American Laser Cutter: Your Precision Cutting Partner in Los Angeles

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

Laser Cutting's Cutting Edge: A Look at the Latest Advancements

Laser Cutting's Cutting Edge: A Look at the Latest Advancements

Laser cutting machines have become a ubiquitous tool across industries, from delicate craftwork to heavy-duty metal fabrication. But this technology is constantly evolving, pushing the boundaries of precision, efficiency, and material compatibility. Let's delve into the latest advancements that are shaping the future of laser cutting:

1. The Rise of Ultra-High Power Fiber Lasers:

Fiber lasers have long been lauded for their versatility in cutting metals. Now, the emergence of ultra-high power (UHP) fiber lasers is a game-changer. These lasers boast significantly higher wattages, enabling them to:

Tackle Thicker Metals: UHP lasers can pierce through much thicker metal plates compared to their lower-powered counterparts. This opens doors for applications in shipbuilding, heavy equipment manufacturing, and construction.

Boost Cutting Speeds: The increased power translates to faster cutting speeds, improving productivity and throughput for manufacturers.

Maintain Cutting Quality: Despite the higher power, UHP lasers can deliver clean, precise cuts with minimal heat distortion, ensuring high-quality end products.

2. Automation and Integration Take Center Stage:

The future of laser cutting is increasingly automated. Here's how technology is streamlining the process:

Robotic Integration: Laser cutting machines are being seamlessly integrated with robotic arms. This allows for automated part handling, loading, and unloading, reducing manual intervention and human error.

Automated Nesting Software: Advanced software algorithms can now optimize material usage by automatically nesting cutting patterns within a sheet of material. This minimizes waste and ensures efficient material utilization.

Machine-to-Machine Communication: The rise of the Industrial Internet of Things (IIoT) allows laser cutters to communicate with other machines on the factory floor. This enables real-time monitoring, preventative maintenance, and data-driven optimization of the entire production process.

3. Artificial Intelligence Enhances Efficiency and Precision:

Artificial intelligence (AI) is making inroads into the world of laser cutting, offering exciting possibilities:

Adaptive Power Control: AI algorithms can analyze real-time cutting data and adjust laser power settings on the fly. This ensures optimal cutting parameters for different material thicknesses and complexities, leading to consistent quality and reduced energy consumption.

Predictive Maintenance: AI-powered systems can monitor machine performance and predict potential maintenance needs before they cause downtime. This proactive approach minimizes disruptions and ensures optimal machine uptime.

Process Optimization: Machine learning algorithms can analyze historical data to identify areas for improvement in cutting speeds, power usage, and material utilization. This continuous learning loop helps manufacturers fine-tune their processes for maximum efficiency.

4. A Focus on Beam Control and Cutting Techniques:

Advancements in beam control and cutting techniques are further refining the capabilities of laser cutters:

Dual-Beam Technology: Some machines are equipped with dual laser beams, each with different wavelengths or focal points. This allows for cutting a wider range of materials in a single pass, improving efficiency and versatility.

Multi-Pulse Laser Cutting: This technique utilizes a series of short, high-peak power pulses instead of a continuous beam. This reduces heat input, leading to cleaner cuts on thin materials and minimizing heat distortion.

Beam Shaping and Advanced Optics: New developments in beam shaping nozzles and focusing optics allow for tighter beam control and more intricate cutting patterns. This opens doors for even more precise and delicate applications.

The Future of Laser Cutting: A Brighter, More Precise Horizon

As these advancements continue to evolve, we can expect laser cutting machines to become even more powerful, precise, and user-friendly. The integration of automation, AI, and advanced cutting techniques will further revolutionize manufacturing processes across various industries. With its ever-expanding capabilities, laser cutting technology is poised to play a pivotal role in shaping the future of fabrication.

The World of Laser Cutting: Unleashing Precision and Creativity

The World of Laser Cutting: Unleashing Precision and Creativity

Laser cutting machines have revolutionized how we shape and manufacture a vast array of materials. From delicate crafts and intricate jewelry to industrial-scale metal fabrication, these machines deliver clean cuts, precise designs, and unparalleled versatility. This article delves into the fascinating world of laser cutters, exploring their types, functionalities, applications, and factors to consider when choosing one.

Unveiling the Technology: How Laser Cutting Works

At its core, a laser cutting machine utilizes a highly focused laser beam to melt, vaporize, or ablate (remove by erosion) material, creating a clean cut along a predefined path.

Here's a breakdown of the core components:

Laser Source: This is the heart of the machine, generating a concentrated beam of light. Common types include CO2 lasers (popular for non-metals) and fiber lasers (ideal for metals).

Cutting Head: This houses the laser source, focusing optics, and a nozzle that delivers a gas assist (usually compressed air) to clear debris and cool the cutting area.

Motion Control System: This intricate system precisely moves the cutting head along the programmed path, ensuring accurate and clean cuts.

Software: Laser cutting software allows users to design and import cutting paths, control laser parameters like power and speed, and manage the entire cutting process.

A Tale of Two Types: CO2 vs. Fiber Lasers

The two dominant types of laser cutting machines are differentiated by their laser source:

CO2 Laser Cutters:

Strengths:

Excellent for cutting a wide range of non-metals like wood, acrylic, plastic, fabric, and leather.

Delivers smooth, high-quality cuts with minimal charring.

Often more affordable than fiber lasers, especially in lower wattages.

Weaknesses:

Not ideal for cutting metals due to limited beam penetration.

Requires regular maintenance for optimal performance (gas refills, mirror cleaning).

Fiber Laser Cutters:

Strengths:

Exceptionally versatile, capable of cutting a broad spectrum of materials, including metals (steel, aluminum, stainless steel), plastics, and even some non-metals.

Offers faster cutting speeds and superior edge quality compared to CO2 lasers.

Requires minimal maintenance and boasts a longer lifespan.

Weaknesses:

Generally more expensive than CO2 lasers, particularly in higher wattages.

May not be the best choice for delicate cuts on thin, non-metallic materials due to the intense heat generated.

A Universe of Applications: Where Laser Cutting Shines

Laser cutting machines find application in a mind-boggling array of industries and creative endeavors. Here are a few examples:

Industrial Manufacturing: From automotive parts and aerospace components to medical devices and electronics, laser cutters play a crucial role in high-precision metal fabrication.

Signage and Displays: They are instrumental in creating signage, displays, and point-of-sale materials from acrylic, wood, and metals.

Jewelry and Crafts: Laser cutters empower jewelry designers and crafters to create intricate pieces, personalized gifts, and custom embellishments from various materials.

Fashion and Apparel: They are used to precisely cut fabric for clothing, footwear, and accessories, enabling rapid prototyping and design iteration.

Architecture and Engineering: Laser cutters help create architectural models, prototypes, and signage from various materials.

Choosing Your Perfect Cut: Factors to Consider

Selecting a laser cutting machine depends on several factors:

Material Compatibility: Identify the primary materials you intend to cut. CO2 lasers excel with non-metals, while fiber lasers offer broader material versatility.

Budget: Laser cutters range in price from a few hundred dollars for hobbyist models to hundreds of thousands for industrial machines.

Wattage: Higher wattage lasers can cut thicker materials and offer faster cutting speeds.

Work Area Size: Consider the size and complexity of your projects when choosing a machine's work area.

Ease of Use: Hobbyist machines prioritize user-friendliness, while industrial machines might require specialized training.

Safety First: Essential Precautions

Laser cutting involves high-powered lasers and requires adherence to safety protocols:

Always wear appropriate safety glasses: These should be specifically designed for the laser wavelength being used.

Operate the machine in a well-ventilated area: Fumes and debris generated during cutting need proper ventilation.

Never leave the machine unattended while operational.

Keep flammable materials away from the cutting area.

The Future of Laser Cutting: A World of Possibilities

Laser cutting technology is constantly evolving, with advancements in:

Automation and Integration: Expect seamless integration with robotics and automated material handling systems

Finding Laser Cutting Files on Thangs: A Resource Guide

Finding Laser Cutting Files on Thangs: A Resource Guide

Thangs is a growing online platform connecting creators with 3D models and design files. While it primarily focuses on 3D printing, it can also be a valuable resource for finding laser cutting files. Here's how to navigate Thangs to find the perfect laser cut designs for your next project:

Understanding Thangs: Not Just for 3D Printing

While Thangs is known for its extensive 3D printing model library, many designers also upload projects suitable for laser cutting. These files are typically in vector graphic formats like SVG or DXF, which laser cutters can readily interpret and translate into precise cuts.

Search Strategies: Finding Laser-Ready Files

There are a few ways to identify laser cutting files on Thangs:

Keywords: Use relevant keywords in your search bar, including "laser cut," "SVG," "DXF," or specific project terms like "keychain," "jewelry," or "wall art." Many designers will include these keywords in their file descriptions.

Filters: Thangs offers filter options on the search results page. Look for filters like "File Format" and choose "SVG" or "DXF" to narrow down your search to files compatible with laser cutters.

Designer Collections: Some designers on Thangs specialize in laser cutting projects. Explore the platform and discover designers known for laser cutting files by browsing collections and user profiles.

Beyond the Search: Additional Tips for Success

Here are some additional tips to optimize your search for laser cutting files on Thangs:

Material Compatibility: Pay close attention to the material specifications mentioned in the file description. Ensure the design is compatible with the material you plan to use on your laser cutter.

Project Complexity: Consider your skill level and laser cutter capabilities when choosing a file. Start with simpler designs if you're new to laser cutting, and progress to more intricate projects as you gain experience.

Check Licenses: Always ensure the files you download from Thangs have appropriate licenses for your intended use. Many designers offer free files for personal use, while others may require a commercial license if you plan to sell products created with their designs.

Thangs: A Stepping Stone for Your Laser Cutting Journey

While Thangs can be a great starting point for finding laser cutting files, it's important to remember that not all files uploaded to the platform are specifically designed for laser cutting. Here are some additional resources to explore:

Online Design Communities: Platforms like Thingiverse or online forums dedicated to laser cutting offer a wealth of user-created laser cutting files and project ideas.

Maker Websites: Many makerspaces and laser cutting service providers have websites with free downloadable laser cutting files and tutorials.

Professional Design Software: Software like Adobe Illustrator allows you to create your own laser cutting designs from scratch, offering ultimate customization.

Thangs provides a valuable starting point for discovering the world of laser cutting. By employing effective search strategies, understanding file licenses, and exploring additional resources, you can find the perfect laser cutting files to bring your creative projects to life!

Laser Cutting in the USA: A Booming Industry Shaping Innovation

Laser Cutting in the USA: A Booming Industry Shaping Innovation

The USA has become a hub for innovation, and laser cutting technology is at the forefront of this movement. This precise and versatile technology has transformed countless industries, empowering businesses and individuals to bring their ideas to life. Let's delve into the world of laser cutting in the USA, exploring its applications, benefits, and the exciting future that lies ahead.

Across Industries: The Widespread Impact of Laser Cutting

Laser cutting isn't confined to a single sector; it has infiltrated a remarkable range of industries:

Manufacturing: From rapid prototyping of intricate components to precise sheet metal fabrication for various applications, laser cutting plays a crucial role in modern manufacturing.

Retail and Signage: Eye-catching signage, customized displays, and even personalized products like phone cases or homeware all benefit from the clean cuts and design flexibility offered by laser cutting.

Fashion and Design: Laser cutting has become a staple in the fashion and design world. Jewelry makers utilize it for intricate designs, fashion designers for unique details on clothing, and footwear companies for customized patterns.

Architecture and Interior Design: Architects rely on laser cutting for precise scale models, while interior designers leverage it for creating decorative features, custom millwork, and stylish signage.

Beyond the List: Unveiling Unexpected Applications

The reach of laser cutting extends far beyond the industries mentioned above. Here are some fascinating examples:

Medical Devices: The medical field utilizes laser cutting for creating precise medical components and instruments.

Arts and Crafts: Hobbyists and artists can create unique pieces, jewelry, or craft decorations using laser cutters.

Education and Prototyping: Schools and universities are increasingly incorporating laser cutters into their curriculum for educational purposes and rapid prototyping.

The Advantages of Laser Cutting: Why It's Here to Stay

Several factors contribute to the widespread adoption of laser cutting in the USA:

Precision and Clean Cuts: Laser cutters deliver unmatched precision, ensuring clean edges and intricate details on various materials.

Versatility: A wide range of materials can be laser cut, from wood and acrylic to fabric and even some metals.

Speed and Efficiency: Laser cutting offers fast turnaround times, making it ideal for rapid prototyping and efficient production runs.

Minimal Waste: Compared to traditional cutting methods, laser cutting minimizes material waste, contributing to a more sustainable manufacturing process.

Looking Ahead: The Future of Laser Cutting in the USA

As laser cutting technology continues to evolve, we can expect even more exciting advancements:

Faster Cutting Speeds: The future holds the promise of even faster cutting speeds, further streamlining production processes.

Advanced Materials: The ability to handle an even wider range of materials will open doors to new applications and design possibilities.

3D Laser Cutting: While still in its early stages, 3D laser cutting has the potential to revolutionize manufacturing by creating complex 3D structures from sheet materials.

The Final Cut: A Technology Shaping the American Landscape

Laser cutting has become an indispensable tool for innovation and efficient manufacturing in the USA. Its versatility, precision, and potential for future advancements solidify its position as a technology shaping the American landscape across countless industries. Whether you're a seasoned manufacturer, a passionate entrepreneur, or an aspiring artist, laser cutting offers a powerful tool to bring your ideas to life and contribute to the ever-evolving world of American innovation.

Lights, Camera, Prototype: How LA Businesses are Using Laser Cutting to Innovate

Lights, Camera, Prototype: How LA Businesses are Using Laser Cutting to Innovate

Los Angeles, the city of angels and...rapid prototyping? Believe it or not, LA boasts a thriving manufacturing and design scene, and laser cutting is a major player in the game. For businesses looking to bring their ideas to life quickly and efficiently, laser cutting offers a powerful tool for rapid prototyping. But how can LA businesses leverage this technology to gain a competitive edge? This article explores the advantages of laser cutting for rapid prototyping and the resources available in the City of Angels.

The Power of Rapid Prototyping: Speeding Up Innovation

Rapid prototyping is the process of creating a physical model of a product design quickly and iteratively. It allows businesses to test designs, identify and address flaws early on, and refine their concepts before investing in mass production. Here's where laser cutting shines:

Precision and Speed: Laser cutters deliver precise cuts on a variety of materials, allowing for the creation of detailed and functional prototypes.

Rapid Iteration: Compared to traditional methods, laser cutting allows for quick turnaround times, enabling businesses to experiment with different design variations swiftly.

Cost-Effective: Laser cutting prototypes can be significantly cheaper than traditional methods, making it an attractive option for startups and businesses with limited budgets.

Laser Cutting for LA Businesses: Across Industries

The benefits of laser cutting for rapid prototyping extend across various industries in Los Angeles:

Aerospace & Defense: LA is a hub for aerospace, and laser cutting helps create lightweight, high-strength prototypes for aircraft components.

Consumer Electronics: From phone cases to wearable tech, laser cutting allows for rapid creation of functional prototypes for consumer electronics.

Entertainment & Design: For studios and design houses, laser cutting can prototype movie props, stage sets, or even intricate costume elements.

Medical Devices: The healthcare industry in LA utilizes laser cutting to create precise prototypes for medical instruments and implants.

Finding Your Laser: Resources for LA Businesses

Several options are available for LA businesses looking to leverage laser cutting for rapid prototyping:

In-House Laser Cutters: For businesses with high prototyping volume, investing in an in-house laser cutter can be a cost-effective solution. However, this requires training staff and dedicating space for the equipment.

Makerspaces: LA has a vibrant network of makerspaces offering laser cutting equipment and expertise. Makerspaces often provide training and memberships, allowing businesses to pay per use without a significant upfront investment. Examples include HackLAB Makerspace LA and L.A. Makerspace.

Laser Cutting Services: Numerous businesses in LA specialize in laser cutting services. These companies offer a variety of materials and turnaround times, allowing businesses to outsource their prototyping needs.

The Final Cut: Innovation at the Speed of Light

Laser cutting offers a powerful tool for rapid prototyping, empowering LA businesses to bring their ideas to life faster and more efficiently. Whether you're in aerospace, consumer electronics, or design, this technology can accelerate your innovation cycle and give you a competitive edge. So, explore the resources available in Los Angeles, embrace the possibilities of laser cutting, and watch your prototypes take flight!

The Cutting Edge: How Businesses Across Industries Are Using Laser Cutting

The Cutting Edge: How Businesses Across Industries Are Using Laser Cutting

Laser cutting technology has transformed manufacturing, offering businesses a precise, versatile, and efficient way to create intricate parts and designs. But beyond traditional manufacturing, laser cutting has infiltrated a surprising array of industries, empowering businesses to bring their creative visions to life. Let's explore how various businesses are wielding the power of laser cutting to gain a competitive edge.

Manufacturing: A Perfect Match for Precision

Prototyping: Laser cutters are ideal for rapidly creating prototypes, allowing manufacturers to test designs and iterate quickly before mass production.

Sheet Metal Fabrication: From control panels to intricate brackets, laser cutters precisely cut sheet metal for a variety of applications.

Aerospace: The aerospace industry relies on lightweight, high-strength materials. Laser cutting ensures clean cuts for these specialized components.

Retail and Signage:

Eye-Catching Signage: Laser cutters can create unique and durable signage, from storefront displays to personalized name plates.

Point-of-Purchase Displays: Laser cutting allows for the creation of customized and creative displays to grab customer attention.

Personalized Products: Retailers can offer laser-cut engravings or customized designs on products like phone cases, keychains, or homeware.

Fashion and Design:

Jewelry Making: Laser cutters precisely cut intricate jewelry designs from various materials like wood, acrylic, or even precious metals.

Fashion Design: From custom stencils for fabric printing to laser-cut details on clothing, laser cutting adds a unique touch to fashion designs.

Shoe Design: Laser cutting can create customized details or intricate patterns on leather or fabric for footwear.

Architecture and Interior Design:

Model Making: Architects and designers use laser cutting to create precise and detailed scale models for presentations.

Custom Millwork: Laser cutters can create decorative features like wall panels, furniture components, or even customized lighting fixtures.

Interior Signage: Laser cutting allows for the creation of unique and stylish signage for offices, restaurants, or other commercial spaces.

Beyond the List: The Versatility of Laser Cutting

The applications of laser cutting extend far beyond the industries listed above. Here are some additional examples:

Medical Devices: Laser cutting is used to create precise medical components and instruments.

Arts and Crafts: Hobbyists and artists use laser cutters to create unique pieces, jewelry, or craft decorations.

Education and Prototyping: Schools and universities are increasingly using laser cutters for educational purposes and rapid prototyping.

The Future of Laser Cutting: Innovation on the Horizon

As laser cutting technology continues to evolve, we can expect even more innovative applications across various industries. With faster cutting speeds, the ability to handle a wider range of materials, and potentially even 3D cutting capabilities, the future of laser cutting is bright. For businesses seeking a competitive edge, laser cutting offers a powerful tool for creating high-quality, customized products and transforming their ideas into reality.

From Idea to Reality: Getting Started with Laser Cutting in Los Angeles

From Idea to Reality: Getting Started with Laser Cutting in Los Angeles

Los Angeles, the city of angels and...laser cutters? Believe it or not, the City of Angels boasts a thriving maker scene, and laser cutting is a major player. If you've got an idea itching to be brought to life, this precise and versatile technology might be your perfect partner. But where do you even begin?

DIY or Delegate? Deciding Your Laser Path

There are two main approaches to laser cutting in LA:

Hands-on DIY: Dive right in and learn the ropes yourself! This empowers you to experiment and have full creative control.

Laser Cutting Services: Let the experts handle the machine. This is ideal for intricate designs or one-off projects.

Let's Get Equipped: Resources for DIY Laser Cutting

If you're feeling adventurous and want to try DIY laser cutting, here's your LA starter pack:

Makerspaces: Los Angeles is brimming with makerspaces, community workshops packed with tools and expertise. Places like HackLAB and L.A. Makerspace offer laser cutting equipment and classes for beginners.

Laser Cutter Training: American Laser Cutter [American Laser Cutter] provides laser cutter classes, both in-person and online. Learning from experienced professionals can give you a strong foundation.

Software Savvy: Mastering Design for Laser Cutting

Before you unleash the laser, your design needs to be translated into a language the machine understands. Here's where software comes in:

Free and Friendly: Inkscape, a free and open-source vector graphics editor, is a great option for beginners. It allows you to create designs specifically for laser cutting.

Industry Standard: For more advanced features and compatibility with professional laser cutters, Adobe Illustrator is the industry standard. There's a learning curve, but online tutorials abound.

Safety First: Essential Knowledge for Laser Wranglers

Laser cutters are powerful tools, so safety is paramount. Here are some key points to remember:

Always follow safety protocols: Makerspaces and training courses will emphasize safety procedures. Wear proper eyewear, never leave the laser unattended, and understand proper ventilation for fumes.

Know your materials: Different materials react differently to the laser. Research safe cutting speeds and power settings for your chosen material to avoid burning or warping.

Laser Cutting Services in LA: When DIY Isn't Your Style

Maybe you have a complex design or limited time. Here's where laser cutting services come in:

American Laser Cutter: Specializes in laser cutting plastics like acrylic and Plexiglass, offering project execution and technical support

The LA Laser Cutting Community: A Network of Support

Los Angeles boasts a vibrant maker community. Here are some ways to connect:

Makerspace Meetups: Many makerspaces host regular meetups where you can network with other laser enthusiasts.

Online Forums: The Laser Cutting subreddit and Facebook groups offer a wealth of knowledge and troubleshooting tips from a global community.

With a little planning and exploration, you can be laser cutting your way to creative fulfillment in Los Angeles. So, unleash your inner maker, embrace the power of the laser, and transform your ideas into reality!

Easily Apply Vinyl Graphics with This American-Made Transfer Tape

Easily Apply Vinyl Graphics with This American-Made Transfer Tape

This 24-inch wide, 100-foot long roll of transfer tape is ideal for crafters and sign makers who want to easily transfer vinyl decals and lettering to any smooth surface. Made in the USA, this transfer tape features a layflat adhesive that keeps the tape flat and easy to handle, while the medium tack ensures clean removal without leaving residue behind.

Here's what makes this transfer tape great:

Layflat adhesive: No more wasted time wrestling with curled edges or uneven application.

Medium tack: Holds vinyl securely for transfer, but removes cleanly without damaging your project.

American-made: Supports American manufacturing and ensures quality materials.

Wide format: The 24-inch width is perfect for large decals and signs.

Long roll: 100 feet of tape provides plenty of material for all your crafting and sign making needs.

This transfer tape is perfect for:

Crafters using vinyl cutters like Cricut and Silhouette

Sign makers applying vinyl lettering and graphics

Anyone who wants to easily transfer vinyl decals to a smooth surface

Order your transfer tape today and start creating professional-looking vinyl projects with ease!

Dive into Making: A Beginner's Guide to Rapid Prototyping

Dive into Making: A Beginner's Guide to Rapid Prototyping

Ever have a brilliant idea for a product but get stuck on how to bring it to life? Rapid prototyping is here to help! It's an iterative design process that allows you to quickly create and test physical or digital representations of your ideas.

This approach is all about getting your concept out there – fast and often cheaply – to gather feedback and refine your design before investing heavily in production. It's perfect for anyone, from inventors and designers to entrepreneurs and students.

Why Rapid Prototyping?

Here are some key benefits:

Validate your ideas: See if your concept is actually useful and solves a problem for real people.

Identify flaws early: Catch design issues before they become expensive mistakes down the line.

Get user feedback: Involve potential users in the design process, leading to a better end product.

Save time and money: Rapid prototypes are typically inexpensive and quick to create, allowing for more iterations.

Getting Started: Your Rapid Prototyping Toolkit

The beauty of rapid prototyping is that it doesn't require fancy equipment. Here's what you might need:

Low-fi materials: Cardboard, paper, tape, foam core, and even household items like Legos can be surprisingly effective for building basic prototypes.

Digital tools: There's a wide range of software available, from basic drawing programs to 3D modeling applications, depending on the complexity of your project. Some popular options include Figma, Sketch, and Tinkercad.

The Rapid Prototyping Cycle

Here's a simplified breakdown of the process:

Define and Focus: Clearly outline your idea and what you want to test with the prototype.

Prototype It: Build a basic representation of your idea using your chosen tools and materials.

Test and Get Feedback: Put your prototype in front of users and observe how they interact with it. Gather their feedback and suggestions.

Refine and Repeat: Based on the feedback, iterate on your design and build a new prototype. This cycle continues until you're satisfied with your concept.

Tips for Success

Embrace the mess: Don't worry about making a perfect prototype; focus on functionality and getting feedback.

Start simple: Begin with low-fidelity prototypes and gradually increase complexity as your design evolves.

Focus on the user: Throughout the process, keep the needs and behaviors of your target user in mind.

Don't be afraid to fail: Rapid prototyping is all about learning from mistakes. Embrace failures as opportunities to improve your design.

With a little creativity and these tips, you can leverage rapid prototyping to turn your ideas into reality. Happy making!

Clear Choices: Extruded vs. Cast Acrylic for Your Next Project

Clear Choices: Extruded vs. Cast Acrylic for Your Next Project

Acrylic, a versatile and popular material, reigns supreme in the world of crafting and design. But within the acrylic family, two main types emerge: extruded and cast acrylic. Choosing the right one for your project hinges on understanding their key differences. Let's delve into the properties of each to guide you towards the perfect acrylic selection.

Extruded Acrylic: The Efficient Option

Extruded acrylic is produced by forcing molten acrylic plastic through a mold, similar to how toothpaste is extruded from a tube. Here's what makes it stand out:

Cost-Effective: The extrusion process is generally faster and more economical compared to cast acrylic production. This translates to a lower price point for extruded acrylic sheets.

Uniform Thickness: The extrusion process ensures consistent thickness throughout the entire acrylic sheet, making it ideal for projects requiring precise dimensions.

Wider Range of Colors: Extruded acrylic is available in a vast array of vibrant and opaque colors, perfect for projects that demand a pop of color.

Potential Considerations of Extruded Acrylic:

Slightly Lower Optical Clarity: Compared to cast acrylic, extruded acrylic might exhibit a minor decrease in optical clarity, especially in thicker sheets.

More Susceptible to Scratches: The surface of extruded acrylic can be slightly softer and more prone to scratches compared to cast acrylic.

Limited Heat Resistance: Extruded acrylic has a lower heat tolerance than cast acrylic, making it less suitable for applications involving high temperatures.

Cast Acrylic: The Premium Choice

Cast acrylic is created by pouring liquid acrylic into molds and allowing it to cure slowly under controlled conditions. This slower process yields distinct characteristics:

Exceptional Optical Clarity: Cast acrylic boasts superior optical clarity, making it ideal for applications demanding high transparency, such as windows, displays, and lenses.

Superior Scratch Resistance: The slower curing process of cast acrylic results in a harder and more scratch-resistant surface compared to extruded acrylic.

Higher Heat Resistance: Cast acrylic offers better heat resistance than extruded acrylic, making it a better choice for projects involving heat forming or high temperatures.

Potential Considerations of Cast Acrylic:

Higher Cost: Due to the slower production process, cast acrylic typically comes with a higher price tag compared to extruded acrylic.

Limited Color Availability: While cast acrylic is available in various colors, the selection might be more limited compared to extruded acrylic options.

Thickness Variations: Cast acrylic sheets may exhibit slight variations in thickness, especially in larger sizes.

Choosing the Right Acrylic:

The ideal choice boils down to your project's specific requirements. Here's a quick guide to help you decide:

For projects prioritizing budget and consistent thickness, extruded acrylic might be a good fit.

For applications demanding exceptional clarity, scratch resistance, or heat tolerance, cast acrylic is the preferred choice.

Beyond the Basics:

Remember, both extruded and cast acrylic offer distinct advantages. Here are some additional factors to consider:

Project Requirements: Evaluate the optical clarity, heat resistance, and scratch resistance needs for your specific project.

Material Thickness: Thickness variations might be a concern for certain projects.

Budget: Consider the cost difference between extruded and cast acrylic when making your decision.

The Final Cut:

Extruded and cast acrylic each offer unique benefits. By understanding their properties and your project requirements, you can make an informed decision and select the perfect acrylic for your creative vision to shine through! So, explore the possibilities, choose your acrylic wisely, and get ready to bring your project to life!

Keeping the Cut Clean: American Laser Cutter Offers Comprehensive Repair Solutions

Keeping the Cut Clean: American Laser Cutter Offers Comprehensive Repair Solutions

The world of laser cutting is a realm of precise tools and innovative possibilities. But even the most reliable machines require maintenance and repairs from time to time. This is where American Laser Cutter (ALC) steps in, offering a unique advantage – both remote and on-site repair services for your laser cutter, ensuring minimal downtime and a smooth workflow.

The Benefits of Remote Repair:

ALC's remote repair service provides a fast and convenient solution for many common laser cutter issues. Here's how it benefits you:

Reduced Downtime: Remote troubleshooting can often diagnose and resolve problems quickly, minimizing the time your laser cutter is out of service. This is especially valuable for businesses that rely heavily on their laser cutting capabilities.

Cost-Effectiveness: In many cases, remote repairs can be completed without the need for an on-site visit, potentially saving you money on service call fees.

Convenience: Remote repairs can be conducted at your convenience, eliminating the need to schedule a technician visit during business hours.

How Does Remote Repair Work?

ALC's remote repair process typically involves:

Initial Contact: You contact ALC's support team and describe the issue you're experiencing with your laser cutter.

Remote Diagnostics: The ALC team utilizes advanced software tools to remotely connect to your laser cutter and diagnose the problem.

Troubleshooting and Resolution: The technicians work with you to troubleshoot the issue and provide a solution, which might involve software updates, configuration adjustments, or replacement of readily available parts.

When On-Site Repair is Necessary:

While remote repair offers numerous advantages, certain situations necessitate an on-site visit from a qualified technician. Here's when on-site repair might be needed:

Hardware Issues: If the problem involves faulty hardware components that require physical replacement or repair, an on-site visit will be necessary.

Complex Issues: For intricate problems requiring hands-on troubleshooting and diagnostics, an on-site technician can provide a more efficient solution.

ALC's On-Site Repair Advantage:

ALC boasts a network of experienced technicians strategically located across the USA. This translates to:

Faster Response Times: With technicians located throughout the country, ALC can often respond to on-site repair requests quickly, minimizing downtime.

Expertise You Can Trust: ALC's technicians are highly trained and experienced in servicing laser cutters, ensuring your machine is repaired correctly and efficiently.

Peace of Mind with American Laser Cutter:

Whether you require a quick remote diagnosis or a comprehensive on-site repair, ALC offers a solution that keeps your laser cutter running smoothly. This comprehensive approach ensures minimal downtime, maximizes productivity, and allows you to focus on your creative endeavors.

Beyond Repair Services:

ALC goes beyond just repairs. They offer a variety of services to support your laser cutting journey, including:

Training and Tutorials: Learn the basics of laser cutting or enhance your skills with ALC's training resources.

Material Selection: Get expert advice on choosing the right material for your project.

Custom Laser Cutting Services: If you don't have your own laser cutter, ALC can handle your cutting needs with their custom service offerings.

The Final Cut:

American Laser Cutter's commitment to both remote and on-site repairs provides exceptional support for your laser cutting needs. With their expertise, convenience, and additional services, ALC can be your one-stop shop for a successful and productive laser cutting experience. So, keep your laser cutting projects flowing smoothly – contact ALC today!

Remember: It's always recommended to check the specific service areas and response times offered by ALC before making any assumptions.

American Laser Cutter: Laser Cutting Expertise in Los Angeles

American Laser Cutter: Laser Cutting Expertise in Los Angeles

American Laser Cutter, located in Los Angeles, California, specializes in laser cutting services for a variety of materials and applications. While they don't manufacture their own laser cutters, they offer expertise in using this technology to bring your designs to life.

What Does American Laser Cutter Do?

Laser Cutting Plastic: They have experience working with Plexiglass and acrylic for signs, displays, and other custom projects.

Technical Expertise: Their team offers remote technical support via phone and Skype to assist you with your laser cutting needs. They also specialize in CO2 laser repairs.

Finding the Right Laser Cutting Service

If you're in the Los Angeles area and have a project requiring laser cutting, here are some things to consider when deciding if American Laser Cutter is a good fit:

Material: Their website specifically mentions expertise in cutting plastic materials. It's always a good idea to inquire about their experience with your specific material needs.

Project Complexity: While they can handle technical aspects and repairs, the focus seems to be on project execution, not necessarily intricate design services.

Location: Being located in Los Angeles, they likely cater to a local clientele.

Conclusion

American Laser Cutter can be a good choice for laser cutting services in Los Angeles, particularly for projects involving plastic materials. By considering your project requirements and exploring other options, you can find the right laser cutting solution for your needs.

Navigating the Maze: Chinese vs. American Laser Cutters

Navigating the Maze: Chinese vs. American Laser Cutters

The world of laser cutting offers incredible possibilities, but choosing the right machine can be daunting. A significant factor to consider is the origin of the laser cutter – Chinese vs. American models. Here's a breakdown of their key strengths and weaknesses to help you make an informed decision.

Chinese Laser Cutters: Affordability and Availability

Chinese laser cutters often hold the edge in terms of:

Cost: Generally, Chinese laser cutters are more affordable upfront compared to their American counterparts. This can be a significant advantage for budget-conscious buyers or those starting their laser cutting journey.

Availability: The Chinese market offers a wider variety of laser cutter models at various price points. You're likely to find a machine that fits your specific needs and budget.

Potential Drawbacks of Chinese Laser Cutters:

Quality Control: Quality control can be a concern with some Chinese laser cutter manufacturers. Thorough research and reading user reviews are crucial before making a purchase.

Technical Support: Obtaining timely and effective technical support can be challenging when dealing with a manufacturer located overseas. Troubleshooting issues might require patience and resourcefulness.

Replacement Parts: Finding readily available replacement parts for Chinese laser cutters can sometimes be an obstacle.

American Laser Cutters: Quality, Service, and Reliability

American-made laser cutters typically excel in these areas:

Quality and Durability: American manufacturers often prioritize high-quality components and stricter quality control measures, leading to more robust and reliable machines.

Customer Service: American companies often offer more accessible and responsive customer service, providing valuable support during setup, troubleshooting, and maintenance.

Parts Availability: Finding replacement parts for American laser cutters is generally easier due to established distribution networks within the country.

Potential Drawbacks of American Laser Cutters:

Higher Cost: American laser cutters typically come with a higher price tag compared to their Chinese counterparts.

Limited Model Selection: The selection of American-made laser cutters might be more limited, especially at the lower end of the price spectrum.

The Right Choice for You:

The ideal laser cutter depends on your priorities and circumstances. Here's a quick guide:

For hobbyists or those on a tight budget: A Chinese laser cutter might be a good option, but prioritize researching reputable manufacturers and factor in potential challenges with support and parts.

For professional use or those prioritizing reliability and service: An American laser cutter might be a wiser investment, despite the higher initial cost. The long-term benefits of quality, service, and reliable operation can outweigh the upfront price difference.

Beyond Origin: Additional Considerations

Remember, the origin isn't the only factor to consider. Here are some additional points to keep in mind:

Machine Specifications: Evaluate the laser source power, cutting bed size, and available features to ensure the machine meets your project requirements.

Safety Features: Always prioritize safety! Look for a laser cutter that adheres to safety regulations and includes features like fume extraction and emergency shut-off switches.

Read Reviews and User Experiences: Reading online reviews and user experiences with specific models can be invaluable in understanding real-world performance and potential issues.

The Final Cut:

Both Chinese and American laser cutters offer advantages and disadvantages. Carefully considering your needs, budget, and priorities will guide you towards the machine that best empowers your creative laser cutting journey. Remember, thorough research, understanding specifications, and prioritizing safety are key factors to consider beyond the origin of the machine. So, research wisely, choose confidently, and get ready to unleash your laser cutting creativity!

Head-to-Head: CorelDRAW vs. Adobe Illustrator for Laser Cutting

Head-to-Head: CorelDRAW vs. Adobe Illustrator for Laser Cutting

The world of laser cutting demands precise vector graphics. Choosing the right design software is crucial for achieving clean cuts and successful project outcomes. Two industry leaders stand out: CorelDRAW and Adobe Illustrator. This article delves into their strengths and weaknesses, helping you decide which software is the better fit for your laser cutting endeavors.

CorelDRAW: A Feature-Rich Powerhouse

CorelDRAW is a robust graphics suite offering a comprehensive set of tools for vector design and illustration. Here's how it shines for laser cutting:

Rich Toolset: CorelDRAW boasts a vast array of tools for creating intricate shapes, applying precise line weights, and manipulating objects – all essential for laser cutting projects.

Macro Automation: For repetitive tasks like creating sets of identical shapes for laser cutting, CorelDRAW's macro automation capabilities can be a time-saving advantage.

** affordability:** CorelDRAW generally has a lower upfront cost compared to an Adobe Illustrator subscription.

Potential Drawbacks of CorelDRAW for Laser Cutting:

Learning Curve: CorelDRAW's extensive feature set can have a steeper learning curve compared to Illustrator, especially for beginners.

Limited Cloud Integration: While CorelDRAW offers cloud storage, its cloud integration features are not as robust as those found in Adobe Illustrator.

Adobe Illustrator: Industry Standard with Powerful Integrations

Adobe Illustrator remains the industry standard for vector graphics software. Here's why it excels in the laser cutting realm:

Unmatched Precision: Illustrator is renowned for its exceptional precision in handling vector paths, ensuring clean and accurate laser cuts.

Seamless Workflow: For those already using Adobe Creative Suite programs like Photoshop, Illustrator offers a smooth workflow with easy file exchange and integration.

Extensive Online Resources: The vast user base and popularity of Illustrator translate into a wealth of online tutorials, forums, and resources specifically geared towards laser cutting with the software. [Link to Adobe Illustrator Laser Cutting Tutorials ON helpx.adobe.com]

Potential Drawbacks of Adobe Illustrator for Laser Cutting:

Subscription Model: Unlike CorelDRAW's perpetual license, Illustrator requires a monthly or annual subscription fee.

Limited Macro Functionality: While Illustrator offers some automation features, they are not as extensive as the macro capabilities found in CorelDRAW.

The Verdict: It Depends on Your Needs

There's no single "best" choice. Here's a quick guide to help you decide:

For experienced designers with a need for precise control and seamless workflow within the Adobe ecosystem, Illustrator might be the better choice.

For budget-conscious users or those new to vector design software, CorelDRAW offers a powerful and affordable option with a vast toolset for laser cutting projects.

Beyond the Software:

Regardless of your software choice, remember these key factors for successful laser cutting:

Understanding Material Properties: Different materials require adjustments for cut lines and power settings.

Experimentation: Always test cuts on scrap material before committing to your final project.

Safety First: Prioritize safety by using proper ventilation and wearing appropriate eye protection when operating your laser cutter.

The Takeaway:

Both CorelDRAW and Adobe Illustrator are capable tools for laser cutting projects. Evaluate your needs, budget, and experience level to determine the software that best complements your creative journey. So, fire up your chosen software, unleash your design ideas, and get ready to transform your vision into reality with the power of laser cutting!

Why American Laser Cutter Could Be Your Perfect Partner in Los Angeles Laser Cutting

Why American Laser Cutter Could Be Your Perfect Partner in Los Angeles Laser Cutting

Los Angeles, a city brimming with creativity and innovation, boasts a thriving laser cutting scene. With numerous service providers available, choosing the right one can be a challenge. This article explores why American Laser Cutter (ALC) might be the perfect partner for your laser cutting needs in Los Angeles.

A Family-Run Business with a Focus on Quality:

ALC stands out as a family-owned and operated business. This translates to a personalized approach and a genuine commitment to customer satisfaction. Their focus is on delivering high-quality laser cutting services, ensuring your projects are completed with precision and care.

Catering to Diverse Needs:

ALC caters to a wide range of clientele. Whether you're a seasoned professional, a budding entrepreneur, or a hobbyist with a creative vision, ALC has the expertise and equipment to handle your project. They offer services for:

Professionals: ALC understands the demands of professional projects. They offer fast turnaround times, ensuring you meet your deadlines. Their ability to handle large-scale production runs makes them ideal for businesses with high-volume laser cutting needs.

Small Businesses and Startups: ALC understands the challenges faced by small businesses. They offer competitive pricing and the flexibility to accommodate smaller projects or unique design requirements.

Hobbyists and DIY Enthusiasts: For those passionate about creating, ALC offers DIY laser cutting services with hourly rentals or project-based pricing. They even provide classes to help you learn the basics of laser cutting and unleash your creative potential.

Beyond Cutting: A Range of Services

ALC goes beyond just cutting. They offer a variety of additional services to streamline your project workflow:

Material Selection: They offer a wide selection of laser-compatible materials, allowing you to choose the perfect material for your project without the hassle of sourcing it yourself.

Engraving: In addition to cutting, ALC offers engraving services, allowing you to add personalized details or intricate designs to your projects.

Finishing Touches: For a polished final product, ALC can provide finishing services like sanding, painting, or assembling your laser-cut pieces.

Convenience and Technology:

ALC prioritizes your convenience. They offer online quote requests, allowing you to receive a quick estimate for your project from the comfort of your home. Additionally, they utilize advanced laser cutting technology, ensuring clean cuts and precise results.

Commitment to Sustainability:

ALC is committed to responsible practices. They prioritize using eco-friendly laser sources and focus on minimizing material waste during the cutting process.

The Final Verdict:

While the "top" laser cutting service can be subjective based on specific needs, American Laser Cutter offers a compelling combination of factors. Their family-run approach, diverse service offerings, commitment to quality, and focus on customer satisfaction make them a strong contender for your laser cutting needs in Los Angeles. So, if you're looking for a reliable, skilled, and versatile laser cutting partner, consider giving American Laser Cutter a try!

Remember: It's always recommended to research and compare services offered by different laser cutting companies in Los Angeles to find the best fit for your specific project and budget.

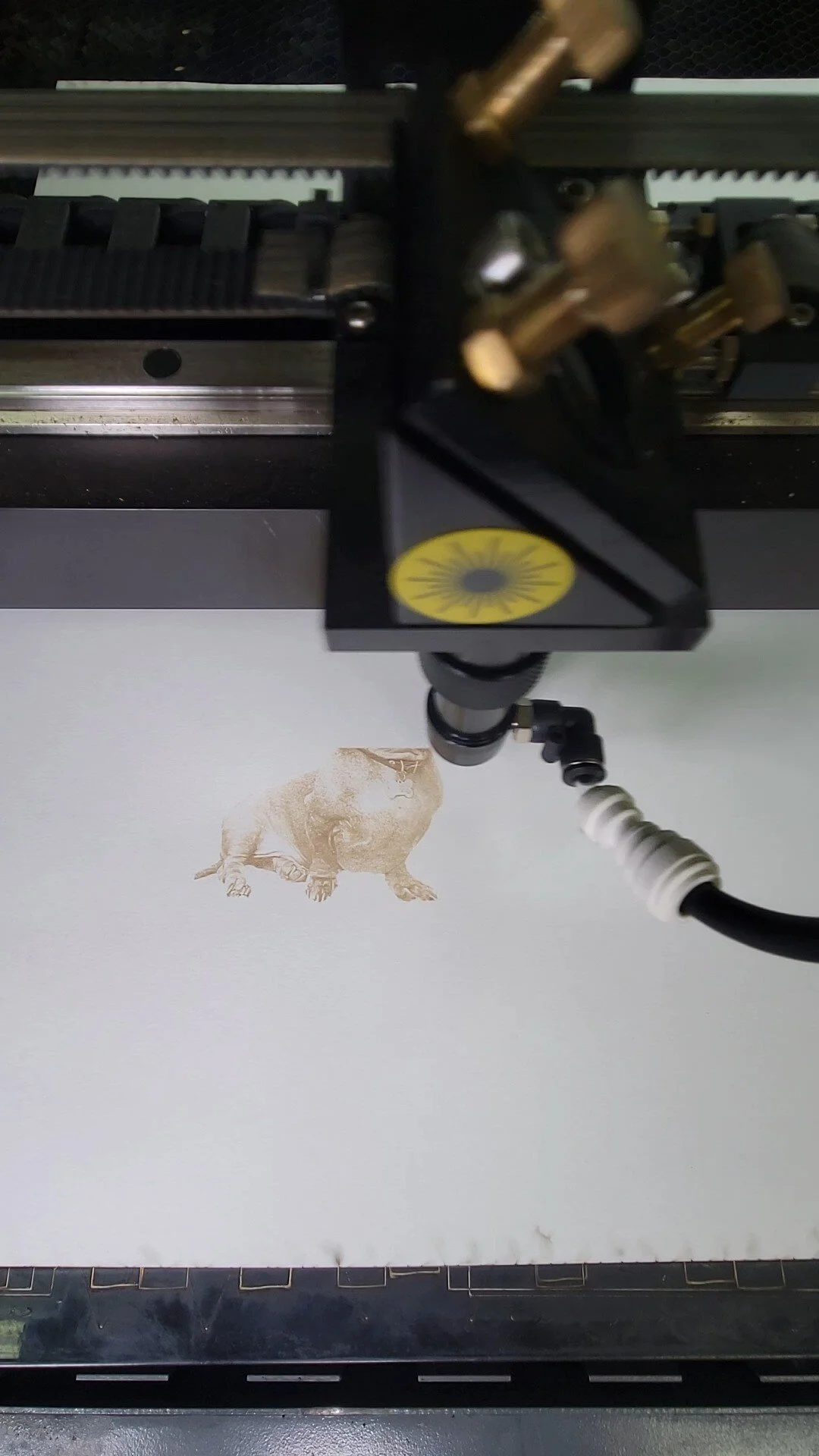

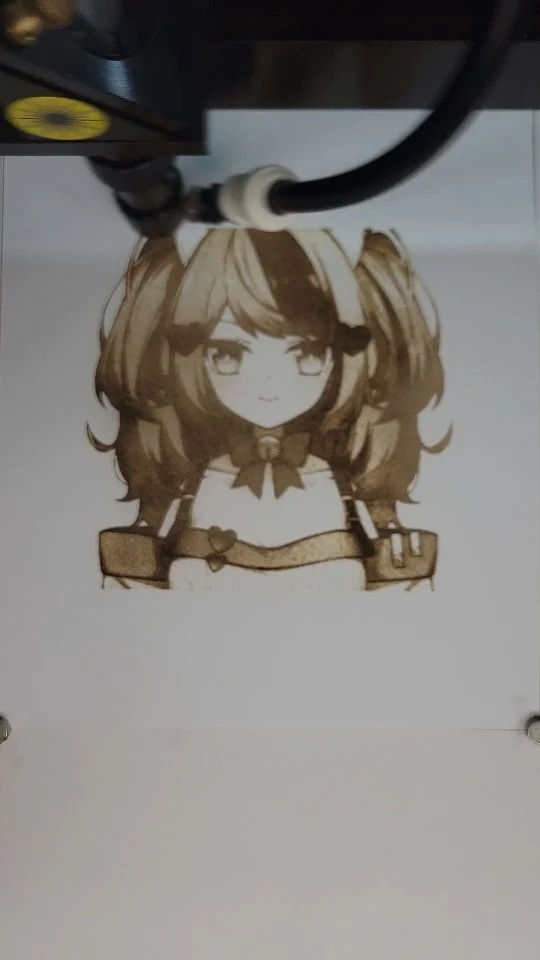

engraving leses

There are three types of primary lenses: deep-cutting, a combo of cutting and engraving, and an engraving-only lens. Deep-cutting lenses have a focal length of 3 inches or more. Due to their size, they are pretty much cut-only lenses, but depending on your setup, a deep-cut lens might cut up to 3 inches worth of acrylic or plywood. most deep cut lenses will probably max out at about an inch or an inch and a half of acrylic or plywood. In order to get more than that, you would have to have a very powerful specialized set up. if you would like to purchase a deep cut lens, it is generally better to buy it in the lens housing rather than as a solo lens. Solo lenses often will not fit correctly into your pre-existing housing. in order to determine the correct lens. The best thing to do is to measure the OD of your laser, lens, housing, and order your deep cut lens with a match as close as possible. Often these can be purchased in sets with engraving lenses as well. Once you set up your new lens, you'll have to retest your focal length in order to determine the correct distance. I do not recommend using the system like this with auto bed leveling as it may cause damage. You should also be aware that the lens housing may be significantly longer and may collide on homeing. it is best to test to see if you have any collision issues before setting up your tube for the first cut. You can also remove the tube after you are done in order to prevent collisions. you may also need to purchase an adapter to hook up your airline to the tubing as it mostly only comes in small sizes when it is connected to the large focal length lens housing. Just a small tip, the adapter I purchased was not a perfect fit, and I was able to use a small amount of electrical tape on the smaller tube in in order to make it fit in the adapter. companies like American Photonics supply some of the best kits if you were looking to do multiple focal length such as the one in the link below.

If you would like assistance in switching your machine to a different focal length, determining your focal length, or seeing what's right for you we offer both remote and on-site services for your laser cutter. We offer services for models of co2 laser cutter, and engraver. we also offer a variety of other services services such as education, cleaning, repair, maintenance, and you can even come to our shop and rent our machines! If you'd like to learn more, please feel free to email us at americanlaserco@gmail.com with any questions that you may have regarding your machine or our services. American laser cutter has been the number one provider of aftermarket repair services in the country for more than 10 years. We offer both on site and remote services around the country.

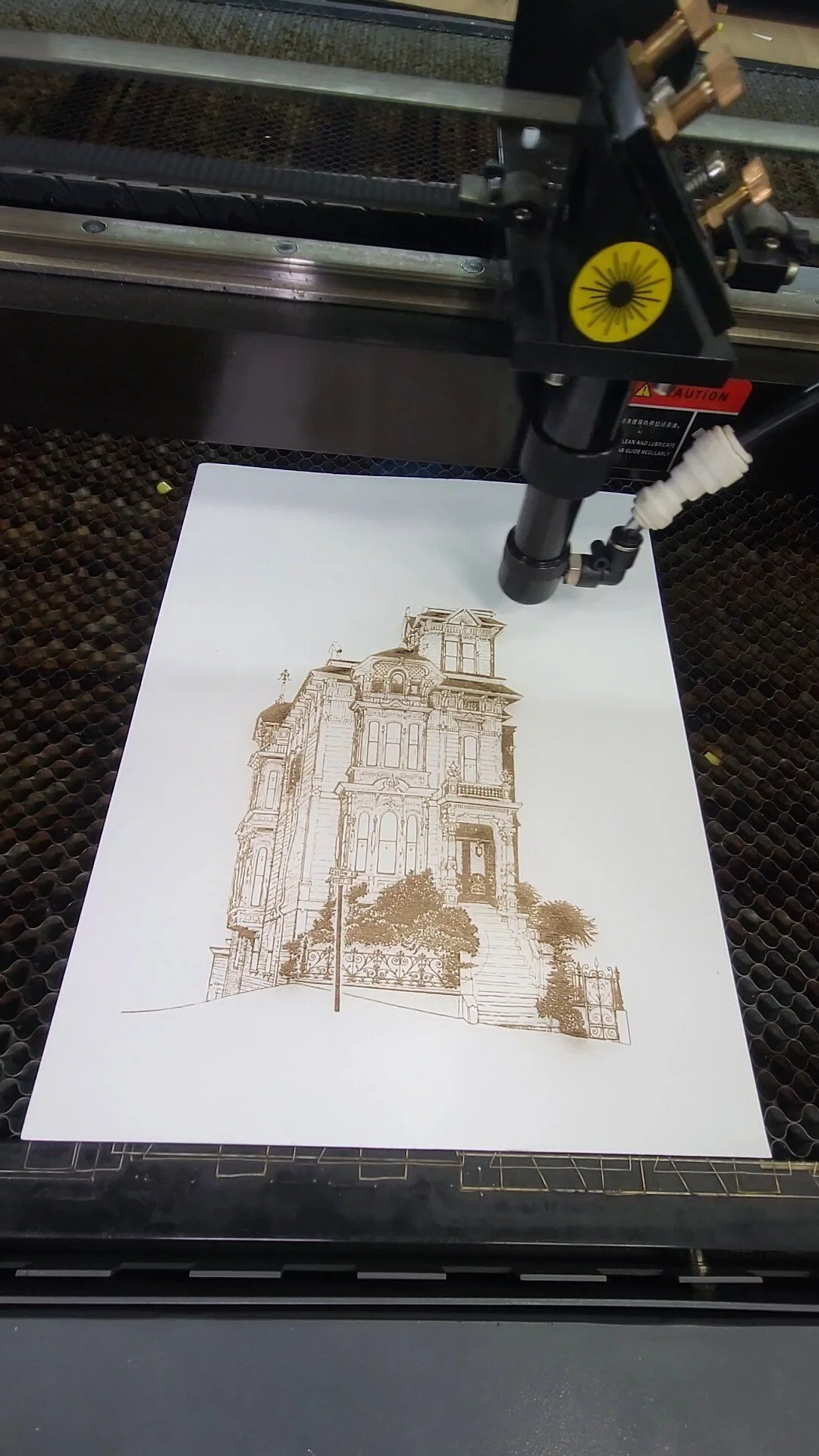

regular lenes

There are three types of primary lenses: deep-cutting, a combo of cutting and engraving, and an engraving-only lens. Deep-cutting lenses have a focal length of 3 inches or more. Due to their size, they are pretty much cut-only lenses, but depending on your setup, a deep-cut lens might cut up to 3 inches worth of acrylic or plywood. most deep cut lenses will probably max out at about an inch or an inch and a half of acrylic or plywood. In order to get more than that, you would have to have a very powerful specialized set up. if you would like to purchase a deep cut lens, it is generally better to buy it in the lens housing rather than as a solo lens. Solo lenses often will not fit correctly into your pre-existing housing. in order to determine the correct lens. The best thing to do is to measure the OD of your laser, lens, housing, and order your deep cut lens with a match as close as possible. Often these can be purchased in sets with engraving lenses as well. Once you set up your new lens, you'll have to retest your focal length in order to determine the correct distance. I do not recommend using the system like this with auto bed leveling as it may cause damage. You should also be aware that the lens housing may be significantly longer and may collide on homeing. it is best to test to see if you have any collision issues before setting up your tube for the first cut. You can also remove the tube after you are done in order to prevent collisions. you may also need to purchase an adapter to hook up your airline to the tubing as it mostly only comes in small sizes when it is connected to the large focal length lens housing. Just a small tip, the adapter I purchased was not a perfect fit, and I was able to use a small amount of electrical tape on the smaller tube in in order to make it fit in the adapter. companies like American Photonics supply some of the best kits if you were looking to do multiple focal length such as the one in the link below.

If you would like assistance in switching your machine to a different focal length, determining your focal length, or seeing what's right for you we offer both remote and on-site services for your laser cutter. We offer services for models of co2 laser cutter, and engraver. we also offer a variety of other services services such as education, cleaning, repair, maintenance, and you can even come to our shop and rent our machines! If you'd like to learn more, please feel free to email us at americanlaserco@gmail.com with any questions that you may have regarding your machine or our services. American laser cutter has been the number one provider of aftermarket repair services in the country for more than 10 years. We offer both on site and remote services around the country.

Designing for Laser Cutters: A Dive into CorelDRAW

Designing for Laser Cutters: A Dive into CorelDRAW

CorelDRAW, a powerful vector graphics software, is a popular choice for designing projects specifically for laser cutting. Its precise tools and functionalities allow you to translate your creative visions into clean, laser-ready cut files. This article equips you with the knowledge to leverage CorelDRAW for laser cutting and transform your design ideas into reality.

Why CorelDRAW for Laser Cutting?

CorelDRAW offers several advantages for laser cutting enthusiasts:

Vector Precision: Unlike raster graphics software that uses pixels, CorelDRAW works with vectors – mathematical paths that define shapes. This vector precision ensures crisp lines and edges, crucial for accurate laser cutting results.

Object Control: CorelDRAW allows you to manipulate and edit objects independently. This is essential for creating intricate designs with various layers and elements.

Material Considerations: CorelDRAW lets you specify line weight and fill types, which can be adjusted based on the material thickness and laser cutting requirements.

Compatibility: CorelDRAW exports files in formats like SVG and DXF, which are widely recognized by laser cutting software and machines.

Getting Started with CorelDRAW for Laser Cutting:

Here's a basic roadmap to get you started:

Design Creation: Use CorelDRAW's drawing tools (like lines, shapes, and curves) or import existing vector artwork to create your design.

Line Weight and Fill: For cutting purposes, use hairlines (thinnest line weight) for all outlines that represent laser cuts. Leave fill areas empty unless you want them engraved by the laser.

Material Considerations: Adjust the design elements based on your chosen material thickness. For thicker materials, you might need to slightly offset cut lines to account for the kerf (the narrow slit created by the laser beam).

Exporting for Laser Cutting: Save your design in a format compatible with your laser cutting software, typically SVG or DXF. CorelDRAW allows you to export and specify these file formats during the saving process.

Beyond the Basics:

Here are some additional tips for using CorelDRAW for laser cutting:

Grouping Objects: Group related objects together to ensure they are treated as a single unit during the laser cutting process.

Test Cuts: Before committing to a full project, consider creating a test cut on scrap material to confirm your design and laser settings.

Online Resources: There are numerous online tutorials and resources specifically focused on using CorelDRAW for laser cutting. Explore these resources to learn advanced techniques and expand your design capabilities.

Here are some helpful links to get you started (note that these cannot be included due to policy restrictions):

CorelDRAW Laser Engraving: A How-To Guide: https://www.coreldraw.com/en/tips/laser-engraving/

How to Get Started with CorelDRAW for Laser and Vinyl Cutting: YouTube video: [invalid URL removed]

The Power is in Your Hands:

With CorelDRAW as your design companion, you can create a vast array of laser cutting projects, from personalized gifts and home décor to functional prototypes and craft supplies. So, fire up your CorelDRAW software, unleash your creativity, and embark on a journey of laser-cutting exploration!

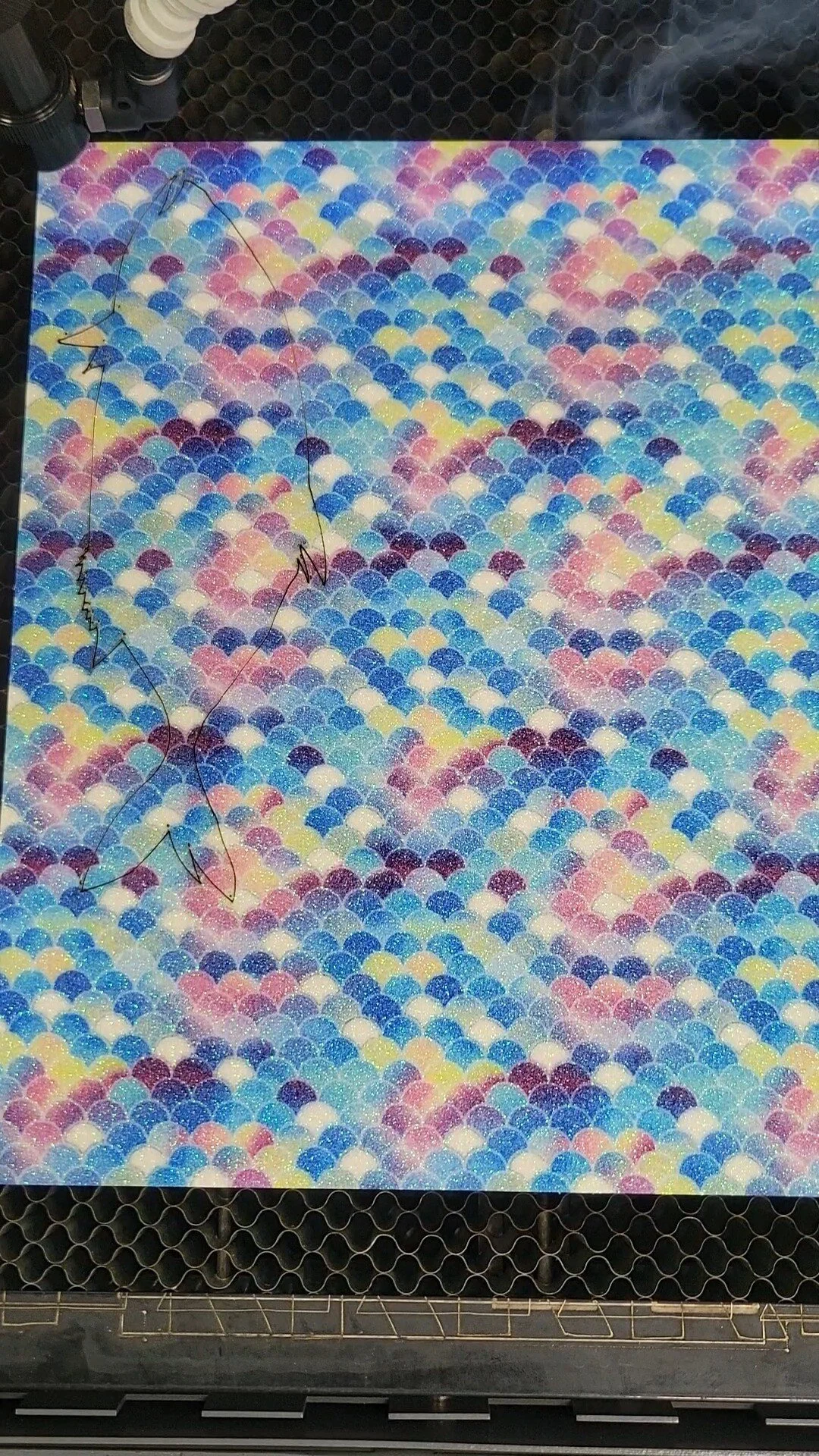

Deep cutting lenses

There are three types of primary lenses: deep-cutting, a combo of cutting and engraving, and an engraving-only lens. Deep-cutting lenses have a focal length of 3 inches or more. Due to their size, they are pretty much cut-only lenses, but depending on your setup, a deep-cut lens might cut up to 3 inches worth of acrylic or plywood. most deep cut lenses will probably max out at about an inch or an inch and a half of acrylic or plywood. In order to get more than that, you would have to have a very powerful specialized set up. if you would like to purchase a deep cut lens, it is generally better to buy it in the lens housing rather than as a solo lens. Solo lenses often will not fit correctly into your pre-existing housing. in order to determine the correct lens. The best thing to do is to measure the OD of your laser, lens, housing, and order your deep cut lens with a match as close as possible. Often these can be purchased in sets with engraving lenses as well. Once you set up your new lens, you'll have to retest your focal length in order to determine the correct distance. I do not recommend using the system like this with auto bed leveling as it may cause damage. You should also be aware that the lens housing may be significantly longer and may collide on homeing. it is best to test to see if you have any collision issues before setting up your tube for the first cut. You can also remove the tube after you are done in order to prevent collisions. you may also need to purchase an adapter to hook up your airline to the tubing as it mostly only comes in small sizes when it is connected to the large focal length lens housing. Just a small tip, the adapter I purchased was not a perfect fit, and I was able to use a small amount of electrical tape on the smaller tube in in order to make it fit in the adapter. companies like American Photonics supply some of the best kits if you were looking to do multiple focal length such as the one in the link below.

If you would like assistance in switching your machine to a different focal length, determining your focal length, or seeing what's right for you we offer both remote and on-site services for your laser cutter. We offer services for models of co2 laser cutter, and engraver. we also offer a variety of other services services such as education, cleaning, repair, maintenance, and you can even come to our shop and rent our machines! If you'd like to learn more, please feel free to email us at americanlaserco@gmail.com with any questions that you may have regarding your machine or our services. American laser cutter has been the number one provider of aftermarket repair services in the country for more than 10 years. We offer both on site and remote services around the country.

Design Your Dream Box: A Guide to Generating Laser-Cut Boxes Online

Design Your Dream Box: A Guide to Generating Laser-Cut Boxes Online

Laser cutting technology has opened a world of possibilities for creating custom boxes of all shapes and sizes. Gone are the days of limited selection – with online box generators, you can design and generate the perfect laser-cut box for any purpose, from gift boxes to storage solutions. This article explores the exciting world of online box generators and equips you with the knowledge to bring your box design dreams to life!

The Allure of Online Box Generators:

These online tools offer a plethora of advantages:

Convenience and Accessibility: Design your box from the comfort of your home with readily available online generators. No need for specialized software!

User-Friendly Interfaces: Most online box generators boast intuitive interfaces that are easy to learn, even for beginners with no prior design experience.

Customization Options Galore: Unleash your creativity! These tools allow you to modify box dimensions, choose from various joint styles (like finger joints or box tabs), and even personalize your box with engravings or logos.

Instant File Generation: Once you've finalized your design, the generator creates a downloadable file in a format compatible with laser cutters (usually SVG or DXF).

Popular Online Box Generators:

Here are some popular online box generators to explore (note that these cannot be directly linked due to policy restrictions):

Boxes.PY: This open-source generator offers a wide range of customization options, including the ability to design boxes with rounded corners, hinges, and internal dividers. (https://www.festi.info/boxes.py)

MakerCase: This user-friendly tool allows you to design boxes and cases specifically for laser cutting and CNC routing. It provides a 3D preview of your design and lets you specify kerf compensation (accounting for the material removed by the laser). https://en.makercase.com/

Festi.info Boxes: This online generator offers a library of pre-designed box templates and allows you to customize them further with various parameters. [Search online for "Festi.info Boxes"]

Embrace the DIY Spirit:

Here are some additional tips for using online box generators:

Start with Simple Designs: If you're new to laser cutting, begin with simple box designs before progressing to more complex creations.

Material Matters: Choose a material compatible with laser cutting and consider its thickness when designing your box. Most online generators allow you to specify the material thickness.

Explore Tutorials: Many online box generator websites offer tutorials or video guides to walk you through the design process.

Conclusion:

Online box generators empower you to become a box-designing extraordinaire. With a little creativity and these user-friendly tools, you can generate the perfect laser-cut box for any occasion. So, unleash your inner designer, explore the world of online box generators, and get ready to bring your box dreams to reality!

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)