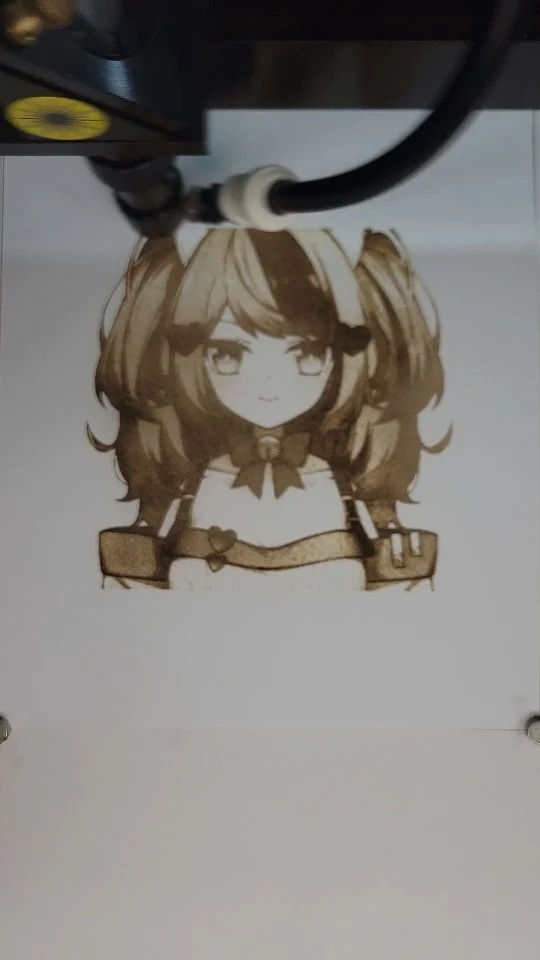

American Laser Cutter: Your Precision Cutting Partner in Los Angeles

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

Top Online Designers for Laser Cutting Projects

Top Online Designers for Laser Cutting Projects

Finding the right designer can elevate your laser cutting projects to new heights. While many freelance platforms offer design services, some specialize in laser cutting-specific designs. Here are some notable options:

Online Design Platforms

Fiverr: Offers a vast pool of designers with varying levels of expertise and pricing.

Upwork: Similar to Fiverr, but often caters to more complex and high-end projects.

Creative Market:

Provides access to pre-designed templates and digital assets that can be customized for laser cutting.

1. Laser cutting digital assets for download designed to impress - Creative Market

Tips for Finding the Right Designer

Clear Communication: Clearly articulate your project vision, including dimensions, materials, and desired style.

Portfolio Review: Assess the designer's previous work to ensure their style aligns with your project.

File Formats: Specify the required file format (e.g., SVG, DXF) for your laser cutter.

Kerf Compensation: Discuss how the designer will account for kerf (material removed during cutting) in the design.

Communication: Maintain open communication throughout the design process to ensure the final product meets your expectations.

Additional Considerations

In-House Design: If you have basic design skills, consider using software like Adobe Illustrator or Inkscape to create your own designs.

Online Design Templates: Explore websites offering free or paid laser cut design templates.

Design Communities: Engage with online communities like Reddit's r/lasercutting for potential collaborations or design inspiration.

By carefully selecting a designer or leveraging available resources, you can create stunning laser cut projects that stand out.

Fiverr: Your Design Partner for Laser Cutting

Fiverr: Your Design Partner for Laser Cutting

Fiverr, a global online marketplace, offers a vast pool of talented designers ready to create custom laser cut files tailored to your needs. Whether you're a hobbyist, small business owner, or professional designer, Fiverr can be a valuable resource for bringing your ideas to life.

How Fiverr Works for Laser Cutting Files

Create a Gig: Clearly outline your project requirements, including dimensions, materials, desired design style, and any specific preferences.

Find a Designer: Browse through designer portfolios, read reviews, and compare prices to find the perfect fit for your project.

Communicate with the Designer: Discuss your ideas, provide feedback, and ensure the designer understands your vision.

Receive Your Files: Once the design is finalized, you'll receive the laser-ready files in a suitable format (e.g., SVG, DXF).

Tips for Success

Be Specific: Clearly communicate your project goals and provide as much detail as possible.

Provide References: Share examples of designs you like to inspire the designer.

Communicate Regularly: Maintain open communication throughout the design process.

Check File Formats: Ensure you receive the correct file format for your laser cutter.

Benefits of Using Fiverr

Cost-Effective: Fiverr offers a wide range of pricing options to fit any budget.

Diverse Talent: Access a global pool of designers with various styles and expertise.

Quick Turnaround: Many designers offer fast delivery options.

No Design Skills Required: Even if you have no design experience, you can still create stunning laser cut projects.

Potential Challenges

Quality Control: It's essential to carefully review the designer's portfolio and read reviews before placing an order.

Communication Barriers: Language and cultural differences can sometimes lead to misunderstandings.

By following these tips and carefully selecting a designer, you can leverage Fiverr to create exceptional laser cut designs that meet your expectations.

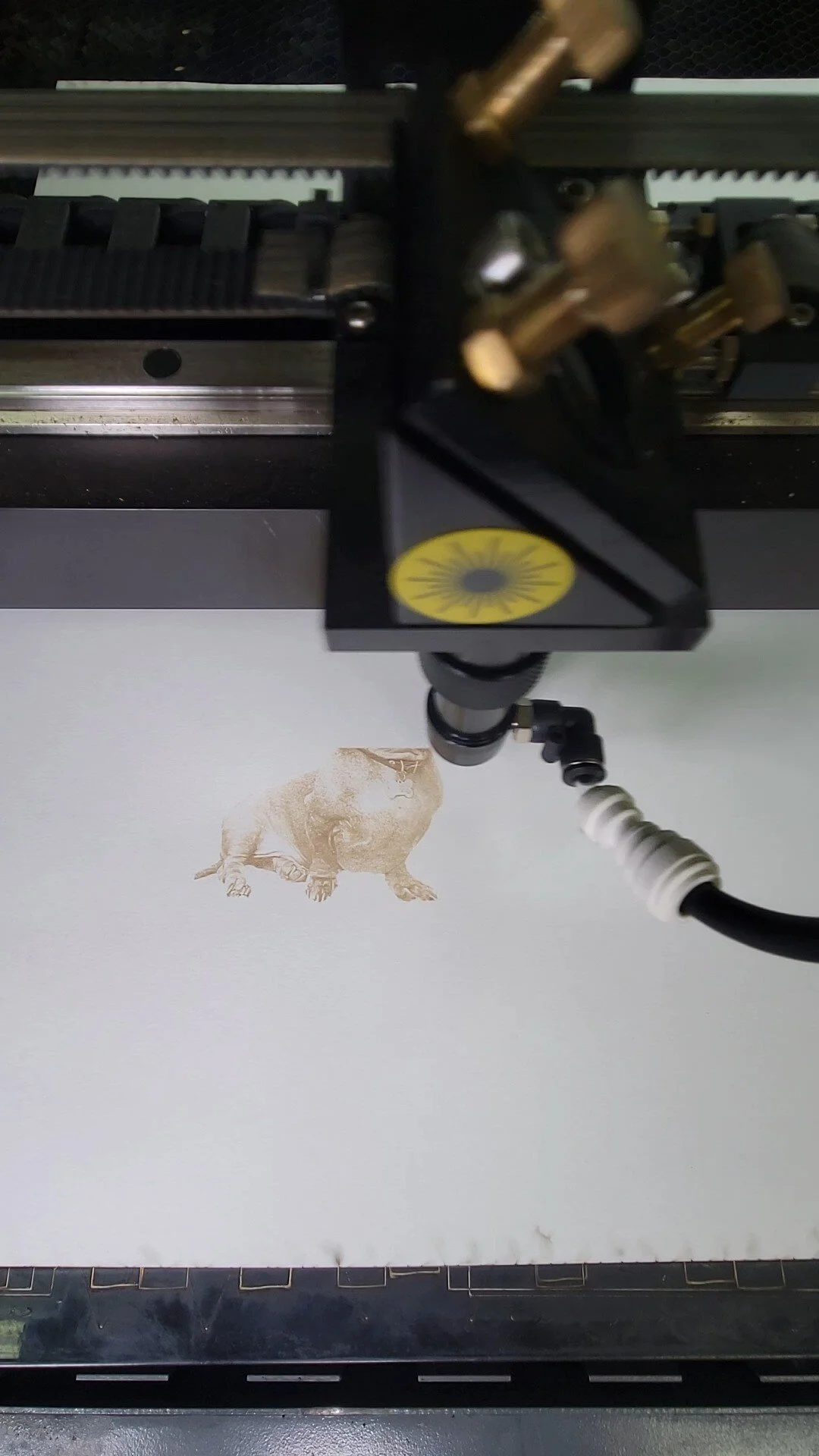

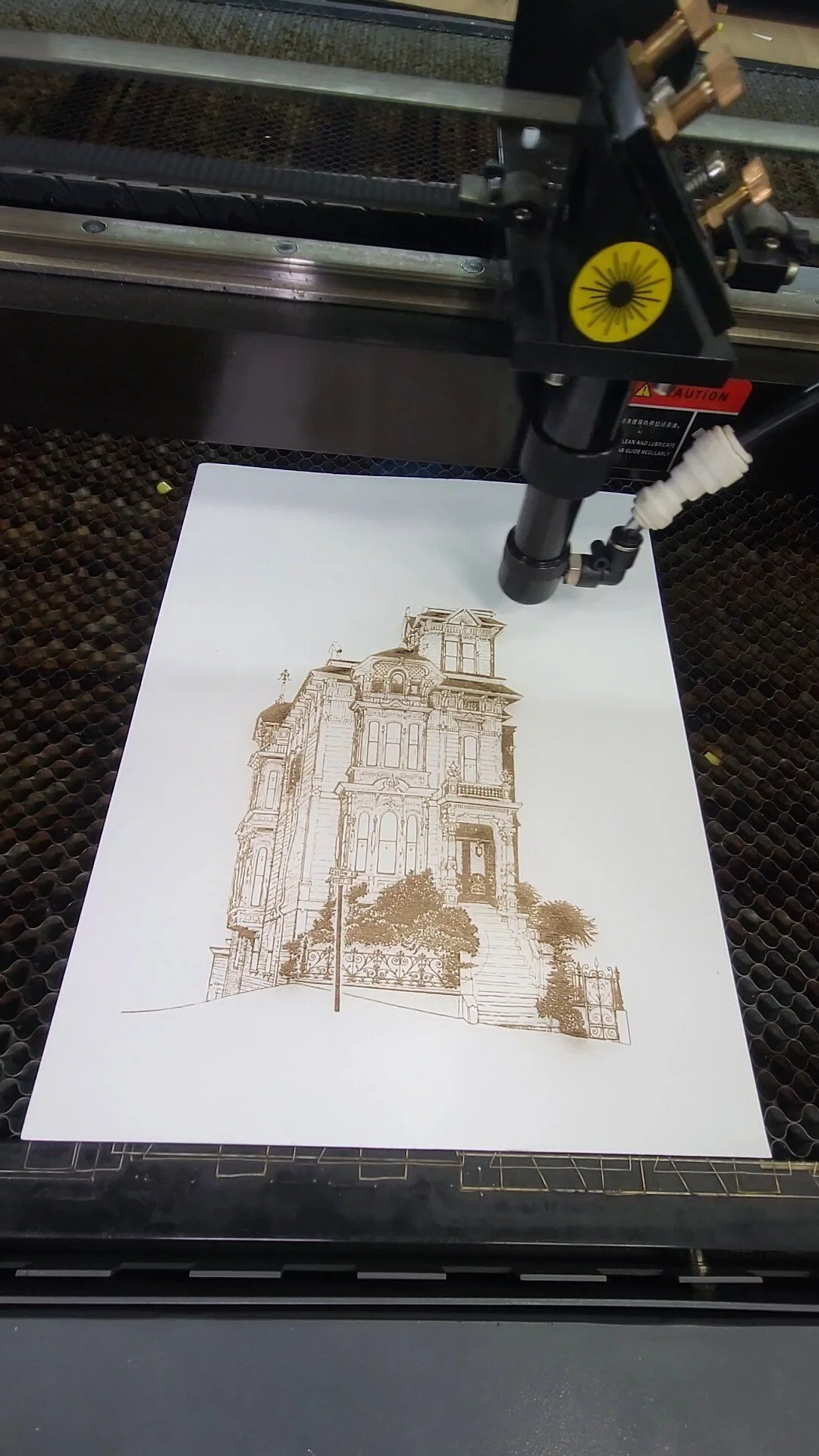

Laser Cutting Paper: A Delicate Art

Laser Cutting Paper: A Delicate Art

Laser cutting paper offers a world of possibilities for creating intricate and stunning designs. From delicate papercuts to functional paper crafts, this technique has gained popularity among artists, designers, and hobbyists alike.

Types of Paper for Laser Cutting

While most papers can be cut with a laser, certain types are better suited for this process:

Cardstock: Provides a sturdy base for intricate designs and holds its shape well.

Paperboard: Thicker than cardstock, ideal for creating boxes, structures, or three-dimensional pieces.

Specialty Papers: Explore papers with different textures, colors, or weights to add depth and interest to your projects.

Laser-Cut Paper: Some manufacturers offer paper specifically designed for laser cutting, with properties optimized for clean cuts and minimal smoke.

Tips for Laser Cutting Paper

Design Optimization: Create designs with clean lines and avoid overly complex details to prevent paper breakage.

Kerf Consideration: Account for the kerf (material removed by the laser) when designing interlocking pieces.

Test Cuts: Experiment with different paper types and laser settings to find the optimal combination.

Ventilation: Ensure proper ventilation to remove smoke and fumes generated during the cutting process.

Creative Paper Cutting Projects

Papercut Art: Create intricate and delicate wall art or decorative pieces.

Paper Flowers: Design beautiful and realistic paper flowers for bouquets or home decor.

Paper Models: Build intricate paper models of buildings, animals, or objects.

Pop-Up Cards: Create interactive and engaging cards with surprising elements.

Paper Packaging: Design unique and eco-friendly packaging for products.

Laser cutting paper opens up a world of creative potential. With careful planning and experimentation, you can create stunning and intricate pieces that will impress.

1. Creative projects with paper: Optimal use of laser cutters - JustLaser

Laser Cutters: Regular Maintenance is Essential

Laser Cutters: Regular Maintenance is Essential

Yes, laser cutters require regular maintenance.

Just like any precision instrument, consistent care ensures optimal performance, longevity, and safety.Neglecting maintenance can lead to decreased cutting quality, increased downtime, and even costly repairs.

1. Laser Cutter Maintenance Guide

2. How to Maintain and Service Your Laser Cutter Machine Effectively

3. Managing maintenance for laser cutting machines - The Fabricator

Regular maintenance involves tasks such as:

Cleaning optics: Removing dust and debris from mirrors and lenses.

Checking air filters: Ensuring proper airflow to prevent overheating.

Lubricating moving parts: Maintaining smooth operation of mechanical components.

1. Laser Cutting Machine Maintenance Guide – Ensuring Optimal Performance

Calibrating the laser: Ensuring accurate cutting and engraving.

1. Everything you need to know about laser machine maintenance - Hobarts

By investing time in routine maintenance, you can significantly extend the life of your laser cutter and enjoy consistent, high-quality results.

1. Everything you need to know about laser machine maintenance - Hobarts

First Steps When Your Laser Cutter Stops Working

First Steps When Your Laser Cutter Stops Working

A sudden halt in your laser cutter's operation can be disruptive. Here's a basic checklist to troubleshoot the issue before seeking professional help:

Safety First

Power Off: Always ensure the laser cutter is unplugged and disconnected from any power source before attempting any repairs.

Basic Checks

Power Supply: Verify that the laser cutter is properly plugged in and receiving power.

Control Panel: Check for error messages or indicators on the control panel.

Software Issues: Try restarting the laser cutter or the computer controlling it.

Air Supply: Ensure the air compressor or fan is working correctly.

Cooling System: Verify that the cooling system is functioning properly.

Material Compatibility: Check if the material you're using is compatible with your laser cutter's settings.

Common Issues

Lens Contamination: A dirty lens can affect laser performance. Clean it gently with lens cleaning paper and isopropyl alcohol.

Mirror Alignment: Misaligned mirrors can cause issues. Consult your user manual for alignment procedures.

Laser Tube Issues: If the laser tube is old or damaged, it might be the culprit. Consult a professional.

If these steps don't resolve the problem, it's time to contact a laser cutter repair specialist.

Remember: Laser cutters involve high voltage and intense light. If you're unsure about any repairs, consult a professional immediately.

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

American Laser Cutter: A Leader in Aftermarket Laser Cutter Repair

American Laser Cutter: A Leader in Aftermarket Laser Cutter Repair

American Laser Cutter is a prominent player in the aftermarket laser cutter repair industry within the United States. As a dedicated service provider, they specialize in repairing and maintaining CO2 laser cutters without being involved in the manufacturing or selling of these machines.

2. Laser Repair Services - American Laser Cutter

This focused approach allows American Laser Cutter to cultivate a deep understanding of laser cutter technology and develop expertise in resolving a wide range of issues. By concentrating solely on repairs and maintenance, they can offer comprehensive solutions to customers across the country.

1. Laser Repair Services - American Laser Cutter

Their commitment to providing top-tier service, coupled with their in-depth knowledge of laser cutters, has solidified American Laser Cutter's position as a trusted and reliable choice for businesses and individuals seeking expert repair solutions.

American Laser Cutter: Your Laser Cutter Repair Experts

American Laser Cutter: Your Laser Cutter Repair Experts

American Laser Cutter has established itself as a leading authority in laser cutter repair and maintenance. With a dedicated focus on this specialized equipment, they offer comprehensive solutions for a wide range of laser cutter issues.

Expert Technicians, Proven Results

The company boasts a team of highly skilled technicians with extensive experience in diagnosing and repairing CO2 laser cutters. Their expertise covers a variety of brands and models, ensuring that clients receive top-notch service regardless of their machine.

2. Laser Repair Services - American Laser Cutter

Comprehensive Repair Services

American Laser Cutter offers a full suite of repair services, including:

Routine maintenance: Preventative care to extend the life of your laser cutter.

Component replacement: Sourcing and installing replacement parts.

Complex repairs: Addressing intricate issues that require specialized knowledge.

Remote troubleshooting: Providing expert guidance and support without on-site visits.

Customer Satisfaction

The company is committed to delivering exceptional customer service. They prioritize quick turnaround times and transparent communication to minimize downtime and keep businesses operating efficiently.If you're facing laser cutter problems, American Laser Cutter is your go-to solution. With their expertise, dedication, and customer-centric approach, they are the ideal partner for keeping your equipment in optimal working condition.

Top 10 Maintenance Tips to Extend Your Laser Cutter's Lifespan

Top 10 Maintenance Tips to Extend Your Laser Cutter's Lifespan

Proper maintenance is essential for maximizing the lifespan and performance of your laser cutter. Here are ten key tips to keep your machine in optimal condition:

Regular Cleaning: Dust, debris, and material residue can accumulate quickly. Clean the machine regularly, focusing on optics, mirrors, and the cutting bed.

Optics Care: Your laser cutter's optics are delicate. Clean them gently with lens cleaning paper and isopropyl alcohol. Avoid touching the lens surface with your fingers.

Air Filtration: A clean air filter prevents contaminants from entering the laser tube. Replace or clean the filter according to the manufacturer's recommendations.

Cooling System Maintenance: Ensure the cooling system is working efficiently. Check for leaks, clogs, and proper coolant levels.

Lubrication: Regularly lubricate moving parts like rails and bearings as per the manufacturer's guidelines.

Software Updates: Keep your laser cutter's software up-to-date with the latest versions to benefit from bug fixes and performance improvements.

Calibration: Periodically calibrate the laser cutter to maintain accuracy and precision.

Power Management: Avoid sudden power surges or fluctuations. Consider using a surge protector.

Regular Inspections: Conduct routine inspections for signs of wear and tear, loose components, or abnormal noises.

Professional Maintenance: Schedule regular professional maintenance checks to identify and address potential issues.

By following these tips, you can significantly extend the lifespan of your laser cutter, improve its performance, and reduce the risk of costly repairs.

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

Getting Assistance for Scheduled Laser Cutter Maintenance

Getting Assistance for Scheduled Laser Cutter Maintenance

Regular maintenance is crucial for optimal laser cutter performance and longevity. Here are several options to get assistance with your scheduled maintenance:

1. 5 Maintenance Tips to Extend the Lifespan of Your Laser Cutter - ACRA Machinery

Manufacturer Support

Warranty Coverage: If your laser cutter is under warranty, the manufacturer might offer scheduled maintenance services.

Technical Assistance: Even out of warranty, they can provide guidance and recommendations for maintenance tasks.

Authorized Service Providers: The manufacturer may recommend specific service providers for maintenance.

Independent Laser Repair Specialists

Specialized Expertise: Laser repair specialists often offer comprehensive maintenance packages.

Customizable Services: They can tailor maintenance plans to your specific needs.

Preventive Measures: Regular maintenance can help identify potential issues before they become major problems.

Online Resources and Communities

DIY Maintenance: Online forums and communities may offer tips and guidance on basic maintenance tasks.

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

Preventive Maintenance Tips

Clean Regularly: Remove dust and debris from the machine and optics.

1. How to Maintain and Service Your Laser Cutter Machine Effectively

Check Cooling System: Ensure the cooling system is functioning properly.

1. Laser Cutting Machine Maintenance Guide – Ensuring Optimal Performance

Lubricate Moving Parts: Follow manufacturer recommendations for lubrication.

Software Updates: Keep the laser cutter's software up-to-date.

By combining these options, you can establish a comprehensive maintenance plan for your laser cutter. Regular upkeep will extend the machine's life, improve performance, and reduce the risk of unexpected breakdowns.

1. Everything you need to know about laser machine maintenance - Hobarts

Repairing Your Laser Cutter: A Guide for the Non-Expert

Repairing Your Laser Cutter: A Guide for the Non-Expert

Disclaimer: Working with lasers involves risks. If you're unsure about any repair, consult a professional.

If you're not electrically inclined, repairing a laser cutter can seem daunting. However, there are steps you can take to address common issues.

Safety First

Power Off: Always ensure the laser cutter is unplugged and disconnected from any power source before attempting any repairs.

Protective Gear: Wear appropriate safety gear, including eye protection, gloves, and a dust mask.

Basic Troubleshooting

Check Connections: Ensure all cables, power cords, and connections are secure.

1. Laser Cutting Machine Maintenance Guide – Ensuring Optimal Performance

Inspect Optics: A dirty lens can affect laser performance. Clean it gently with a lens cleaning kit.

Air Filter: A clogged air filter can cause overheating. Clean or replace it.

Software Issues: Try restarting the laser cutter or reinstalling the software.

Seek Professional Help

If basic checks don't resolve the issue, it's time to involve an expert:

Manufacturer Support: Contact the manufacturer for warranty claims or technical assistance.

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

Online Resources: Explore online forums and communities for recommendations.

Preventative Maintenance

Regular care can prevent future problems:

Cleaning: Keep the laser cutter clean and free from debris.

Cooling System: Check the cooling system for proper function.

Software Updates: Keep the laser cutter's software up-to-date.

Remember: While some basic troubleshooting can be done independently, laser cutters contain high-voltage components. If you're unsure about any repair, consult a professional.

By following these guidelines and prioritizing safety, you can extend the life of your laser cutter and minimize downtime.

Would you like to know more about specific laser cutter problems or how to find a reliable repair service?

Laser Cutter Repair for the Electronics Novice

Laser Cutter Repair for the Electronics Novice

If you're not electrically inclined, repairing a laser cutter might seem daunting. However, there are steps you can take to address common issues and find professional help when needed.

Basic Troubleshooting

Check Power Supply: Ensure the laser cutter is properly plugged in and receiving power.

Inspect Connections: Verify that all cables and connections are secure.

Clean Optics: A dirty lens can affect laser performance. Clean it carefully using appropriate cleaning supplies.

Check Air Filter: A clogged air filter can cause overheating. Clean or replace it as needed.

Software Issues: Try restarting the laser cutter or updating the software.

Seek Professional Help

If basic troubleshooting doesn't resolve the issue, it's time to involve a professional.

Manufacturer Support: Contact the laser cutter's manufacturer for warranty claims or technical assistance.

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

Online Resources: Search for repair services in your area or consider remote repair options.

Preventive Maintenance

Regular maintenance can help prevent future problems:

Clean Regularly: Keep the laser cutter free from dust and debris.

Check Cooling System: Ensure the cooling system is functioning properly.

Software Updates: Keep the laser cutter's software up-to-date.

Remember: Safety is paramount when working with laser equipment. If you're unsure about any repair, consult a professional.

By following these guidelines and seeking expert assistance when necessary, you can increase the lifespan and performance of your laser cutter.

Finding Professional Assistance for Your Laser Cutter

Finding Professional Assistance for Your Laser Cutter

When your laser cutter malfunctions, seeking professional help can save time and prevent further damage. Here's how to find the right assistance:

1. Manufacturer Support:

Check Warranty: If your laser cutter is still under warranty, contact the manufacturer for support.

Technical Assistance: Even out of warranty, they might offer troubleshooting advice or refer you to authorized service providers.

2. Laser Repair Specialists:

Local Options: Search for laser repair services in your area.

Online Directories: Use platforms like Google Maps, Yelp, or industry-specific directories to find specialists.

Expertise: Look for companies with experience in your specific laser cutter model.

3. Online Forums and Communities:

Seek Recommendations: Laser-related forums often have users sharing experiences with repair services.

DIY Troubleshooting: While not a replacement for professional help, online communities can provide valuable tips.

4. Remote Repair Services:

Convenience: Consider remote repair services for troubleshooting and diagnostics.

Time-Saving: Avoids on-site visits and potential downtime.

Tips for Choosing a Professional:

Experience: Look for companies with a proven track record in laser cutter repair.

Certifications: Check for relevant certifications or accreditations.

Customer Reviews: Read reviews to assess customer satisfaction.

Quotes: Obtain quotes from multiple providers to compare prices and services.

By following these steps and carefully selecting a professional, you can ensure your laser cutter receives the necessary care and attention.

Would you like to know more about specific questions to ask a potential laser cutter repair technician?

Laser Cut Jewelry: A Cut Above the Rest

Laser Cut Jewelry: A Cut Above the Rest

Laser cutting has revolutionized the jewelry-making process, allowing for intricate designs and precision that were once unimaginable. This technology has opened up a world of possibilities for both jewelry designers and enthusiasts.

1. Lasers for Jewelry and Watchmaking - Power Technology, Inc.

2. How Technology is Revolutionizing the World of Jewelry Design and Manufacturing

The Beauty of Laser Cut Jewelry

Intricate Designs: Laser cutting enables the creation of incredibly detailed and delicate patterns that would be impossible to achieve with traditional methods.

Customization: With laser cutting, you can personalize jewelry with names, dates, or special symbols.

Variety of Materials: From wood and acrylic to metal and leather, laser cutting can be applied to a wide range of materials, offering endless creative options.

Durability: Laser-cut jewelry is often characterized by its durability, as the cutting process creates clean and precise edges.

1. Laser Cut Jewelry–The Unique Beauty Created by Laser Technology - dxtech laser

Popular Laser Cut Jewelry Styles

Geometric Designs: Clean lines and angular shapes create a modern and minimalist aesthetic.

Floral Motifs: Delicate floral patterns add a touch of femininity and elegance.

Personalized Pieces: Create unique jewelry with names, initials, or special dates.

Layered Designs: Combine multiple laser-cut elements for a dimensional and eye-catching look.

Tips for Creating Laser Cut Jewelry

Design Software: Use design software to create your desired patterns and shapes.

Material Selection: Choose a material that complements your design and meets your desired aesthetic.

Kerf Compensation: Consider the kerf (material removed by the laser) when designing interlocking pieces.

Finishing Touches: Enhance the beauty of your jewelry with additional finishes like polishing, plating, or painting.

1. 5 Incredible Reasons to Use Laser Cutters for Jewelry Making - 3D Universe

Laser cut jewelry offers a unique blend of artistry and technology, allowing for the creation of truly extraordinary pieces. Whether you're a jewelry designer or a hobbyist, exploring the possibilities of laser cutting is sure to inspire your creativity.

Need Online Assistance for Your Laser Cutter?

Need Online Assistance for Your Laser Cutter?

Encountering issues with your laser cutter can be frustrating, especially when you need to keep production running smoothly. Fortunately, several avenues for online assistance are available.

1. Laser Cutter Online Tech Support

1. Manufacturer Support:

Check Warranty: If your laser cutter is still under warranty, contact the manufacturer for support.

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

2. Online Forums and Communities:

Seek Advice: Platforms like Reddit, Facebook groups, or laser-specific forums can offer valuable insights from other users facing similar issues.

DIY Troubleshooting: You might find solutions to common problems shared by other users.

3. Video Tutorials and Online Courses:

Learning Resources: Platforms like YouTube and Udemy offer numerous tutorials on laser cutter operation, maintenance, and troubleshooting.

Hands-on Learning: Visual guides can help you understand complex issues better.

4. Remote Repair Services:

Expert Assistance: Consider companies specializing in remote laser cutter repair for professional troubleshooting and guidance.

Time-Saving: Remote assistance can often resolve issues without the need for on-site visits.

5. Online Parts and Accessories Suppliers:

Component Replacement: Some suppliers offer troubleshooting guides or technical support for parts they sell.

Tips for Effective Online Assistance:

Clear Problem Description: Provide detailed information about the issue, including error messages or unusual behavior.

Gather Information: Have your laser cutter's model number, serial number, and software version ready.

Share Images or Videos: Visual aids can help others understand the problem better.

Backup Data: Create backups of your laser cutter's settings and files before making significant changes.

By combining these resources and following these tips, you can increase your chances of resolving laser cutter issues efficiently.

Would you like to know more about specific online resources or troubleshooting steps for common laser cutter problems?

American Laser Cutter: The Premier Aftermarket Laser Cutter Repair Company

American Laser Cutter: The Premier Aftermarket Laser Cutter Repair Company

American Laser Cutter has solidified its position as the leading aftermarket technical repair company for laser cutters.

With a steadfast commitment to excellence, they have earned a reputation for providing unparalleled service and expertise.

Unmatched Expertise At the core of American Laser Cutter's success is their team of highly skilled technicians. Possessing an in-depth understanding of various laser cutter models and components, they excel in diagnosing and resolving complex issues. Their extensive experience allows them to efficiently identify problems and implement effective solutions.

Comprehensive Repair Services American Laser Cutter offers a wide range of repair services to cater to the diverse needs of its customers. From routine maintenance and component replacement to advanced troubleshooting and system upgrades, they provide comprehensive solutions. Their commitment to staying updated with the latest industry advancements ensures that they can handle any challenge that arises.

1. Laser Repair Services - American Laser Cutter

Customer Satisfaction American Laser Cutter prioritizes customer satisfaction above all else. They understand the critical role that laser cutters play in businesses and strive to minimize downtime. Their prompt and efficient service, coupled with transparent communication, has earned them a loyal customer base.

Cost-Effective Solutions As an aftermarket repair company, American Laser Cutter offers competitive pricing without compromising on quality. They provide cost-effective solutions to keep your laser cutter operating at peak performance.

Dedicated to Customer Success American Laser Cutter goes beyond providing repair services. They offer valuable advice and support to help customers optimize their laser cutter's performance and extend its lifespan. Their dedication to customer success sets them apart as a true industry leader.

By choosing American Laser Cutter, you can be confident that your laser cutter is in the hands of experts who are committed to delivering exceptional service.

Would you like to know more about a specific aspect of American Laser Cutter's services?

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

Learn How to Operate Your Laser Cutter with Expert Guidance

Learn How to Operate Your Laser Cutter with Expert Guidance

Mastering the intricacies of a CO2 laser cutter can be a steep learning curve. Thankfully, services like American Laser Cutter offer invaluable support to help you become a proficient operator.

Benefits of Expert Training

In-Depth Knowledge: Experts can provide comprehensive training on all aspects of laser cutter operation, from basic controls to advanced techniques.

Time Savings: Learning from experienced professionals can significantly reduce your learning curve, allowing you to start producing quality results faster.

Safety First: Proper training emphasizes safety protocols, ensuring you operate the machine responsibly.

Troubleshooting Assistance: Experts can teach you how to identify and resolve common issues, minimizing downtime.

Maximizing Productivity: Learn how to optimize your laser cutter's settings for different materials and projects.

Best Practices: Gain insights into industry best practices to improve your overall efficiency.

Personalized Support

American Laser Cutter's training programs often include personalized attention, allowing you to ask questions and receive tailored guidance based on your specific needs.

Ongoing Support

Many training providers offer ongoing support, such as email or phone assistance, to help you as you gain experience.

By investing in professional training, you'll not only become a confident laser cutter operator but also unlock the full potential of your machine.

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

American Laser Cutter: Your Remote CO2 Laser Repair Experts

American Laser Cutter: Your Remote CO2 Laser Repair Experts

When your CO2 laser cutter encounters issues, downtime can be costly and frustrating. American Laser Cutter offers a solution with their professional online repair assistance.

Specialized in CO2 Laser Cutters Unlike many repair services that handle a variety of equipment, American Laser Cutter focuses exclusively on CO2 laser cutters. This specialization ensures their technicians possess in-depth knowledge and expertise to tackle even the most complex problems.

1. Laser Repair Services - American Laser Cutter

Remote Troubleshooting and Repair Their remote assistance service allows technicians to diagnose and resolve issues without the need for on-site visits. This saves you time and money while minimizing disruptions to your workflow.

1. Laser Cutter Online Tech Support

Nationwide Coverage No matter where you are located in the United States, American Laser Cutter can provide remote support for your CO2 laser cutter. Their team is available to assist you with a wide range of issues, from software glitches to hardware malfunctions.

1. Laser Repair Services - American Laser Cutter

2. Laser Cutter Online Tech Support

Beyond Remote Support In addition to online assistance, American Laser Cutter also offers on-site repair services for those situations that require hands-on attention.

If you're experiencing problems with your CO2 laser cutter, American Laser Cutter is a valuable resource to consider for efficient and effective repairs.

Finding a Company for Remote Laser Cutter Repair Assistance

Finding a Company for Remote Laser Cutter Repair Assistance

Remote repair assistance can be a game-changer when your laser cutter malfunctions. Here's how to find a reliable company to help you:

1. Manufacturer's Support:

Check Warranty: If your laser cutter is still under warranty, contact the manufacturer for remote support.

Technical Assistance: Even out of warranty, they might offer technical guidance or troubleshooting steps.

Manufacturer support issues: if you are having issues contacting your manufacturer or getting timely and quality service, we recommend reaching out to an independent Laser repair service like American laser cutter.

2. Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

3. Online Forums and Communities:

User Recommendations: Laser-related forums often have users sharing experiences with remote repair services.

Troubleshooting Tips: You might find solutions to common problems without needing external help.

Key Considerations When Choosing a Provider:

Expertise: Ensure the company has experience with your specific laser cutter model.

Availability: Check their operating hours and response times.

Security: Verify their data security protocols to protect your system.

Cost: Compare pricing and service packages.

Customer Reviews: Look for testimonials and feedback from previous clients.

Tips for a Successful Remote Repair Session:

Clear Communication: Describe the issue in detail, including error messages or unusual behavior.

Provide Access: Grant the technician remote access to your laser cutter's control system.

Prepare Information: Have the laser cutter's model number, serial number, and software version ready.

By following these steps and carefully selecting a provider, you can efficiently resolve laser cutter issues without on-site technicians.

Can't Find Local Laser Cutter Repair? Here's What to Do

Can't Find Local Laser Cutter Repair? Here's What to Do

Finding a local expert to repair your laser cutter can be challenging. If you've exhausted your local options, don't despair. Here are some alternative solutions:

Expand Your Search

Manufacturer support issues: if you are having issues contacting your manufacturer or getting timely and quality service, we recommend reaching out to an independent Laser repair service like American laser cutter. They offer both on site and remote repair services.

Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

DIY Repairs and Troubleshooting

Online Resources: There are numerous online forums and communities dedicated to laser cutters where users share troubleshooting tips and DIY repair guides.

Basic Maintenance: Check for common issues like clogged air filters, loose connections, or software glitches before seeking professional help.

YouTube Tutorials: Many laser cutter owners share helpful repair videos on platforms like YouTube.

Shipping Your Laser Cutter

Packaging: If you find a suitable repair service outside your local area, you may need to ship your laser cutter. Proper packaging is essential to prevent damage during transit.

Shipping Costs: Factor in shipping costs when considering this option.

Preventive Maintenance

Regular Cleaning: Keeping your laser cutter clean can prevent many issues.

Software Updates: Ensure your laser cutter's software is up-to-date.

Cooling System Check: Regularly inspect and maintain the cooling system.

Remember: While DIY repairs can save money, always prioritize safety. If you're unsure about any procedure, consult a professional.

By exploring these options and being patient, you can increase your chances of finding a solution for your laser cutter repair needs.

When Your Laser Cutter Manufacturer Fails You: Finding Alternative Support

When Your Laser Cutter Manufacturer Fails You: Finding Alternative Support

Dealing with a unresponsive or unhelpful laser cutter manufacturer can be frustrating. Fortunately, there are several avenues you can explore to get the support and repairs you need.

Independent Laser Repair Specialists

Manufacturer support issues: if you are having issues contacting your manufacturer or getting timely and quality service, we recommend reaching out to an independent Laser repair service like American laser cutter.

. Laser Repair Specialist:

Expertise: Companies specializing in laser repair have the knowledge and tools to diagnose and fix various issues.

Specialized Expertise: These technicians often have in-depth knowledge of various laser cutter models and components.

Quick Turnaround: Many independent repair services prioritize customer satisfaction and offer timely solutions.

Competitive Pricing: Independent repair shops can often provide more competitive rates than original equipment manufacturers (OEMs).

Online Communities and Forums

Peer-to-Peer Support: Online forums and communities dedicated to laser cutters are a valuable resource for troubleshooting and advice.

DIY Solutions: You might find step-by-step guides or workarounds for common issues.

Recommendations: Other users can recommend reliable repair services or parts suppliers.

Aftermarket Parts Suppliers

Component Replacement: If you can identify the faulty component, you might be able to purchase a replacement from an aftermarket supplier.

Cost-Effective Option: Aftermarket parts are often more affordable than OEM parts.

Local Electronics Repair Shops

General Troubleshooting: While not laser experts, they might be able to diagnose and fix basic electrical issues.

Quick and Convenient: Local repair shops offer the convenience of in-person service.

Important Considerations

Documentation: Gather all relevant documentation, including purchase receipts, manuals, and previous repair records.

Backup Data: Create backups of your laser cutter's software and settings to avoid data loss.

Safety First: Always prioritize safety when working on or around laser equipment.

By exploring these options, you can increase your chances of finding a reliable solution for your laser cutter problems, even if your manufacturer is not providing adequate support.

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)