charm shines in minimalist coaster designs. Laser cut simple geometric shapes or leave the natural wood grain as the star of the show. Finish them with a light coat of sealant for added protection.

Elegant Jewelry: Laser cut intricate shapes or delicate lace patterns from wood veneer to create one-of-a-kind earrings, pendants, or brooches.

Unlocking Potential: Advanced Laser Cutting Techniques for Experienced Makers

Unlocking Potential: Advanced Laser Cutting Techniques for Experienced Makers

You've mastered the basics of laser cutting, churning out coasters and keychains with impressive precision. Now, it's time to push the boundaries and explore the advanced techniques that elevate your projects from ordinary to extraordinary. This article delves into the world of advanced laser cutting, empowering you to unlock the full potential of your laser cutter.

Mastering the Multi-Layer: Creating Depth and Dimension

Simple flat cuts are no longer enough. Multi-layer cutting allows you to create stunning 3D effects by stacking and adhering laser-cut pieces. Here's how to take it a step further:

Box Joints and Interlocking Designs: Move beyond glue for a more robust construction. Design interlocking tabs and slots that seamlessly connect your laser-cut layers, creating sturdy boxes or decorative sculptures.

Color Gradients and Layered Effects: Utilize contrasting or complementary colored materials to create depth and visual intrigue. Imagine a layered cityscape with buildings crafted from different colored acrylic sheets or a portrait with subtle gradations achieved through stacked wood veneers.

Engraving with Precision: Exploring the Art of Depth Control

Laser engraving isn't just surface-level. By adjusting laser power and speed settings, you can achieve different engraving depths, creating stunning textured effects:

Shallow Raster Engraving: This technique creates a subtle, almost textured, effect on the material's surface. It's ideal for adding intricate details or logos to your projects.

Deep Raster Engraving: Increase the laser power and delve deeper into the material, creating a more pronounced engraved image. This technique is perfect for creating realistic photo engravings or adding text with a pronounced depth.

Vector Engraving: For clean, crisp lines, utilize vector engraving. This technique precisely follows the vector paths of your design, ideal for detailed illustrations, technical schematics, or personalized monograms.

Conquering Curves: The Power of Rotary Attachments

The world of laser cutting isn't limited to flat surfaces. With a rotary attachment, you can tackle cylindrical objects, opening up a whole new realm of possibilities:

Personalized Drinkware: Engrave custom logos, names, or even intricate designs on mugs, tumblers, or even wine glasses.

Unique Rolling Pins: Craft personalized rolling pins with engraved patterns that transfer onto cookies, fondant, or even clay creations.

Custom Baseball Bats: Engrave team logos, player names, or inspirational messages onto wooden baseball bats for a unique and personalized gift.

Safety First: A Constant Companion in Advanced Techniques

As you push the boundaries of laser cutting, safety remains paramount. Here are some additional precautions to consider when using advanced techniques:

Ventilation: Multi-layer cutting and deep engraving can generate more fumes. Ensure proper ventilation to remove airborne particles.

Material Compatibility: Not all materials are created equal. Research the suitability of different materials for advanced techniques like deep engraving or rotary cutting to avoid damage or warping.

Test Cuts: Before diving into your final project, always perform test cuts on scrap material to ensure your settings achieve the desired results and avoid wasting valuable materials.

The Journey Continues: A World of Exploration Awaits

The world of advanced laser cutting is a playground for exploration and creative expression. By mastering multi-layer creations, exploring engraving depth control, and conquering curves with rotary attachments, you'll transform your laser cutting skills and elevate your projects to a whole new level. So, embrace the challenge, unleash your creativity, and embark on a journey of laser-powered innovation!

The Maker Mindset: Building a Thriving Laser Cutting Business

The Maker Mindset: Building a Thriving Laser Cutting Business

Your passion for laser cutting has ignited a spark – a dream of transforming your hobby into a thriving business. But where do you begin? This article equips you with the roadmap to navigate the exciting yet challenging world of laser cutting entrepreneurship.

Finding Your Niche: Where Your Passion Meets Opportunity

The first step is identifying a niche market. Dive deep into your interests and explore what problem your laser cutting skills can solve. Here are some areas to consider:

Personalized Products: Monogrammed gifts, custom phone cases, or laser-cut puzzles featuring family photos are all examples of personalized creations with a high perceived value.

Home & Decor: Laser-cut wall art, decorative coasters, or intricate lampshades cater to the desire for unique home decor pieces.

Event & Party Supplies: Personalized wedding coasters, custom cake toppers, or laser-cut signage can add a special touch to events and celebrations.

Stationery & Organizational Tools: Laser-cut desk organizers, custom notebooks, or personalized bookmarks tap into the market for functional yet stylish stationery.

Know Your Numbers: Pricing for Profit

Once you've identified your niche, it's time to establish pricing that covers your costs and generates a profit. Here's a breakdown of factors to consider:

Material Costs: Factor in the cost of the material you'll be using for your laser-cut products.

Machine Time: Determine your laser cutter's hourly operating cost to account for wear and tear.

Labor Costs: If you plan to outsource any design or finishing work, factor those costs as well.

Profit Margin: Set a healthy profit margin that allows you to reinvest in your business and grow.

Building Your Online Storefront: Where Customers Find You

In today's digital world, an online presence is crucial. Here are some options for setting up your shop:

E-commerce Platforms: Platforms like Etsy or Shopify offer user-friendly interfaces to create your online store and manage sales.

Independent Website: For a more customized experience, consider building your own website. This allows for greater control over branding and customer experience but requires more technical expertise.

Spreading the Word: Marketing Strategies for Laser-Cut Success

With your online store established, it's time to attract customers. Here are some marketing strategies to consider:

Social Media Marketing: Showcase your laser-cut creations on platforms like Instagram and Pinterest. Engage with potential customers and run targeted ads to reach your ideal audience.

Content Marketing: Create blog posts or tutorials showcasing your laser cutting skills and the benefits of your products. This establishes you as an expert and attracts organic traffic.

Collaboration: Partner with local businesses or complementary crafters for cross-promotion opportunities. This broadens your reach and exposes your work to a new audience.

Remember, Building a Business Takes Time

Building a thriving laser cutting business requires dedication, patience, and a willingness to learn. Continuously refine your product offerings, stay updated on design trends, and prioritize excellent customer service. Most importantly, never lose sight of the passion that ignited your laser cutting journey in the first place. With hard work, creativity, and this roadmap as your guide, you can transform your laser cutting hobby into a successful and fulfilling business.

Unleash Your Inner Maker: Top Spots to Find Free Laser Cutting Files

Unleash Your Inner Maker: Top Spots to Find Free Laser Cutting Files

The world of laser cutting is a playground for creativity, transforming digital designs into tangible objects with a burst of light. But before that first cut, you need a design to unleash the magic. Luckily, the internet abounds with free laser cutting files, offering a treasure trove of inspiration and project ideas. This article explores the top destinations to find these free laser cutting files, empowering you to fuel your laser adventures without breaking the bank.

Treasure Troves of Free Files: Online Sharing Communities

The internet thrives on sharing, and the laser cutting community is no exception. Here are some online platforms overflowing with free laser cutting files:

Thingiverse: This massive repository of 3D printable files also boasts a wealth of SVG (Scalable Vector Graphics) files ideal for laser cutting. Explore categories like "Home" or "Toys & Games" to discover everything from coasters and phone stands to intricate puzzles and decorative wall hangings. https://www.thingiverse.com/

The Silhouette Design Store: While not exclusively free, the Silhouette Design Store offers a generous selection of free SVG files. These files are specifically designed for Silhouette brand cutting machines, but they are often compatible with other laser cutters as well. Their website provides clear search filters to find free files by project type, difficulty level, and even material compatibility. https://www.silhouetteamerica.com/

Freepik: This online platform offers a vast collection of free vector graphics, many of which can be readily used for laser cutting. Freepik allows users to download a limited number of free files per day with attribution required. For an extended library and commercial use rights, premium subscriptions are available. https://www.freepik.com/

Beyond the Usual Suspects: Unveiling Hidden Gems

While these online communities are popular starting points, here are some hidden gems offering unique free laser cutting file resources:

Maker Websites & Blogs: Many laser cutter manufacturers and hobbyist websites maintain blogs or resource sections overflowing with free laser cutting files. These files often showcase the capabilities of specific machines and can be a valuable source of inspiration. Use search engines to find websites related to your laser cutter model or specific project interests.

Educational Resources: Websites dedicated to STEM (Science, Technology, Engineering, and Math) education sometimes provide free laser cutting files for educational purposes. These files can be particularly useful for parents and educators looking for engaging and hands-on learning activities. Search online for educational resources related to laser cutting or STEM activities.

YouTube Tutorials: Many laser cutting tutorials on YouTube include free downloadable files used in the video demonstration. This allows you to follow along with the tutorial and create the project yourself. Explore YouTube channels dedicated to laser cutting for project inspiration and free file downloads.

A Few Cautions Before You Download:

While free resources are fantastic, there are a few things to keep in mind before downloading:

Licensing: Always check the licensing terms associated with a free file. Some may require attribution or limit commercial use.

File Compatibility: Ensure the downloaded file format (often SVG or DXF) is compatible with your laser cutting software.

Complexity: Free files can range in complexity. Choose projects that match your skill level and laser cutter's capabilities for a successful outcome.

Conclusion: Fueling Your Laser Cutting Journey

With a little exploration, you can unlock a universe of free laser cutting files online. From established online communities to hidden gems like educational resources and YouTube tutorials, there's a wealth of inspiration waiting to be discovered. So, fire up your laser cutter, embrace the free file resources, and embark on a journey of laser-powered creativity!

Starter Projects for Laser Cutting Beginners

Conquering Your First Cut: Stellar Starter Projects for Laser Cutting Beginners

The world of laser cutting beckons with its promise of precise cuts, innovative designs, and the ability to transform ideas into tangible creations. But for beginners, the vast array of possibilities can feel overwhelming. Where do you even begin? Worry not, aspiring laser enthusiasts! This guide unveils a range of fantastic first projects to kickstart your laser cutting adventure.

Embrace Functionality with Everyday Items:

Coasters with Flair: Laser-cut coasters are a classic yet versatile beginner project. Experiment with different shapes, intricate patterns, or even personalized messages to create unique and functional coasters for your home or as thoughtful gifts.

Keychain Mania: Unleash your creativity with custom keychains. Design intricate shapes, logos, or even incorporate layered materials for a touch of depth. These personalized keychains make excellent keepsakes or small business promotional items.

Organizational Bliss: Laser cutting empowers you to create organizers for your workspace or home. Design and cut pen holders, desk organizers, or even phone stands. These functional projects allow you to personalize your space while practicing your laser cutting skills.

Unleash Your Inner Decorator:

Wall Art Wonders: Transform your blank walls into stunning displays with laser-cut wall art. Design intricate geometric patterns, inspirational quotes, or even layered silhouettes for a unique and personalized touch.

Dimensional Delights: Laser cutting allows you to create beautiful 3D objects. Design and cut simple geometric shapes or even utilize online templates to create stunning 3D ornaments, decorative boxes, or even miniature laser-cut houses.

Candlelight Ambiance: Laser cutting breathes new life into candles. Design and cut intricate patterns onto wooden candle holders or create personalized candle bases for a touch of elegance and a warm, diffused glow.

Learning Through Play:

Puzzles for All Ages: Laser cutting allows you to create custom puzzles. Design simple puzzles for children or more intricate ones for adults, featuring landscapes, famous artworks, or even personalized designs. Puzzles are a fun and educational way to practice your laser cutting skills and engage with others.

Board Game Bonanza: Level up your board game nights with laser-cut game pieces. Design custom pieces for existing games or even create entirely new board games with unique laser-cut components. This project is a perfect blend of creativity, practicality, and a touch of friendly competition.

Stencils for All Occasions: Laser cutting opens doors for creating stencils for various purposes. Design stencils for crafting projects, cake decorating, or even personalized signage. Stencils offer a practical application of your laser cutting skills and add a touch of personalization to various endeavors.

Remember:

Start Simple: For your first project, prioritize designs that are not overly complex. This allows you to focus on learning the laser cutter's operation and safety protocols before tackling intricate projects.

Material Matters: Choose materials suitable for beginners, such as wood, acrylic, or cardboard. These materials are generally affordable, easy to cut, and offer a good margin for error.

Safety First: Always prioritize safety when operating a laser cutter. Wear proper eye protection, work in a well-ventilated area, and consult the Material Safety Data Sheet (MSDS/SDS) for the material you're using.

Laser Cutting: A Journey of Creativity

By starting with these achievable and engaging projects, you'll gain valuable experience, refine your laser cutting skills, and unlock the boundless potential of this technology. So, embrace the learning process, experiment with different designs, and watch your creativity take flight with laser cutting!

Your Guide to Getting Started with Laser Cutting

From Sketch to Prototype: Your Guide to Getting Started with Laser Cutting

The allure of laser cutters is undeniable. These powerful tools translate ideas into reality with unmatched precision, making them ideal for rapid prototyping. But for beginners, the world of laser cutting can seem intimidating. Fear not, aspiring makers and entrepreneurs! This guide will equip you with the knowledge and resources to get started with laser cutting prototypes.

Planning Your Prototype Journey:

Define Your Project: Before diving headfirst, clearly define your project's purpose and desired functionality. What problem are you trying to solve, or what product are you creating? This will guide your material selection and design process.

Embrace Design Software: Familiarize yourself with basic design software like Adobe Illustrator or Inkscape. These programs allow you to create digital designs (DXF files) that the laser cutter can understand. Online tutorials and courses can help you navigate these programs effectively.

Consider Material Options: Laser cutters handle a wide range of materials, each with its own properties. Wood, acrylic, and cardboard are popular choices for beginners due to their affordability and ease of use. Research different materials and their suitability for your project's needs.

Exploring Your Prototyping Options:

Laser Cutting Services: Many makerspaces, fabrication labs, and even online services offer laser cutting services. This is a fantastic option for beginners to experiment with laser cutting without a significant upfront investment. These services often provide training and assistance to ensure you get the results you need.

Desktop Laser Cutters: For those with dedicated workspace and budget, a desktop laser cutter offers ultimate flexibility and control over the prototyping process. However, carefully research different models and consider factors like cutting area, material compatibility, and ease of use before making a purchase.

Safety First: A Top Priority

Laser cutting involves powerful lasers, so safety is paramount. Here are some crucial safety measures to remember:

Consult the Material Safety Data Sheet (MSDS/SDS): Always review the MSDS/SDS for the material you're using. This document outlines potential hazards associated with laser cutting that specific material and provides information on proper ventilation, safe handling, and necessary personal protective equipment (PPE).

Wear Eye Protection: Invest in laser safety glasses that are specifically designed for the wavelength of your laser cutter.

Work in a Ventilated Area: Laser cutting can generate fumes and dust particles. Ensure proper ventilation to remove these harmful elements from your workspace.

Learning Resources and Experimentation:

Online Resources: The internet is a treasure trove of information on laser cutting. Explore online tutorials, forums, and websites dedicated to laser cutting. These resources can provide valuable tips, project inspiration, and troubleshooting advice.

Start Simple: For your first project, begin with a simple design. This allows you to get comfortable with the laser cutter's operation and safety protocols before tackling more complex projects.

Embrace Experimentation: Don't be afraid to experiment with different materials, design elements, and laser settings. Experimentation is a crucial part of the learning process, allowing you to refine your skills and discover the full potential of laser cutting for your prototypes.

Laser Cutting: A Gateway to Innovation

Laser cutting opens doors for rapid prototyping, empowering you to take your ideas from sketch to reality in a streamlined and efficient manner. By following these steps, prioritizing safety, and embracing experimentation, you'll be well on your way to becoming a laser cutting pro and crafting exceptional prototypes that propel your projects forward. So, unleash your creativity, embrace the power of laser cutting, and embark on your prototyping journey today!

Why MSDS are Crucial for Safe Laser Cutting Projects

Don't Get Cut Short: Why MSDS are Crucial for Safe Laser Cutting Projects

Laser cutters are powerful tools, transforming ideas into reality with precise cuts on various materials. But with this power comes responsibility – the responsibility to prioritize safety throughout the laser cutting process. Here's where a seemingly innocuous document called the Material Safety Data Sheet (MSDS), now often referred to as a Safety Data Sheet (SDS), becomes your essential guide.

MSDS/SDS: Your Roadmap to Safe Laser Cutting

An MSDS/SDS is a comprehensive document that details the physical and chemical properties of a material, along with potential hazards associated with its use. For laser cutting, an MSDS/SDS is critical because it provides crucial information to ensure a safe and successful project. Here's why:

Identifying Potential Hazards: Laser cutting interacts with materials in a unique way. The MSDS/SDS outlines potential hazards that may arise during the cutting process, such as the emission of harmful fumes or the risk of fire.

Choosing the Right Material: Not all materials are created equal for laser cutting. The MSDS/SDS can help you determine if a particular material is suitable for laser cutting based on its flammability, reactivity with laser beams, or potential for generating toxic byproducts.

Understanding Proper Ventilation: The MSDS/SDS specifies the appropriate ventilation requirements for cutting a specific material. This ensures you have proper airflow to remove harmful fumes or dust particles generated during the cutting process.

Safe Handling and Storage: The MSDS/SDS outlines safe handling and storage procedures for the material you're using. This includes information on personal protective equipment (PPE) requirements, proper disposal methods, and any specific storage recommendations.

The Dangers of Ignoring the MSDS/SDS

Skipping the MSDS/SDS can lead to serious consequences, jeopardizing both your safety and the success of your project:

Health Risks: Exposure to harmful fumes or dust particles can cause respiratory problems, skin irritation, or even eye damage. The MSDS/SDS outlines these potential risks and helps you take necessary precautions.

Fire Hazards: Using the wrong material or neglecting proper ventilation can increase the risk of fire during laser cutting. The MSDS/SDS provides information on the material's flammability and helps you establish safe cutting parameters.

Project Failure: Some materials may react poorly to laser cutting, resulting in warped or melted pieces. Referring to the MSDS/SDS can help you choose suitable materials for optimal cutting results.

Finding the MSDS/SDS and Using it Effectively

Manufacturer's Website: Most manufacturers readily provide the MSDS/SDS for their materials on their website.

Material Suppliers: Request an MSDS/SDS from your material supplier when purchasing materials for laser cutting.

Understanding the Information: While the MSDS/SDS may contain technical jargon, focus on key sections like hazard identification, ventilation requirements, and PPE recommendations.

Laser Cutting Safety: A Shared Responsibility

Laser cutting safety is a shared responsibility between the user, the manufacturer, and the material supplier. By prioritizing the information provided in the MSDS/SDS, you can make informed decisions about material selection, ventilation requirements, and necessary safety measures.

Remember: A successful laser cutting project is not just about precision and creativity; it's about prioritizing safety. So, before you embark on your next laser cutting adventure, make the MSDS/SDS your trusted companion. It's a small step that can lead to a world of safe and rewarding laser cutting experiences.

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)