American Laser Cutter: Your Precision Cutting Partner in Los Angeles

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

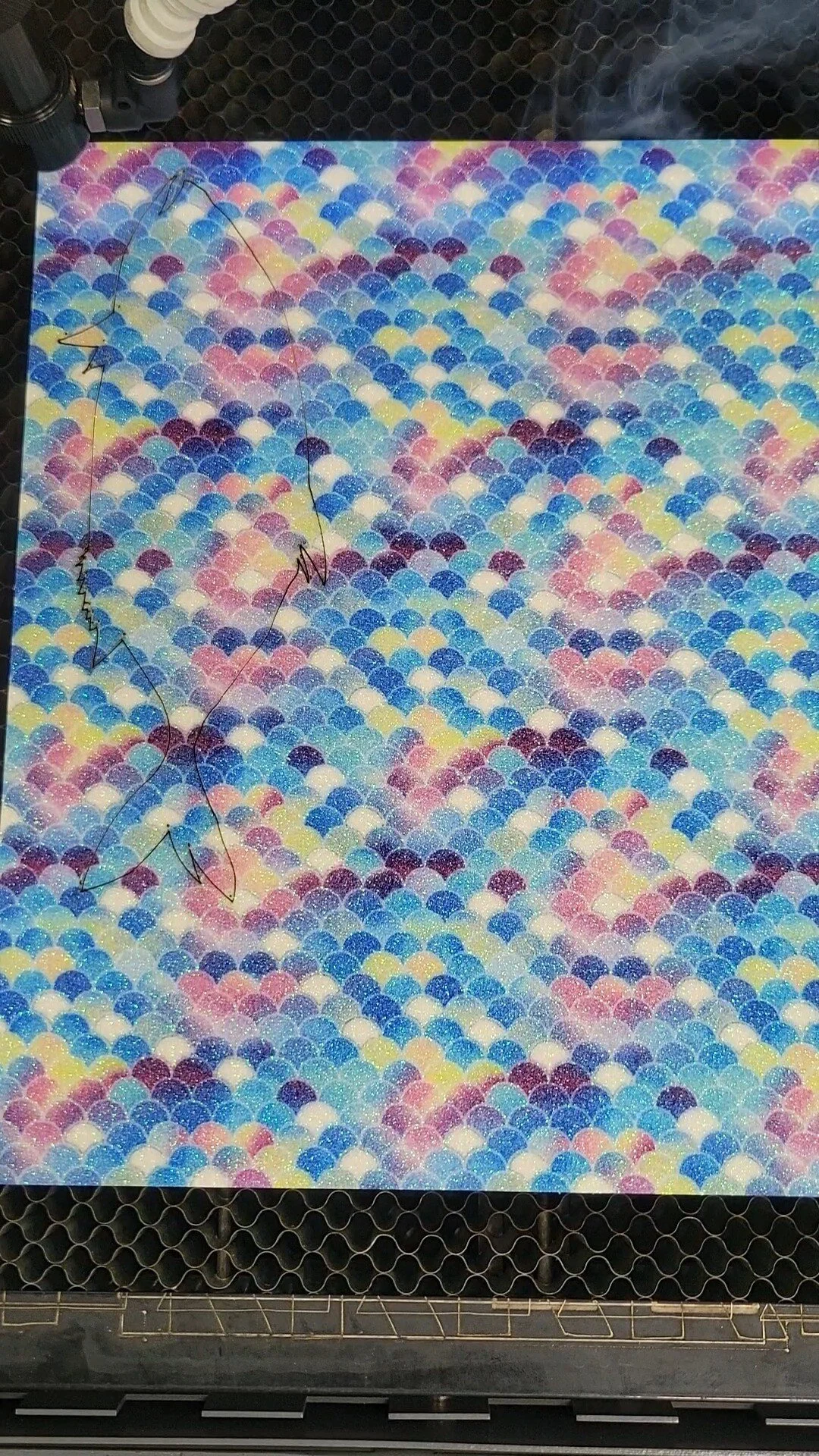

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

Who offers DIY laser cutting in Los Angeles?

Craving DIY laser cutting in LA? Look into American Laser Cutter. They offer access to high-powered machines & guidance. Pick your perfect match! #LosAngeles #lasercutting #DIY

Where is the best place to get laser cutting done in Los Angeles?

In LA & need laser cutting done? American Laser Cutter does it all! Precise cuts on acrylic, wood, plastic & more. Check them out for prototypes, signs, or unleash your creativity! #lasercutting #LosAngeles #makerspace

American laser cutter: laser cutting in Los Angeles

Need precise laser cutting in LA? Look no further than American Laser Cutter! They handle acrylic, wood, plastic & more. From prototypes to personalized gifts, they bring your vision to life. #lasercutting #LosAngeles #makerspace

What can you do with a laser cutter?

Unleash your creativity with a laser cutter! ✂️ Make personalized gifts, signs, coasters & more! Cut intricate designs in wood, acrylic, fabric & even leather! #lasercutting #diy #makerspace

Capturing Memories in Light: A Guide to Laser Engraving Photos

Capturing Memories in Light: A Guide to Laser Engraving Photos

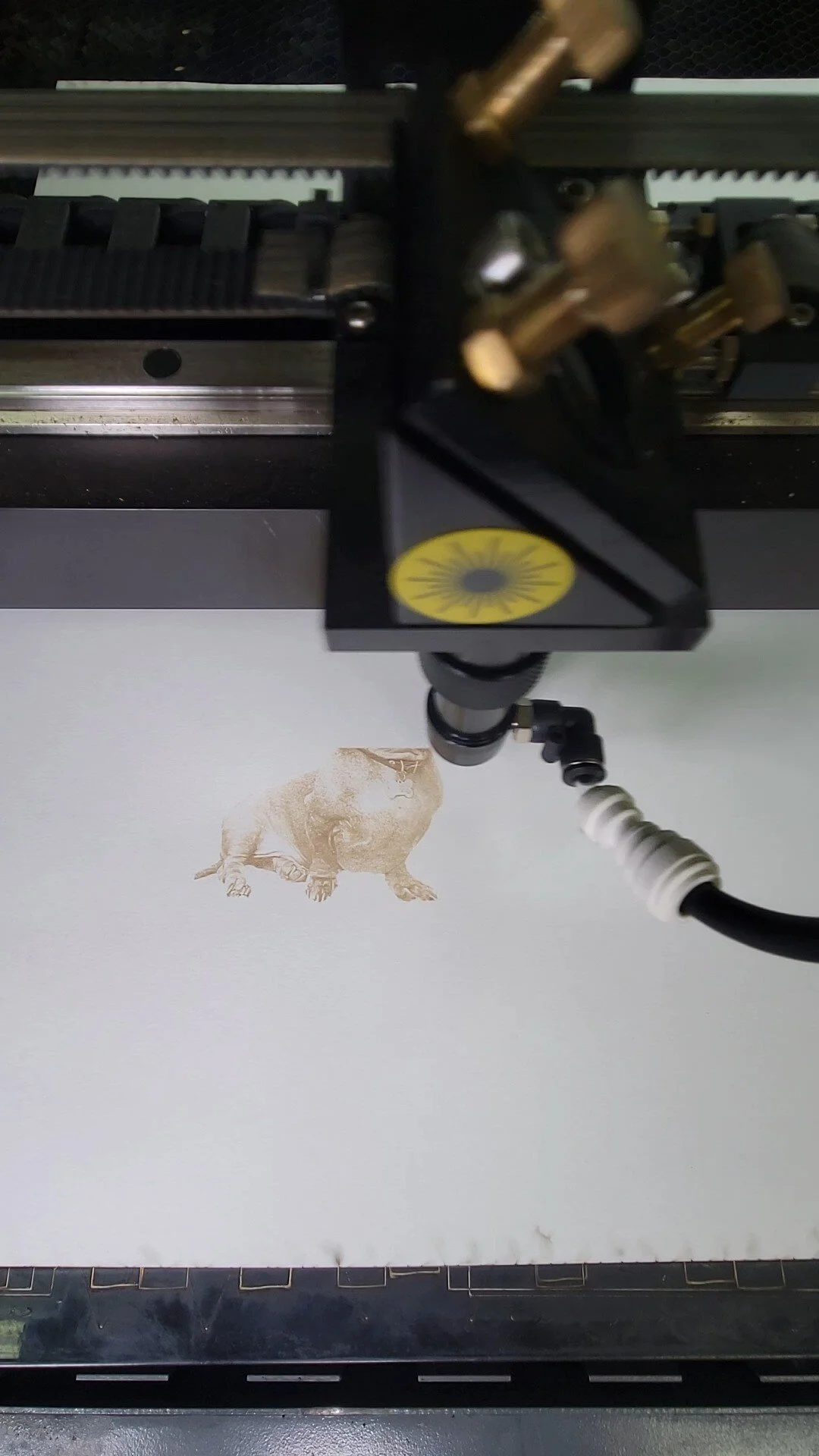

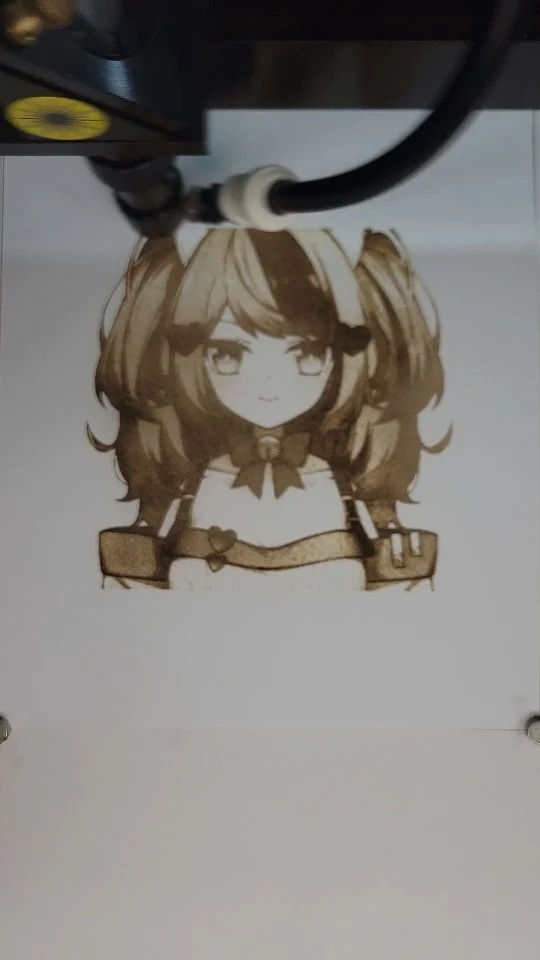

Laser engraving isn't limited to crisp lines and bold text. With the right techniques, you can use this technology to etch photos onto various materials, creating unique and personalized keepsakes. While it requires more finesse than standard engraving, laser engraving photos opens doors to a world of creative possibilities. Here's your guide to capturing those precious memories in laser-engraved light:

Choosing Your Tools: Laser Selection and Material Compatibility

Laser Power Matters: For photo engraving, a CO2 laser is generally preferred due to its ability to deliver a wider range of power levels. This allows for finer detail and control over the engraving process. Consult your laser user manual or a professional service provider to ensure compatibility.

Material Musings: The choice of material significantly impacts the outcome. Wood, acrylic, and some types of leather are popular options for photo engraving. Experiment with different materials to find one that complements your desired aesthetic.

Preparing Your Photo for Laser Magic

Black and White is Key: Laser engraving relies on variations in light and dark. Convert your photo to grayscale or black and white before engraving. Online photo editing tools or software can help you achieve this.

Finding the Right Balance: Adjust the contrast of your photo. High-contrast images with well-defined shadows and highlights translate best to laser engraving. Tools like Photoshop allow for contrast adjustments.

Dithering Decisions: Dithering is a process that uses tiny dots to create the illusion of grayscale tones. Experiment with different dithering patterns (available in most photo editing software) to find one that balances detail and smoothness in the engraved image.

Safety First: Essential Precautions

Fume Extraction is Crucial: Laser engraving any material, but especially photos, produces smoke and fumes. Ensure your laser is equipped with a proper fume extraction system to remove these airborne particles and maintain a safe working environment.

Goggles for Safety: Wear laser-safety glasses that are appropriate for your laser's wavelength to protect your eyes from the laser beam.

Engraving Your Memories: Bringing the Photo to Life

Test and Refine: Before engraving your final piece, do a test run on a scrap piece of material with the same settings. This allows you to fine-tune the laser power and dithering for optimal results.

The Engraving Process: Once satisfied with your test results, load your material and photo into the laser and initiate the engraving process. This can take time depending on the photo size and complexity.

Post-Processing Perfection (Optional):

Light Touch-Ups: Depending on the material, you might consider light sanding to remove any surface charring or debris. Always test this on a hidden area first to ensure it doesn't damage the engraved details.

Seal it Up (Optional): For certain materials like wood, applying a clear sealant can help protect the engraved image and enhance its visual appeal.

Beyond the Snapshot: Exploring Creative Possibilities

Multiple Photos, One Creation: Combine elements from multiple photos to create a unique collage or personalized design for your engraved piece.

Engraving on Curved Surfaces: While flat surfaces are ideal, some lasers can accommodate slightly curved objects. This opens doors for engraving photos on mugs, coasters, or other curved keepsakes.

Laser Engraving Photos: A Lasting Impression

By embracing the power of laser engraving, you can transform cherished photos into beautiful and enduring keepsakes. From personalized gifts and home décor to unique business cards and sentimental keepsakes, the possibilities are endless. So, dust off those favorite photos, grab your laser, and get ready to capture memories in a whole new light.

Etching Elegance: A Guide to Laser Engraving Paper

Etching Elegance: A Guide to Laser Engraving Paper

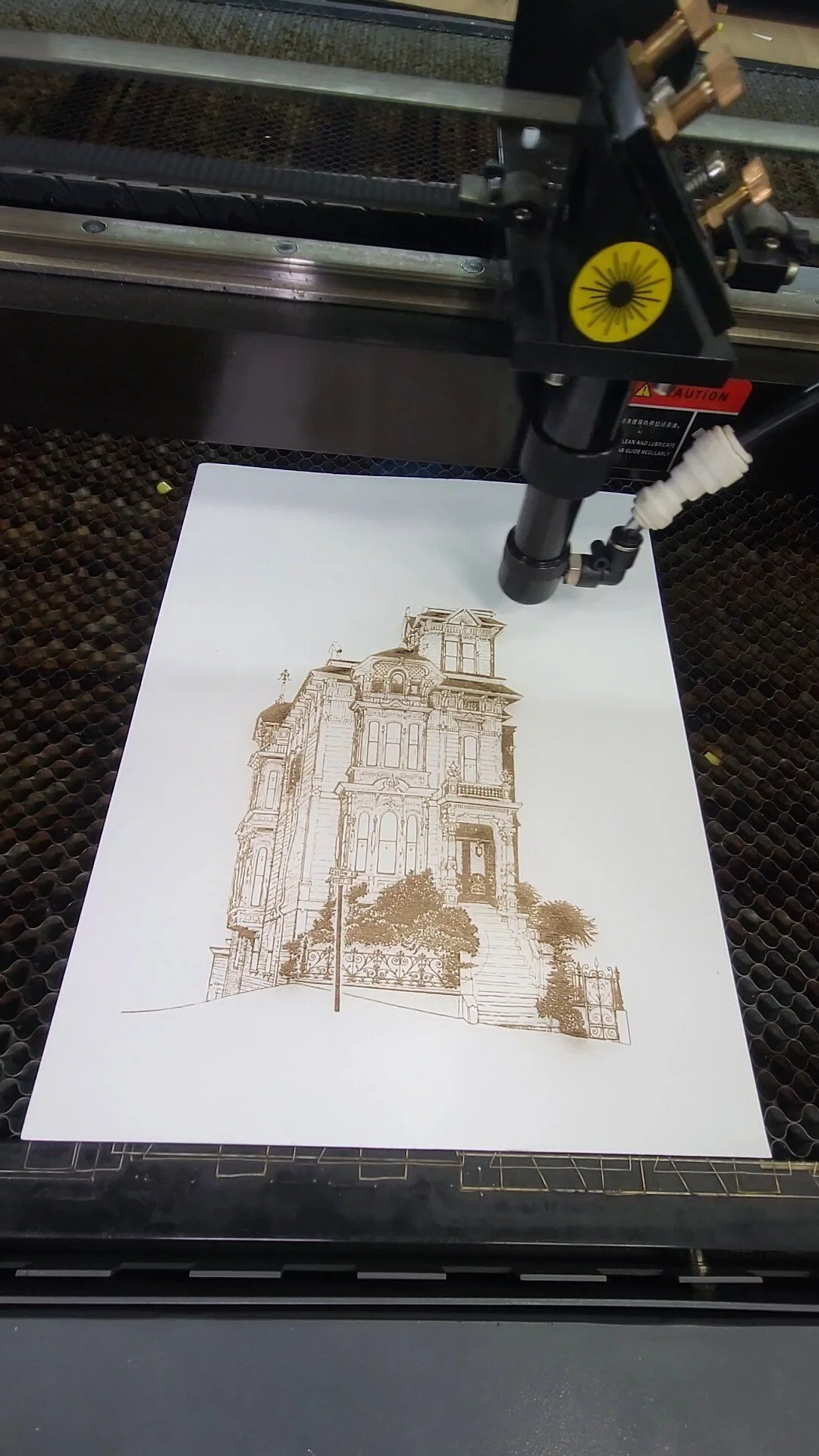

Paper, the humble canvas of countless ideas, takes on a new dimension with laser engraving. This technique goes beyond simple printing, creating beautiful textures, delicate details, and a touch of sophistication to your paper projects. While it might seem daunting, laser engraving paper is achievable with the right preparation and knowledge. Here's your guide to unlocking the potential of laser engraving on paper:

Choosing Your Weapon: Laser Selection and Paper Compatibility

Not All Lasers Are Created Equal: While CO2 lasers are the industry standard for engraving, some diode lasers might also be suitable for paper, depending on their power and wavelength. Consult your laser user manual or a professional service provider to ensure compatibility.

Paper Power: Not all paper is created equal for laser engraving. Opt for heavyweight, acid-free paper that can withstand the laser's heat. Consider papers specifically designed for laser engraving, which often have improved char resistance.

Design and Optimization: Preparing Your Masterpiece

Design with Care: Laser engraving works best with high-contrast, vector-based images. Simple line art, text, and logos translate well. Avoid photographs or images with heavy shading, as they might not translate clearly with laser engraving.

Optimizing for Success: Adjust your laser settings based on the paper thickness and desired engraving depth. Start with lower power settings and experiment on scrap paper to achieve the optimal balance between detail and charring. Consult your laser's user manual or online resources for specific settings recommendations.

Safety First: Essential Precautions

Fume Extraction is Key: Laser engraving paper produces smoke and fumes. Ensure your laser is equipped with a proper fume extraction system to remove these airborne particles and maintain a safe working environment.

Keep it Clear: Clear away any flammable materials from your laser's workspace to minimize fire hazards. Always supervise the laser engraving process and never leave it unattended.

Engraving Elegance: Bringing Your Design to Life

The Big Moment: Once your design is optimized and safety precautions are in place, it's time to engrave! Load your paper into the laser and initiate the engraving process. Patience is key – depending on the design complexity and paper size, engraving can take time.

Post-Processing Perfection: Depending on your desired outcome, you might consider light sanding to remove any surface charring. Test this on a scrap piece first to ensure the sanding doesn't damage the engraved details.

Beyond the Basics: Exploring Creative Possibilities

Multi-Layered Magic: Consider layering different colored papers to create stunning depth and visual interest in your engraved designs.

The Power of Stencils: Use laser-engraved paper as a stencil for other creative projects, like painting or spray-painting designs onto different surfaces.

Laser Engraving Paper: A World of Creative Potential

With a little preparation and the power of laser engraving, you can transform ordinary paper into extraordinary creations. From personalized invitations and unique coasters to elegant business cards and beautiful artwork, the possibilities are endless. So, unleash your inner artist, embrace the precision of laser engraving, and elevate your paper projects to a whole new level of sophistication.

The Power of Precision: Cutting Through Thick Acrylic with Laser Technology

The Power of Precision: Cutting Through Thick Acrylic with Laser Technology

For artists, designers, and makers, acrylic has become a ubiquitous material. Prized for its versatility, aesthetics, and durability, acrylic finds applications in countless projects – from signage and displays to art pieces and functional prototypes. However, working with thicker acrylic sheets can present challenges when traditional cutting methods are employed.

Enter laser cutting – a revolutionary technology that offers unmatched precision and the ability to conquer even the most substantial acrylic projects. Here's why laser cutting is the perfect solution for cutting through thick, half-inch acrylic:

Clean Cuts, Every Time:

Laser Sharp: Unlike traditional methods like saws or knives, which can leave behind rough edges and potential chipping, laser cutting utilizes a focused beam of light. This translates to incredibly clean and precise cuts, ensuring a professional finish for your even the most intricate designs on your half-inch acrylic.

Unveiling Design Possibilities:

Beyond the Basics: Laser cutting isn't limited to just straight cuts. It allows for the creation of highly detailed patterns, intricate lettering, and even custom designs on your acrylic pieces. This opens doors for unique and visually striking creations, pushing the boundaries of what's possible with acrylic.

Conquering Thickness:

Half-Inch Hero: Not all laser cutters are created equal. Many machines struggle with thicker materials. However, laser cutting technology has advanced significantly. Modern laser cutters, like those found in reputable laser cutting service providers, can effortlessly handle acrylic sheets up to a half-inch thick. This empowers you to create sturdy signs, dimensional displays, and substantial functional prototypes – all from the ever-popular acrylic.

The Advantages of Using Thick Acrylic:

Strength and Stability: Half-inch acrylic offers substantial advantages over thinner sheets. It provides superior strength and stability, making it ideal for projects that require structural integrity. This can be particularly beneficial for signage, displays, and functional prototypes.

Enhanced Visual Impact: Thicker acrylic creates a more substantial and impressive presence. It adds a touch of luxury and can elevate the perceived value of your creation. This is especially impactful for signage and art pieces.

Beyond the Cut: Additional Benefits of Laser Cutting

Streamlined Workflow: Many laser cutting service providers offer user-friendly online platforms. This allows you to upload your designs and receive a quick quote, eliminating the need for time-consuming consultations.

Material Versatility: While acrylic is a popular choice, laser cutters can handle a wider range of materials. This allows for greater flexibility and opens doors to exploring new creative avenues in your projects.

Expert Guidance: Reputable laser cutting service providers have a team of experts on hand to assist you. They can offer valuable advice on design optimization, material selection, and ensure your project achieves the desired outcome.

Laser Cutting: Transforming Your Acrylic Visions into Reality

Laser cutting technology has revolutionized the way we work with acrylic, especially for thicker sheets. By offering unmatched precision, the ability to create intricate designs, and conquering substantial thicknesses, laser cutting empowers you to bring your creative visions to life. So, ditch the traditional methods, embrace the power of laser cutting, and transform your half-inch acrylic projects into stunning realities.

American Laser Cutter: Your One-Stop Shop for Precise Acrylic Cutting in Los Angeles

American Laser Cutter: Your One-Stop Shop for Precise Acrylic Cutting in Los Angeles

Attention, Los Angeles makers, designers, and entrepreneurs! Look no further for your acrylic cutting needs than American Laser Cutter (ALC). They're the leading experts in laser cutting, offering unmatched precision and the ability to handle acrylic sheets up to a remarkable 1/2 inch thick.

Why Choose American Laser Cutter for Your Acrylic Projects?

Clean Cuts, Every Time: Laser cutting utilizes a focused beam of light, delivering unparalleled precision when cutting intricate designs and shapes into your acrylic. This eliminates the rough edges and potential for chipping associated with traditional cutting methods, resulting in a clean, professional finish for your projects.

Beyond the Flat Cut: ALC's laser cutting technology allows you to go beyond simple flat cuts. They can create intricate details, lettering, and even custom designs on your acrylic pieces, adding a unique touch to your creations.

Thicker is Better: Not all laser cutting services are created equal. ALC boasts the ability to cut through acrylic sheets up to a half-inch thick. This opens doors for creating sturdy signs, displays, art pieces, and functional prototypes – all from the versatile and attractive material that is acrylic.

The Benefits of Using Acrylic

Versatility Unbound: Acrylic is a popular choice for a wide variety of projects due to its versatility. It comes in a vast array of colors and finishes, from crystal clear to vibrant and opaque options. It's also lightweight, durable, and weather-resistant, making it suitable for indoor and outdoor applications.

Enhanced Aesthetics: Laser cutting acrylic creates a polished and professional look. The clean edges and ability to incorporate intricate details elevate the visual appeal of your projects, whether it's a custom sign for your business or a unique art piece for your home.

Functional and Beautiful: Don't be fooled by its good looks – acrylic is a surprisingly functional material. It's strong, shock-resistant, and offers excellent clarity. This makes it ideal for creating functional prototypes, display cases, and even household items.

American Laser Cutter: More Than Just Cutting

Seamless Workflow: ALC offers its services online, allowing you to upload your designs and receive a quick quote. This streamlines your workflow and eliminates the need for lengthy consultations.

Experience You Can Trust: The team at ALC is comprised of laser cutting experts who are passionate about helping you bring your ideas to life. They offer their expertise and guidance to ensure your project is a success.

Perfect for All Needs: Whether you're a hobbyist working on a personal project or a business owner requiring high-volume production, ALC caters to your needs. Their services are perfect for designers, artists, entrepreneurs, and anyone who wants to add a touch of laser-cut precision to their creations.

From Concept to Creation in Los Angeles

If you're in Los Angeles and searching for a reliable and precise acrylic cutting solution, look no further than American Laser Cutter. With their state-of-the-art laser cutting technology, ability to handle thick acrylic sheets, and commitment to quality, they're your one-stop shop for transforming your acrylic dreams into stunning realities. So, unleash your creativity, embrace the potential of laser cutting, and let American Laser Cutter be your partner in bringing your vision to life.

Beyond the Blade: How Laser Cutting Revolutionizes Sign Making

Beyond the Blade: How Laser Cutting Revolutionizes Sign Making

For decades, sign shops and manufacturers have relied on traditional methods like carving, sawing, and bending to create eye-catching signage. However, the landscape is rapidly changing. Enter laser cutting – a precise and versatile technology that's transforming the sign industry, offering a multitude of advantages over traditional methods. Here's how laser cutting is redefining the art of sign making:

Sharpening Up Your Sign Game: Precision Takes Center Stage

Unmatched Accuracy: Laser cutting utilizes a focused beam of light, achieving unparalleled precision when cutting intricate designs and lettering. This allows sign makers to create complex logos, delicate fonts, and fine details with remarkable clarity, elevating the overall quality and visual impact of their signs.

Clean Cuts, Consistent Results: Unlike traditional methods that can leave rough edges, laser cutting delivers clean, crisp cuts every time. This eliminates the need for extensive post-processing steps like sanding or deburring, saving time and labor costs.

Expanding Your Sign Horizons: Material Mastery

Material Menagerie: Laser cutting boasts remarkable versatility, capable of handling a wide range of sign-making materials like acrylic, wood, metal, and even some plastics. This opens doors to creating unique and innovative signs that cater to a broader range of client needs and aesthetic preferences.

Lightweight Signs, Big Impact: Laser cutting allows for the creation of lightweight signs without compromising on durability. This is particularly beneficial for large-scale signs or those mounted on walls or ceilings, reducing installation complexity and potential weight limitations.

Speeding Up Production: Time is Money

Faster Turnarounds: Laser cutting significantly reduces production time compared to traditional methods. Designs can be uploaded to the laser cutter directly, eliminating time-consuming setup processes. This translates to faster project completion times and the ability to meet tight deadlines more efficiently.

Prototyping Powerhouse: For custom signs, laser cutting allows for the rapid creation of prototypes. This enables sign makers to experiment with different designs and get client approval before full-scale production, streamlining the design process and minimizing costly errors.

Beyond the Cut: Additional Benefits for Sign Makers

Design Flexibility: Laser cutting integrates seamlessly with design software. This allows for easy modifications to existing designs and the creation of truly custom signage that reflects a brand's unique identity.

Reduced Waste: Laser cutting software optimizes material placement, minimizing waste during the cutting process. This translates to cost savings on materials and promotes a more sustainable approach to sign making.

Multi-Layered Magic: Laser cutting can be used to create layered signs with depth and dimension. This adds a touch of sophistication and visual interest to any sign, making it stand out from the competition.

A Brighter Future for Signs: Laser Cutting Leads the Way

Laser cutting is no longer just an option, it's becoming an essential tool for sign shops and manufacturers. Its ability to deliver unmatched precision, work with a variety of materials, and expedite production processes allows sign makers to create high-quality, unique signage that meets the demands of today's competitive market. So, ditch the traditional methods, embrace the laser, and watch your sign business illuminate the path to success, one precise cut at a time.

From Prototype to Profit: How Laser Cutting Saves Businesses Money

From Prototype to Profit: How Laser Cutting Saves Businesses Money

In today's competitive business landscape, every penny counts. Businesses constantly seek ways to streamline processes, reduce waste, and ultimately, boost their bottom line. Enter laser cutting – a technology that's no longer confined to industrial giants. For businesses of all sizes, laser cutting offers a multitude of cost-saving advantages, transforming the way products are designed, prototyped, and manufactured.

Slashing Production Costs Across the Board:

Prototype Powerhouse: Laser cutting empowers businesses to create prototypes in-house, eliminating the need for expensive outsourced fabrication. This allows for rapid design iteration and testing, minimizing costly mistakes during full-scale production.

Small Batch Bonanza: Gone are the days of minimum order quantities. Laser cutting allows for the creation of small batches of custom products, ideal for testing new market ideas or catering to niche audiences. This reduces the risk of overstocking and wasted inventory.

Material Magic: With laser cutting, businesses can source materials directly, potentially at lower costs compared to pre-fabricated items. They have complete control over material selection, allowing them to find cost-effective options that meet their project needs.

Beyond the Bottom Line: Savings in Disguise

Time is Money: Laser cutting eliminates the back-and-forth communication and waiting times associated with traditional manufacturing. Businesses can create designs on their own schedule, expediting the production process and potentially getting products to market faster.

Reduced Waste, Increased Savings: Laser cutting software allows for optimized material placement, minimizing waste during the cutting process. This translates to cost savings on materials and promotes a more sustainable approach to production.

Salvaged Treasures: Laser cutting opens doors to utilizing salvaged or scrap materials. Transform thrifted finds or leftover materials into unique products, adding a touch of upcycling magic to your offerings while saving money on brand new materials.

Making the Cut: Considerations Before You Invest

DIY vs. Do It For Me: Evaluate your needs. For occasional projects, consider outsourcing laser cutting services. For frequent use, purchasing a personal laser cutter might be cost-effective in the long run.

Membership Perks: Explore public makerspaces with laser cutters. Membership fees can offer access to laser cutting equipment alongside additional tools and resources.

Learning Curve Savings: While DIY laser cutting offers cost savings, it involves a learning curve. Factor in the potential costs of materials and the time investment needed to master the technology before calculating your overall savings.

The Future of Frugal Fabrication

Laser cutting is revolutionizing the way businesses operate. From slashing production costs to reducing waste, this technology empowers businesses to become more efficient and profitable. So, ditch the hefty price tags, embrace laser cutting, and embark on a journey of cost-effective creation. Remember, with a little planning and some laser know-how, you can transform your business from prototype to profit, one precise cut at a time.

Lights, Camera, Laser Cut! How This Tech is Transforming Filmmaking

Lights, Camera, Laser Cut! How This Tech is Transforming Filmmaking

The world of filmmaking thrives on imagination and meticulous detail. From futuristic cityscapes to intricate costumes, creating a believable cinematic experience requires an arsenal of tools and techniques. Enter laser cutting – a technology rapidly making its way onto Hollywood's high-tech stage. Here's how laser cutting is transforming the film industry, one precise cut at a time:

Building Block Bonanza: Set Design Gets a Laser Edge

Detailed Sets, Faster Builds: Laser cutting allows scenic designers to create intricate set pieces with unmatched precision. From detailed facades and decorative panels to customized furniture and architectural elements, laser cutters bring imagination to life with remarkable speed and accuracy. This translates to faster set construction and reduced overall production time.

Lightweighting the Scene: Laser cutting allows for the creation of lightweight yet sturdy set pieces. This is particularly beneficial for large-scale structures or props that need to be easily moved or suspended.

Costume Capers: Laser Cutting Threads the Look

Haute Couture Goes High-Tech: Laser cutting adds a touch of high-tech magic to costume design. Intricate patterns, delicate lacework, and even layered fabric details can be achieved with laser precision, creating unique and eye-catching costumes that stand out on screen.

Armor Up!: Laser cutting isn't just for delicate fabrics. The technology can be used to create intricate armor pieces, costume accessories, and even helmets for sci-fi or fantasy films. The clean cuts and ability to handle a variety of materials ensure a polished look and a touch of futuristic flair.

Prop Perfection: From Practical to Fantastical

Weapons with Wow Factor: Laser cutting can create realistic-looking, yet safe, prop weapons. From futuristic firearms to intricate swords and shields, laser cutters deliver the detail and clean cuts necessary to bring these props to life.

Futuristic Flair: Laser cutting excels at creating props with a futuristic or otherworldly feel. Think alien gadgets, control panels, or even spaceship parts – the possibilities are endless. The ability to incorporate lighting elements alongside the cutting process further enhances the futuristic aesthetic.

Beyond the Cut: Additional Benefits for Filmmakers

Safety First: Laser cutting eliminates the need for sharp blades or other potentially dangerous tools during prop and set creation. This translates to a safer working environment for film crews.

Repeatability and Customization: The digital nature of laser cutting ensures consistent results. This is crucial for creating multiple identical props or set pieces for complex scenes with multiple takes. Additionally, laser cutting allows for easy customization of designs, enabling filmmakers to adapt props or sets to their specific needs.

Waste Reduction: Laser cutting software optimizes material placement, minimizing waste during the cutting process. This translates to cost savings and promotes a more sustainable approach to film production.

A Collaborative Future: Laser Cutting and Beyond

Laser cutting represents a powerful tool for filmmakers, but it's just one piece of the puzzle. The true magic lies in the collaboration between designers, engineers, and the laser cutting experts who translate creative visions into tangible realities. As this technology continues to evolve and become more accessible, we can expect to see even more innovative applications emerge, pushing the boundaries of what's possible in the ever-evolving world of filmmaking. So, the next time you're captivated by a stunning set design or a meticulously crafted prop, remember, there's a good chance a laser cutter played a behind-the-scenes role in creating that cinematic magic.

Sharper, Faster, Better: Why Laser Cutting Outshines Traditional Manufacturing

Sharper, Faster, Better: Why Laser Cutting Outshines Traditional Manufacturing

In the ever-evolving world of manufacturing, precision and efficiency reign supreme. Traditional methods, while reliable, can sometimes struggle to keep pace with the demands of modern production. Enter laser cutting – a technology that's revolutionizing various industries with its clean cuts, unparalleled speed, and remarkable versatility. Here's why laser cutting often outshines traditional manufacturing techniques:

Precision Takes Center Stage:

Microscopic Marvels: Unlike traditional methods that rely on blades or punches, laser cutting utilizes a focused beam of light, achieving unmatched accuracy. This allows for intricate designs and features to be cut with incredible detail, ideal for delicate components in electronics or intricate patterns in jewelry.

Repeatability Reigns: Laser cutting is a computer-controlled process, ensuring consistent results every time. This eliminates human error and guarantees identical parts, crucial for maintaining quality control in high-volume production runs.

Speed Demon of the Manufacturing World:

Time is Money: Laser cutters operate at lightning speed, significantly reducing production time compared to traditional methods. This translates to faster turnaround times, increased productivity, and the ability to meet tight deadlines more efficiently.

Minimal Setup, Maximum Output: Unlike traditional methods that require extensive setup and tool adjustments, laser cutting boasts minimal setup time. This allows for quick transitions between different designs, maximizing production time and minimizing downtime.

Material Mastery: A World of Possibilities

Material Menagerie: Laser cutting boasts remarkable versatility, capable of handling a wide range of materials. From delicate fabrics and thin plastics to robust metals and even some types of wood, laser cutting offers a level of material flexibility that traditional methods struggle to match. This opens doors for innovative product design and broader applications.

Minimal Material Waste: Laser cutting software allows for optimized material placement, minimizing waste during the cutting process. This translates to cost savings on materials and promotes a more sustainable approach to manufacturing.

Beyond the Cut: Additional Advantages of Laser Cutting

Clean Cuts, Reduced Finishing: Laser cutting delivers clean, burr-free edges, minimizing the need for extensive post-processing steps such as sanding or deburring. This translates to a more streamlined production process and reduced labor costs.

Reduced Heat Affected Zone (HAZ): Unlike some traditional methods that generate significant heat, laser cutting offers a narrow heat-affected zone. This minimizes material distortion and warping, ensuring the integrity of the final product.

Scalability for Growth: Laser cutting systems can be easily scaled to accommodate changing production demands. This allows manufacturers to adapt to market fluctuations and future growth needs without significant upfront investments in new machinery.

When Traditional Methods Still Reign Supreme

It's important to acknowledge that traditional manufacturing techniques still hold a place in certain situations. For instance, very thick materials or bulk material removal might be better suited for processes like stamping or waterjet cutting. The ideal manufacturing method depends on the specific material, project requirements, and production volume.

The Future of Manufacturing is Sharp

Laser cutting technology is rapidly transforming the manufacturing landscape. Its ability to deliver unmatched precision, speed, and material versatility is pushing the boundaries of what's possible. As laser cutting technology continues to evolve and become more accessible, we can expect to see even wider adoption across various industries. So, the next time you see a meticulously crafted product or marvel at a complex electronic device, remember, there's a good chance a laser played a role in bringing that vision to life.

SoCal Takes the Crown: Why Southern California Reigns Supreme in US Manufacturing

SoCal Takes the Crown: Why Southern California Reigns Supreme in US Manufacturing

While headlines often herald the decline of American manufacturing, a powerhouse quietly persists on the West Coast. Southern California, with its sprawling industrial centers and rich history of innovation, holds the undisputed title of the manufacturing capital of the United States. Here's a deep dive into the factors that solidify SoCal's reign:

A Legacy of Industrial Might:

World War II Spark: Southern California's manufacturing prowess can be traced back to World War II. The region's vast aerospace industry boomed as a result of government contracts, laying the foundation for a skilled workforce and a robust infrastructure.

Aerospace Ascendancy: Following the war, Southern California continued to dominate the aerospace sector. Companies like Boeing, Lockheed Martin, and Northrop Grumman remain headquartered here, attracting a talent pool of engineers, designers, and manufacturing specialists. This focus on high-tech, precision manufacturing continues to shape the region's identity.

A Strategic Location and Infrastructure:

Twin Ports Powerhouse: Los Angeles and Long Beach boast the busiest container ports in the United States, handling a significant portion of the nation's imports and exports. This unparalleled access to global trade lanes facilitates the movement of raw materials and finished goods, making Southern California a strategic hub for manufacturers.

A Network of Transportation Arteries: An extensive network of freeways, rail lines, and airports connects Southern California to domestic and international markets. This efficient transportation system allows manufacturers to receive materials quickly and ship their products efficiently, fostering a dynamic and competitive environment.

Beyond the Basics: A Diverse Manufacturing Landscape

Tech Titan Territory: Southern California isn't just about airplanes and ships. The region is a hotbed for tech innovation, with a booming tech industry that thrives alongside traditional manufacturing. This synergy fosters collaboration and the development of cutting-edge technologies that are then integrated into the manufacturing process, keeping SoCal at the forefront of efficiency and quality.

A Hub for Entertainment and Lifestyle: Hollywood and the broader entertainment industry call Southern California home. This translates to a demand for specialized manufacturing, from film and television production equipment to costumes and props. This niche market adds another layer to the region's diverse manufacturing landscape.

Challenges and Considerations:

Cost of Living Concerns: Southern California's high cost of living can be a barrier for some manufacturers. However, the skilled workforce, robust infrastructure, and access to markets often outweigh these concerns for many companies.

Environmental Impact: Manufacturing can have a significant environmental impact. However, Southern California is a leader in adopting sustainable practices, with many manufacturers implementing eco-friendly processes and materials.

The Future of Manufacturing in SoCal

Southern California's manufacturing sector is constantly evolving. With its strong foundation, strategic location, and commitment to innovation, the region is well-positioned to maintain its dominance in the years to come. We can expect to see continued growth in high-tech manufacturing, a focus on sustainability, and a deeper integration of technology within the manufacturing process. SoCal's reign as the manufacturing capital of the US seems likely to continue for the foreseeable future.

Sun, Surf, and Sharp Cuts: Why Los Angeles Reigns Supreme in DIY Laser Cutting

Sun, Surf, and Sharp Cuts: Why Los Angeles Reigns Supreme in DIY Laser Cutting

The City of Angels isn't just a haven for celebrities and sunshine. Los Angeles is quietly carving its niche as the premier destination for do-it-yourself (DIY) laser cutting in the United States. Here's why LA cuts above the rest:

A Thriving Maker Scene:

Makerspace Mania: Los Angeles boasts a vibrant network of makerspaces, many equipped with state-of-the-art laser cutters. These hubs provide access to the technology, foster collaboration, and offer workshops for beginners. From TechShop LA to Hivemind Makerspace, the options cater to every skill level and project need.

DIY Service Powerhouse: LA isn't short on service providers offering DIY laser cutting options. Businesses like American Laser Cutter and Lasers Over Los Angeles cater to both hobbyists and entrepreneurs, providing user-friendly interfaces and a variety of materials to choose from.

A City Built on Creativity:

Design-Driven Culture: Los Angeles is a melting pot of creativity, fostering a strong design culture. This translates to a high demand for laser cutting services, pushing the boundaries of innovation and accessibility. From architects refining their models to fashion designers crafting custom jewelry, the applications are endless.

Tech-Savvy Community: Angelenos are a tech-savvy bunch, readily embracing new technologies. This early adoption of DIY laser cutting fuels the industry's growth and ensures a constant influx of fresh ideas and applications.

Beyond the Coast: Advantages Unique to LA

Climate Control: Los Angeles' mild climate minimizes the risk of humidity-related issues with laser cutting materials, unlike some coastal cities. This translates to more consistent results and less material warping during the cutting process.

Manufacturing Hub: LA sits in close proximity to major manufacturing centers. This easy access to a wide variety of materials at competitive prices empowers DIY laser cutters to experiment and find the perfect fit for their projects.

A Supportive Community: The DIY laser cutting scene in LA thrives on collaboration. Online forums, meetups, and workshops foster a supportive community where makers can share knowledge, troubleshoot challenges, and inspire each other's creativity.

California Dreamin' of Laser-Cut Creations

Los Angeles offers a unique blend of sunshine, innovation, and a thriving maker scene, making it the ideal breeding ground for DIY laser cutting. With its abundance of resources, supportive community, and ideal climate, LA empowers anyone to become a maker and transform their ideas into tangible laser-cut realities. So, whether you're a seasoned artisan or a curious newcomer, Los Angeles welcomes you with open arms (and powerful lasers) to join the DIY laser cutting revolution!

It's important to note that while Los Angeles has a strong case for being a leader in DIY laser cutting, other cities might have unique strengths or advantages depending on specific criteria. This article highlights the factors that make LA a compelling choice.

The Top Spots for DIY Laser Cutting in Los Angeles: Unleash Your Inner Maker

The Top Spots for DIY Laser Cutting in Los Angeles: Unleash Your Inner Maker

Los Angeles, the land of sunshine, dreams, and now, DIY laser cutting! This exciting technology is becoming increasingly accessible, empowering Angelenos to transform their ideas into tangible objects. Whether you're a budding entrepreneur, a crafty hobbyist, or an architect refining your designs, DIY laser cutting offers a gateway to endless creative possibilities. But with so many options available, where do you begin? Fear not, fellow makers, for this guide will unveil the top spots for DIY laser cutting in the City of Angels!

pen_spark

1. American Laser Cutter

Opens in a new window www.americanlaserco.com

American Laser Cutter, Los Angeles

Located in the heart of downtown LA, American Laser Cutter offers a one-stop shop for all your DIY laser cutting needs. They provide both DIY services and classes, making them perfect for beginners and experienced makers alike. Their user-friendly approach and expertise will have you laser cutting like a pro in no time.

2. Los Angeles Public Library - Octavia Lab

Opens in a new window youmedia.org

Los Angeles Public Library Octavia Lab

For those seeking a budget-friendly option, the Los Angeles Public Library system offers limited access to laser cutters through their Octavia Lab. While membership or residency requirements may apply, and usage typically requires prior training and scheduling, it's a great opportunity to experiment with laser cutting before investing in your own setup.

3. Public Makerspaces with Laser Cutters

Los Angeles boasts a thriving maker scene, and many public makerspaces offer laser cutters for member use. These spaces provide a collaborative environment, access to various tools and resources, and the opportunity to connect with other makers. Some popular options include:

TechShop LA: Offers a vast array of tools and equipment, including laser cutters.

Hivemind Makerspace: Provides laser cutting services alongside 3D printing and woodworking equipment.

LA Makerspace: A membership-based makerspace with laser cutting capabilities and a focus on creative collaboration.

Choosing the Right Spot for You

With so many fantastic options available, the best place for DIY laser cutting in Los Angeles depends on your specific needs and preferences. Here are some factors to consider:

Budget: DIY laser cutting services typically charge by the minute or project complexity. Public libraries and makerspaces offer a more economical option, but with limited access and scheduling constraints.

Experience Level: If you're a beginner, opting for a service provider with classes or tutorials can be beneficial. More experienced makers might prefer the flexibility and control offered by independent shops.

Project Requirements: Consider the size and complexity of your project. Some facilities might have limitations on material size or thickness.

The Future of Making is Here

DIY laser cutting is democratizing the world of creation in Los Angeles. It empowers individuals to become makers, entrepreneurs, and bring their ideas to life. So, grab your digital design files, explore the possibilities offered by DIY laser cutting in LA, and get ready to transform your vision into reality!

From Sketch to Scale Model: Why DIY Laser Cutting Empowers LA Architects

From Sketch to Scale Model: Why DIY Laser Cutting Empowers LA Architects

Los Angeles, a city known for its architectural marvels, is now witnessing a new wave of creation – fueled by do-it-yourself (DIY) laser cutting. This technology, once relegated to industrial settings, is transforming the way architects in LA approach their craft. By putting the power of precise cutting directly in their hands, DIY laser cutting empowers architects to create intricate models, refine designs faster, and explore their vision with unprecedented freedom.

Building Dreams, One Precise Cut at a Time:

Rapid Prototyping for Faster Design Iteration: Gone are the days of laborious hand-crafted models. Laser cutting allows architects to create detailed scale models in a fraction of the time. This rapid prototyping fosters faster design iteration, enabling exploration of various options and quicker feedback loops with clients and stakeholders.

Unmatched Precision for Intricate Details: Laser cutting delivers unparalleled accuracy, crucial for showcasing complex architectural elements. From intricate facades and delicate latticework to precise landscaping features, laser-cut models bring architectural visions to life with stunning detail.

Material Versatility for Exploration and Presentation: Laser cutters handle a wide range of materials like wood, acrylic, and even some metals. This allows architects to experiment with different materials, not just for model making, but also to explore the materiality of their designs in a tangible way.

Beyond the Model: A Multifaceted Tool for Architects

Creating Presentation-Ready Masterpieces: Laser-cut models aren't just for internal design exploration. The high level of detail and precision allows architects to create stunning presentation models that impress clients and secure project approvals.

Functional Model Prototyping: Laser cutting can be used to create functional models with moving parts. These models allow for testing spatial flow, user experience, and even building systems within the model itself, fostering a deeper understanding of the design's functionality.

Custom Signage and Design Elements: From laser-cut building identification signs to architectural inlays for furniture or walls, DIY laser cutting allows architects to extend their design vision beyond the model and into the built environment itself.

The LA Advantage: A Thriving Maker Scene

Los Angeles boasts a vibrant maker scene with numerous resources for architects interested in DIY laser cutting:

Makerspaces with Laser Cutters: Several public libraries and private makerspaces offer laser cutters for member use. These spaces provide access to the technology and a collaborative environment for architects to learn and network.

DIY Laser Cutting Services: Many service providers in LA offer DIY options, allowing architects to upload their designs and choose materials for precise cutting. This is a convenient option for one-off projects or those requiring specialized materials.

A Few Considerations Before You Cut:

Learning Curve: While user-friendly, laser cutting requires some basic training. Familiarize yourself with design software and safety protocols before diving in.

Project Suitability: DIY laser cutting might not be ideal for all architectural models, particularly large-scale ones. Evaluate the project's needs and choose the most appropriate approach.

Safety First: Laser cutting involves powerful lasers and can generate fumes. Always prioritize safety by following proper protocols and wearing necessary protective gear.

The Future of Architectural Design in LA

DIY laser cutting is revolutionizing the way architects in Los Angeles approach their craft. It empowers them to explore design concepts rapidly, showcase their vision with unmatched precision, and even create functional prototypes. As the technology becomes more accessible and integrated with design workflows, we can expect even more innovative and creative applications to emerge, shaping the future of architectural design in the City of Angels. So, LA architects, grab your digital files, embrace the laser cutter, and watch your architectural dreams transform into precise realities.

From Textbooks to Tangible Projects: Why DIY Laser Cutting is a Boon for LA Students

From Textbooks to Tangible Projects: Why DIY Laser Cutting is a Boon for LA Students

Los Angeles, a melting pot of creativity and innovation, offers a unique opportunity for students: the chance to delve into the exciting world of DIY laser cutting. This technology, once confined to industrial settings, is becoming increasingly accessible, empowering students to bridge the gap between theory and practice, transforming ideas into tangible objects. So, whether you're a budding engineer, a future fashion designer, or simply a curious learner, here's why DIY laser cutting is a game-changer for LA students:

Igniting the Spark of Innovation:

Learning by Doing: Laser cutting allows students to take their classroom knowledge and apply it in a real-world setting. Transforming digital designs into physical objects fosters a deeper understanding of design principles, engineering concepts, and material properties.

Prototyping Playground: Students can bring their ideas to life quickly and affordably. This rapid prototyping allows for testing, iterating, and refining designs – a crucial skill in today's innovation-driven world.

Unlocking Creativity: DIY laser cutting empowers students to express themselves artistically. From designing personalized jewelry to creating unique school project presentations, the possibilities for creative exploration are endless.

Sharpening Skills for the Future:

STEM Education Revolution: Laser cutting injects a dose of excitement into STEM education. Students can visualize complex scientific and engineering concepts through hands-on creation, fostering a love for these critical fields.

Building a Competitive Edge: Understanding laser cutting technology and its applications can give LA students a valuable edge in future job markets. This skillset is increasingly sought after in various industries, from product design to architecture.

Problem-Solving Prowess: The process of creating laser-cut projects involves problem-solving and critical thinking. Students need to consider material selection, design optimization, and potential challenges, honing valuable skills applicable to all aspects of life.

Learning Opportunities in the City of Angels:

Public Makerspaces: Several Los Angeles Public Libraries offer limited access to laser cutters through their makerspaces. These spaces provide a platform for students to experiment and learn the basics of laser cutting technology.

Educational Programs: Some schools and universities in LA are incorporating laser cutting into their curriculum, offering dedicated workshops and classes for students to explore this technology.

DIY Laser Cutting Services with Student Discounts: Several service providers in LA offer DIY laser cutting options with student discounts. These businesses can be a valuable resource for students working on individual projects or participating in design competitions.

Safety and Considerations:

Safety First: Laser cutting involves powerful lasers and can generate fumes. Always prioritize safety by following proper protocols and wearing necessary protective gear when using a laser cutter.

Parental Guidance: For younger students, it's crucial for parents or guardians to be present and supervise their laser cutting activities.

Design Software Skills: Most laser cutters require designs in specific file formats. Students can benefit from learning basic design software skills to create compatible files for their projects.

The Future of Learning in LA

DIY laser cutting is transforming the educational landscape in Los Angeles. It offers students a dynamic platform to bridge the gap between theory and practice, fostering innovation, creativity, and valuable 21st-century skills. So, LA students, embrace the laser cutter, unleash your inner maker, and embark on a journey of learning that goes beyond textbooks and into the exciting realm of hands-on creation!

Cut Costs, Not Creativity: Exploring the Savings of DIY Laser Cutting in LA

Cut Costs, Not Creativity: Exploring the Savings of DIY Laser Cutting in LA

Los Angeles, the land of dreams and...expensive everything? While creativity thrives in the City of Angels, bringing those artistic visions to life can often hit your wallet hard. But fear not, crafty Angelenos! DIY laser cutting offers a ray of hope, slashing costs and empowering you to become a maker without breaking the bank. Let's delve into the financial benefits of wielding your own laser in the land of sunshine:

Slashing Production Costs:

From Prototype to Production: Skip the middleman! Laser cutting allows you to create prototypes in-house, eliminating the need for expensive outsourced fabrication. Refine your design, iterate quickly, and bring your product to life without hefty upfront costs.

Small Batch Bonanza: No minimum order quantities here! DIY laser cutting empowers you to create small batches of custom items, perfect for testing the market with new product ideas or catering to niche clientele. This eliminates the risk of overstocking and wasted inventory.

Material Magic: DIY laser cutting allows you to source materials directly, potentially at lower costs compared to pre-fabricated items. You have complete control over material selection, allowing you to find cost-effective options that suit your project needs.

Beyond the Bottom Line: Savings in Disguise

Time is Money: DIY laser cutting eliminates the back-and-forth communication and waiting times associated with traditional manufacturing. With your own laser cutter, you can create designs on your own schedule, saving valuable time and potentially expediting your project timeline.

Reduced Waste, Increased Savings: Laser cutting software allows for optimized material placement, minimizing waste during the cutting process. This translates to cost savings on materials and promotes a more sustainable approach to creation.

Unlocking Hidden Gems: DIY laser cutting opens doors to utilizing salvaged or scrap materials. Transform thrifted finds or leftover materials into unique creations, adding a touch of upcycling magic to your projects while saving money on brand new materials.

Counting Your Cuts: Considerations Before You Invest

Laser Rental vs. Ownership: Evaluate your needs. For occasional projects, consider renting laser cutting time at a service provider. For frequent use, purchasing a personal laser cutter might be cost-effective in the long run.

Membership Perks: Explore public makerspaces with laser cutters. Membership fees might offer cost-effective access to laser cutting equipment, along with additional tools and resources.

Learning Curve Savings: While DIY laser cutting offers cost savings, there's a learning curve. Factor in the time and potential material costs associated with mastering the technology before calculating your overall savings.

The Future of Frugal Fabrication

DIY laser cutting is revolutionizing the way Angelenos create. It empowers individuals to become self-sufficient makers, slashing production costs, reducing waste, and fostering creative freedom. So, ditch the hefty price tags, embrace the DIY spirit, and embark on a journey of laser-cut creativity in the City of Angels! Remember, with a little planning and some laser know-how, you can transform your artistic vision into reality without breaking the bank.

DIY Laser Cutting in Los Angeles: From Idea to Reality

DIY Laser Cutting in Los Angeles: From Idea to Reality

Los Angeles, the city of creativity and innovation, now offers exciting possibilities for the DIY enthusiast with a passion for laser cutting. This technology, once limited to industrial settings, is becoming increasingly accessible, allowing you to transform your ideas into tangible objects. So, whether you're a budding entrepreneur, a crafty hobbyist, or simply someone who enjoys a good project, here's your guide to DIY laser cutting in the City of Angels:

The Freedom to Create: Why DIY Laser Cutting?

Bring Your Designs to Life: Laser cutting empowers you to become the maker. Translate your digital designs – from intricate jewelry pieces to personalized home décor – into reality with precise cuts on various materials.

Unleash Your Inner Entrepreneur: Prototype product ideas, create custom packaging for your small business, or craft unique merchandise – laser cutting allows you to bring your entrepreneurial vision to life without the constraints of traditional manufacturing.

A World of Customization: Gone are the days of limited design options. Laser cutting empowers you to personalize everything, from phone cases with your own artwork to custom coasters for your next gathering.

Learning Through Doing: DIY laser cutting is a fantastic way to learn about design principles, material properties, and the power of technology. It's a fun and engaging way to expand your skillset.

Where to Get Your Cut On: DIY Laser Cutting Options in LA

Laser Cutting Services with DIY Options:

Several laser cutting service providers in Los Angeles offer options for DIY enthusiasts. These businesses typically allow you to upload your designs and choose your materials, while they handle the cutting process. Some even provide introductory classes or tutorials to get you started. * American Laser Cutter offers DIY laser cutting services and classes in downtown LA.

Public Makerspaces with Laser Cutters:

The Los Angeles Public Library system offers limited access to laser cutters through their Octavia Lab. Membership or residency requirements may apply, and usage typically requires prior training and scheduling. It's a good option for occasional projects or trying out the technology before investing in your own setup. Here's more information: * Los Angeles Public Library - Octavia Lab

Considerations Before You Cut:

Know Your Design Software: Most laser cutters require designs in specific file formats like DXF or SVG. Familiarize yourself with design software like Adobe Illustrator or Inkscape to create compatible files.

Choose Your Material Wisely: Different materials have different cutting properties and safety considerations. Research the suitability of your chosen material for laser cutting and ensure it's compatible with the available laser cutter.

Safety First: Laser cutting involves powerful lasers and can generate fumes. Always follow safety protocols set by the service provider or makerspace, and wear proper eye protection when operating the laser cutter.

The Future of Making in LA

DIY laser cutting is democratizing the world of creation in Los Angeles. With its growing accessibility and vast creative potential, this technology empowers individuals to become makers, entrepreneurs, and bring their ideas to life. So, grab your digital design files, explore the possibilities offered by DIY laser cutting in LA, and get ready to transform your vision into reality!

Sharper Than a Scalpel: Laser Cutting's Precision Revolutionizes the Pharmaceutical Industry

The world of pharmaceuticals is all about precision and efficiency. Lives depend on the accuracy of medications and the reliability of medical devices. This is where laser cutting technology steps in, offering a sharp edge to various aspects of pharmaceutical manufacturing and packaging. Let's explore how laser cutting is revolutionizing the pharmaceutical industry:

A Cut Above the Rest: Advantages of Laser Cutting

Unmatched Precision: Laser cutting delivers unparalleled accuracy, crucial for creating components for medical devices and instruments. Intricate microfluidics channels, delicate catheter designs, and precisely sized filters can all be produced with clean, burr-free edges, ensuring optimal performance and sterility.

Speed and Efficiency: Gone are the days of slow, traditional manufacturing processes. Laser cutters automate the cutting process, allowing for high-volume production of identical parts with minimal setup time. This translates to faster turnaround times and increased efficiency in production lines.

Material Versatility: Laser cutting can handle a wide range of materials relevant to pharmaceuticals. From stainless steel for surgical instruments to biocompatible plastics for drug delivery devices, laser cutters offer the flexibility to work with various materials needed in the industry.

Reduced Waste and Cost Savings: Laser cutting software allows for optimized material placement, minimizing waste during the cutting process. This not only reduces material costs but also promotes a more sustainable manufacturing approach.

Sharper Tools for a Healthier Future: Applications in Pharmaceuticals

Microfluidics Manufacturing: Laser cutting is ideal for creating the intricate channels and microfluidic pathways on microfluidic chips used in diagnostics and drug delivery systems. The precise cuts ensure optimal fluid flow and functionality of these miniaturized devices.

Filter Fabrication: Laser cutting allows for the creation of precise filter elements with specific pore sizes, crucial for various pharmaceutical applications. From air filters in sterile environments to filters used in drug purification processes, laser cutting ensures consistently sized pores for optimal performance.

Medical Device Components: Stents, catheters, and other medical devices often require intricate designs and delicate features. Laser cutting enables the creation of these components with the necessary precision and sterility, ensuring their functionality and safety within the human body.

Packaging Solutions: The pharmaceutical industry demands tamper-evident and secure packaging. Laser cutting can be used to create intricate opening mechanisms on blister packs or security features on medical device packaging, enhancing product integrity and patient safety.

Beyond the Cut: Additional Benefits

Enhanced Sterility: Laser cutting is a non-contact process, minimizing the risk of contamination compared to traditional cutting methods. This is crucial for maintaining sterility in pharmaceutical manufacturing environments.

Reduced Maintenance: Laser cutters require minimal maintenance compared to traditional machinery, leading to increased uptime and reduced production downtime.

Scalability for Growth: Laser cutting systems can be easily scaled to accommodate changing production demands. This allows pharmaceutical companies to adapt to market fluctuations and future growth needs.

The Future of Precision Manufacturing:

Laser cutting technology is rapidly transforming the pharmaceutical industry. Its ability to deliver unmatched precision, speed, and material versatility is revolutionizing the way medical devices, instruments, and packaging are manufactured. As laser technology continues to evolve, we can expect to see even more innovative applications emerge, shaping a future of sharper tools for a healthier tomorrow.

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)