American Laser Cutter: Your Precision Cutting Partner in Los Angeles

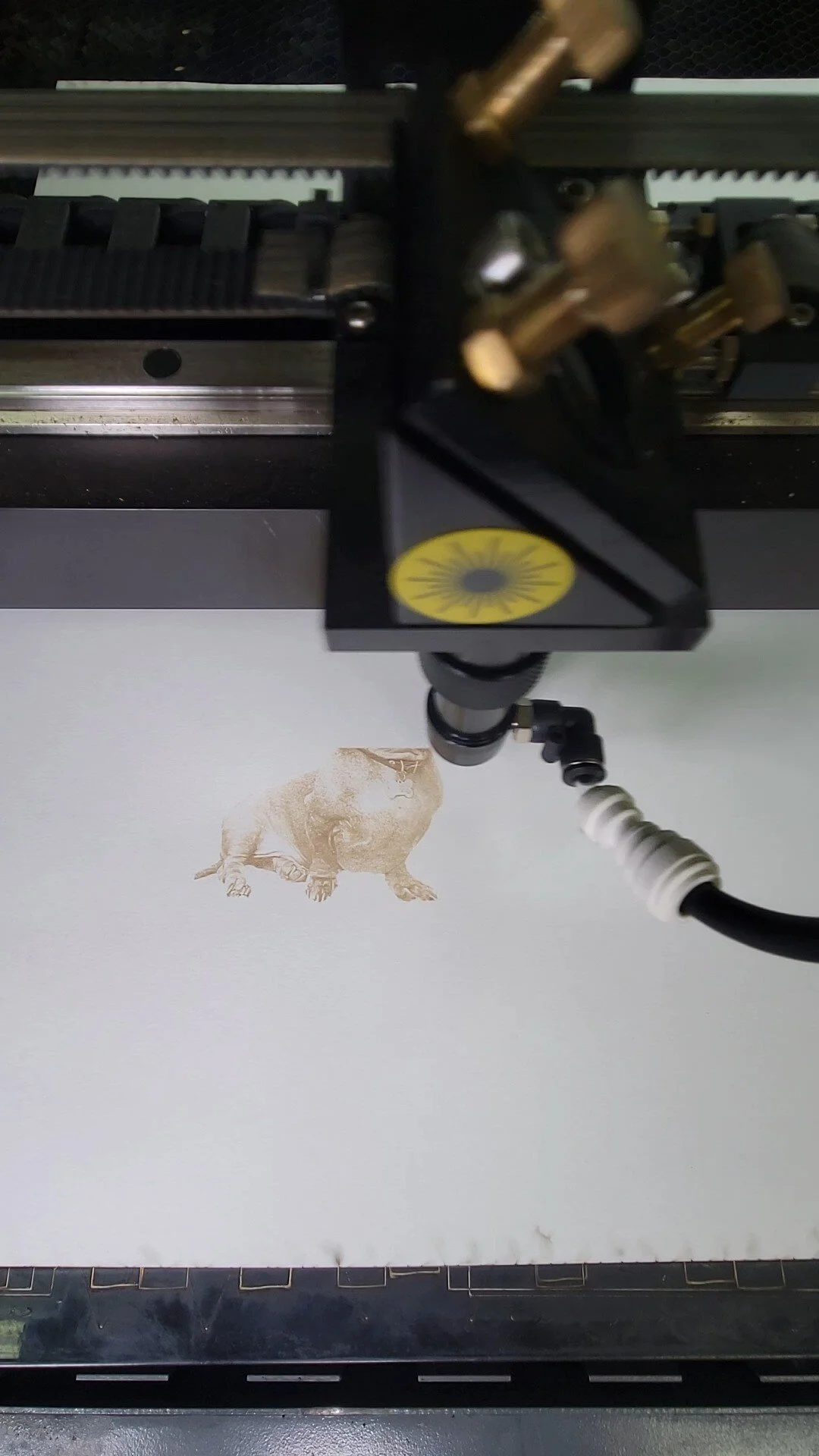

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

Building Dreams: Laser Cutting Revolutionizes Architectural Modeling

Building Dreams: Laser Cutting Revolutionizes Architectural Modeling

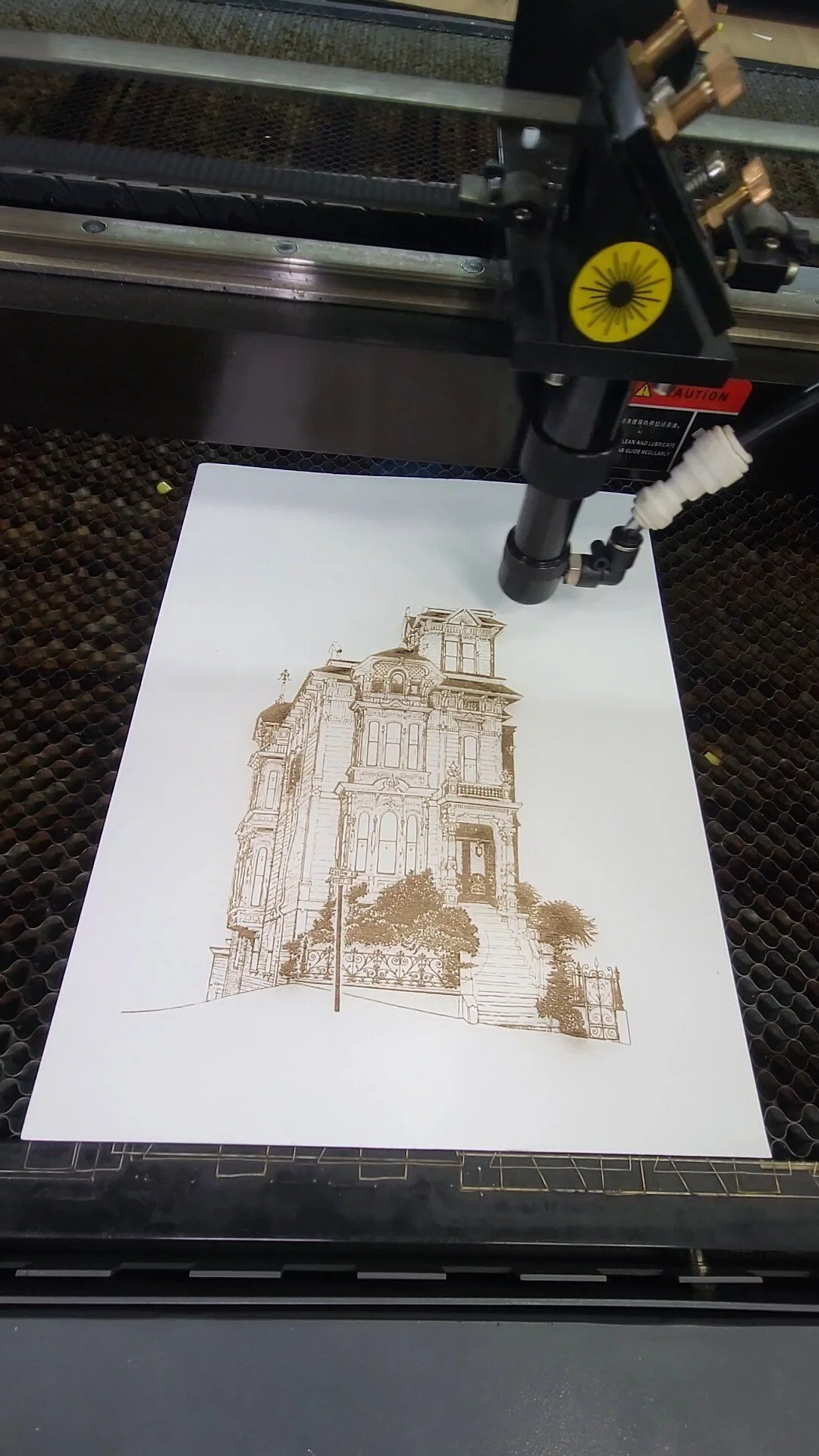

Architectural models have long been a cornerstone of the design and communication process. From intricate physical models to digital renderings, these representations allow architects to visualize, test, and refine their ideas before construction begins. However, the introduction of laser cutting technology has ushered in a new era of architectural modeling, offering unparalleled precision, speed, and creative freedom.

Beyond the Balsa Wood:

Traditionally, architectural models were crafted from wood, cardboard, or foam board. While these materials offer some flexibility, they can be time-consuming to work with and often lack the precision required for intricate details. Laser cutting disrupts this paradigm:

Precision Takes Center Stage: Laser cutters deliver unmatched accuracy, allowing for the creation of highly detailed models with sharp edges and complex geometries. This level of precision ensures the model faithfully reflects the architect's vision.

Speeding Up the Design Process: Gone are the days of laborious hand-cutting. Laser cutters automate the process, translating digital designs into physical models in a fraction of the time. This rapid turnaround allows for faster iteration and exploration of design options.

Material Versatility: Laser cutters can handle a wide range of materials, including wood, acrylic, and even some metals. This opens doors for architects to experiment with different materials and create models that not only showcase the design but also explore the materiality of the building itself.

Sustainability Gains Traction: Laser cutting software allows for optimized material placement, minimizing waste. Additionally, some materials like wood and acrylic can be sourced from sustainable sources, making laser cutting a more eco-friendly approach to model making.

A Showcase of Creative Applications:

Conceptual Design Exploration: Laser cutting allows architects to quickly create rough models to test basic massing and spatial relationships early in the design process. These rapid prototypes facilitate communication and feedback, leading to more informed design decisions.

Detailed Presentation Models: Highly detailed models with intricate facades, cladding details, and landscaping elements can be created to impress clients and stakeholders. The precision of laser cutting ensures a high-quality final product that accurately represents the architectural intent.

Functional Models: Laser cutting can be used to create models with interactive elements, such as movable walls or operable windows. These functional models allow for in-depth testing of spatial flow, user experience, and even building systems within the model itself.

The Future of Architectural Modeling:

Laser cutting technology is transforming the way architects create models. It offers a powerful combination of speed, precision, and versatility that was previously unattainable. As laser cutting technology continues to evolve and become more accessible, we can expect to see even more innovative and creative applications emerge, further blurring the lines between the physical and digital realms of architectural design. So, the next time you see a stunning architectural model, remember, it might just be the result of a laser cutter's precise dance, translating dreams into miniature realities.

A Cut Above: The Allure of Laser Cutting Acrylic

A Cut Above: The Allure of Laser Cutting Acrylic

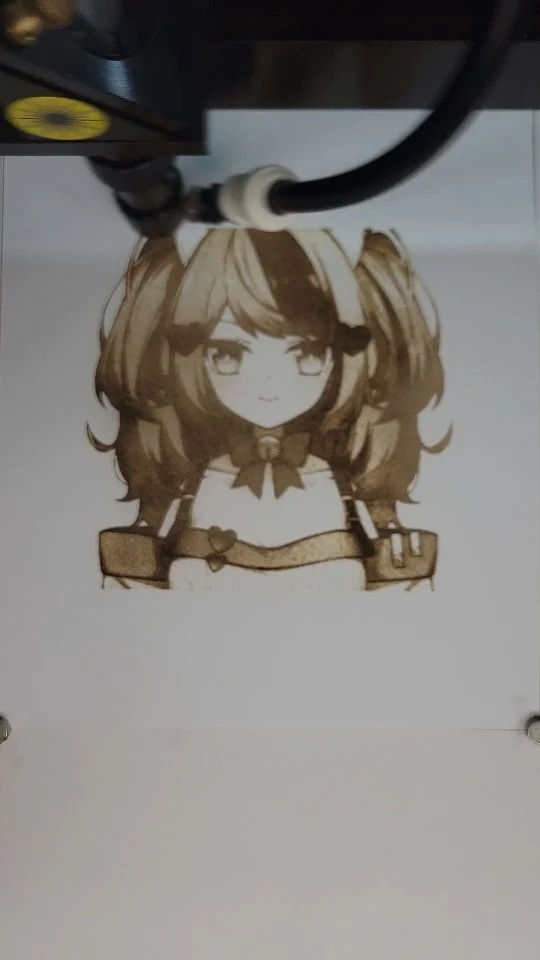

Acrylic, a versatile and ubiquitous material, takes on a whole new life when wielded with the precision of a laser cutter. This dynamic pairing offers a treasure trove of creative potential for makers, crafters, and artists alike. Let's delve into the world of laser cutting acrylic and explore the reasons why it has become a favorite tool in the maker's arsenal.

Why Acrylic? A Match Made in Maker Heaven:

Clarity and Brilliance: Acrylic boasts unmatched clarity, allowing light to pass through beautifully. This opens doors for creative projects like lampshades, custom lighting fixtures, or even signage with vibrant backlighting.

A Kaleidoscope of Colors: From crystal clear to neon brights and even mirrored finishes, the vast array of acrylic colors caters to any aesthetic vision. Combine different colors in layers to create stunning 3D effects or play with light diffusion for captivating projects.

Clean Cuts and Flawless Edges: Laser cutting delivers unparalleled precision, resulting in clean, polished edges on your acrylic creations. No more worrying about frayed or uneven cuts – you get a professional finish every time.

Versatility for All Skill Levels: Acrylic's ease of use makes it perfect for beginners. The material is relatively forgiving, allowing for experimentation and learning the ropes of laser cutting. For experienced makers, the vast potential for intricate designs and complex projects pushes the boundaries of creativity.

A World of Creative Possibilities:

Stationery with Flair: Laser cut acrylic can transform your workspace. Create sleek pen holders, personalized acrylic organizers, or coasters with intricate designs to add a touch of modern elegance to your desk.

Home Decor with Pizazz: Wall hangings with geometric patterns, layered acrylic table numbers for a special event, or custom-designed cake toppers – laser cut acrylic elevates your home decor with a touch of modern sophistication.

Signage Solutions: From sleek business signs to personalized nameplates, laser cut acrylic offers a professional and durable solution for signage needs. The clarity of the material allows for crisp lettering and vibrant colors for maximum impact.

Art with an Edge: Laser cut acrylic sheets become a canvas for artistic expression. Experiment with layering different colors and textures, or create 3D sculptures with intricate details. The possibilities for artistic exploration are boundless.

A Few Helpful Tips:

Choosing the Right Acrylic: Cast acrylic is generally preferred for laser cutting due to its better optical properties and cleaner cut edges. Extruded acrylic can be used as well, but may result in a cloudy white finish on the cut edges.

Safety First: Laser cutting acrylic can generate fumes. Always ensure proper ventilation in your workspace and wear protective eyewear to shield your eyes from the laser beam.

Masking Matters: Acrylic often comes with a protective paper layer on both sides. During laser cutting, keep one side masked to prevent scorching or unwanted marks on the finished product.

The Future of Acrylic Fabrication:

Laser cutting has become an indispensable tool for working with acrylic. Its precision, versatility, and ability to produce high-quality results make it a favorite among crafters, hobbyists, and even small businesses. So, unleash your creativity, embrace the clean cuts of laser technology, and transform ordinary acrylic into extraordinary creations!

Sharp Style: The Art of Laser Cutting

Leather, a timeless material prized for its durability and elegance, takes on a whole new dimension with laser cutting technology. This dynamic duo allows crafters and artists to create intricate designs and precise cuts, breathing new life into leather projects. Whether you're a seasoned leatherworker or a curious beginner, here's a deep dive into the world of laser cutting leather:

Advantages of a Sharper Edge:

Precision Cuts: Unlike traditional hand tools, a laser cutter delivers unparalleled precision. Intricate designs, delicate details, and perfectly curved lines are all achievable with clean, crisp edges. This level of detail elevates your leatherwork to a professional level.

Speed and Efficiency: Bid farewell to laborious hours spent hand-cutting intricate patterns. Laser cutting automates the process, allowing you to create multiples or even personalize each piece with lightning speed. This efficiency is a boon for production runs or creating custom designs for clients.

Material Versatility: Laser cutting caters to a wider range of leather thicknesses than traditional tools. From thin, supple garment leather to thicker veg-tan crafting leather, you can experiment and create projects with a beautiful balance of form and function.

Reduced Waste: Laser cutting software allows for optimized material placement, minimizing wasted leather scraps. This eco-conscious approach is a major benefit, especially when working with expensive or exotic leathers.

Unleashing Your Creativity:

Apparel Accents: Laser cutting opens doors to a world of fashion possibilities. Create custom appliques for jackets, intricate lace overlays for dresses, or personalized belts with unique buckle loops. The possibilities for adorning garments are endless.

Jewelry with Flair: Laser cut leather transforms into stunning earrings, intricate pendants, or layered leather bracelets. Experiment with different textures and colors to create one-of-a-kind pieces that showcase your unique style.

Home Decor with Character: Leather coasters adorned with intricate laser-cut designs become a sophisticated addition to any coffee table. Laser cut wall hangings with geometric patterns or nature-inspired motifs add a touch of modern elegance to your home decor.

Personalized Stationery: Laser cut leather adds a touch of luxury to notebooks, journals, or even phone covers. Personalize them with names, monograms, or intricate designs for a truly unique and handcrafted feel.

A Few Pointers to Consider:

Leather Selection: Not all leather is created equal for laser cutting. Opt for vegetable-tanned leather, free of dyes or finishes that may react poorly to the laser. Avoid chrome-tanned leather, as it can emit harmful fumes during cutting.

Laser Settings Matter: Experiment with different power and speed settings to achieve the desired results. Start with lower settings and gradually increase them to avoid burning or charring the leather.

Fume Extraction is Key: Laser cutting leather releases fumes. Ensure proper ventilation in your workspace to avoid inhaling harmful particles. Consider using a fume extractor specifically designed for laser cutters.

The Future of Leatherworking:

Laser cutting is rapidly transforming leatherworking, making it more accessible and efficient for crafters of all skill levels. With its ability to create intricate designs, reduce waste, and produce high-quality results, laser cutting opens doors to a world of creative possibilities. So, embrace the sharp edge of technology and elevate your leatherwork to a whole new level!

Beyond the Usual: Exploring Uncommon Materials for Laser Cutting

Beyond the Usual: Exploring Uncommon Materials for Laser Cutting

The whirring hum of the laser cutter, the acrid scent of burning material – for laser enthusiasts, it's a symphony of creation. But the canvas? Often limited to wood, acrylic, and the occasional metal sheet. While these materials offer versatility, there's a whole world of unconventional materials waiting to be explored by the adventurous laser artist. Let's break free from the norm and delve into the intriguing possibilities of these lesser-known laser cutting materials:

Natural Wonders:

Leaves: Nature's pre-designed templates! Dried leaves, especially those with intricate vein structures, can be laser cut to create stunning lampshades, decorative coasters, or even delicate jewelry. Experiment with different leaf thicknesses and varieties for surprising results. Remember: Ensure leaves are completely dry and free of any flammable residues before laser cutting.

Cork: Sustainable and surprisingly versatile, cork offers a warm, natural aesthetic. Laser cut cork sheets into coasters with intricate geometric patterns, or create unique bulletin board tiles with custom lettering. The natural charring from the laser adds a rustic touch.

Gourds: These fascinating gourds, like the Vietnamese Ao Dai, can be transformed into beautiful laser-cut lanterns. The intricate designs allow light to peek through, creating a mesmerizing interplay of light and shadow.

Pushing the Boundaries:

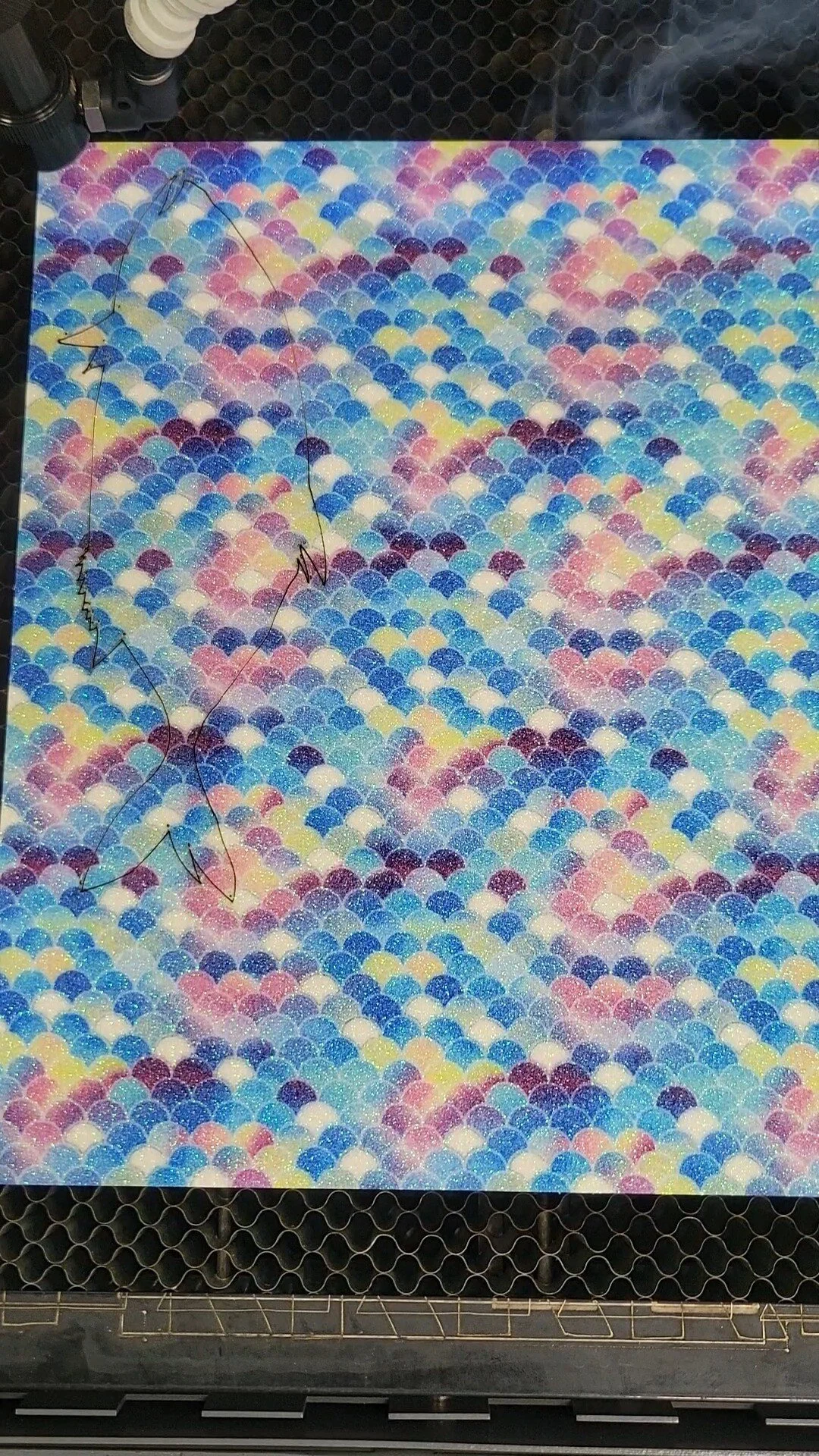

Fabric: Laser cutting fabric opens doors to a world of creative possibilities. Design custom stencils, intricate lace patterns for clothing embellishments, or even create unique fabric jewelry with clean-cut edges. Choose natural fibers like cotton or linen for best results, and adjust laser settings for optimal cutting without burning.

Leather Scraps: Upcycle those leftover leather scraps into beautiful laser-cut earrings, personalized keychains, or even decorative coasters. The rich texture of leather takes on a new dimension with intricate cutouts, adding a touch of luxury to your creations. Caution: Laser cutting leather releases strong fumes, so proper ventilation and following safety protocols are essential.

A Few Words of Caution:

Always prioritize safety when experimenting with new materials. Research the material's properties beforehand, ensuring it's compatible with laser cutting and won't release harmful fumes. Start with small test cuts to determine the appropriate settings and minimize wasted material.

The Final Cut:

Laser cutting offers immense creative potential, and these uncommon materials open doors to a world of artistic exploration. So, embrace the unconventional, unleash your creativity, and let your laser cutter transform the unexpected into extraordinary works of art.

Free File Frenzy: Top Resources for 3D Printer and Laser Cutter Files

Free File Frenzy: Top Resources for 3D Printer and Laser Cutter Files

The world of 3D printing and laser cutting is brimming with creative potential, but sometimes that initial hurdle can be finding the perfect file to bring your vision to life. Fear not, makers and creators! This guide delves into the treasure troves of the internet, where a plethora of free, high-quality files await to unleash your creative spirit.

Free File Havens for 3D Printing:

Thingiverse: This behemoth of a website is a goldmine for 3D printable files, boasting a vast collection across diverse categories. Thingiverse offers user-friendly search functions, detailed previews, and active forums for troubleshooting and inspiration.

MyMiniFactory: Another popular platform, MyMiniFactory caters specifically to 3D printable figurines and miniatures. With a focus on high-quality models and a strong community of designers, this website is a haven for hobbyists and tabletop gamers.

Cults3D: Embrace the global design scene with Cults3D. This international platform offers a wide range of 3D printable files, with a focus on supporting independent designers through a variety of licensing options, including free models.

NASA 3D printable models: Calling all space enthusiasts! NASA offers a unique collection of 3D printable models featuring iconic spacecraft, historical artifacts, and even anatomical models related to space exploration.

Yeggi: Feeling overwhelmed by the sheer number of options? Yeggi is a fantastic search engine specifically designed for 3D printable files. Simply enter your desired object and let Yeggi scour the web, presenting you with relevant files from various repositories.

Laser Cutter File Bonanza:

Freepik: A well-known resource for graphic designers, Freepik also offers a treasure trove of free SVG (Scalable Vector Graphics) files, perfect for laser cutting projects. With a diverse collection ranging from home décor to seasonal crafts, Freepik is a great place to find inspiration and ready-to-cut designs.

DXF Downloads: This website lives up to its name, providing a comprehensive library of free DXF (Drawing Exchange Format) files specifically designed for laser cutters. From intricate jewelry designs to functional organizers, DXF Downloads offers a variety of options for makers of all skill levels.

The Laser Cutting Guru: This website by a laser enthusiast features a curated collection of free laser cutting files, tutorials, and project ideas. The Laser Cutting Guru offers a friendly and informative atmosphere, making it a great resource for beginners.

Techniks: For laser cutting projects with a focus on functionality and practicality, Techniks is a valuable resource. Their website offers a selection of free downloadable DXF files for toolboxes, organizers, and other useful designs.

Vecteezy: Similar to Freepik, Vecteezy boasts a vast collection of free SVG files. While not exclusively focused on laser cutting, the diverse range of designs and the user-friendly search filters make it a great place to find inspiration and potentially modify existing files for your laser cutter.

Beyond the Free Files:

While these resources offer a fantastic starting point, remember that many websites also provide premium file libraries with a wider selection of designs and higher levels of detail. Consider exploring these options once you've honed your skills and are ready for more complex projects.

Happy Making!

With a little exploration, you'll be well on your way to transforming free files into fantastic creations. So, fire up your 3D printer or laser cutter, unleash your creativity, and get ready to experience the joy of making something truly unique!

The Case for Creation: Why You Should Own a 3D Printer

The Case for Creation: Why You Should Own a 3D Printer

The ability to transform ideas into tangible objects has always held a certain magic. 3D printing technology takes that magic and injects it with a healthy dose of practicality, making it a powerful tool for hobbyists, entrepreneurs, and anyone in between. But with so many gadgets vying for your attention, why should you consider adding a 3D printer to your collection? Here's a breakdown of the compelling reasons why owning a 3D printer can unlock a world of creation and innovation.

Unleash Your Inner Maker:

Prototyping Playground: Imagine turning your ideas into physical models in a matter of hours. 3D printing allows you to create prototypes quickly and affordably, test their functionality, and iterate on designs without the constraints of traditional methods. This rapid feedback loop fuels the creative process and brings your inventions to life faster than ever.

Custom Creations on Demand: Say goodbye to limited design options! With a 3D printer, you become the designer and manufacturer. From ergonomic tools for your workshop to personalized phone cases that reflect your unique style, the possibilities for creating custom objects are endless.

Fuel Your Passion for Learning:

STEM Education Revolution: Learning about complex scientific and engineering concepts just got a whole lot more engaging. 3D printing allows students to visualize and hold objects in their hands, fostering a deeper understanding of how things work. It's a dynamic learning experience that bridges the gap between theory and practice.

Hands-on Exploration for All Ages: 3D printing is more than just a tool; it's a spark for curiosity and a love for learning. The ability to bring concepts to life in the real world ignites creativity, problem-solving skills, and critical thinking – valuable assets for anyone, regardless of age or background.

Empower Your Entrepreneurial Spirit:

Rapid Prototyping for Businesses: Small businesses can leverage the power of 3D printing to create prototypes for new products, gather valuable customer feedback through physical testing, and refine their designs before investing in mass production. This rapid iteration cycle translates to faster product development and a competitive edge in the market.

On-Demand Manufacturing Made Easy: Forget the limitations of traditional manufacturing processes. 3D printing allows for small-batch production or custom-made items, catering to niche markets and offering greater control over your product line. This empowers businesses to be more responsive to customer needs and embrace a more agile manufacturing approach.

Embrace a Sustainable Future:

Reduce, Reuse, Reimagine: 3D printing utilizes only the material needed for the object being created, minimizing waste compared to traditional subtractive manufacturing methods. This environmentally friendly approach is a step towards a more sustainable future.

Prototyping Revolution: No more creating multiple physical prototypes and discarding them after testing. 3D printing allows for rapid iteration and testing within the digital realm, reducing the environmental impact of product development.

A Skillset for the Future:

3D printing technology is rapidly evolving, and the ability to design and print objects is becoming an increasingly valuable skill. Owning a 3D printer equips you with the knowledge and experience to navigate this exciting technological landscape, opening doors to new career opportunities and creative endeavors.

The Takeaway:

A 3D printer is more than just a machine; it's a gateway to a world of creation, innovation, and learning. Whether you're a hobbyist with a passion for tinkering, an entrepreneur with a groundbreaking idea, or simply someone who enjoys bringing their imagination to life, a 3D printer can empower you to turn dreams into reality. So, take the plunge, embrace the future of creation, and start printing your own world!

The Future in Your Hands: Unveiling the Advantages of Learning 3D Printing

The Future in Your Hands: Unveiling the Advantages of Learning 3D Printing

The world of creation is undergoing a revolution, and at the forefront stands 3D printing technology. Once relegated to science fiction, 3D printers are now accessible to hobbyists and entrepreneurs alike, transforming ideas into tangible objects with a click. But beyond the novelty, what are the real advantages of learning this powerful skill? Let's dive into the many reasons why 3D printing should be your next creative conquest.

Unleash Your Inner Inventor:

Prototyping Made Easy: Breathe life into your ideas quickly and affordably. 3D printing allows you to create physical prototypes of your inventions, test their functionality, and iterate rapidly without relying on expensive traditional methods.

Custom Creations: Gone are the days of limited design options. 3D printing empowers you to design and create objects tailored to your specific needs and preferences. From ergonomic tools to personalized phone cases, the possibilities are endless.

Fuel Your Passion for Learning:

STEM Education: 3D printing bridges the gap between theory and practice. By visualizing and holding 3D models, students gain a deeper understanding of complex scientific and engineering concepts. It's learning by doing, in a whole new dimension!

Hands-on Exploration: 3D printing ignites curiosity and a love for learning. The ability to bring concepts to life fosters creativity, problem-solving skills, and critical thinking – valuable assets in any field.

Empower Your Entrepreneurial Spirit:

Rapid Prototyping for Businesses: Small businesses can leverage 3D printing to create prototypes for new products, test designs with customers, and gain valuable feedback before investing in mass production.

On-Demand Manufacturing: 3D printing allows for small-batch production or custom-made items, catering to niche markets and offering greater flexibility to entrepreneurs. This technology empowers businesses to be more responsive to customer needs.

Embrace a Sustainable Future:

Reduce Waste: 3D printing utilizes only the material needed for the object being created, minimizing waste compared to traditional manufacturing processes.

Prototyping Revolution: No more creating multiple physical prototypes – 3D printing allows for rapid iteration and testing, reducing the environmental impact of product development.

A Skillset for the Future:

3D printing is more than just a cool hobby; it's a valuable skill for the future. As the technology continues to evolve and becomes more accessible, the ability to design and print 3D objects will be increasingly sought after across various industries.

The Takeaway:

Learning 3D printing is an investment in your creativity, problem-solving abilities, and future potential. It opens doors to a world of possibilities, from rapid prototyping to creating one-of-a-kind objects. So, don't wait! Embrace the future and unleash the power of 3D printing today!

The Showdown: 3D Printers vs. Laser Cutters - Choosing the Right Tool for the Job

The Showdown: 3D Printers vs. Laser Cutters - Choosing the Right Tool for the Job

When it comes to transforming ideas into reality, both 3D printers and laser cutters offer exciting possibilities. But with distinct functionalities, choosing the right tool depends on your project's specific needs. Let's delve into the core differences between these powerful machines to help you make an informed decision.

Building vs. Cutting:

3D Printing: An additive manufacturing process that builds objects layer by layer from a filament or powder material. This allows for the creation of complex 3D shapes and intricate designs.

Laser Cutting: A subtractive manufacturing process that utilizes a laser beam to cut precise shapes from flat sheets of material. Laser cutters excel at creating clean, 2D designs on wood, acrylic, fabric, and even some metals.

Material Versatility:

3D Printing: Offers a wider range of material options, including plastics, metals, resins, and even food-grade materials for specific applications.

Laser Cutting: Material choices are generally limited to flat sheets and depend on the laser's power and the material's cutting compatibility. Common materials include wood, acrylic, paper, fabric, and some thin metals.

Complexity and Detail:

3D Printing: Capable of creating highly detailed and intricate objects with complex geometries. However, layer lines and surface finish can sometimes be limitations.

Laser Cutting: Produces clean, precise cuts with minimal to no physical tool wear. Ideal for creating intricate 2D designs and sharp edges.

Speed and Cost:

3D Printing: Printing times can vary greatly depending on the size and complexity of the object. Material costs can also be higher for certain filaments or powders.

Laser Cutting: Generally faster than 3D printing, especially for simpler designs. Material costs are typically lower as sheet materials are often more affordable.

Applications:

3D Printing: Prototyping, product design, architectural models, custom figurines, prosthetics, and even functional tools.

Laser Cutting: Custom signage, jewelry making, scrapbooking embellishments, packaging prototypes, model building components, and personalized gifts.

Choosing the Right Tool:

So, which one reigns supreme? It truly depends on your project's requirements:

For creating 3D objects with complex designs: 3D printer is the clear winner.

For precise cutting and creating intricate 2D designs: Laser cutter takes the lead.

For working with a wider range of materials: 3D printer offers more flexibility.

For faster turnaround times and potentially lower material costs: Laser cutter might be a better choice for simpler projects.

The Dream Team:

In an ideal world, some makers have both tools in their arsenal! The ability to 3D print a custom mold and then laser cut intricate details onto it opens doors to even more creative possibilities.

The Final Cut:

Both 3D printers and laser cutters are powerful tools that empower creativity. Understanding their core functionalities and limitations will equip you to choose the right tool for your project, bringing your ideas to life, one layer or precise cut at a time.

Laser Cutter Repair Showdown: Online Assistance vs. In-Person Help

Laser Cutter Repair Showdown: Online Assistance vs. In-Person Help

Your laser cutter throws a tantrum – refusing to cooperate. Don't fret, creator! You have two main options for getting it back in fighting shape: online repair assistance or the trusty local repair technician. Let's delve into the pros and cons of each approach, helping you decide which path leads to the quickest and most successful repair.

The Convenience of Online Laser Cutter Repair:

Remote Diagnostics: Imagine a world where a laser whiz kid diagnoses your machine from afar! Many online repair services offer this through video conferencing, allowing them to pinpoint the problem without a physical visit. This saves you time and eliminates the hassle of transporting your bulky laser cutter.

Global Expertise Pool: Unlike local options, online services tap into a vast network of laser specialists worldwide. This broader reach grants access to a wider range of knowledge and experience, especially beneficial for rare laser cutter models or complex repairs.

Real-Time Support: No more waiting for a technician's schedule to align with yours. Online services often offer real-time support via chat, email, or video calls. This allows for immediate guidance and potentially resolves the issue on the spot, minimizing downtime.

Cost-Effectiveness: For minor repairs or troubleshooting, online guidance can be a budget saver. Qualified technicians can help you diagnose the problem and potentially walk you through simple fixes yourself, avoiding unnecessary service call charges.

However, Online Help Isn't Without Its Limitations:

Limited Hands-on Ability: Online technicians can't physically interact with your machine, potentially hindering their ability to diagnose complex issues or perform intricate repairs.

Communication Challenges: Clear communication is crucial for successful online repair. Technical jargon or unclear descriptions can lead to misunderstandings and delays.

Safety Concerns: For repairs involving delicate components or electrical work, a qualified technician's in-person expertise is irreplaceable to ensure safety.

The Benefits of In-Person Laser Cutter Repair:

Hands-on Expertise: There's no substitute for a technician physically inspecting your machine. They can identify problems that might be missed by remote diagnostics and perform repairs requiring dexterity and specialized tools.

Faster Turnarounds (Sometimes): For complex repairs that require part replacements or intricate adjustments, in-person service can sometimes be faster. The technician has all the necessary tools and resources readily available.

Peace of Mind: Having a qualified professional physically repair your machine can offer peace of mind, knowing the job is done right while adhering to safety protocols.

However, Local Help Has Its Drawbacks Too:

Limited Availability: Local repair technicians might have limited experience with specific laser cutter models or be geographically unavailable in some areas.

Potential Delays: Scheduling a technician visit and waiting for them to arrive can lead to downtime, especially if their schedule is full.

Travel Costs: Depending on your location, local service might incur travel charges which can add to the overall repair cost.

Choosing the Right Repair Approach:

Complexity of the Problem: For minor software issues or basic troubleshooting, online assistance can be a good starting point. However, for complex hardware repairs or safety concerns, an in-person technician is the safer choice.

Your Comfort Level: Are you comfortable following online instructions and potentially performing minor repairs yourself? If not, local service might be a better fit.

Time Constraints: If you need a quick turnaround, consider the availability of local technicians and the potential delays involved. Online assistance might be faster for straightforward issues.

Conclusion:

Both online and in-person laser cutter repair offer distinct advantages. Carefully consider the nature of the problem, your technical expertise, and time constraints before choosing the right path. Remember, the ultimate goal is to get your laser cutter back in top shape, so don't hesitate to leverage the best of both worlds if necessary. Happy creating!

Beyond the Bench: How Online Laser Cutter Repair Can Get You Cutting Again

Beyond the Bench: How Online Laser Cutter Repair Can Get You Cutting Again

Your once-reliable laser cutter splutters and coughs, its once-precise beam a flickering shadow of its former glory. Panic might set in, but fear not, creative soul! The digital age offers a solution beyond the local repair shop – professional online laser cutter repair assistance. Here's why venturing into the world of online repair can get your creative flow back on track, faster than ever.

Connecting with Laser Experts Virtually:

Remote Diagnostics: Imagine a world where a seasoned laser technician can diagnose your machine's woes from miles away. Many online repair services offer remote diagnostics, utilizing video conferencing and screen sharing to pinpoint the problem. This eliminates the hassle of physically transporting your bulky laser cutter and allows for faster troubleshooting.

A Broader Pool of Expertise: Unlike local repair options, online services tap into a global network of laser specialists. You gain access to a wider range of knowledge and experience compared to relying solely on technicians in your area. This is especially beneficial for less common laser cutter models or complex repairs.

Real-Time Support: Gone are the days of waiting for a technician to visit your workshop. Online repair services often offer real-time support through chat, email, or video calls. This allows you to receive immediate guidance and potentially resolve the issue on the spot, minimizing downtime.

Cost-Effective Solutions: For minor repairs or troubleshooting, online guidance can save you money. Qualified technicians can help you diagnose the problem and potentially walk you through simple fixes yourself, avoiding unnecessary service call charges.

Before You Go Online:

Gather Information: The more details you have about the issue, the better. This includes error messages, unusual noises, the type of project you were working on when the problem arose, and any troubleshooting steps you've already tried.

Prepare Your Workspace: For smooth remote diagnostics, ensure your workspace is well-lit and have a stable internet connection. This allows the technician to clearly see your machine and communicate effectively.

Have Your Model Number Handy: Knowing your specific laser cutter model is crucial for the technician to access relevant repair manuals and offer accurate troubleshooting steps.

The Final Cut: A Collaborative Approach to Repair

While online professional repair offers a convenient and potentially cost-effective solution, it's a collaborative effort. By providing clear information and following the technician's guidance, you become an active participant in the repair process. Remember, for complex repairs or safety concerns, seeking a local technician for hands-on service might be necessary.

Conclusion:

The digital age empowers you to access a wealth of expertise from the comfort of your workshop. The next time your laser cutter sputters, don't despair. Embrace the power of online professional repair services and get back to creating with confidence, knowing a network of laser experts is just a click away.

Don't Get Burned: Why DIY Laser Cutter Mirror and Lens Alignment is a Recipe for Disaster

Don't Get Burned: Why DIY Laser Cutter Mirror and Lens Alignment is a Recipe for Disaster

Your laser cutter is a marvel of precision engineering, channeling a powerful beam of light to create intricate designs. But that power demands careful handling, especially when it comes to the heart of the machine: the mirrors and lenses. Here's why tinkering with these components yourself is a risky proposition and why seeking professional help is the smarter – and safer – choice.

The Delicate Dance of Laser Light:

Invisible Beam: Laser cutters operate with an invisible beam of light. Unlike a flashlight, misalignment here isn't readily apparent, making mistakes easy to miss and potentially dangerous.

Precise Focus: The mirrors and lenses work in concert to focus the laser beam to a tiny point, the key to clean cuts. Even slight misalignment can cause the beam to diverge, delivering scattered and potentially weak energy.

Safety Hazards: A misaligned beam can strike unintended targets, potentially damaging the machine itself or worse, posing a serious safety risk.

The Pitfalls of DIY Alignment:

Specialized Tools and Knowledge: Proper alignment requires specialized tools and a deep understanding of laser optics. Without these, achieving precise adjustments is near impossible, and even minor missteps can worsen the situation.

Hidden Damage: Misalignment can sometimes be a symptom of deeper issues like mirror degradation or lens damage. A professional can diagnose these underlying problems and provide a proper solution.

Wasting Time and Resources: Unsuccessful DIY attempts can lead to wasted time and frustration, potentially requiring professional intervention anyway, adding to the overall cost.

The Advantages of Professional Alignment:

Trained Expertise: A qualified technician possesses the knowledge, experience, and specialized tools to precisely align your laser cutter's mirrors and lenses.

Safety First: Professionals prioritize safety and ensure all adjustments are made within safe operating parameters.

Guaranteed Performance: By ensuring proper alignment, a qualified technician guarantees your laser cutter operates at its optimal performance level.

Signs You Need Professional Alignment:

Reduced Cutting Quality: Uneven cuts, jagged edges, or excessive burning around the cut line can all be signs of misalignment.

Weak Cutting Power: If your laser cutter struggles to cut through materials it previously handled with ease, it might be due to a misaligned beam.

Erratic Operation: Unexpected shutdowns or error messages can sometimes indicate issues with the laser beam path.

Investing in Safety and Performance:

While the temptation to tackle DIY repairs might be strong, when it comes to laser cutter mirror and lens alignment, the risks far outweigh the rewards. Leaving it to the professionals ensures your machine operates safely, efficiently, and delivers the precise results you expect. Remember, a qualified technician is an investment in the safety, longevity, and optimal performance of your valuable laser cutter. So, keep your creative focus on your projects, and leave the laser focus to the professionals!

The Monthly Maintenance Checklist: Keeping Your Laser Cutter Running Smoothly

The Monthly Maintenance Checklist: Keeping Your Laser Cutter Running Smoothly

Your laser cutter is a powerful tool, transforming ideas into reality with precise cuts and intricate designs. But like any workhorse, it needs regular care to keep it operating at peak performance. While professional maintenance is crucial, there's a lot you can do yourself to ensure your laser cutter stays in top shape – and that's where monthly maintenance comes in.

Why Monthly Maintenance Matters:

Preventative Care: Regular maintenance catches minor issues before they snowball into major repairs or costly downtime.

Optimal Performance: A well-maintained laser cutter delivers cleaner cuts, consistent power output, and improved overall efficiency.

Extended Lifespan: Regular cleaning and adjustments minimize wear and tear, extending the life of your valuable machine.

Safety First: Monthly maintenance ensures all safety features are functioning properly, minimizing the risk of accidents.

Your Monthly Laser Cutter Maintenance Checklist:

Cleaning:

Lens and Mirrors: Dust and debris on the lens and mirrors can significantly impact cutting performance. Use a cleaning solution recommended by your laser cutter manufacturer and lint-free wipes to gently clean these delicate components. Never touch the lens or mirrors with your bare hands, as oils from your skin can damage the coatings.

Machine Interior: Vacuum dust and debris from the interior of the machine, paying close attention to areas around the cutting bed, exhaust system, and rails. This improves airflow and prevents material buildup that could affect performance.

Exhaust System: Check the exhaust filter and clean or replace it according to the manufacturer's instructions. A clogged filter reduces airflow and can lead to overheating and potential damage.

Inspection:

Visual Inspection: Look for any signs of physical damage, loose parts, or unusual wear and tear on belts, rails, or the cutting head.

Water Levels (if applicable): Some laser cutters utilize water cooling systems. Check the water level and top it off with distilled water if necessary. Refer to your user manual for specific instructions.

Additional Tips:

Maintain a Logbook: Keep a record of your monthly maintenance activities, including cleaning, inspections, and any adjustments made. This helps you track your machine's health and identify any recurring issues.

Consult Your User Manual: Your user manual is a valuable resource for specific maintenance procedures and recommended cleaning solutions for your particular laser cutter model.

Conclusion:

A few minutes of monthly maintenance can go a long way in keeping your laser cutter running smoothly and delivering professional results. By incorporating these simple steps into your routine, you can ensure your creative flow remains uninterrupted and your laser cutter continues to be a reliable partner in your creative endeavors. Remember, an ounce of prevention is worth a pound of cure – so grab your cleaning supplies and keep your laser cutting sharp!

Keep Your Laser Cutting Sharp: Why Invest in Professional Maintenance

Keep Your Laser Cutting Sharp: Why Invest in Professional Maintenance

Your laser cutter is the backbone of your creative process, transforming ideas into reality with precise cuts and intricate designs. But just like any hardworking tool, it requires regular care to maintain peak performance. Here's why investing in professional laser cutter maintenance is a smart decision for creators and businesses alike.

The Benefits of Professional Laser Cutter Maintenance:

Preventative Measures: Think of it like taking your car for an oil change. Professional maintenance technicians proactively identify potential problems before they snowball into major repairs or downtime. This can save you money and frustration in the long run.

Extended Lifespan: Regular maintenance ensures your laser cutter operates within optimal parameters, reducing wear and tear on critical components. This translates to a longer lifespan for your valuable machine.

Optimized Performance: A well-maintained laser cutter delivers cleaner cuts, consistent power output, and improved overall efficiency. This translates to professional-looking results and faster project completion times.

Safety First: Regular maintenance ensures all safety features are functioning properly, minimizing the risk of accidents or injuries.

Expert Knowledge: Trained technicians possess the knowledge and experience to identify and address any laser cutter issues specific to your model and usage patterns.

What Does Professional Laser Cutter Maintenance Entail?

The specifics may vary depending on your machine and service provider, but common procedures include:

Cleaning and Inspection: Technicians thoroughly clean the laser head, mirrors, and other critical components to ensure optimal beam quality and cutting performance. They also inspect all systems for signs of wear and tear.

Calibration and Adjustments: Over time, laser cutters can require calibration adjustments to maintain accurate focus and cutting power. Professionals have the tools and expertise to perform these calibrations with precision.

Alignment Checks: Mirrors and lenses within the laser cutter assembly need to be properly aligned for optimal beam path and cutting efficiency. Technicians can identify and rectify any alignment issues.

Software Updates: Some laser cutters have firmware updates that can improve performance or introduce new features. Professionals can ensure your machine has the latest software installed.

Investing in Your Creative Future:

While the upfront cost of professional maintenance might seem like an additional expense, the long-term benefits outweigh the cost:

Reduced Downtime: Preventative maintenance helps avoid unexpected breakdowns, saving you valuable time and production delays.

Fewer Repairs: Identifying and addressing minor issues early on can prevent them from escalating into major repairs down the line.

Enhanced Resale Value: A well-maintained laser cutter with a documented service history will command a higher resale value if you decide to upgrade in the future.

Conclusion:

By investing in professional laser cutter maintenance, you're not just protecting your investment; you're ensuring your creative flow remains uninterrupted. With a well-maintained machine, you can focus on what matters most – bringing your ideas to life with confidence and precision. So, schedule your professional maintenance appointment today, and keep your laser cutting sharp!

When Your Laser Cutter Goes Dark: Finding Local Repair Solutions

When Your Laser Cutter Goes Dark: Finding Local Repair Solutions

Your laser cutter is the workhorse of your workshop, transforming ideas into reality with precise cuts and intricate designs. But what happens when your trusty machine sputters and stalls? Don't fret, laser warriors! This guide will equip you with strategies for finding local repair heroes to get your creative flow back on track.

Signs You Need Local Laser Cutter Repair:

Reduced Cutting Performance: Are your cuts becoming dull, uneven, or showing signs of melting? This could indicate problems with laser focus, power calibration, or even malfunctioning mirrors.

Erratic Operation: Unexpected shutdowns, error messages, or unresponsive controls are all red flags that point towards underlying technical issues best addressed by a professional.

Unusual Noises: Grinding, clanging, or other strange noises emanating from your laser cutter are clear signs that something is amiss internally. Ignoring these could lead to further damage.

Smoke or Burning Smells: These are definite cause for alarm and a clear indication that professional intervention is necessary to prevent further damage to your machine or potential safety hazards.

Why Go Local? The Benefits of Local Laser Cutter Repair:

Faster Turnaround Times: Local technicians often offer quicker turnaround times compared to sending your machine out for repair. This minimizes downtime and gets you back to creating sooner.

Reduced Shipping Costs: Shipping a bulky and potentially heavy laser cutter can be expensive. Local repair eliminates these costs.

Personalized Service: Local technicians can provide a more personalized service, taking the time to understand your specific machine and problem.

Supporting Local Businesses: By choosing a local repair specialist, you're contributing to your community's economy.

Finding the Perfect Local Laser Cutter Repair Technician:

Manufacturer Support: Many laser cutter manufacturers offer repair services or have a network of authorized technicians in your area. Check your machine's manual or contact the manufacturer for recommendations.

Online Directories: Websites like Angie's List [invalid URL removed] or HomeAdvisor can help you find qualified repair professionals in your area. Look for technicians with experience in servicing your specific laser cutter model.

Word-of-Mouth Recommendations: Ask fellow laser enthusiasts, makerspaces, or local art supply stores for recommendations on reputable repair technicians.

Local Business Directories: Search online directories or business review websites like Yelp to find repair shops in your area. Read reviews to gauge customer experiences.

When Contacting a Local Repair Professional:

Be Prepared: Have your laser cutter model number, serial number, and a clear description of the problem ready when you contact a technician.

Ask Questions: Don't hesitate to inquire about the technician's experience with your specific laser cutter model and their repair process.

Get a Quote: Before proceeding with repairs, obtain a written estimate for the cost of service. This helps you manage your budget and avoid surprise fees.

The Final Cut: Prevention is Key

While local repair professionals are lifesavers when your laser cutter goes down, an ounce of prevention is worth a pound of cure:

Regular Maintenance: Following the manufacturer's recommended maintenance schedule can help prevent problems and extend the lifespan of your laser cutter.

Proper Use: Ensure you're using your laser cutter correctly and within its specified capabilities to minimize the risk of damage.

By recognizing the signs of trouble and seeking local repair help when needed, you can ensure your laser cutter continues to be a reliable tool for bringing your creative visions to life. Remember, a local repair professional can often diagnose and fix the issue quickly and efficiently, getting you back to creating in no time. So, breathe easy, find your local laser hero, and keep those creative sparks flying!

The Balancing Act: Unveiling the Challenges of Laser Cutter Focus

The Balancing Act: Unveiling the Challenges of Laser Cutter Focus

The magic of a laser cutter lies in its ability to transform a beam of light into a precise cutting tool. But achieving that precise cut hinges on a crucial factor: focus. Just like a blurry camera lens can ruin a photo, an improperly focused laser can wreak havoc on your project. Let's delve into the complexities of laser cutter focus and the challenges that come with achieving that perfect cutting point.

The Science Behind the Focus:

A laser cutter focuses a beam of light through a series of lenses to create a tiny, high-intensity point. This point, known as the focal point, is where the laser's cutting power is most concentrated. The distance between the laser source and the focal point is critical. Think of it like a magnifying glass focusing sunlight to a burning point.

The Balancing Act: Material Thickness and Focal Length

The ideal focal point for cutting depends on the thickness and type of material you're working with. Here's why:

Thicker Materials: For thicker materials, the focal point needs to be slightly below the surface of the material. This ensures the laser beam penetrates deeply enough for a clean cut all the way through.

Thinner Materials: Conversely, for thin materials, the focal point needs to be precisely at the surface. If the focal point is too low, the laser beam might over-penetrate, melting or burning the material instead of cutting it cleanly.

Challenges in Achieving Perfect Focus:

Several factors can make achieving perfect focus a challenge:

Material Variations: Even slight variations in material thickness within your project can require adjustments to the focal point.

Lens Degradation: Over time, laser cutter lenses can degrade, impacting beam quality and making it harder to achieve a sharp focus.

Machine Calibration: Even minor misalignments in the laser cutter's mirrors or lens assembly can throw the focus off.

Consequences of Improper Focus:

Uneven Cuts: An improperly focused laser can create uneven or ragged cuts, compromising the quality of your project.

Material Damage: If the focus is too low, the laser can melt or burn the material, leaving behind unwanted marks or deformations.

Reduced Cutting Efficiency: An improperly focused laser might take longer to cut through the material, impacting your productivity.

Overcoming Focus Challenges:

Machine Calibration: Regularly checking and calibrating your laser cutter according to the manufacturer's instructions is crucial for maintaining proper focus.

Focus Test Cuts: Before starting your actual project, perform test cuts on scrap material to fine-tune the focus for the specific material thickness you're using.

Autofocus Features: Some laser cutters come equipped with autofocus features that can automatically adjust the focal point based on the material thickness.

The Final Focus:

Laser cutter focus might seem like a technical hurdle, but understanding the importance and challenges associated with it empowers you to achieve clean cuts and professional-looking results. By combining knowledge, proper maintenance, and a bit of trial and error, you can master the art of laser cutter focus and unlock the full potential of your creative laser adventures. Happy (and focused) cutting!

Don't Panic and Push the Button: Seeking Professional Help for Laser Cutter Repair

Don't Panic and Push the Button: Seeking Professional Help for Laser Cutter Repair

Your laser cutter is the workhorse of your creative process, churning out intricate designs and bringing your ideas to life. But what happens when your trusty machine sputters and stalls? Fear not, laser warriors! This article will guide you through the signs that professional repair is necessary and the steps to take to find a qualified technician.

Signs You Need Professional Laser Cutter Help:

Reduced Cutting Quality: Are your cuts becoming dull, uneven, or showing signs of melting? This could indicate problems with laser focus, power calibration, or even malfunctioning mirrors.

Erratic Operation: Unexpected shutdowns, error messages, or unresponsive controls are all red flags that point towards underlying technical issues.

Unusual Noises: Grinding, clanging, or other strange noises emanating from your laser cutter are clear signs that something is amiss internally.

Smoke or Burning smells are definite cause for alarm and a clear indication that professional intervention is necessary to prevent further damage.

Safety Concerns: If you suspect any issues related to laser safety, such as faulty interlocks or malfunctioning fume extraction systems, prioritize seeking professional help immediately.

Why DIY May Not Be the Answer:

Laser cutters are complex machines, and attempting repairs without proper training and experience can be dangerous and even worsen the problem. Qualified technicians possess the knowledge, tools, and spare parts to diagnose issues accurately and perform repairs safely and efficiently.

Finding the Right Laser Cutter Repair Professional:

Online Resources: Websites like https://www.americanlaserco.com/remote-laser or online forums dedicated to laser cutting can be a valuable resource for finding qualified repair professionals in your area.

Local Service Providers: Search online directories or ask fellow laser enthusiasts for recommendations on reputable repair technicians in your area.

When Contacting a Repair Professional:

Be Prepared: Have your laser cutter model number, serial number, and a clear description of the problem ready when you contact a technician.

Ask Questions: Don't hesitate to ask about the technician's experience with your specific laser cutter model and their repair process.

Get a Quote: Before proceeding with repairs, obtain a written estimate for the cost of service.

Prevention is Key:

Regular Maintenance: Following the manufacturer's recommended maintenance schedule can help prevent problems and extend the lifespan of your laser cutter.

Proper Use: Ensure you're using your laser cutter correctly and within its specified capabilities to minimize the risk of damage.

By recognizing the signs of trouble and seeking professional help when needed, you can ensure your laser cutter continues to be a reliable tool for bringing your creative visions to life. Remember, a timely repair by a qualified technician can save you time, money, and frustration in the long run. So, keep calm, and let the professionals handle it!

Top 10 Must-Have Accessories for Your Laser Cutter

Top 10 Must-Have Accessories for Your Laser Cutter

A laser cutter can be an incredibly versatile tool for creating a variety of amazing projects. But to get the most out of your laser cutter, there are a few key accessories that can make your life easier,

improve project safety and results, and even expand your creative horizons. Here's a look at the top must-have accessories for your laser cutter, conveniently available on Amazon:

Honeycomb Cutting Table:

Opens in a new window www.amazon.com

Honeycomb Cutting Table for laser cutter

A honeycomb cutting table is an essential upgrade for any laser cutter user. This table features a perforated metal surface that allows smoke and fumes to easily escape during the cutting process. This not only improves air quality in your workspace but also helps to prevent burns on the bottom of your project from reflected laser beams.

Air Assist Kit:

Opens in a new window www.amazon.com

Air Assist Kit for laser cutter

An air assist kit helps to keep your cutting area clean and free of debris by directing a constant stream of compressed air towards the cutting zone. This compressed air helps to blow away smoke, fumes, and any molten material that may be generated during the cutting process. This can lead to cleaner cuts, sharper edges, and a reduction in the amount of post-processing required on your projects.

Exhaust Fan:

Opens in a new window www.stylecnc.com

Exhaust Fan for laser cutter

Having a proper exhaust system is crucial for safe laser cutting operation. An exhaust fan helps to remove smoke, fumes, and airborne particles created during the cutting process. This not only improves air quality but also helps to protect you from harmful fumes and particulates.

Laser Safety Glasses:

Opens in a new window amazon.com

Laser Safety Glasses

Safety should always be your top priority when using a laser cutter. Laser safety glasses are essential for protecting your eyes from the harmful laser beam. Choose glasses with the appropriate wavelength rating for your specific laser cutter.

Fume Extractor:

Opens in a new window www.amazon.com

Fume Extractor for laser cutter

While an exhaust fan helps to remove fumes and smoke from your workspace, a fume extractor goes a step further by filtering out harmful particulates before releasing the clean air back into the environment. This is especially important if you are using your laser cutter to cut materials that may release toxic fumes.

Magnetic Sheet:

Opens in a new window www.jpplus.com

Magnetic Sheet for laser cutter

A magnetic sheet can be a helpful addition to your laser cutter bed. The magnetic hold keeps your material securely in place during cutting, eliminating the need for clamps or tape. This can be especially helpful for working with smaller or thinner materials.

Rolling Mat:

Opens in a new window abbyamy.en.made-in-china.com

Rolling Mat for laser cutter

A silicone rolling mat can be a versatile addition to your laser cutter workspace. This mat protects your work surface from heat and debris, and it can also be used as a non-slip surface for prepping materials or laying out your project.

Light Source:

Opens in a new window www.linkedin.com

Light Source for laser cutter

Having a good light source near your laser cutter can be helpful for several reasons. It can improve visibility of your project during cutting, making it easier to monitor progress and identify any potential issues. Good lighting can also help with alignment and material placement.

Digital Caliper:

Opens in a new window amazon.com

Digital Caliper

A digital caliper is a precise measuring tool that can be used to ensure your materials are the correct size for your laser cutter. This can help to avoid cutting mistakes and wasted materials.

Software Library:

Opens in a new window www.lasercontrolcard.com

Software Library for laser cutter

If you're new to laser cutting, investing in a software library of pre-made designs can be a great way to get started. These libraries offer a wide variety of designs that you can use for inspiration or directly import into your laser cutting software.

With these top 10 accessories, you can elevate your laser cutting experience, improve project safety and results, and open up a world of creative possibilities. Remember to research and ensure compatibility with your specific laser cutter model before making any purchases. Happy laser cutting!

Shining a Light on Innovation: What's New in Laser Cutting

Laser cutting has become a vital tool for makers, manufacturers, and artists alike. But this technology is constantly evolving, offering new capabilities and making the process more efficient and user-friendly. Here's a look at some of the exciting trends in laser cutting:

1. Advancements in Laser Source Technology

More Powerful Diode Lasers: Traditionally, CO2 lasers have been the workhorse of laser cutting. However, diode lasers are becoming increasingly powerful. New models boast higher wattages, allowing them to tackle thicker materials like wood and even some metals.

Improved Beam Quality: Recent advancements are leading to diode lasers with a tighter beam focus. This translates to cleaner cuts and finer details, particularly beneficial for intricate designs.

2. User-Friendly Features for Everyone

Automatic Focus Adjustment: Gone are the days of manually fiddling with lenses. Modern machines can automatically adjust the focal length based on the material and thickness, ensuring optimal cutting performance.

Touchscreen Controls and Mobile Apps: The need for complex software interfaces is fading. Many new laser cutters offer intuitive touchscreen controls and even mobile app connectivity, making them easier to learn and operate.

3. Automation Takes Center Stage

Faster Material Handling: Laser cutting speed is impressive, but waiting for material loading and unloading can slow things down. Advanced automation systems can now handle these tasks swiftly, maximizing machine uptime.

Integrated Sorting and Stacking: Automation doesn't stop at loading. New systems can sort cut parts and stack them efficiently, saving time and minimizing post-processing work.

4. A Brighter Future for Laser Cutting

The future of laser cutting is bright. As technology continues to develop, we can expect even more powerful and versatile machines. We may also see the rise of new cutting techniques and the exploration of novel materials compatible with laser cutting. This will undoubtedly open doors for even more creative and innovative applications.

Whether you're a seasoned laser pro or just starting, these advancements make laser cutting more accessible and efficient than ever before. So, stay tuned as this exciting technology continues to revolutionize the way we create!

share

more_vert

Can you write a longer blog post about laser cutting?

volume_up

Laser Cutting: From Sci-Fi Dream to Maker's Playground - A Deep Dive

Remember those scenes in sci-fi movies where a laser beam effortlessly slices through metal? Well, laser cutting has come a long way from the realm of fiction and is now a widely used technology for makers, manufacturers, and artists.

But what exactly is laser cutting, and how does it work? In simple terms, a laser cutter focuses a powerful beam of light onto a material, directing a concentrated heat source that melts, vaporizes, or burns away the material along a predefined path. This allows for precise cutting of intricate designs on a vast array of materials.

A History Etched in Light: The Evolution of Laser Cutting

The concept of laser cutting emerged in the 1960s with the invention of the CO2 laser. Early machines were bulky, expensive, and limited in their capabilities. However, advancements in laser technology and computer control systems made laser cutting progressively more accessible and versatile.

Today, we see a diverse range of laser cutters available, from desktop-sized models suitable for hobbyists to industrial machines capable of handling thick metals and other challenging materials.

Beyond the Beam: Materials Laser Cutting Can Handle

The versatility of laser cutting is truly impressive. Here's a glimpse into the materials commonly used:

Wood: From delicate plywood crafts to intricate furniture components, laser cutters excel at precise wood cutting.

Acrylic: Laser cutting shines with acrylic, creating clear or colored signage, decorative pieces, and even custom jewelry.

Metals: While some require higher-powered lasers, thin sheets of metals like steel, aluminum, and brass can be laser cut for prototypes, electronics enclosures, and artistic creations.

Fabric: Laser cutting allows for clean, fray-free edges on fabrics, perfect for creating precise appliques, personalized clothing, and technical textiles.

Paper and Cardboard: From intricate greeting cards and packaging inserts to complex 3D models, laser cutting breathes life into paper and cardboard projects.

The list doesn't stop there! With proper settings and expertise, laser cutters can also handle materials like leather, rubber, and even some plastics.

Shining a Light on Applications: Where Laser Cutting Takes Flight

The applications of laser cutting are vast and ever-expanding. Here are some prominent areas where laser cutting plays a crucial role:

Prototyping: Laser cutters enable rapid creation of functional prototypes for product development, allowing for quick design iterations and testing.

Manufacturing: From intricate electronic components to customized parts for various industries, laser cutting offers precise and efficient production capabilities.

Crafting and DIY: Makers leverage laser cutters to create personalized gifts, home décor, unique jewelry, and a vast array of creative projects.

Signage and Displays: Laser cutting allows for precise creation of signs, banners, and displays with crisp lettering, intricate designs, and various materials.

Fashion and Apparel: Laser cutting takes fabric manipulation to a whole new level, enabling the creation of custom clothing, appliques, and unique design elements.

These are just a few examples, and the possibilities are truly limited only by one's imagination and the ever-evolving capabilities of laser cutting technology.

A Look Ahead: The Future of Laser Cutting

The future of laser cutting promises even greater advancements. Here's what we can expect to see:

More Powerful and Compact Lasers: The development of even more powerful and compact lasers will open doors for cutting thicker and more diverse materials.

Enhanced Automation and Integration: Expect to see increased automation in material handling, sorting, and integration with design software for a more streamlined workflow.

Novel Cutting Techniques: New techniques like laser percussion drilling and remote laser welding may be integrated into laser cutting systems, expanding their capabilities.

As laser cutting technology continues to evolve, one thing is certain: it will remain a vital tool for makers, manufacturers, and artists alike, pushing the boundaries of creativity and innovation. So, whether you're a seasoned laser user or just starting to explore this exciting technology, the future of laser cutting promises to be bright, precise, and full of endless possibilities.

share

more_vert

edit

Write 1000 word blog post about what's new in laser cutting

edit

Show drafts

Draft 1

Laser Cutting 2.0: A Revolution in Precision and Possibility

Laser cutting has become an indispensable tool in various industries, from rapid prototyping for engineers to crafting unique pieces fo...

Draft 1

Laser Cutting 2.0: A Revolution in Precision and Possibility

Laser cutting has become an indispensable tool in various industries, from rapid prototyping for engineers to crafting unique pieces for artists. This technology, once confined to bulky industrial machines, has evolved significantly in recent years. Let's delve deeper into the exciting innovations that are shaping the future of laser cutting.

A Beam Brighter Than Ever: Advancements in Laser Source Technology

The core of any laser cutter is its light source. Traditionally, CO2 lasers have reigned supreme, offering excellent cutting capabilities. However, the landscape is shifting with two key advancements:

The Rise of Powerful Diode Lasers: Diode lasers are becoming increasingly more powerful, making them viable alternatives to CO2 lasers. Their compact size allows for smaller and more affordable laser cutters. New models boast higher wattages, enabling them to tackle thicker materials like wood and even some metals. This opens doors for a wider range of users exploring laser cutting applications.

Improved Beam Quality: Beyond just power, beam quality plays a crucial role in cutting precision. Recent advancements are leading to diode lasers with a tighter beam focus. This translates to cleaner cuts with minimal heat-affected zones, ideal for intricate designs and delicate materials like thin acrylic or fabric. Additionally, a more focused beam reduces overall material waste, making laser cutting more sustainable.

User-Centric Innovations: Simplifying the Cutting Experience

Laser cutting has traditionally been associated with a significant learning curve. However, recent innovations are making it more accessible and user-friendly than ever before:

Automatic Focus Adjustment: Gone are the days of manually fiddling with lenses to achieve optimal focus. Modern laser cutters can now automatically adjust the focal length based on the material and its thickness. This ensures consistently precise cuts across various projects, eliminating human error and saving valuable setup time.

Touchscreen Controls and Mobile App Integration: Complex software interfaces and intricate button combinations are becoming a thing of the past. Many new laser cutters offer intuitive touchscreen controls with user-friendly interfaces. Some even boast mobile app connectivity, allowing for remote monitoring and job control. This simplifies operation for both seasoned users who appreciate efficiency and those new to laser cutting, allowing them to quickly grasp the basics.

The Rise of Automation: Taking Efficiency to New Heights

Laser cutting is known for its speed and precision, but there's always room for improvement. The integration of automation systems is pushing the boundaries of efficiency in laser cutting workflows:

Faster Material Handling Systems: While laser cutting itself is lightning-fast, the process can be slowed down by manual loading and unloading of materials. Advanced automation systems are now being incorporated into laser cutters. These systems can swiftly load and unload materials, maximizing machine uptime and throughput. This is particularly beneficial for high-volume production runs, where even small delays can significantly impact production timelines.

Integrated Sorting and Stacking Solutions: Automation doesn't stop at loading and unloading. New systems can sort cut pieces from different projects and efficiently stack them based on size or design. This not only saves time but also minimizes post-processing work like manual sorting and organization. This creates a more streamlined workflow, allowing users to focus on design and operation rather than handling finished pieces.

Beyond the Cutting Edge: Exploring New Materials and Techniques

The realm of materials compatible with laser cutting is constantly expanding. Here's a glimpse into some exciting possibilities:

Emerging Materials: With advancements in laser technology, previously challenging materials are becoming more accessible for laser cutting. New research is exploring the potential of laser cutting on materials like certain plastics, composites, and even thin sheets of glass. This opens doors for innovative applications in various industries.

Multi-Head Systems: For applications demanding diverse cutting techniques on a single project, multi-head laser cutting systems are being developed. These innovative machines can house multiple laser heads, each equipped with different wavelengths or functionalities. This allows for simultaneous cutting, etching, marking, and even micro-machining on the same material, creating new possibilities for complex designs and integrated functionality.

A Vision for the Future: Where Laser Cutting is Headed

The future of laser cutting is brimming with exciting possibilities. Here's what we can expect to see in the coming years:

Artificial Intelligence Integration: AI has the potential to revolutionize laser cutting by automating parameter optimization and process control. This could allow the machine to analyze the material, design complexity, and desired outcome and automatically adjust settings for optimal results. This would further reduce waste, improve cut quality, and make the process even more user-friendly.

Integration with Cloud-Based Design and Manufacturing Platforms: The future may see seamless integration of laser cutting with cloud-based design and manufacturing platforms. This would allow for collaborative design, remote monitoring of the cutting process, and on-demand manufacturing

Draft 2

Laser Cutting: A Revolution in Precision - Exploring Cutting-Edge Advancements

Laser cutting has transformed from a futuristic fantasy to a cornerstone technology for makers, manufacturers, and ar...

Draft 2

Laser Cutting: A Revolution in Precision - Exploring Cutting-Edge Advancements

Laser cutting has transformed from a futuristic fantasy to a cornerstone technology for makers, manufacturers, and artists. Its ability to precisely cut intricate designs on a vast array of materials has revolutionized the way we create.

But innovation in this field never stops. This post delves into the latest advancements that are pushing the boundaries of what's possible with laser cutting.

A Beam of Innovation: Advancements in Laser Source Technology

Power Up with Diode Lasers: Traditionally, CO2 lasers have been the dominant force in laser cutting. While they remain powerful tools, new advancements in diode lasers are changing the game.

These compact and energy-efficient lasers are becoming increasingly powerful, boasting higher wattages that can tackle thicker materials. This opens doors for projects involving wood, some metals, and other previously limited options.

Sharpening the Focus: Even beyond increased power, advancements are leading to diode lasers with a tighter beam focus. This translates to cleaner cuts with minimal heat-affected zones, crucial for achieving precise details in intricate designs. Artists and craftspeople working with delicate materials like thin wood or fabric will undoubtedly benefit from this improvement.

A User-Friendly Revolution: Making Laser Cutting More Accessible

Technology advancements are making laser cutting not only more powerful but also more user-friendly. Here's how:

Farewell Fiddling, Hello Automation: One major improvement is the rise of automatic focus adjustment. This eliminates the need for manual adjustments with lenses, ensuring optimal cutting performance regardless of material thickness.

Touchscreens and Apps Take Control: Complex software interfaces are becoming a thing of the past. Many new laser cutters boast user-friendly touchscreen controls for easy operation. Some even offer mobile app connectivity, allowing control and monitoring directly from smartphones or tablets. This simplifies the learning curve and makes laser cutting more accessible to beginners.

Automation Takes Center Stage: Streamlining the Workflow

The integration of automation technologies is transforming the laser cutting experience. Here's how it's boosting efficiency:

Faster Material Handling: Laser cutting itself is fast, but waiting for material loading and unloading can hinder production. Advanced automation systems can now handle these tasks swiftly, maximizing machine uptime and allowing operators to focus on design and post-processing.

Smart Sorting and Stacking: Automation doesn't stop at loading. New systems can sort cut parts based on design or project, and even automatically stack them efficiently. This saves time and minimizes post-processing work, further streamlining the workflow.