American Laser Cutter: Your Precision Cutting Partner in Los Angeles

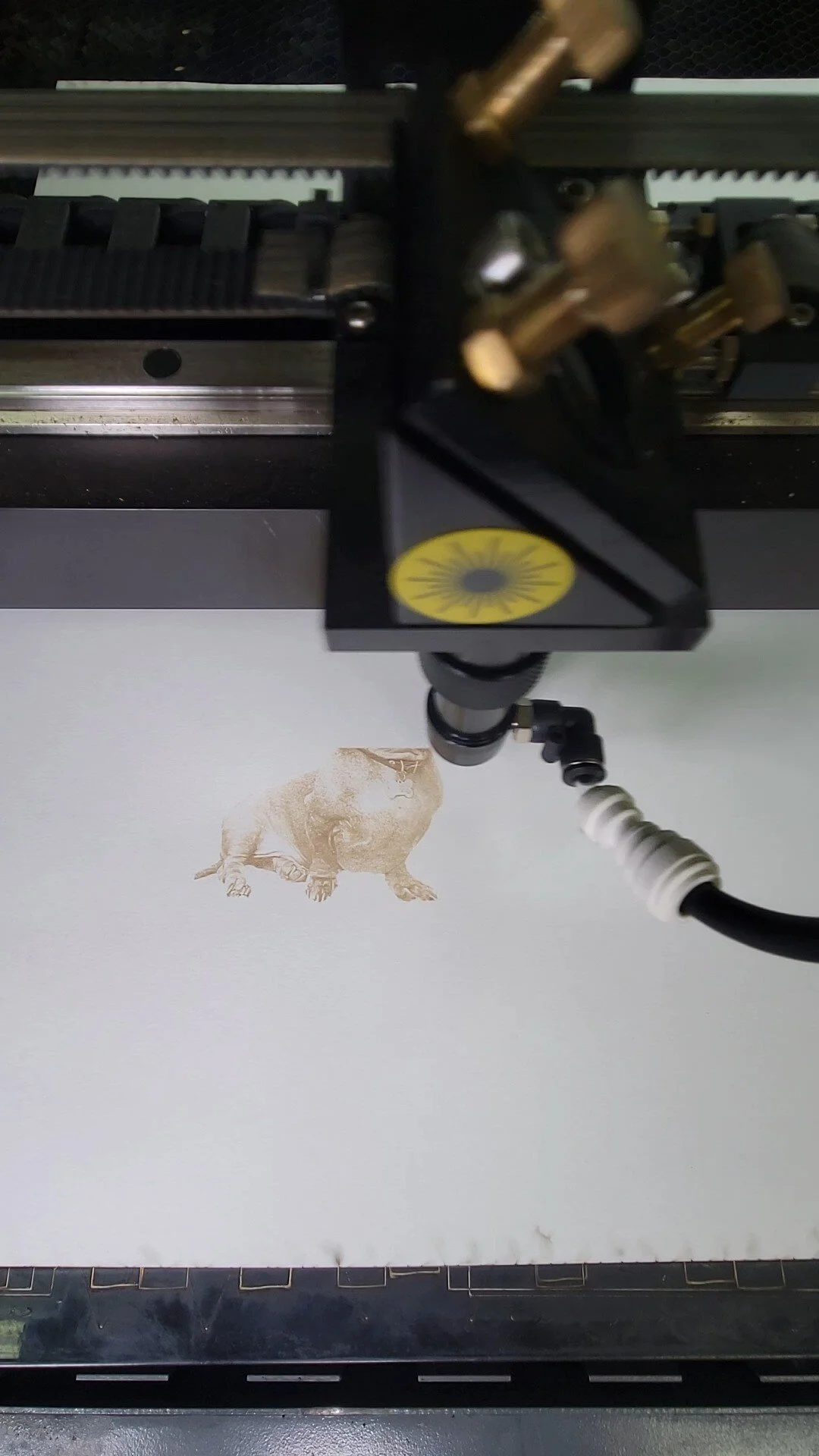

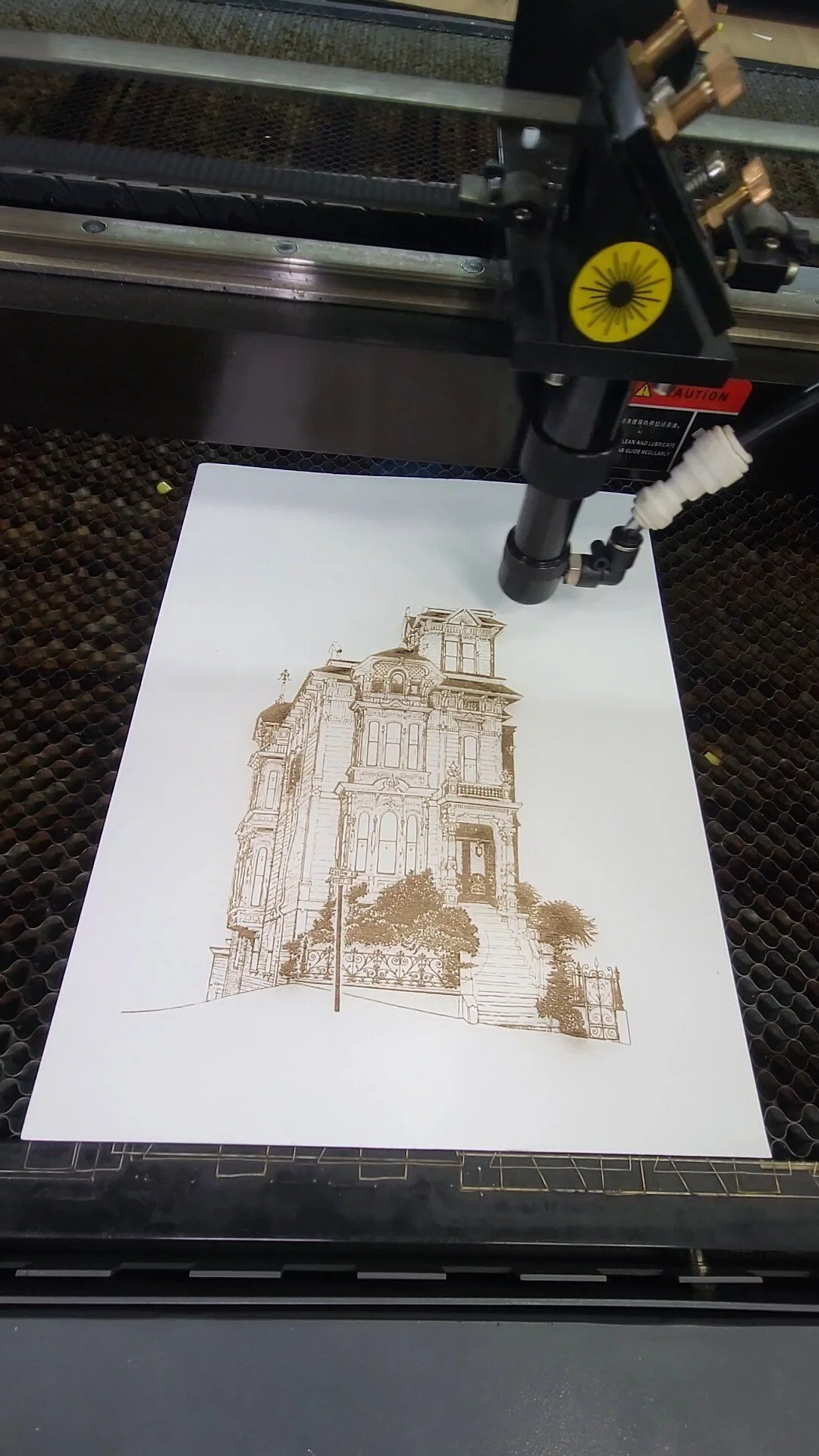

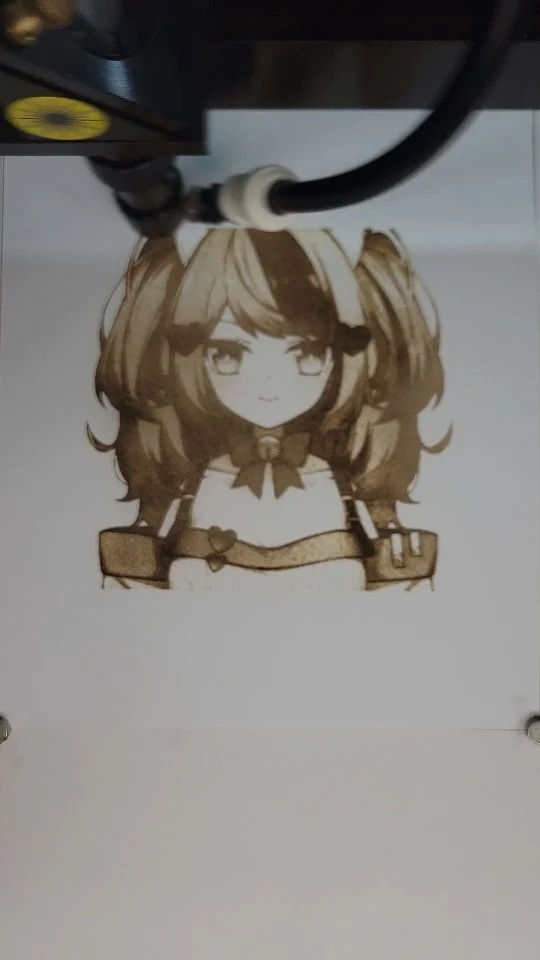

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

My Laser Cutter Stopped Working: Who to Contact?

My Laser Cutter Stopped Working: Who to Contact?

A malfunctioning laser cutter can be a significant setback for any business or hobbyist. Knowing who to contact for assistance is crucial. Here's a breakdown of your options:

1. Manufacturer or Supplier:

Warranty Coverage: If your laser cutter is still under warranty, contact the manufacturer or supplier immediately. They might provide free repairs or replacements.

Technical Support: Even if your warranty has expired, they can offer troubleshooting advice or refer you to qualified technicians.

Manufacturer support issues: if you are having issues contacting your manufacturer or getting timely and quality service, we recommend reaching out to an independent Laser repair service like American laser cutter.

2. Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

Quick Turnaround: They often offer expedited services to minimize downtime.

3. Online Forums and Communities:

User Support: Online forums dedicated to laser cutters often have users who can share troubleshooting tips or recommend repair services.

DIY Solutions: Some issues might have simple solutions that can be found through online research.

Steps to Take Before Contacting Anyone:

Check Basic Issues: Ensure the laser cutter is properly plugged in, turned on, and that all cables are securely connected.

Review User Manual: Look for troubleshooting guides or error codes in the manual.

Inspect for Physical Damage: Check for any visible signs of damage to the machine or its components.

Remember: When contacting a repair service, provide as much detail as possible about the problem, including error messages, unusual noises, or specific symptoms. This information will help them diagnose the issue efficiently.

Why CO2 Laser Cutters Have Minimum and Maximum Power Settings

Why CO2 Laser Cutters Have Minimum and Maximum Power Settings

CO2 laser cutters operate within a specific power range for optimal performance and longevity. Understanding why these limitations exist is crucial for effective use of the machine. As a general rule of thumb most laser tubes will fire between 10% and 80% successfully. It is generally not recommended to go below or above those settings.

The Role of Minimum Power

Laser Tube Stability: Below a certain power level, the laser tube might not produce a stable beam, leading to inconsistent results.

Material Interaction: when is CO2 laser cutter goes around a corner or a curve it becomes more efficient in its power output so the minimum power setting is there to prevent you from overpowering corners and curves

Software Limitations: Some laser cutter software might have a minimum power threshold to ensure proper operation.

The Role of Maximum Power

Laser Tube Protection: Exceeding the maximum power rating can overheat the laser tube, reducing its lifespan and potentially damaging it.

Optical Component Integrity: High power levels can stress the optics, leading to decreased performance and even damage.

Fire Hazard: Excessive power can ignite materials, posing a safety risk.

Material Interaction: when is CO2 laser cutter goes in a straight line that is when it is using its maximum power setting.

Factors Affecting Power Range

Laser Tube Type: Different laser tubes have varying power capacities and characteristics.

Cooling System: An efficient cooling system allows for higher power output without overheating.

Power Supply: The power supply's capacity influences the maximum power available.

Importance of Adhering to Power Limits

Consistent Results: Operating within the recommended power range ensures predictable and reliable cuts.

Extended Laser Life: Protecting the laser tube and optics prolongs the machine's lifespan.

Safety: Adhering to power limits reduces the risk of accidents and damage.

By understanding the reasons behind minimum and maximum power settings, you can optimize your laser cutter's performance, extend its lifespan, and ensure a safe working environment.

Power and Speed: The Dynamic Duo of CO2 Laser Cutting

Power and Speed: The Dynamic Duo of CO2 Laser Cutting

The relationship between power and speed in a CO2 laser cutter is intricate and crucial to achieving optimal results.

These two factors work in tandem to determine the quality and efficiency of your cuts.

1. A Deep Dive Into Laser Cutter Speed And Power - Make Magazine

2. Speed and Power of Laser Cutting: The Ultimate Guide - Baison

Understanding the Basics

Power: Measured in watts, it's the laser's energy output. Higher power enables cutting thicker materials or achieving faster cutting speeds.

1. CO2 Laser Power: Effect on Cutting Capability

2. Laser Cutting Metal: The Link Between Power, Thickness, and Speed - Baison

Speed: Measured in inches or millimeters per minute, it's the movement of the laser head. Faster speeds are generally used for thinner materials or less detailed cuts.

The Interplay

Material Thickness: Thicker materials require higher power and slower speeds to ensure a clean cut through the material.

Material Type: Different materials have varying absorption rates for laser energy. This affects the optimal power and speed settings.

Cut Quality: Higher power and slower speeds typically result in cleaner, more precise cuts. However, excessive power can lead to melting or burning.

Efficiency: Finding the right balance of power and speed is essential for maximizing productivity. Too much power can waste energy, while too low a speed can extend cutting time.

Experimentation is Key

While there are general guidelines, the ideal power and speed settings often require experimentation. Factors such as focus, nozzle type, and gas assist also influence the outcome. Most laser cutter software allows you to adjust these parameters to fine-tune your results.

Common Mistakes

Overpowering: Using excessive power can damage the material and the laser tube.

Underpowering: Insufficient power can result in incomplete cuts or burnt edges.

Incorrect Speed: Too fast or too slow a speed can affect cut quality and efficiency.

By understanding the interplay between power and speed, you can optimize your CO2 laser cutter for various materials and applications. Experimentation and careful adjustments will help you achieve the best results for your specific needs.

The Benefits of Upgrading Your Laser Cutter Optics

The Benefits of Upgrading Your Laser Cutter Optics

The heart of any laser cutter is its optics. These components, including mirrors, lenses, and focusing heads, directly impact the quality, speed, and efficiency of your cutting process.

Upgrading your optics can yield significant benefits:

1. 8 Steps of the Laser Cutting Process - Xometry

Improved Cut Quality

Cleaner Edges: Upgraded optics produce cleaner, smoother cuts with fewer burrs and imperfections.

Enhanced Detail: For intricate designs, better optics can capture finer details with precision.

Consistent Results: High-quality optics contribute to more consistent and predictable cut quality.

Increased Cutting Speed

Faster Processing: Improved optics can often handle higher laser power, leading to faster cutting speeds.

Increased Throughput: Faster cutting means more parts produced in less time, boosting productivity.

1. How Does Laser Cutting Improve The Efficiency And Productivity of Manufacturing?

Reduced Production Time: Quicker processing times contribute to shorter lead times and faster order fulfillment.

Longer Optic Lifespan

Durability: Premium optics are engineered to withstand higher temperatures and pressures.

Reduced Maintenance: Less frequent cleaning and replacement can save time and money.

Consistent Performance: Durable optics maintain their performance over time.

Energy Efficiency

Optimized Power Usage: Upgraded optics can better utilize laser energy, reducing waste.

Lower Operating Costs: Less energy consumption translates into lower utility bills.

Environmental Benefits: Reduced energy consumption contributes to a smaller environmental footprint.

Expanded Material Compatibility

Versatility: High-quality optics can handle a wider range of materials, from thin acrylic to thick metals.

Improved Cutting Performance: Better optics can achieve cleaner cuts on challenging materials.

New Application Opportunities: Expand your product offerings with the ability to cut new materials.

Upgrading your laser cutter optics is an investment that can deliver substantial returns. By improving cut quality, increasing speed, and enhancing efficiency, you can gain a competitive edge in your industry.

Why Laser Cutter Maintenance is Essential

Why Laser Cutter Maintenance is Essential

Regular maintenance of your CO2 laser cutter is not just a recommendation; it's a necessity for optimal performance, longevity, and safety.

Neglecting maintenance can lead to costly repairs, downtime, and even hazardous situations. Here’s why:

1. How to Maintain and Service Your Laser Cutter Machine Effectively

2. Laser Cutting Machine Maintenance Guide – Ensuring Optimal Performance

Enhanced Performance

Precision Cutting: Regular cleaning of lenses and mirrors ensures accurate and clean cuts.

1. how to clean laser focus lenses and mirrors USA - Trotec Laser

Speed and Efficiency: A well-maintained machine operates at peak performance, increasing production speed.

1. How to Maintain and Service Your Laser Cutter Machine Effectively

Consistent Quality: Consistent maintenance leads to consistent output, reducing the need for rework.

1. Laser Cutting Machine Maintenance Guide – Ensuring Optimal Performance

Extended Lifespan

Reduced Wear and Tear: Regular cleaning and lubrication minimize wear on machine components.

1. How to Maintain and Service Your Laser Cutter Machine Effectively

Early Detection of Issues: Routine inspections help identify potential problems before they escalate.

1. Laser Cutting Machine Maintenance Guide – Ensuring Optimal Performance

Optimized Component Life: Proper maintenance prolongs the life of expensive components like the laser tube.

Cost Savings

Preventative Maintenance: Addressing small issues early prevents costly breakdowns.

1. How to Maintain and Service Your Laser Cutter Machine Effectively

Reduced Downtime: A well-maintained machine experiences fewer unexpected interruptions.

1. Laser Cutting Machine Maintenance Guide – Ensuring Optimal Performance

Lower Repair Bills: Regular maintenance can significantly reduce repair costs.

1. Laser Cutting Machine Maintenance Guide – Ensuring Optimal Performance

Safety

Fire Prevention: Clean optics and proper ventilation reduce the risk of fire hazards.

Reduced Emissions: Regular maintenance helps minimize harmful emissions.

Operator Protection: A well-maintained machine is safer for operators.

Increased Productivity

Optimized Uptime: Minimal downtime means more production time.

Consistent Output: Reliable performance leads to increased productivity.

Improved Product Quality: Consistent cuts and engravings enhance product quality.

By investing time and resources in regular laser cutter maintenance, you're not just prolonging the life of your machine but also ensuring its optimal performance, safety, and efficiency. It's an investment that pays off in the long run.

1. How to Maintain and Service Your Laser Cutter Machine Effectively

How Often Should You Maintain Your CO2 Laser Cutter?

How Often Should You Maintain Your CO2 Laser Cutter?

Regular maintenance is crucial for ensuring the longevity and optimal performance of your CO2 laser cutter.

While specific maintenance schedules can vary depending on the machine's usage, environment, and material type, here's a general guideline:

1. CO2 Laser Cutter Maintenance Guide & Servicing Checklist

Daily Maintenance

Inspect for debris: Clear away any material scraps or dust from the work area and machine components.

Check air filter: Ensure the air filter is clean to maintain proper airflow and prevent overheating.

Monitor coolant levels: Keep the coolant reservoir filled to protect the laser tube.

Weekly Maintenance

Clean optics: Gently clean mirrors and lenses with isopropyl alcohol and lens paper to prevent damage from debris.

Inspect laser tube: Check for any visible signs of damage or wear.

Check water quality: If using a water-cooled laser, test the water quality and replace if necessary.

Monthly Maintenance

Deep clean machine: Thoroughly clean the entire machine, including the interior and exterior.

Check hoses and connections: Inspect for wear, leaks, or loose connections.

Calibrate laser: Ensure accurate cutting and engraving by recalibrating the machine.

Quarterly or Semi-Annually Maintenance

Professional service: Consider scheduling a professional inspection and maintenance service.

Replace consumable parts: Replace worn-out parts like nozzles, air filters, and other consumables.

Check for software updates: Update the machine's software to benefit from the latest features and bug fixes.

Factors Affecting Maintenance Frequency

Usage: Heavy-duty use requires more frequent maintenance.

Material type: Some materials produce more debris or fumes than others.

Environment: Dusty or dirty environments necessitate more cleaning.

Remember: This is a general guideline. Always refer to your laser cutter's user manual for specific maintenance recommendations. Regular inspections and preventive maintenance will help extend the life of your machine and ensure consistent performance.

Remote vs. On-Site Laser Repair: When to Choose Which

Remote vs. On-Site Laser Repair: When to Choose Which

Laser technology is ubiquitous in modern industries, from manufacturing to healthcare. When these precision instruments malfunction, it can lead to significant downtime and financial losses. The decision between remote and on-site laser repair can be critical. Let's explore the advantages of each option to help you make an informed choice.

When to Choose Remote Laser Repair

Remote laser repair, facilitated by advanced diagnostics and remote access tools, has become increasingly viable. This option is ideal for:

Minor Issues: Problems like software glitches, parameter adjustments, or basic troubleshooting can often be resolved remotely without the need for an on-site technician.

Time-Sensitive Repairs: If downtime is critical, remote repair can often be initiated and resolved more quickly than waiting for an on-site technician to arrive.

Cost-Effective Solutions: In many cases, remote repair can be more cost-effective as it eliminates travel expenses and reduces labor hours.

Limited Access: For lasers in remote or hazardous locations, remote repair can be the safest and most practical option.

When to Choose On-Site Laser Repair

While remote repair offers many advantages, there are instances when on-site intervention is necessary:

Hardware Failures: If the laser's physical components are damaged, an on-site technician will need to replace or repair them.

Complex Issues: For intricate problems requiring hands-on examination and adjustments, on-site repair is often the best approach.

Preventive Maintenance: Regular on-site inspections and maintenance can help prevent future breakdowns and optimize laser performance.

Calibration and Alignment: Precise calibration and alignment of laser components usually require on-site expertise.

Factors to Consider

When deciding between remote and on-site laser repair, consider the following factors:

Laser Type and Complexity: The laser's model, age, and complexity will influence the feasibility of remote repair.

Downtime Costs: Evaluate the financial impact of downtime to determine if remote repair's speed benefits outweigh the potential need for on-site intervention.

Repair Provider Expertise: Ensure your repair provider offers both remote and on-site services to provide flexibility.

Remote Access Capabilities: Verify that your laser system has the necessary hardware and software for remote diagnostics and control.

By carefully considering these factors, you can select the most appropriate repair option for your specific situation, minimizing downtime and optimizing laser performance.

A Treasure Trove of Creativity: Top Websites for Free Laser Cutting Vector Files

A Treasure Trove of Creativity: Top Websites for Free Laser Cutting Vector Files

The allure of laser cutting lies in its ability to transform digital designs into tangible objects. But for those new to the laser cutting world, the prospect of creating intricate vector designs from scratch can seem daunting. Fear not, creative minds! This article unveils a treasure trove of websites offering a plethora of free vector files specifically designed for laser cutting.

We'll explore top websites catering to diverse design styles and project needs. So, grab your favorite design software, delve into these online resources, and embark on your laser cutting adventure with a library of inspiring designs at your fingertips!

1. Freepik: A Design Powerhouse with Free Laser Cutting Files

Freepik https://www.freepik.com/ is a well-known design platform offering a vast collection of free and premium design assets. While the platform primarily focuses on stock photos and illustrations, it also boasts a dedicated section for free laser cutting vector files.

Here's what makes Freepik a great choice for finding free laser cutting files:

Variety of Designs: Explore a diverse range of designs, including mandalas, geometric patterns, lettering, and even decorative elements for home décor.

Easy Search: Utilize the search bar with keywords like "laser cut" or specific themes to find relevant files.

File Format Flexibility: Freepik offers downloads in various formats, including SVG (Scalable Vector Graphics), the preferred format for laser cutting software.

Attribution Required: Most free files on Freepik require attribution to the designer. Ensure you understand the licensing terms before using the files for commercial purposes.

2. Free Vector Stock: A Hub for Royalty-Free Vector Resources

Free Vector Stock [invalid URL removed] lives up to its name – a treasure trove of royalty-free vector graphics, including a dedicated section for laser cutting files.

Here's why Free Vector Stock deserves a spot in your laser cutting resource list:

High-Quality Designs: The website boasts a collection of high-quality vector files readily downloadable for your laser cutting projects.

Clear Categorization: Browse through well-organized categories like animals, nature, and objects, making it easy to find the perfect design for your needs.

Commercial Use Flexibility: Many free files on Free Vector Stock allow for commercial use, eliminating licensing concerns for crafters selling their laser-cut creations.

Download Options: Choose from various file formats, including SVG, ensuring compatibility with your laser cutting software.

3. The Noun Project: A Library of Recognizable Icons for Laser Cutting

The Noun Project https://thenounproject.com/ is a unique platform offering a vast collection of icons and symbols. While not exclusively focused on laser cutting, The Noun Project's library can be a valuable resource for finding simple and recognizable icons that translate well into laser-cut projects.

Here's how The Noun Project can empower your laser cutting creativity:

Extensive Icon Library: Search through thousands of icons encompassing virtually any theme imaginable.

Simple Designs: The minimalist nature of the icons makes them ideal for laser cutting, ensuring clean and precise cuts.

Customization Opportunities: Use the downloaded icon as a starting point and modify it within your design software for a personalized touch.

Commercial Use Flexibility: Many icons on The Noun Project allow for commercial use with attribution, opening up possibilities for crafters selling their creations.

4. DXF Download: A Resource for Diverse Cutting Files

DXF Download caters to a wider range of CNC (Computer Numerical Control) machines, including laser cutters. While not all files are specifically categorized for laser cutting, the website offers a vast collection of downloadable DXF (Drawing Exchange Format) files suitable for various projects.

Here's what makes DXF Download a valuable resource for laser cutting enthusiasts:

Extensive File Library: Explore a diverse range of designs, including 3D models, puzzle templates, and even decorative elements for home décor.

Material Considerations: Many files provide suggestions on compatible materials for laser cutting, ensuring successful project execution.

Project Complexity: The website offers files catering to various skill levels, from beginner-friendly designs to more intricate projects for experienced laser cutters.

Download Options: Files are typically available in DXF format, readily importable into most laser cutting software with minimal adjustments.

Laser Cut Box Generators: Your Box-Making Best Friend

Laser Cut Box Generators: Your Box-Making Best Friend

Laser cutting boxes is a popular project, but designing them from scratch can be time-consuming. Thankfully, laser cut box generators have emerged as invaluable tools for simplifying the process.

What is a Laser Cut Box Generator?

A laser cut box generator is a software tool or online platform that automates the design process for creating box patterns.

By inputting desired dimensions, material thickness, and specific design parameters, you can generate detailed cutting files in minutes.

1. Laser Box Generator Programs - sandbox - UMIACS wiki

2. Online File Generators for Laser Cutting - Maker Design Lab

Benefits of Using a Laser Cut Box Generator

Time-saving: Quickly generate complex box designs without manual drafting.

Precision: Ensures accurate dimensions and joint fit for perfect assembly.

Customization: Many generators offer options to customize box size, shape, and lid styles.

Variety of Box Types: From simple boxes to intricate designs with multiple folds and tabs, there's a generator for every need.

Popular Laser Cut Box Generators

While there are many options available, some popular choices include:

MakerCase: Offers a user-friendly interface and a variety of box styles.

Online CAD tools: Platforms like Tinkercad or Fusion 360 can be used to create custom box designs.

Custom scripts: For advanced users, creating custom scripts can offer maximum flexibility.

Tips for Using Box Generators

Understand kerf: Factor in the material thickness and kerf (the width of the cut) for accurate dimensions.

Experiment with designs: Try different box styles and sizes to find the perfect fit for your project.

Test assembly: Build a prototype to ensure the design functions as intended before cutting multiple pieces.

Material choice: Consider the material's thickness and strength when selecting box dimensions.

By utilizing laser cut box generators, you can significantly streamline your box-making process and achieve professional-looking results. With a little experimentation, you'll be creating custom boxes in no time.

Top 10 Laser Cutting YouTube Channels to Follow

Top 10 Laser Cutting YouTube Channels to Follow

YouTube is a treasure trove of knowledge and inspiration for laser cutting enthusiasts. Here are ten channels that stand out for their informative content, creative projects, and engaging presentations:

Educational and Informative Channels

Make Something Inc: Offers a wealth of tutorials, tips, and tricks for laser cutting, from beginner to advanced levels.

The Wood Whisperer: While primarily focused on woodworking, this channel features excellent laser cutting segments with detailed explanations.

Laser Cut Studio: Provides in-depth tutorials and reviews of laser cutting machines and software.

The Stained Workshop: Offers a blend of woodworking and laser cutting projects, with clear instructions and stunning results.

Creative and Inspirational Channels

Jinsoaki: Known for intricate papercut art, this channel showcases the beauty and precision of laser cutting.

LaserDad: Offers a variety of projects, from home decor to functional items, with a focus on practical tips.

The Maker's Muse: Features a wide range of laser cut projects, inspiring creativity and experimentation.

Laser Cut Crafts: Offers a collection of creative and easy-to-follow laser cutting projects.

Business and Entrepreneurship

Make or Break Shop: Provides valuable insights into turning laser cutting into a profitable business.

Laser Business Top Seller: Shares tips and strategies for selling laser cut products online.

These channels offer a diverse range of content, from beginner tutorials to advanced techniques and business advice. By following these creators, you'll gain valuable knowledge, inspiration, and a deeper understanding of laser cutting.

Beginner-Friendly Laser Cutting Projects

Beginner-Friendly Laser Cutting Projects

Starting a new hobby can be overwhelming, but with laser cutting, the learning curve is both fun and rewarding. Here are some beginner-friendly projects to kickstart your laser cutting journey:

Simple and Satisfying Projects:

Coasters: A classic starting point. Experiment with different materials, designs, and engravings.

Keychains: Personalize with initials, names, or simple designs.

Phone Stands: A practical and visually appealing project that can be customized with various styles.

Bookmarks: Simple yet effective, allowing you to experiment with different shapes and materials.

Papercut Art: Start with basic shapes and gradually increase complexity as you gain confidence.

Learning Through Making:

Engraved Cutting Boards: Practice engraving text, logos, or simple designs onto wood.

Acrylic Ornaments: Create decorative pieces for any occasion, from Christmas ornaments to personalized gifts.

Wooden Puzzles: Begin with simple shapes and gradually increase difficulty as you master the process.

Cardstock Boxes: Explore the art of creating intricate boxes with lids.

Leather Keychains or Tags: Experiment with different leather types and engraving techniques.

Tips for Beginners:

Start small: Begin with simple designs to understand the laser cutter's capabilities.

Experiment with materials: Try different materials to discover their properties and how they interact with the laser.

Practice makes perfect: Don't be afraid to make mistakes. Learning from errors is part of the process.

Online resources: Utilize tutorials, forums, and communities for guidance and inspiration.

Safety first: Always prioritize safety by wearing protective gear and following machine guidelines.

Remember, the key to enjoying laser cutting is to have fun and experiment. With each project, you'll gain confidence and discover new possibilities.

10 Inspiring Laser Cut Projects to Ignite Your Creativity

10 Inspiring Laser Cut Projects to Ignite Your Creativity

Laser cutting offers endless possibilities, from intricate home decor to functional items. Here are ten captivating projects to inspire your next creation:

Home Decor

Intricate Wall Art: Create stunning geometric or floral patterns for a modern or bohemian aesthetic.

Personalized Wooden Signs: Design custom signs with names, quotes, or logos for a personal touch.

Elegant Lamp Shades: Cut intricate patterns into acrylic or wood for unique and stylish lampshades.

Functional Items

Custom Jewelry: Laser cut delicate pendants, earrings, or bracelets from wood, acrylic, or metal.

Personalized Phone Cases: Create one-of-a-kind phone cases with intricate designs or custom engravings.

Kitchen Accessories: Design and cut functional items like cutting boards, coasters, or utensil holders.

Creative Projects

3D Puzzles: Challenge yourself with intricate interlocking puzzle designs made from wood or acrylic.

Model Kits: Create detailed models of cars, airplanes, or buildings for hobbyists or collectors.

Custom Furniture: Design and build unique furniture pieces with laser-cut components.

Personalized Gifts: Create thoughtful presents like custom keychains, bookmarks, or gift tags.

These projects are just a starting point. The possibilities are endless with laser cutting. Remember to experiment with different materials, designs, and techniques to discover your unique style.

Sparking Creativity: Introducing Kids to Laser Cutting

Sparking Creativity: Introducing Kids to Laser Cutting

Laser cutting offers an exciting and engaging way to introduce kids to the world of design, engineering, and technology. This hands-on activity can foster creativity, problem-solving skills, and a passion for STEM.

1. How Laser Cutter Brings New Inspiration to the Classroom - Makeblock

2. Laser-focused learning: Unveiling the benefits of laser cutters in STEM education - Hobarts

Safety First

Before diving into laser cutting with kids, safety is paramount.

Supervision: Always supervise children when operating a laser cutter.

Eye Protection: Ensure everyone wears appropriate safety goggles.

Fire Safety: Have a fire extinguisher readily available.

Material Selection: Choose non-toxic and non-flammable materials.

Age-Appropriate Projects

Start with simple projects to build confidence and interest.

Younger Kids: Focus on basic shapes, puzzles, and decorations using safe materials like cardstock or acrylic.

Older Kids: Introduce more complex designs involving wood or other materials, encouraging experimentation with different cutting techniques.

Design and Creativity

Digital Design Tools: Introduce kids to design software like Inkscape or Adobe Illustrator to create their own designs.

Hand-Drawn Sketches: Encourage kids to sketch their ideas before transferring them to digital format.

Iterative Design: Emphasize the importance of testing and refining designs.

Learning Opportunities

STEM Education: Laser cutting can be a fun way to teach concepts like geometry, physics, and engineering.

Problem-Solving: Encourage kids to troubleshoot issues and find solutions.

Collaboration: Promote teamwork and shared learning experiences.

Safety and Responsibility

Machine Operation: Teach kids about the laser cutter's controls and safety features.

Material Handling: Explain the importance of handling materials carefully.

Project Planning: Encourage kids to plan their projects and consider potential challenges.

Making it Fun

Rewards: Celebrate achievements and encourage exploration.

Sharing: Create opportunities for kids to showcase their work.

Inspiration: Expose kids to a variety of laser-cut projects to spark their imagination.

By following these guidelines and fostering a safe and creative environment, you can introduce kids to the exciting world of laser cutting, empowering them to become future innovators.

Laser-Specific Materials: A Cutting Edge Industry

Laser-Specific Materials: A Cutting Edge Industry

While laser cutters can work with a vast array of materials, certain substances are optimized for this process. These laser-specific materials are engineered to interact optimally with laser beams, producing superior results in terms of cut quality, speed, and durability.

1. The Complete Laser Cutting Materials List - xTool

Types of Laser-Specific Materials

Acrylic Sheets: Renowned for their clarity and versatility, acrylic sheets are widely used in laser cutting for creating signs, displays, and decorative items. They offer clean cuts with minimal edge melting.

1. Laser Cutting & Engraving Acrylic Sheets | Nova Display Systems

MDF (Medium-Density Fiberboard): Specifically designed for laser cutting, MDF provides consistent results and minimal smoke or fumes. It’s ideal for intricate designs and detailed engravings.

1. Designing with Confidence: Integrating the Best MDF Boards in Your Projects - Medium

Laser-Cuttable Wood: Some wood varieties are treated or engineered to be more compatible with laser cutting. These woods often have reduced smoke and charring, resulting in cleaner cuts.

Laser-Gravable Metals: Certain metals are coated or treated to enhance their ability to absorb laser energy, leading to better engraving and marking results.

Laser-Cuttable Fabrics: Specially designed fabrics are available with properties that minimize fraying and melting during the laser cutting process.

Key Benefits of Laser-Specific Materials

Improved Cut Quality: These materials are formulated to produce cleaner, more precise cuts with minimal edge imperfections.

Faster Processing: Optimized materials often allow for higher laser power and speed, increasing productivity.

Reduced Smoke and Fumes: Many laser-specific materials generate less smoke and harmful fumes during the cutting process.

Consistent Results: Engineered materials provide more reliable and predictable outcomes.

Where to Find Laser-Specific Materials

While many standard materials can be used for laser cutting, sourcing materials specifically designed for this process can significantly enhance your projects. Look for suppliers specializing in laser cutting materials or consult with your laser cutter manufacturer for recommendations.

Note: Always test new materials on a small scale before starting a large project to ensure compatibility and desired results.

By utilizing laser-specific materials, you can elevate your laser cutting projects to new heights, achieving exceptional quality and efficiency.

Choosing the Right Plywood for Laser Cutting

Choosing the Right Plywood for Laser Cutting

Selecting the appropriate plywood for laser cutting is crucial for achieving optimal results. Several factors influence the suitability of plywood for this process.

Plywood Types for Laser Cutting

Baltic Birch Plywood: Often considered the gold standard for laser cutting due to its consistent quality, minimal voids, and clean cuts. It's ideal for intricate designs and precise work.

Poplar Plywood: A more affordable option, poplar plywood offers a good balance of cost and quality. However, it may have more voids and variations in thickness.

1. Poplar plywood: a good choice for the construction industry - Propopulus

MDF (Medium-Density Fiberboard): While not technically plywood, MDF is frequently used for laser cutting due to its smooth surface and consistent density. It's excellent for intricate details but can produce more smoke and fumes than plywood.

Factors to Consider

Plywood Grade: Higher-grade plywood typically has fewer imperfections, resulting in cleaner cuts.

Thickness: The thickness of the plywood will influence the laser cutting settings and the overall project.

Veneer Quality: The type and quality of the veneer can affect the appearance of the finished product.

Glue Lines: Excessive glue lines can interfere with the laser cutting process and produce uneven results.

Grain Direction: The direction of the wood grain can impact the cutting process and the appearance of the finished product.

1. THE ULTIMATE GUIDE FOR CHOOSING PLYWOOD FOR LASER CUTTING

Tips for Success

Test Different Plywoods: Experiment with different types of plywood to find the best fit for your project.

Optimize Laser Settings: Adjust laser power, speed, and focus to achieve the desired cut quality.

Ventilation: Ensure proper ventilation to remove smoke and fumes generated during the cutting process.

Safety First: Always wear protective gear, such as safety glasses and a dust mask.

By carefully considering these factors and conducting thorough testing, you can select the perfect plywood for your laser cutting projects and achieve exceptional results.

Understanding Laser Cut Kerf

Understanding Laser Cut Kerf

When working with laser cutters, it's essential to understand the concept of kerf. Kerf refers to the width of material that is removed during the laser cutting process. Essentially, it's the gap left behind as the laser vaporizes or melts away a portion of the material.

1. Understanding laser kerf when cutting - CutLaserCut

Factors Affecting Kerf Width

Several factors influence the kerf width:

Material type: Different materials react differently to the laser beam. Thinner materials tend to have smaller kerfs.

Laser power: Higher power settings typically result in wider kerfs.

1. What is Kerf in Laser Cutting & What does Laser Kerf mean? - RazorLAB

Laser focus: The focus of the laser beam impacts the size of the cut.

Cutting speed: Slower speeds can lead to wider kerfs.

Gas assist (if applicable): The type and pressure of the gas used can influence kerf width.

Importance of Kerf in Design

Accurately accounting for kerf is crucial for achieving precise results. If ignored, it can lead to parts that don't fit together as intended or unexpected dimensions. Here are some key considerations:

1. Design for Laser Cutting | making@stanford

Interlocking parts: For puzzle pieces or interlocking joints, compensate for the kerf by adjusting the design to ensure a proper fit.

Tight tolerances: If your project requires precise dimensions, carefully consider the kerf and compensate accordingly.

Material thickness: Thicker materials generally have wider kerfs, so adjust your design to accommodate this.

Experimental testing: It's often helpful to create test cuts to determine the exact kerf width for your specific material and laser settings.

1. Kerf Correction for Laser Cutting With MakerCase : 7 Steps - Instructables

Compensating for Kerf

To compensate for kerf, you can:

Increase design dimensions: Add the kerf width to your design to account for the material removed.

Use kerf compensation features: Some laser cutting software offers built-in kerf compensation tools.

Experimental adjustments: Make small adjustments to your design based on test cuts.

By understanding kerf and taking appropriate measures, you can significantly improve the accuracy and quality of your laser-cut projects.

DIY Laser Cutting: Your First Steps into the World of Laser Cutting

DIY Laser Cutting: Your First Steps into the World of Laser Cutting

Diving headfirst into owning a laser cutter might be daunting, but starting with DIY laser cutting services offers a fantastic way to explore the technology without the hefty upfront investment.

Why Start with DIY Laser Cutting?

Accessibility: It's a low-barrier entry point for those curious about laser cutting.

Experimentation: Try different materials and designs without the commitment of owning a machine.

Cost-Effective: Ideal for small projects or one-off designs.

Learning Curve: Understand the process and limitations before investing in your own equipment.

Finding a DIY Laser Cutting Service

Numerous online platforms and local makerspaces offer DIY laser cutting services. When selecting a service, consider the following:

Material Options: Ensure they offer the materials you need for your project.

File Formats: Check if they accept the design file formats you use (e.g., SVG, DXF).

Cut Quality: Review customer reviews or request samples to assess the quality of their cuts.

Pricing: Compare prices to find the best value for your money.

Turnaround Time: Consider how quickly you need your project completed.

Design Preparation

Once you've chosen a service, prepare your design:

Vector Graphics: Create your design using vector-based software like Adobe Illustrator, Inkscape, or CorelDraw.

File Format: Save your design as a compatible file format (SVG, DXF, etc.) as required by the service.

Kerf Consideration: Understand the kerf (material removed by the laser) and adjust your design accordingly.

1. What Is Laser Cutting Kerf? - KRRASS CNC Press Brake Online Shop

Test Cuts: Consider starting with smaller test cuts to refine your design and settings before committing to the full project.

Tips for Success

Clear Communication: Provide detailed instructions and specifications to the service provider.

Material Selection: Choose materials suitable for laser cutting and consider their thickness.

Design Optimization: Simplify your design for efficient cutting and reduce costs.

Safety Considerations: Familiarize yourself with laser cutting safety guidelines, even when using a service.

By following these steps and taking advantage of DIY laser cutting services, you can gain valuable experience and knowledge before deciding to invest in your own laser cutter.

LightBurn: The Powerhouse of Laser Cutting Software

LightBurn: The Powerhouse of Laser Cutting Software

LightBurn has become the go-to software for many laser cutter enthusiasts and professionals alike. Its robust feature set empowers users to create intricate designs, optimize laser settings, and streamline their workflow. Let's delve into some of its standout features.

1. Maximizing Your Laser Cutting Potential with Lightburn Software

Design and Editing

Vector Graphics: LightBurn excels at handling vector graphics, allowing for precise control over shapes, lines, and curves.

Image Tracing: Easily convert raster images (like photos) into editable vector graphics for laser cutting or engraving.

1. How to Import & Edit Designs Using Lightburn Software - OMTech Laser

Node Editing: Manipulate individual points on a path for detailed adjustments and customization.

Text Tools: Create text with various fonts, sizes, and styles, offering flexibility for text-based designs.

Laser Control

Power and Speed Control: Fine-tune laser parameters for optimal cutting or engraving results based on material and desired outcome.

Multiple Passes: Create intricate details and deeper cuts by setting up multiple passes with varying power and speed.

Offsetting: Easily create outlines or inner cuts by offsetting shapes.

Raster Engraving: Convert images into grayscale data for high-quality photo engraving.

1. Demystifying the Lightburn GRAYSCALE Image Mode - YouTube

Workflow Optimization

Job Management: Organize and manage multiple projects efficiently with the job manager.

Layer Management: Work with multiple layers of objects for complex designs and easy editing.

Camera Integration: Align materials accurately using the camera feature on compatible laser cutters.

Presets: Save and load custom settings for different materials and laser types to streamline workflow.

Additional Features

Variable Power: Gradually increase or decrease laser power during a cut for precise control.

Vector Hatching: Create fills with various patterns for artistic effects.

Import/Export: Work with a variety of file formats, including AI, SVG, DXF, and more.

1. Importing Files From Other Programs into Lightburn | Thunder Laser Canada

Plugin Ecosystem: Expand LightBurn's capabilities with third-party plugins.

LightBurn's comprehensive feature set makes it a valuable asset for laser cutter users of all skill levels. Whether you're a hobbyist or a professional, this software can help you achieve your creative vision.

1. Understanding LightBurn Software: Features and Pricing Guide - Monport Laser

LightBurn: The Ultimate Partner for Your Laser Cutter

LightBurn: The Ultimate Partner for Your Laser Cutter

LightBurn software has become an indispensable tool for many laser cutter users. It offers a range of features and benefits that significantly enhance the laser cutting experience.

1. Laser with Lightburn: The Best Laser Engraver Software!

2. Exploring the Key Features of LightBurn Engraving Software

Why Choose LightBurn?

Intuitive Interface: LightBurn boasts a user-friendly interface that makes it accessible to both beginners and experienced users. Its straightforward layout allows for efficient workflow and minimal learning curve.

Comprehensive Design Tools: With robust design capabilities, LightBurn empowers users to create intricate designs, edit vector graphics, and import various file formats (AI, SVG, DXF, etc.).

Precise Laser Control: The software offers granular control over laser parameters such as power, speed, and frequency, allowing for fine-tuning of cuts and engravings.

1. Exploring the Key Features of LightBurn Engraving Software

Image Processing: LightBurn excels in converting raster images into vector graphics, making it ideal for photo engraving and creating detailed patterns.

Camera Integration: Some laser cutters can be equipped with cameras, and LightBurn can utilize this feature to accurately position and align materials.

1. Maximizing Your Laser Cutting Potential with Lightburn Software

Job Management: Efficiently organize and manage multiple projects with LightBurn's job management system.

Compatibility: LightBurn supports a wide range of laser cutters, making it a versatile choice for different machines.

1. The Difference Between LightBurn and LaserGRBL - ACMER laser engraver

Community and Support: A thriving online community provides valuable resources, tutorials, and support for LightBurn users.

How LightBurn Enhances Your Laser Cutting Experience

By using LightBurn, you can:

Increase Productivity: Streamline your workflow and reduce setup time.

Improve Accuracy: Achieve precise cuts and engravings with advanced control options.

1. Integrating Your OMTech Laser with LightBurn: A Step-by-Step Guide - Monport Laser

Expand Creative Possibilities: Explore new design techniques and materials.

Save Time and Money: Optimize material usage and reduce errors.

In conclusion, LightBurn is a powerful and versatile software that can significantly enhance your laser cutting experience. Whether you're a hobbyist or a professional, investing in LightBurn can be a game-changer for your projects.

1. Maximizing Your Laser Cutting Potential with Lightburn Software

Why You Should Never Use Non-Laser Safe Materials with a Laser Cutter

Why You Should Never Use Non-Laser Safe Materials with a Laser Cutter

Laser cutters are powerful tools capable of precise and intricate cutting, engraving, and marking on a variety of materials. However, it’s crucial to understand that not all materials are safe for laser cutting. Using non-laser safe materials can lead to a host of problems, from damaging the machine to creating hazardous fumes.

1. Laser Cutter Safety: 4 Materials You Should Never Cut - SSI Packaging Group Inc

Dangers of Using Non-Laser Safe Materials

Machine Damage: Non-laser safe materials can melt, burn, or ignite, damaging the laser cutter’s optics, bed, and internal components. This can result in costly repairs or even the complete loss of the machine.

1. Materials that cannot be processed with a laser - JustLaser

Health Hazards: Some materials release toxic fumes or particles when cut with a laser. These can be harmful if inhaled, causing respiratory problems or other health issues.

1. Understand the Different Fumes When Laser Cutting

2. Lase Dust Hazards: Engraving Health Risks from Laser Fumes - IP Systems

Fire Risk: Certain materials are highly flammable and can ignite when exposed to the laser beam, posing a serious fire hazard.

Inaccurate Cuts: Non-laser safe materials may not cut cleanly, resulting in poor quality and wasted material.

Common Non-Laser Safe Materials

PVC: Releases toxic fumes, including chlorine gas, which is harmful to both humans and the machine.

1. Laser Cutter Safety: 4 Materials You Should Never Cut - SSI Packaging Group Inc

Polycarbonate: Melts and sticks to the laser bed, causing damage and creating a mess.

Fiberglass: Releases harmful fibers into the air, which can cause respiratory problems.

Certain plastics: Some plastics contain additives that can release toxic fumes when cut.

Materials with coatings: Coatings can melt, burn, or release harmful fumes.

Safety Precautions

Always check the material safety data sheet (MSDS) before cutting any material.

Use a fume extraction system to remove harmful fumes.

Wear appropriate personal protective equipment, including safety glasses and gloves.

Follow the laser cutter manufacturer's guidelines.

By understanding the risks and taking necessary precautions, you can safely and effectively use your laser cutter to create amazing projects.

Remember: When in doubt, it's always better to err on the side of caution and choose a laser-safe material.

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)