American Laser Cutter: Your Precision Cutting Partner in Los Angeles

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

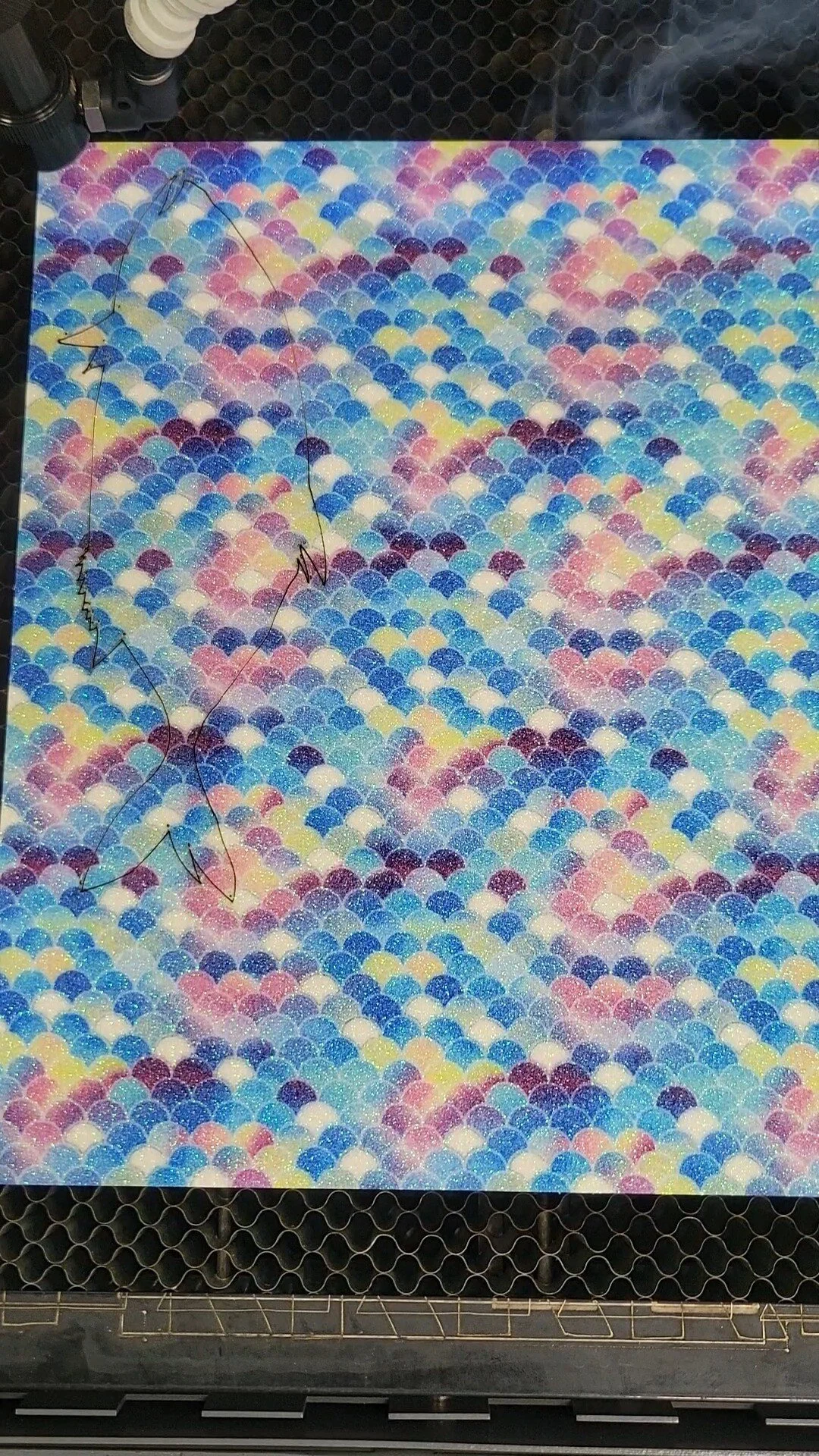

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

Laser Cutting and CNC are not the same thing

If you're in the manufacturing or art industry, you may have heard the terms 'laser cutting' and 'CNC' thrown around. While they may seem interchangeable, Laser Cutting and CNC are not the same thing. Here, we'll explore the differences between the two technologies.

Laser Cutting relies on a highly focused laser beam to cut through materials such as wood, metal, acrylic, and more. The laser melts, burns, or vaporizes the material along a predetermined path, guided by a computer program.

CNC, on the other hand, refers to Computer Numerical Control. It's a manufacturing process that involves the use of a pre-programmed computer software that tells the machine what to do. A CNC machine is programmed to cut materials like wood, plastics, and metals using a variety of cutting tools.

So, what sets these two technologies apart? It all comes down to the method of cutting and the type of machine used. With Laser Cutting, you get a smoother and more accurate cut due to the precision of the laser beam. CNC machines, on the other hand, can cut through denser materials with higher torque as a result of their cutting tools.

Overall, both Laser Cutting and CNC have their advantages and disadvantages, and the choice between the two will depend on the project at hand. While Laser Cutting offers a more precise cut, it may not be ideal for thick or dense materials. For that reason, CNC may be a better option. Understanding these differences is key to choosing the right technolo

the most popular programs used in conjunction with laser cutters.

Laser cutters have become a popular tool in many industries, ranging from architecture and engineering to art and design. With their precision and versatility, laser cutters allow you to create intricate and detailed designs in a variety of materials, from wood and plastic to metal and fabric. However, in order to use a laser cutter properly, you will need to have the right software. In this post, we will explore some of the most popular programs used in conjunction with laser cutters.

Adobe Illustrator: This vector graphics editor is a favorite among laser cutter users. It allows you to create and edit designs with precision, and also provides a range of tools for exporting your designs to different file formats.

CorelDRAW: Another popular vector graphics editor, CorelDRAW offers a range of features that make it easy to create designs for laser cutting. One distinct advantage of CorelDRAW is its compatibility with a wide range of file types, including DXF, EPS, and PDF.

AutoCAD: Often used by architects and engineers, AutoCAD is a 2D and 3D design software that can be used in conjunction with laser cutters. It offers precision and advanced tools for design, as well as integration with other programs such as Adobe Illustrator and CorelDRAW.

SketchUp: This 3D modeling software is popular among designers and architects, and can be used to create designs for laser cutting. While it does not offer the precision and advanced tools of other programs on this list, it is easy to use and allows you to create detailed 3D models quickly.

Overall, choosing the right program will depend on your needs and level of experience. Adobe Illustrator and CorelDRAW are great options for those looking for precise vector graphics editing, while AutoCAD and SketchUp are better suited for those looking to create detailed 3D models. Whatever program you choose, make sure to familiarize yourself with its capabilities and features in order to get the most out of your laser cutting experience.

Here are 10 fun DIY projects to try with your trusty laser cutter this summer

Summer is here and it’s time to get creative! Whether you’re looking to create some decorative pieces for your home, a unique gift for a loved one, or want to start your own small crafting business, a laser cutter is a versatile tool that can help you achieve your goals. Here are 10 fun DIY projects to try with your trusty laser cutter this summer:

1. Customized keychains

2. Wooden sunglasses

3. Personalized phone cases

4. Intricate jewelry

5. Acrylic signs and displays

6. Engraved cutting boards or coasters

7. Laser cut wall art

8. Intricate paper cutting and origami designs

9. Decorative lampshades

10. Wooden puzzles and brain teasers

With these projects, you’ll be able to unlock your creative potential and make something truly unique. So start firing up your laser cutter and let your i

t is hard to learn how to use a laser cutter?

Laser cutters have become increasingly popular in the past years. With many cheap and reliable laser cutters available, more and more people are considering buying one for their home workshop. However, one of the most crucial questions that beginners ask is whether it is hard to learn how to use a laser cutter.

In reality, the difficulty level of learning how to operate a laser cutter will depend on various factors such as experience with similar machinery, familiarity with design software, and the complexity of the task at hand. However, with dedication and practice, anyone can master this technology.

Firstly, it is important to take the time to familiarize oneself with the machine’s features, read the manual, and watch tutorials to understand how the laser cutter works. Then, beginners must learn how to create designs that are compatible with the machine using design software such as Adobe Illustrator or CorelDRAW.

Laser cutters are versatile and can cut through a variety of materials, such as wood, acrylic, leather, and paper. However, depending on the project, adjusting settings such as power, speed, and focus will be necessary. This requires some trial and error, but with patience, one can achieve the desired outcome.

While there may be a learning curve when it comes to using a laser cutter, it is not impossible to master. With practice, one can learn to create intricate and beautiful designs with ease. So if you are interested in purchasing a laser cutter, do not let the fear of the unknown hold you back. Give yourself time and patience, and soon you will be creating works of art with your very own laser cutter.

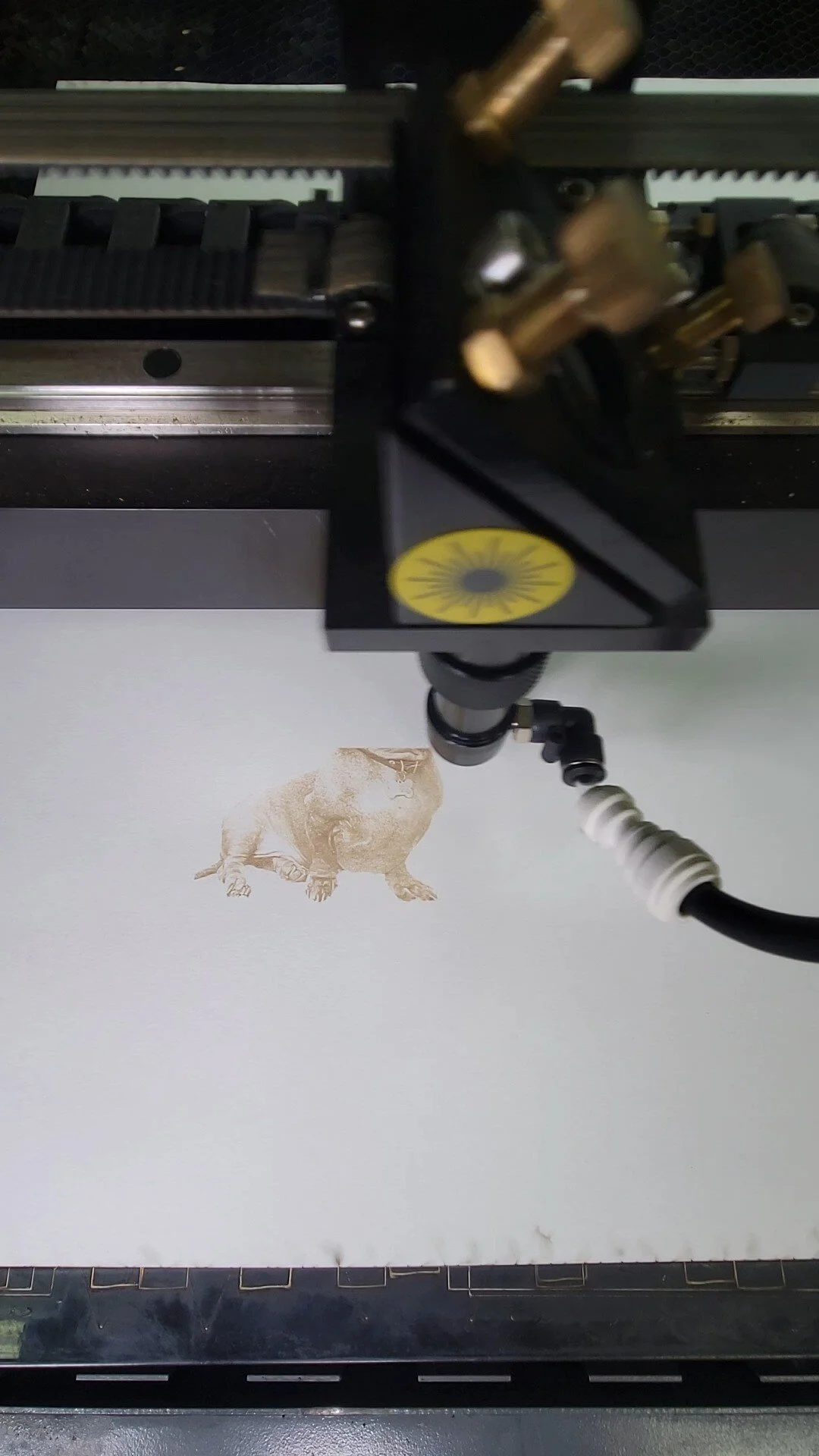

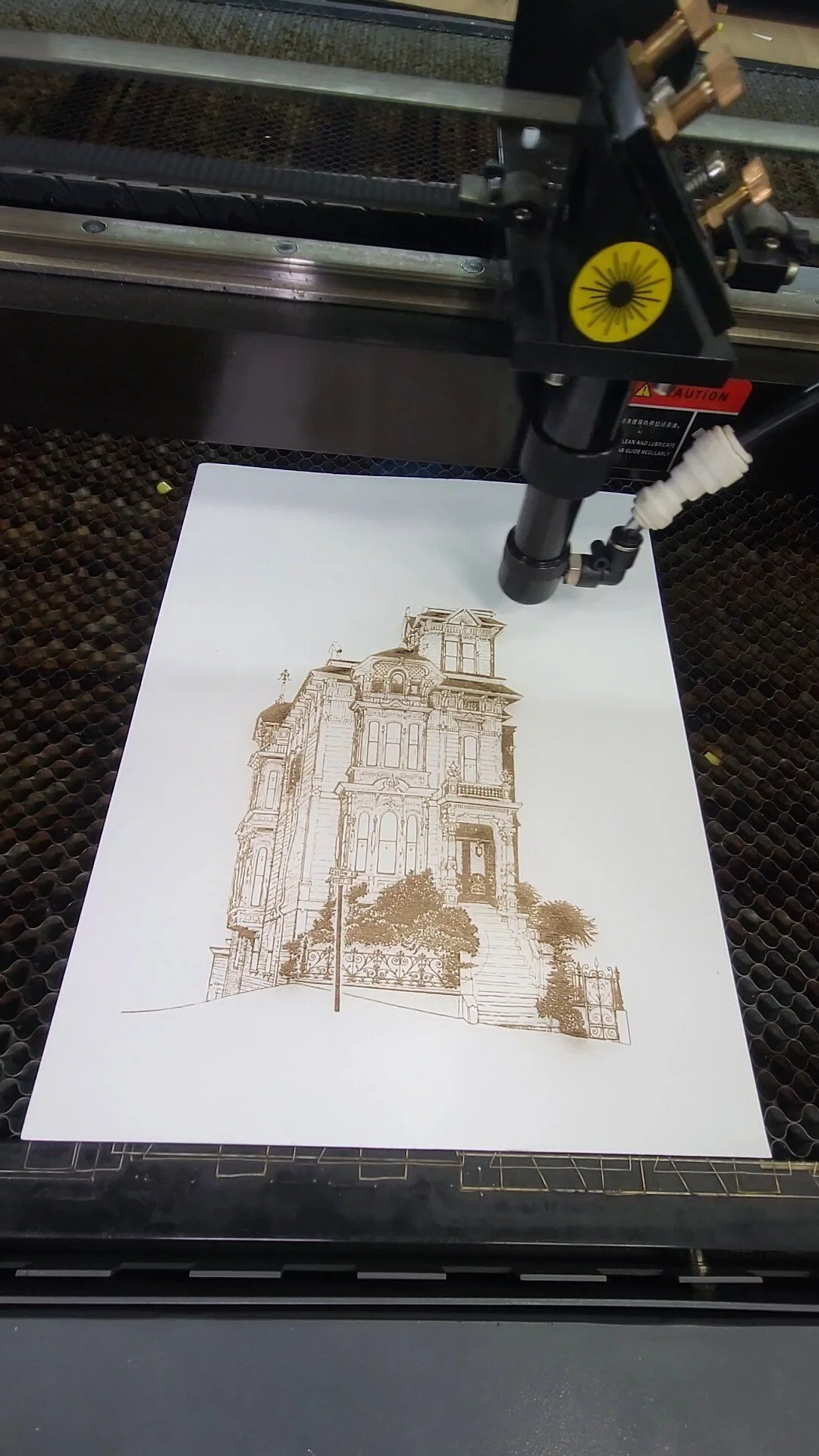

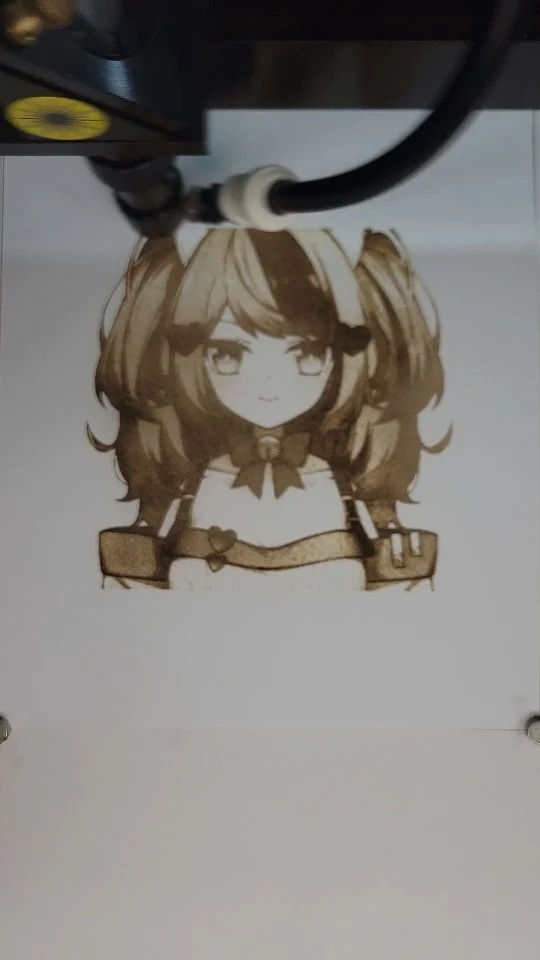

the world of laser engraving

Laser engraving technology has come a long way in recent years, becoming an increasingly popular choice for DIY enthusiasts and professionals alike. With so many options available on the market, it can be difficult to know which laser engraver is the best fit for your needs. In this guide, we’ll take a deep dive into the world of laser engraving and explore some of the key factors you should consider when choosing a laser engraver.

First and foremost, it’s important to consider the size of the engraving area. If you plan on engraving small objects or detailed designs, a machine with a smaller engraving area may be sufficient. However, if you’re looking to take on larger projects, you’ll want to invest in a laser engraver with a larger work area.

Another key factor to consider is the laser power. Higher laser power generally allows for faster engraving and the ability to work with a wider range of materials, but also comes with a higher price tag. It’s important to weigh your budget against your desired cutting and engraving capabilities to determine the ideal machine for your needs.

Machine durability and user interface are also important factors to consider. Look for a machine with a sturdy build and user-friendly software that’s intuitive to use, even for beginners.

Lastly, consider the brand reputation and customer support. Look for machines from reputable manufacturers with a proven track record of quality and reliability. Additionally, make sure you have access to customer support in case you have any questions or issues with your machine.

In conclusion, choosing the best laser engraver depends on your specific needs and budget. Consider factors such as engraving area, laser power, durability, and customer support to determine the ideal machine for your engraving projects. With the right laser engraver, the possibilities for creativity and customization are endless.

If you're looking to extend the life of your cherished photos and turn them into a piece of art, laser engraving might be an option worth considering

If you're looking to extend the life of your cherished photos and turn them into a piece of art, laser engraving might be an option worth considering. The process involves using a laser beam to carve out an image into a chosen material. So, can you laser engrave photos? The answer is a resounding yes.

However, the key to getting high-quality laser engraving for your photos lies in choosing the right material. Laser engraving can be done on a variety of materials such as wood, glass, metal, and even plastic. Each material has its unique properties, which affect how the engraving will turn out.

For instance, wood and plastic are flexible and can hold images well, but it may not have the same level of detail as glass or metal. Meanwhile, glass and metal produce intricate and crystal-clear engravings that can last a lifetime. It's also important to consider the type of image you want to engrave. High-resolution photos with clear backgrounds work best for laser engraving. The quality of the photo will affect the outcome of the engraving.

Apart from preserving memories, laser engraving photos can also be an excellent gift idea. From birthdays to weddings and anniversaries, engraved photos are a great way to show you care and make your gift special. It's also an excellent way to personalize your belongings. You can engrave photos onto anything from phone cases, jewelry, and even watches.

In conclusion, laser engraving can be a fantastic way to preserve your memories and turn them into a unique piece of art. With the right material and image quality, laser engraving photos can leave you with a beautiful keepsake that lasts a lifetime. So, go ahead, give it a try, and let your creativity run wild.

Here are some tips on how to maintain your laser cutter

A laser cutter is an extremely useful tool for creating intricate designs and precise cuts. However, like any machine, it requires regular maintenance in order to ensure it remains in good working order. Here are some tips on how to maintain your laser cutter:

1. Keep it clean: Regularly clean the bed of your laser cutter and ensure it is free of dust, debris, or other materials that could become stuck to the surface.

2. Check the mirrors and lenses: Dust, smoke, and other debris can collect on the mirrors and lenses in your laser cutter, which can affect the quality of your cuts. Regularly check and clean these components to ensure they are clean and free of debris.

3. Check the belts and pulleys: Your laser cutter's belts and pulleys are important components that help to ensure smooth operation. Regularly inspect and tighten these components to ensure they are functioning properly.

4. Lubricate moving parts: Moving parts, such as the gantry and X-Y axis, require lubrication in order to operate smoothly. Consult your owner's manual for the recommended lubrication schedule and type of lubricant to use.

By following these simple tips, you can help to ensure your laser cutter remains in good working order for years to come. Remember, regular maintenance is key to extending the life of any machine.

Printers and laser cutters are two common devices used in printing and manufacturing industries.

Printers and laser cutters are two common devices used in printing and manufacturing industries. While they may look similar, they are not the same thing. Understanding the differences between these two devices is crucial before deciding which one to use for your project.

Printers are used to produce hard copies of digital documents or images on paper. They work by spraying ink onto a piece of paper using several nozzles. There are different types of printers, including inkjet, laser, and dot matrix printers. They differ in terms of the technology used to produce ink on paper and the quality of the final output.

Laser cutters, on the other hand, use an intense beam of light to cut through materials such as wood, metal, and plastic. They work by directing the laser beam precisely onto the material's surface to create complex and intricate designs. They are commonly used in the manufacturing industry to create parts for machines or cut patterns on fabrics and other materials.

In summary, while both printers and laser cutters use technology to produce output, they serve different purposes. Printers produce hard copies of digital documents on paper, while laser cutters cut through materials to create precise patterns or designs. Knowing the difference between these two devices can help you make informed decisions on which one to use for your next project.

Here are some tips and tricks to help you make the most of your laser cutting investment

Laser cutting has quickly become one of the most popular methods for creating precision cuts in a variety of materials. From industrial manufacturing to DIY projects, the versatility and accuracy of laser cutting make it an ideal choice for anyone looking to turn a profit. Here are some tips and tricks to help you make the most of your laser cutting investment:

1. Choose the right material. Not all materials are suited for laser cutting, so it's important to choose materials that will cut cleanly and without burning. Some common options include wood, acrylic, and paper products.

2. Optimize your file designs. Laser cutting machines require digital files to operate, so it's crucial that your designs are optimized for the cutting process. Make sure the file is properly formatted and that all curves and lines are connected.

3. Invest in quality equipment. Cutting corners on equipment may save money initially, but it can cost you more in the long run. Investing in a high-quality laser cutter will ensure that your cuts are precise and that your equipment will last for years to come.

4. Price out your products appropriately. Make sure you're accounting for the cost of materials, labor, and overhead when pricing your products. Remember that your time and skills are valuable, so don't be afraid to charge what your work is worth.

By following these tips, you can increase your profits and build a successful business with laser cutting.

we have compiled the top 10 fun facts that will make you appreciate it even more!

Laser cutters are one of the most fascinating modern inventions today. With its ability to create intricate designs, engrave on materials, and make accurate cuts, it is an impressive piece of technology. If you want to learn more about laser cutters, we have compiled the top 10 fun facts that will make you appreciate it even more!

1. Laser cutters were invented in 1967 and were used in industrial settings to cut metal.

2. Laser cutters are capable of cutting through many different materials, including wood, acrylic, leather, paper, and even food!

3. The heat from the laser beam is so intense that it can vaporize materials, making it completely disappear.

4. Laser cutters use a focused beam of light to cut, engrave, or etch materials with extreme precision.

5. Laser cutters come in various sizes and types, from small hobby machines to industrial-sized ones.

6. Most laser cutters use a carbon dioxide laser, which produces a wavelength of 10.6 micrometers.

7. With a laser cutter, you can create intricate designs that are impossible to achieve with traditional cutting methods.

8. Laser cutters are highly efficient, producing little waste and using less energy than other cutting methods.

9. Laser cutters can create three-dimensional objects by cutting and stacking layers of material.

10. Laser cutting technology is advancing rapidly, and some models can now use AI to detect defects and adjust for more precise cuts.

Laser cutters are undoubtedly fascinating machines, and these facts only scratch the surface of what they can do. As technology continues to evolve, so does the potential for laser cutters, and we can't wait to see what the future holds!

Here are 10 things to avoid when using a laser cutter.

Laser cutters are versatile tools that can be used for a variety of projects such as creating signage, engraving designs on a range of materials, and cutting shapes out of wood or acrylic. While laser cutters offer many opportunities for creation, it is important to proceed with caution to ensure safety and to avoid costly mistakes. Here are 10 things to avoid when using a laser cutter.

1. Using materials that aren't compatible with the cutter

2. Ignoring the laser cutter's maintenance schedule

3. Being impatient and rushing the project

4. Starting the project without a clear plan

5. Storing combustible materials near the laser cutter

6. Touching the laser

7. Not wearing the appropriate safety gear

8. Leaving the laser cutter unattended while it's in use

9. Running the laser cutter without proper ventilation

10. Not properly cleaning the laser cutter after each use.

By following these tips, you can use a laser cutter safely and avoid common mistakes that can lead to injury or damage to the equipment. Remember, laser cutters are powerful tools that must be handled with care and respect. With the right precautions, you can create amazing things with a laser cutter.

One common question that many people have is whether laser cutters and laser printers are the same thing.

When it comes to modern technology, the line between different devices can often blur. One common question that many people have is whether laser cutters and laser printers are the same thing. In short, the answer is no. While both devices utilize lasers to perform tasks, the way in which they do so is vastly different.

Laser printers use a laser to transfer toner or ink onto paper to create prints of documents, images or designs. They are primarily used for printing purposes and are found in homes, offices, and schools. Whereas, laser cutters create intricate designs, patterns, or shapes on a variety of materials such as wood, plastic, and metal. They are widely used in manufacturing facilities, small businesses, and makerspaces.

The major difference between the two devices lies in the mechanism they use to achieve their tasks. Laser printers typically use a rotating mirror to direct the laser beam onto the paper, while laser cutters use a fixed mirror to move the laser beam across the material. Additionally, laser cutters are much more precise and versatile than laser printers due to their varying beam intensities and the ability to use various materials.

In conclusion, while laser cutters and printers both utilize laser technology, they are two completely different machines that are designed for two separate purposes. It is essential to understand the difference if you plan on utilizing these devices in your work or leisure. Laser printers are great for creating stunning designs and prints, and laser cutters are perfect for all your cutting, carving and engraving needs!

Here are 10 ideas for things you can do with your laser cutter right now

If you have a laser cutter, you know just how versatile and powerful a tool it can be. Here are 10 ideas for things you can do with your laser cutter right now:

1. Create custom jewelry. Use your laser cutter to make unique earrings, necklaces, and bracelets out of wood, acrylic, or even leather.

2. Cut intricate designs for clothing. Use your laser cutter to add intricate patterns and shapes to clothing items such as t-shirts, sweatshirts, and hats.

3. Make custom invitations. Impress your friends and family with custom laser-cut invitations for weddings, birthdays, or any special event.

4. Create custom signage. Use your laser cutter to create unique signs for your business, family events, or home decor.

5. Cut custom stencils for artwork. Make interesting and unique art by using laser cut stencils on canvas and paper.

6. Personalize phone cases. Create unique phone cases for yourself or as gifts by using your laser cutter to etch or cut custom designs on them.

7. Make custom wooden puzzles. Make personalized wooden puzzles using your laser cutter for the ultimate personalized gift.

8. Create custom stamps. Get creative with stamp making by using your laser cutter to create custom stamps in any design.

9. Cut custom cake toppers. Make personalized cake toppers for birthdays and weddings that no one else will have.

10. Create custom home decor. Use your laser cutter to make unique home decor items such as lamp shades, vase covers, and wall art.

These are just a few ideas, but the possibilities are endless with a laser cutter. With a little imagination and creativity, you can use your laser cutter to make anything.

Are you a creative person who loves working with your hands?

Are you a creative person who loves working with your hands? Do you dream of owning your own small business? If so, starting a business with a laser cutter might be the perfect option for you.

Here are ten steps to launching your small business with a laser cutter:

1. Do your research: Before you invest in a laser cutter, research the market to ensure there is demand for laser cut products in your area.

2. Create a business plan: Develop a plan for your small business, including your target market, marketing strategy, and financial projections.

3. Choose a laser cutter: Consider the type and size of laser cutter that will best suit your needs.

4. Determine your workspace: Set up a clean and organized workspace to operate your laser cutter from.

5. Establish a budget: Calculate the costs of materials, equipment, and other expenses to ensure that your business is financially viable.

6. Develop a product line: Create a variety of products to sell, such as jewelry, home decor, or customized gifts.

7. Build a website: Establish an online presence for your business by creating a website to display your products and accept orders.

8. Market your business: Advertise your business on social media, and attend craft shows and fairs to generate interest and sales.

9. Get licensed and insured: Obtain a business license and liability insurance to protect yourself and your business.

10. Start cutting: Once you have everything in place, start creating and selling your laser cut products! Remember to update your strategy and adapt to changes along the way.

Good luck on your entrepreneurial journey!

When it comes to precision cutting in industrial settings, nothing beats industrial laser cutting.

When it comes to precision cutting in industrial settings, nothing beats industrial laser cutting. A technique that uses lasers to cut different materials, this process has gained popularity in a wide range of fields, from automotive to aerospace, and from electronics to medical. But what is industrial laser cutting?

In simple terms, industrial laser cutting involves using a high-powered laser beam to melt, vaporize, or burn through different types of materials, including metals, plastics, ceramics, glass, and wood. This process can create intricate and precise cuts, even in complex shapes and designs, with minimal heat-affected zones and minimal material waste.

There are different types of lasers used in industrial laser cutting, including CO2 lasers, fiber lasers, and solid-state lasers. These lasers differ in terms of their wavelength, power, and pulse duration, and each offers specific advantages and limitations depending on the application.

Industrial laser cutting finds its applications in various industries, from automotive and aerospace to medical devices and consumer electronics. This process can cut metal tubes, sheets, and plates in various thicknesses and sizes, create complex patterns and designs, and engrave logos, serial numbers, and other markings.

Overall, industrial laser cutting is a versatile and efficient technique that allows for high-precision cutting in a wide range of materials and applications. Its popularity is growing by the day as industries look for cost-effective and efficient ways of manufacturing products with high precision and quality. So the next time you see a precisely cut metal piece in an industrial setup, know that it could be a result of industrial laser cutting.

sign companies must be innovative and creative to stand out among their competition.

In today’s world, sign companies must be innovative and creative to stand out among their competition. One way sign companies can stay ahead of the game is by utilizing laser cutting machines to create their signage.

Laser cutters offer a high level of precision and speed that other cutting machines can’t match. This means that sign companies can create intricate designs and patterns at a faster pace, allowing for quicker turnaround times. In addition, laser cutters can cut a wide range of materials, including wood, acrylic, and metal. This means that sign companies can create customized signs on various surfaces.

Another benefit of using laser cutters for sign companies is that they allow for more creativity in the designing process. With a laser cutter, it is possible to cut complex shapes, patterns, and even photos into a sign. This level of customization can create unique and eye-catching signage that stands out from the crowd.

Additionally, laser cutting machines are easy to operate, meaning that sign companies can have their staff trained quickly and efficiently. With simple design software, companies can create their designs quickly and have their signs cut in no time. This also means that design changes can be made with ease, without having to scrap an entire sign.

In conclusion, the use of laser cutters for sign companies presents many benefits, including increased precision, speed, customization, and ease of use. With these advantages, sign companies can create unique and eye-catching signage that takes their business to the next level.

Printing companies are constantly looking for ways to improve their services and offer more value to their customers

Printing companies are constantly looking for ways to improve their services and offer more value to their customers. One way to do this is by incorporating a laser cutter into their operations.

Laser cutters offer a range of benefits to printing companies. First and foremost, they allow for precise and intricate cutting of a variety of materials, from paper to vinyl to wood. This opens up new possibilities for printed products, such as customized cards, invitations, packaging, and even signage.

In addition to expanding the range of products that printing companies can offer, laser cutters also increase efficiency. They can cut materials at a much faster rate than traditional methods, saving time and money in the production process. This means that printing companies can take on more clients or orders without sacrificing quality or turnaround time.

Another advantage of laser cutters is that they can be programmed to cut intricate designs automatically, which saves time and labor costs. This also reduces the chance of errors or mistakes in the cutting process, leading to a higher quality finished product.

Finally, incorporating a laser cutter into their operations can help printing companies stand out in a crowded market. Customers are always looking for unique and creative solutions, and laser cutting offers new opportunities for customization and personalization.

In summary, laser cutters are a valuable investment for printing companies. By offering more options, increasing efficiency, and improving the quality of printed products, they can help businesses grow and succeed in a competitive industry.

One way to do this is by incorporating a laser cutter into their operations.

Laser cutters offer a range of benefits to printing companies. First and foremost, they allow for precise and intricate cutting of a variety of materials, from paper to vinyl to wood. This opens up new possibilities for printed products, such as customized cards, invitations, packaging, and even signage.

In addition to expanding the range of products that printing companies can offer, laser cutters also increase efficiency. They can cut materials at a much faster rate than traditional methods, saving time and money in the production process. This means that printing companies can take on more clients or orders without sacrificing quality or turnaround time.

Another advantage of laser cutters is that they can be programmed to cut intricate designs automatically, which saves time and labor costs. This also reduces the chance of errors or mistakes in the cutting process, leading to a higher quality finished product.

Finally, incorporating a laser cutter into their operations can help printing companies stand out in a crowded market. Customers are always looking for unique and creative solutions, and laser cutting offers new opportunities for customization and personalization.

In summary, laser cutters are a valuable investment for printing companies. By offering more options, increasing efficiency, and improving the quality of printed products, they can help businesses grow and succeed in a competitive industry.

Product development can be a laborious process

Product development can be a laborious process, involving multiple iterations and lengthy production cycles. But what if there was a tool that could streamline the process and reduce the time to market? Enter the laser cutter, an increasingly popular tool for prototyping and production alike. Here are 5 tips for using a laser cutter to rapidly develop your product:

1. Start with a CAD Model: A laser cutter needs a digital design to work with. Starting with a 3D CAD model ensures accuracy and helps identify potential design flaws early on.

2. Choose the Right Material: Not all materials are suitable for laser cutting. Consider the thickness, composition, and finish of your material to ensure a successful cut.

3. Optimize Your Settings: Each laser cutter has its own set of optimal settings for a given material. Take the time to experiment and find the right combination of speed, power, and focal length for your specific material.

4. Test & Iterate: Before diving into production, test your design and make necessary tweaks. Running small batches of prototypes allows for efficient iteration and adjustment.

5. Collaborate & Outsource: If you don't have access to a laser cutter, don't fret! Collaborate with makerspaces, fab labs, or outsource to specialized laser cutting services. This can be a cost-effective solution that lets you focus on your design while leaving the production to the experts.

In conclusion, a laser cutter can be a powerful tool for rapid development and prototyping. By following these tips, you can harness the full potential of laser cutting and take your product from concept to market in record time.

Are you tired of waiting weeks or even months for a prototype to be manufactured?

Are you tired of waiting weeks or even months for a prototype to be manufactured? Rapid prototyping solutions have been a game changer for engineers and designers alike. One of the most exciting and efficient ways to produce prototypes is through the use of a laser cutter. Even better, the process is simpler than you may think. Here’s a quick guide to getting started with rapid prototyping using a laser cutter.

Firstly, you must create a CAD design of your product. There are a plethora of software options available that can convert your idea into a physical blueprint. You’ll want to make sure your design is properly optimized before printing.

Next, choose your material. Wood and acrylic are great options for laser cutting. Once you have your design and material, you’ll need to send it to the laser cutter. This process is quick and seamless. It only takes a few minutes to physically cut your product, as opposed to traditional manufacturing that can take weeks, if not months.

Finally, you’ll want to inspect your prototype for any defects. Whether you need to make minor tweaks or overhaul your design, this quick process ensures that you’re not wasting weeks waiting on a physical prototype that doesn’t even work properly.

Using a laser cutter for rapid prototyping is amazingly efficient. It allows designers to iterate their designs quickly, and to save cost and time. Plus, laser cutter technology is continuously advancing to make prototyping even more efficient. So why wait months for a prototype, when you can have one in just hours with a laser cutter?

prototyping remains a critical stage in the product development cycle

In today's fast-paced technological world, prototyping remains a critical stage in the product development cycle. Prototyping allows you to test your ideas, designs, and concepts before mass production, which saves you time and money. Prototyping with a laser cutter is a game-changer in the prototyping world and allows for precision, speed, and versatility.

Laser cutting is a manufacturing method that uses a high-powered laser beam to cut and etch materials quickly and accurately. With a laser cutter, you can make complex shapes, intricate designs, and detailed cuts with ease.

Creating prototypes with a laser cutter allows you to see and touch your ideas so you can determine if it meets your specifications. The material options available with laser cutters include wood, acrylic, plastic, and even metal.

Aside from cutting, a laser cutter can also engrave lines and logos onto the material’s surface, giving an added touch of uniqueness to your prototypes. Using a laser cutter is not just limited to designing products. You can create promotional materials, architectural models, and personalized gifts too.

Laser cutting technology is rapidly becoming more accessible, making prototyping with a laser cutter more affordable than ever. It allows for speed, accuracy, and a wide range of options and is a fantastic tool for any product development professional or enthusiast.

In conclusion, if you're looking for a way to streamline your prototyping process, consider incorporating a laser cutter into your toolkit. Its precision, speed, and versatility can help you create unique, functional, and beautiful prototypes in no time. Happy prototyping!

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)