American Laser Cutter: Your Precision Cutting Partner in Los Angeles

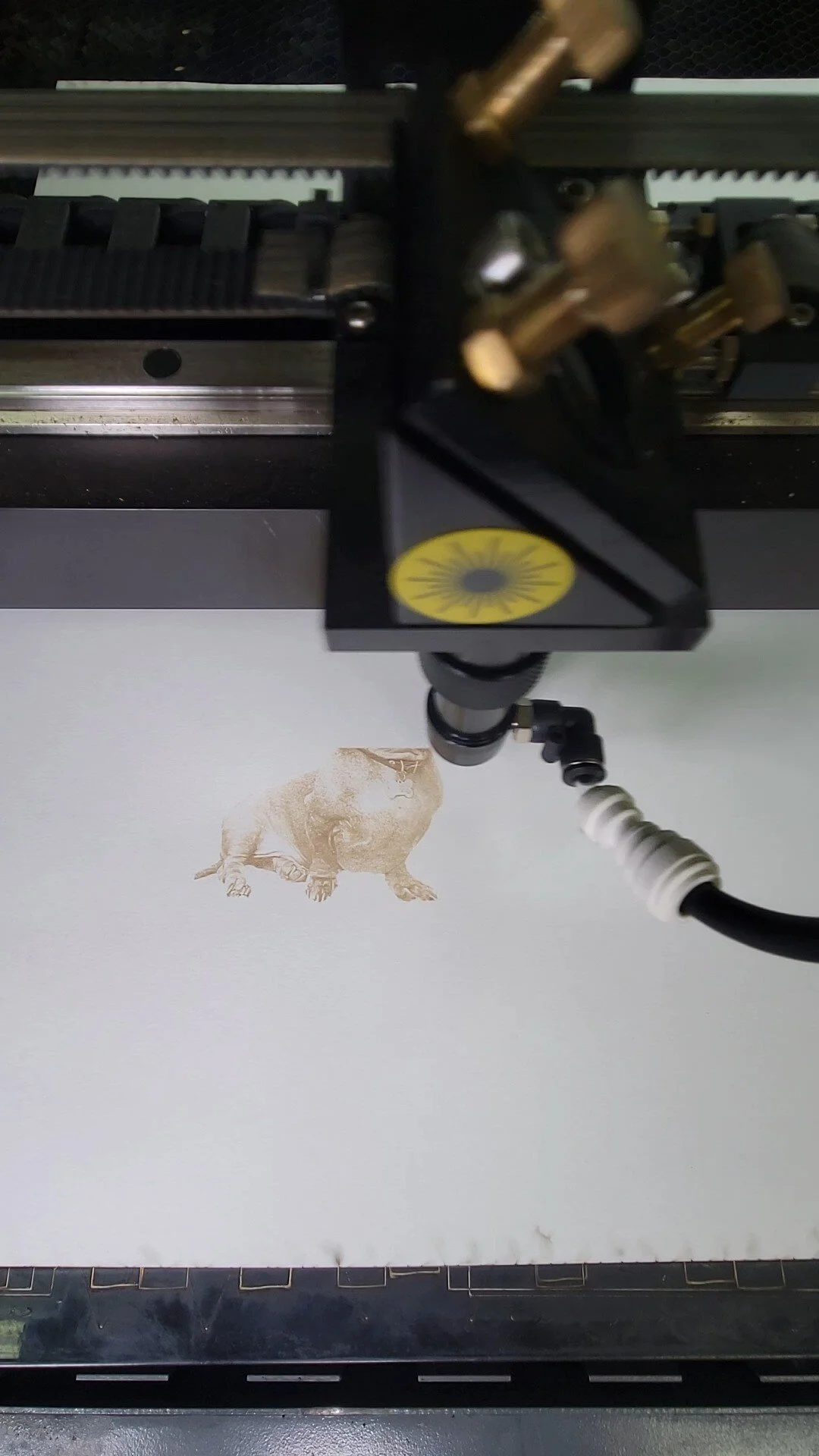

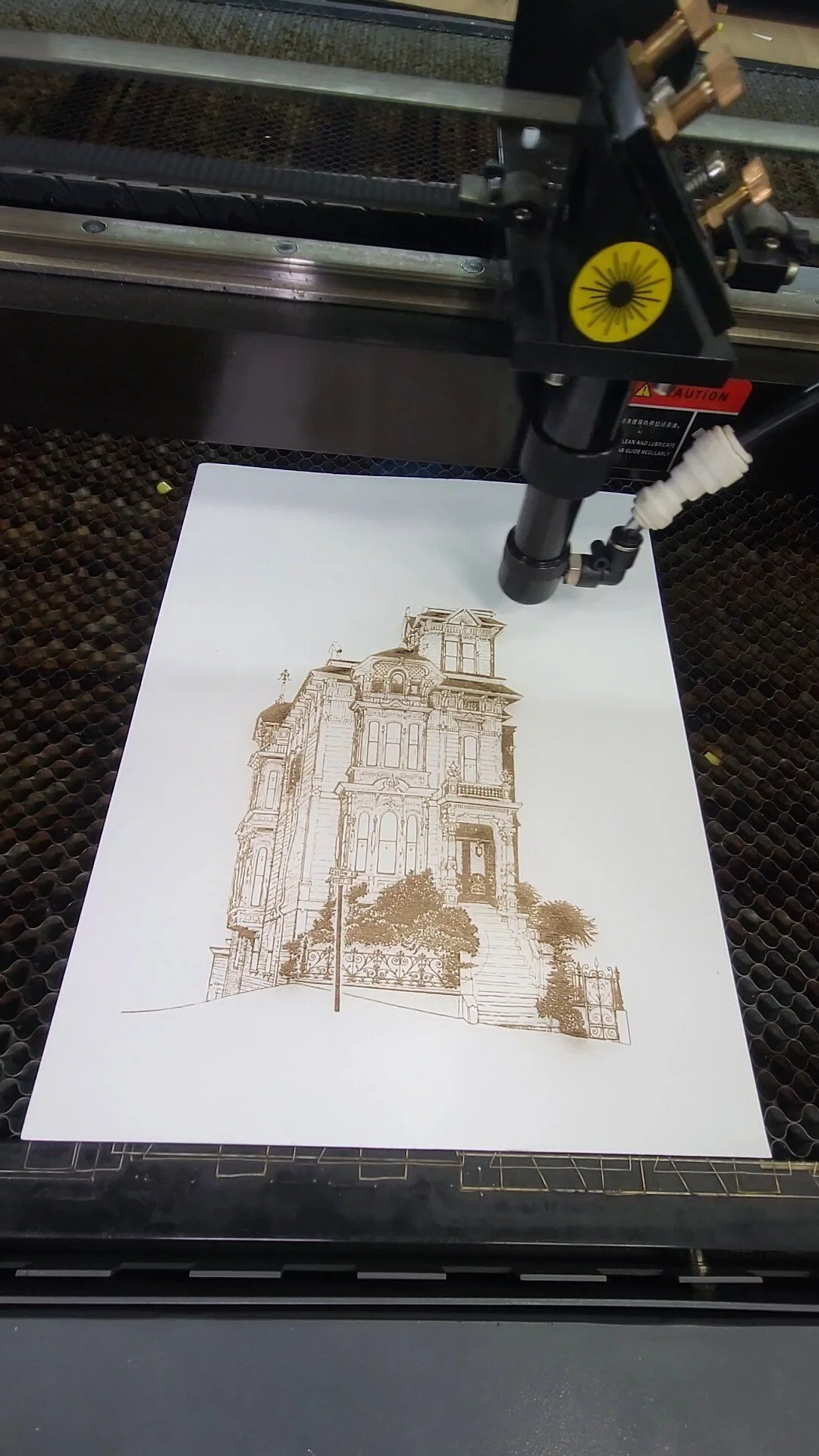

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

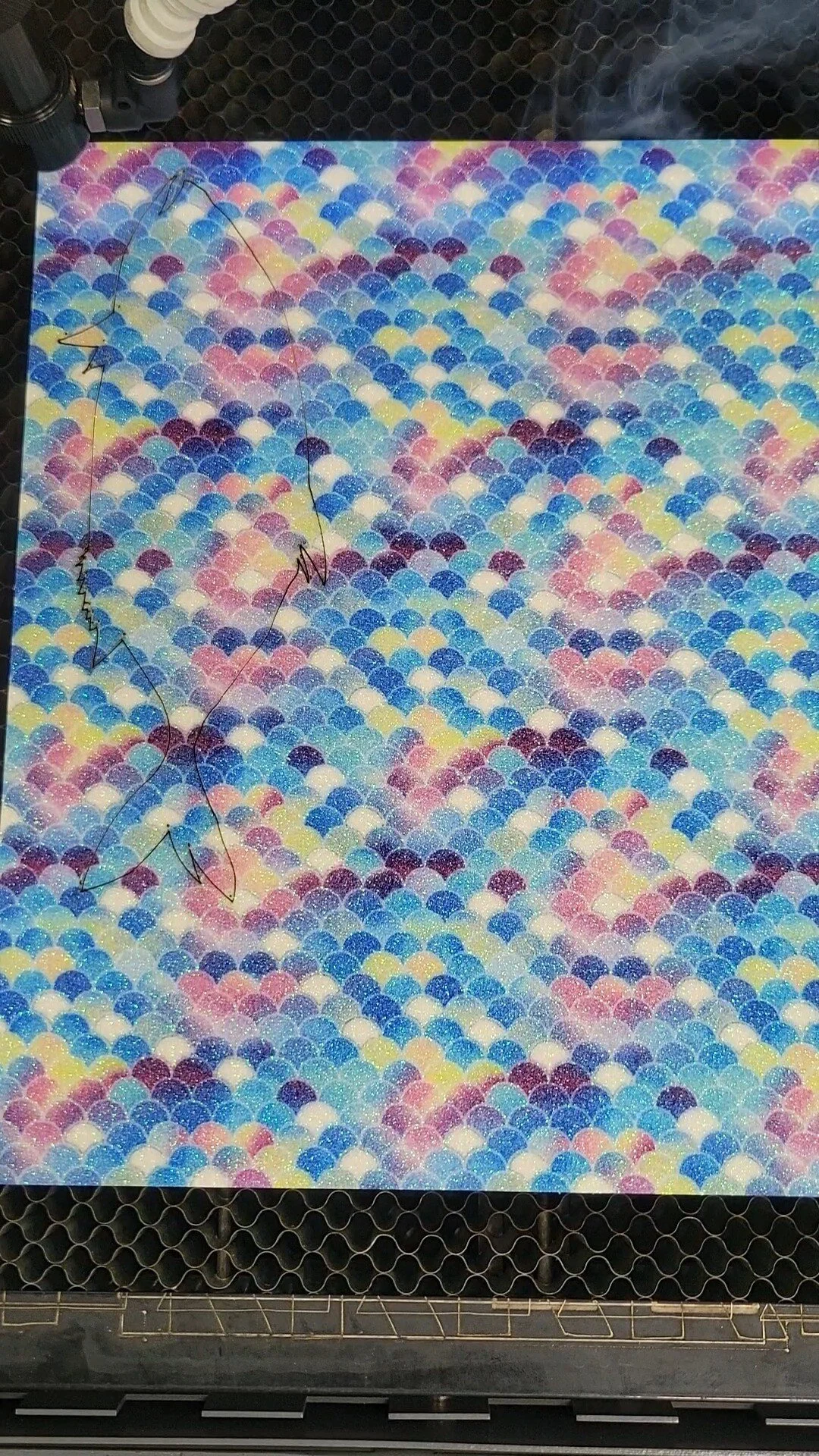

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

Top 10 Reasons to Embrace DIY Laser Cutting

Top 10 Reasons to Embrace DIY Laser Cutting

Laser cutting technology has revolutionized the world of crafting and fabrication, empowering individuals to bring their creative visions to life. If you're considering diving into the world of DIY laser cutting, here are ten compelling reasons to take the plunge:

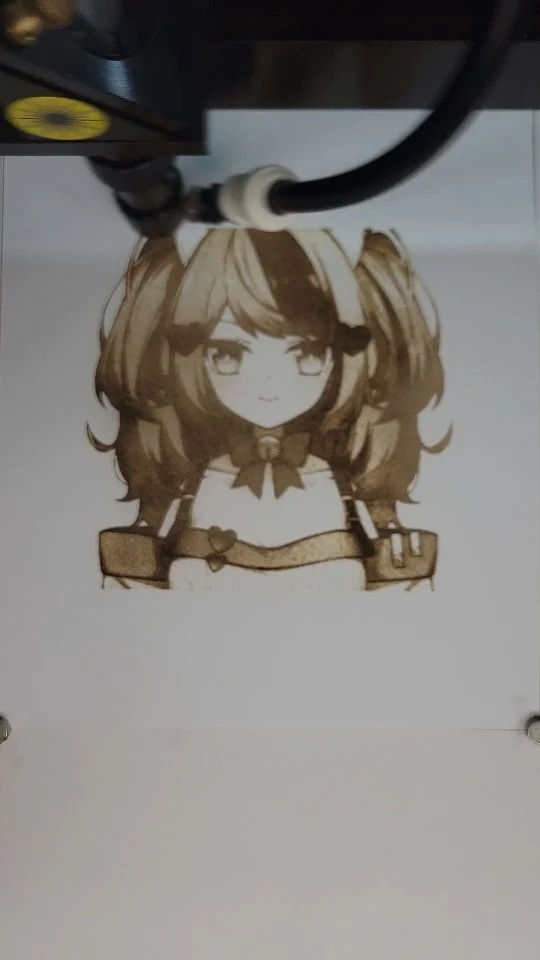

1. Unleash Your Creativity: Laser cutting offers unparalleled precision and versatility, allowing you to create intricate designs and complex shapes that were once unimaginable. Let your imagination run wild and bring your unique ideas to life.

2. Personalized Creations: Create one-of-a-kind gifts, home decor, or accessories that reflect your personal style and taste. Laser cutting allows you to add a touch of personalization to any project.

3. Prototyping Made Easy: Quickly and efficiently prototype new designs without the need for expensive tooling or manufacturing processes. This accelerates product development and reduces time-to-market.

4. Cost-Effective Production: Laser cutting can be a cost-effective solution for small-scale production runs. You can produce high-quality products without the need for large-scale manufacturing facilities.

5. Precision and Accuracy: Laser cutters deliver exceptional precision, ensuring your projects are cut with accuracy and consistency. This is especially valuable for intricate designs and complex shapes.

6. Versatility of Materials: Laser cutting can be used on a wide range of materials, including wood, acrylic, metal, fabric, and more. This opens up a world of creative possibilities.

7. Sustainability: Laser cutting often results in minimal material waste, making it a more sustainable option compared to traditional manufacturing methods.

8. Learn a New Skill: Mastering laser cutting technology can be a rewarding and fulfilling experience. It's a valuable skill that can open doors to new opportunities and creative endeavors.

9. Connect with a Community: Join a local makerspace or online community to connect with other laser cutting enthusiasts. Collaborating with others can inspire new ideas and provide valuable support.

10. Endless Possibilities: The applications for laser cutting are virtually limitless. From jewelry and home decor to industrial components, the possibilities are endless. Let your imagination run wild and explore the exciting world of laser cutting.

Ready to Dive In?

Whether you're a seasoned maker or just starting your creative journey, laser cutting offers a world of possibilities. By embracing this technology, you can unlock your full potential and bring your unique ideas to life.

Top 10 Reasons to Rent a Laser

Top 10 Reasons to Rent a Laser Cutter

Laser cutters have become indispensable tools for a wide range of applications, from crafting intricate designs to prototyping new products. If you're considering renting a laser cutter, here are ten compelling reasons to take the plunge:

1. Flexibility and Convenience: Renting a laser cutter offers the flexibility to use the machine when you need it, without the long-term commitment of ownership. This is ideal for one-off projects, seasonal needs, or if you're unsure about the long-term investment.

2. Access to Advanced Technology: Laser cutter rental companies often have the latest models, providing you with access to cutting-edge features and capabilities.

3. Cost-Effective Solution: Renting a laser cutter can be more economical than purchasing one outright, especially for occasional or short-term use.

4. Expert Support: Many rental companies offer technical support to assist you throughout your rental period, ensuring you get the most out of the machine.

5. Wide Range of Applications: Laser cutters can be used for a variety of purposes, including: * Crafting custom products * Prototyping new designs * Creating personalized gifts * Producing small-scale production runs * And more!

6. Precision and Accuracy: Laser cutters are known for their precision and accuracy, allowing you to create intricate designs with ease.

7. Versatility: Laser cutters can work with a wide range of materials, including wood, acrylic, metal, fabric, and more.

8. Speed and Efficiency: Laser cutting is a relatively fast process, allowing you to quickly create your designs.

9. Reduced Waste: Laser cutters minimize material waste, making them a more sustainable option compared to traditional cutting methods.

10. Creative Freedom: With a laser cutter, you can bring your creative ideas to life and explore new design possibilities.

Conclusion:

Renting a laser cutter offers numerous benefits for individuals and businesses alike. Whether you're a hobbyist, a small business owner, or a professional designer, laser cutting can help you achieve your goals. By considering the factors mentioned above, you can make an informed decision about whether renting a laser cutter is right for you.

Rent a Laser Cutter: Your Gateway to Cutting-Edge Technology

Rent a Laser Cutter: Your Gateway to Cutting-Edge Technology

Are you eager to explore the world of laser cutting without the hefty investment of purchasing your own machine? Renting a laser cutter offers a flexible and cost-effective solution that allows you to access advanced technology without the upfront costs.

Why Rent a Laser Cutter?

Flexibility: Renting a laser cutter provides the freedom to use the machine when you need it, without the long-term commitment of ownership. This is ideal for one-off projects, seasonal needs, or if you're unsure about the long-term investment.

Access to Advanced Technology: Laser cutter rental companies often have the latest models, ensuring you have access to cutting-edge features and capabilities.

Cost-Effective: Renting a laser cutter can be more economical than purchasing one outright, especially for occasional or short-term use.

Expert Support: Many rental companies offer technical support to assist you throughout your rental period, ensuring you get the most out of the machine.

What to Consider When Renting a Laser Cutter:

Type of Laser: Different lasers (CO2, fiber, etc.) are suitable for different materials. Determine which type aligns with your project needs.

Power and Cutting Area: The power and size of the laser cutter will affect its capabilities. Consider the dimensions and complexity of your projects.

Rental Terms: Understand the rental company's policies regarding minimum rental periods, hourly rates, and late fees.

Training and Support: Inquire about any training or support services offered by the rental company.

Benefits of Renting a Laser Cutter:

Experiment and Learn: Renting a laser cutter allows you to explore its capabilities and learn new techniques without the financial commitment of ownership.

Prototype and Test: Create prototypes and test your designs before committing to a full-scale production.

Access to Specialized Features: Certain laser cutters have advanced features like automatic focusing or rotary attachments. Renting allows you to access these capabilities without the upfront investment.

Flexibility for Small Businesses: For small businesses, renting a laser cutter can be a cost-effective way to offer laser cutting services to clients without the overhead of owning a machine.

Conclusion:

Renting a laser cutter is a great way to explore the possibilities of this versatile technology without the long-term commitment of ownership. By considering factors like type of laser, power, rental terms, and support services, you can find the perfect rental option to meet your needs and bring your creative projects to life.

Renting a Laser Cutter: A Guide for Beginners

Renting a Laser Cutter: A Guide for Beginners

Laser cutters have become indispensable tools for a wide range of applications, from crafting intricate designs to prototyping new products. If you're considering renting a laser cutter, here's a guide to help you get started.

Why Rent a Laser Cutter?

Flexibility: Renting allows you to explore the capabilities of laser cutting without the long-term commitment of purchasing a machine.

Cost-Effective: Renting can be more economical than owning, especially for occasional or short-term use.

Access to Advanced Technology: Rental companies often have the latest laser cutter models, providing you with access to cutting-edge technology.

Expert Support: Many rental companies offer technical support to assist you with your projects.

Factors to Consider When Renting:

Type of Laser: Different lasers (CO2, fiber, etc.) are suitable for different materials. Determine which type aligns with your project needs.

Power and Cutting Area: The power and size of the laser cutter will affect its capabilities. Consider the dimensions and complexity of your projects.

Rental Terms: Understand the rental company's policies regarding minimum rental periods, hourly rates, and late fees.

Training and Support: Inquire about any training or support services offered by the rental company. This can be helpful if you're new to laser cutting.

Tips for Renting a Laser Cutter:

Plan Ahead: Book your rental in advance, especially during peak times.

Familiarize Yourself with Safety: Ensure you understand the safety guidelines for operating a laser cutter.

Bring Your Own Materials: Unless the rental company provides them, bring your own materials for cutting.

Follow Instructions: Adhere to the rental company's guidelines and instructions for using the laser cutter.

Where to Rent a Laser Cutter:

Makerspaces and Fab Labs: These community workshops often have laser cutters available for rent.

Equipment Rental Companies: Specialized equipment rental companies may offer laser cutters for rent.

Online Marketplaces: Websites like Craigslist or local online marketplaces might have individuals or businesses renting out their laser cutters.

By following these guidelines, you can successfully rent a laser cutter and bring your creative projects to life.

Your Guide to DIY Laser Cutting Facilities

Unleash Your Inner Maker: Your Guide to DIY Laser Cutting Facilities

Are you a budding maker, designer, or entrepreneur eager to bring your creative visions to life? A DIY laser cutting facility is the perfect place to explore your potential and turn your ideas into reality. These collaborative spaces offer access to state-of-the-art laser cutting technology, expert guidance, and a supportive community of fellow makers.

What is a DIY Laser Cutting Facility?

A DIY laser cutting facility is a shared workspace equipped with laser cutters that are accessible to the public. These facilities provide a platform for individuals and businesses to experiment with laser cutting technology, prototype new designs, and create unique products.

Benefits of Using a DIY Laser Cutting Facility:

Accessibility: DIY laser cutting facilities offer affordable access to laser cutting technology, making it accessible to a wider range of individuals and businesses.

Flexibility: You can use the facility on an as-needed basis, without the long-term commitment of owning your own laser cutter.

Expert Guidance: Many facilities offer training and support to help you get started with laser cutting and maximize its potential.

Community and Collaboration: Connect with other makers and designers, share ideas, and collaborate on projects.

Cost-Effective: Using a DIY laser cutting facility can be more cost-effective than purchasing your own laser cutter, especially for occasional or small-scale projects.

Things to Consider When Choosing a DIY Laser Cutting Facility:

Equipment: Ensure the facility has the type and size of laser cutter that meets your project requirements.

Materials: Check if the facility provides materials or if you need to bring your own.

Membership Fees: Some facilities may charge membership fees or hourly rates.

Safety Protocols: Make sure the facility has strict safety protocols in place to ensure a safe working environment.

Training and Support: Inquire about the availability of training and support services to help you get started with laser cutting.

Popular DIY Laser Cutting Facilities in Los Angeles:

American laser cutter

Conclusion:

A DIY laser cutting facility is an excellent resource for makers, designers, and entrepreneurs looking to explore the possibilities of laser cutting technology. By leveraging the expertise and equipment available at these facilities, you can bring your creative visions to life and unlock your full potential.

Hourly Laser Cutter Rental

Hourly Laser Cutter Rental: The Flexible Solution for Your Projects

Renting a laser cutter by the hour offers several advantages for individuals and businesses looking to explore laser cutting technology without the long-term commitment of purchasing a machine. Here are some of the key benefits:

Flexibility and Convenience:

Short-Term Needs: Hourly rental is ideal for one-off projects, small-scale production runs, or quick experiments.

No Long-Term Commitment: Avoid the financial burden of owning a laser cutter and enjoy the flexibility of renting only when you need it.

Access to Advanced Technology: Rent state-of-the-art laser cutters without the upfront investment, giving you access to the latest features and capabilities.

Cost-Effective Solution:

Avoid Upfront Costs: Renting eliminates the need for a significant upfront investment in a laser cutter, making it a more affordable option for many.

Pay Only for What You Use: With hourly rental, you only pay for the time you actually use the laser cutter, avoiding unnecessary costs.

Reduced Overhead: Renting can help you avoid the overhead costs associated with owning a laser cutter, such as maintenance, insurance, and storage.

Expert Support and Training:

Guidance and Assistance: Many laser cutter rental companies offer technical support and training to help you get the most out of the equipment.

Learn and Experiment: Renting provides a great opportunity to learn about laser cutting technology and experiment with different materials and techniques.

Ideal for a Variety of Projects:

Prototyping: Create prototypes quickly and efficiently for new products or designs.

Small-Scale Production: Produce small quantities of custom items or products.

Hobby Projects: Explore your creativity and create unique items for personal use or as gifts.

Educational Purposes: Use laser cutting for educational demonstrations or student projects.

Conclusion:

Hourly laser cutter rental offers a flexible, cost-effective, and convenient solution for individuals and businesses looking to explore the benefits of laser cutting technology without the long-term commitment of purchasing a machine. By renting a laser cutter, you can access advanced equipment, receive expert support, and bring your creative ideas to life.

Rent a Laser Cutter in California

Rent a Laser Cutter in California: Unleash Your Creativity

Are you looking to bring your design ideas to life without the hefty investment of purchasing a laser cutter? Renting a laser cutter in California offers a flexible and cost-effective solution for individuals and businesses alike.

Why Rent a Laser Cutter?

Flexibility: Renting a laser cutter allows you to explore its capabilities without long-term commitment. It's perfect for one-off projects, seasonal needs, or if you're unsure about the long-term investment.

Cost-Effective: Renting a laser cutter can be more economical than purchasing one outright, especially for occasional use.

Access to Advanced Technology: Laser cutters are state-of-the-art machines that offer precision and efficiency. Renting allows you to access this advanced technology without the upfront cost.

Expert Support: Many rental companies offer technical support to help you get the most out of your laser cutter.

Where to Rent a Laser Cutter in California:

California is home to numerous laser cutter rental companies, offering a variety of options to suit your needs. Here are some factors to consider when choosing a rental company:

Location: Look for a rental company that is conveniently located near you.

Popular Laser Cutter Rental Locations in California:

Los Angeles: American Laser Cutter, https://www.americanlaserco.com/about-samples

Tips for Renting a Laser Cutter:

Plan Ahead: Book your rental in advance, especially during peak times.

Understand the Machine: Familiarize yourself with the laser cutter you'll be using to get the most out of it.

Safety First: Follow all safety guidelines provided by the rental company.

By following these tips, you can successfully rent a laser cutter in California and bring your creative projects to life.

Renting a Laser Cutter at American Laser Cutter

Dive into Laser Cutting: The Benefits of Renting a Laser Cutter at American Laser Cutter

Are you eager to explore the world of laser cutting but hesitant about investing in your own machine? Renting a laser cutter from American Laser Cutter offers a flexible and cost-effective solution to unleash your creativity and bring your projects to life.

Why Rent a Laser Cutter?

Explore Without Commitment: Renting a laser cutter allows you to test the waters without the long-term financial commitment of purchasing your own machine. This is ideal for those who are new to laser cutting or unsure about the frequency of their usage.

Access Advanced Technology: Our laser cutters are state-of-the-art, equipped with the latest technology to ensure precision and efficiency. You'll have access to cutting-edge capabilities without the upfront investment.

Flexibility and Scalability: Renting a laser cutter provides the flexibility to adjust your usage based on your project needs. Whether you need a machine for a one-time project or ongoing use, we have rental options to suit your requirements.

Cost-Effective Solution: Renting a laser cutter can be more economical than purchasing one, especially for occasional or short-term use. It allows you to spread out the costs and avoid the overhead of owning and maintaining your own machine.

Benefits of Renting from American Laser Cutter:

Convenient Location: Our facility is conveniently located in Los Angeles, making it easy for you to access our laser cutters.

Variety of Lasers: We offer a range of laser cutters with different power levels and cutting areas to accommodate your specific project requirements.

Expert Support: Our team of experienced technicians is available to assist you throughout your rental period, providing guidance and troubleshooting support.

Affordable Rates: We offer competitive rental rates, making laser cutting accessible for individuals and businesses of all sizes.

Ready to Get Started?

Contact us today to learn more about our laser cutter rental options and to schedule your rental. We're excited to help you bring your creative vision to life!

Rent a Laser Cutter in Los Angeles

Rent a Laser Cutter in Los Angeles: Unleash Your Creativity with American Laser Cutter

Are you looking to bring your design ideas to life without the hefty investment of purchasing a laser cutter? American Laser Cutter offers a convenient and affordable solution: our laser cutter rental services.

Why Rent a Laser Cutter?

Flexibility: Renting a laser cutter allows you to explore its capabilities without long-term commitment. It's perfect for one-off projects, seasonal needs, or if you're unsure about the long-term investment.

Cost-Effective: Renting a laser cutter can be more economical than purchasing one outright, especially for occasional use.

Access to Advanced Technology: Our laser cutters are state-of-the-art, equipped with the latest technology to ensure precision and efficiency.

Expert Support: Our team of experienced technicians is available to assist you throughout your rental period, providing guidance and troubleshooting support.

Our Laser Cutter Rental Options:

We offer a variety of laser cutter rental options to suit your specific needs:

Hourly Rental: Rent a laser cutter by the hour for short-term projects or quick experiments.

Daily Rental: Rent a laser cutter for a day to complete more extensive projects or to test its capabilities before making a long-term decision.

Weekly or Monthly Rental: For larger projects or ongoing needs, consider our weekly or monthly rental plans.

Benefits of Renting from American Laser Cutter:

Convenient Location: Our facility is conveniently located in Los Angeles, making it easy for you to access our laser cutters.

Variety of Lasers: We offer a range of laser cutters with different power levels and cutting areas to accommodate your specific project requirements.

Expert Training: If you're new to laser cutting, we can provide training to help you get started and use our equipment effectively.

Affordable Rates: Our rental rates are competitive, making laser cutting accessible for individuals and businesses of all sizes.

Ready to Get Started?

Contact us today to learn more about our laser cutter rental options and to schedule your rental. We're excited to help you bring your creative vision to life!

Laser Engraving Granite: A Challenge Accepted

Laser Engraving Granite: A Challenge Accepted

Laser engraving granite is a demanding process that requires specialized equipment and expertise. While it presents challenges, the results can be truly remarkable.

Challenges of Laser Engraving Granite

Material Hardness:

Granite is a highly durable material, making it resistant to laser etching.

Heat Generation: The laser's energy can cause the granite to heat up rapidly, potentially damaging the material or the laser.

Dust and Debris: The engraving process generates fine granite dust, which can be harmful to the machine and operator.

Equipment and Settings

High-Power Laser: A CO2 laser with sufficient power is essential for effectively engraving granite.

Focus and Speed: Precise focus and optimal cutting speed are crucial for achieving desired results.

Ventilation: Proper ventilation is necessary to remove dust and fumes generated during the process.

Safety Equipment: Protective gear, including goggles, gloves, and a dust mask, is mandatory.

Design Considerations

Simplicity: Complex designs might not be suitable due to the material's hardness and the laser's limitations.

Contrast: Darker granite provides better contrast for engraved text or images.

Depth: The depth of the engraving will depend on the laser's power and the granite's composition.

Applications of Laser Engraved Granite

Memorial Stones: Creating personalized and durable memorials.

Architectural Elements: Engraving designs on granite tiles or countertops.

Awards and Plaques: Producing high-quality and long-lasting awards.

Industrial Markers: Engraving identification numbers or logos on granite components.

While laser engraving granite is a challenging process, the results can be stunning and long-lasting. With the right equipment, expertise, and safety precautions, it's possible to create beautiful and durable products.

Top YouTube Channels to Ignite Your Laser Cutting Passion

Top YouTube Channels to Ignite Your Laser Cutting Passion

The allure of laser cutting lies in its ability to transform digital dreams into tangible realities. But for those new to this exciting realm, navigating the world of laser settings, software intricacies, and project ideas can feel overwhelming. Fear not, aspiring laser enthusiasts! YouTube provides a treasure trove of informative channels dedicated to teaching the ins and outs of laser cutting. This curated list explores the top 10 YouTube channels to equip you with the knowledge and skills to embark on your laser cutting journey with confidence.

1. Make: Hands-On Learning with Tested

MAKE Magazine's channel, Make: is a haven for DIY enthusiasts, and their laser cutting content is no exception. The "Tested" series features informative videos on various laser cutting topics. Expect clear explanations from the always-entertaining Adam Savage and his team, covering everything from essential techniques for beginners to in-depth explorations of specific materials and project ideas.

2. Laser Everything: A Community Hub for All Things Laser

Laser Everything https://www.youtube.com/c/lasereverything is a one-stop shop for laser cutting knowledge. This channel boasts a vast library of videos covering everything from laser buying guides and software tutorials to in-depth material settings and project inspiration. Laser Everything also fosters a vibrant online community through their website and social media platforms, allowing you to connect with other laser enthusiasts.

3. Mr. Beam: A Beginner-Friendly Introduction to Laser Cutting

Mr. Beam https://www.youtube.com/@mrbean is an excellent resource for those new to laser cutting. Their videos are presented in a clear and concise manner, making complex concepts easy to understand. Mr. Beam offers tutorials on basic laser cutting techniques, software navigation, and project ideas designed specifically for beginners. They also showcase various laser machines, helping you visualize how laser cutting functions in real-world scenarios.

4. Just Laser: Expertise from an Experienced Laser Enthusiast

Justin Laser https://www.youtube.com/channel/UCRR28oXgje2iDaN4TVQ_Epg is a wealth of knowledge for laser cutting enthusiasts. Justin, the creator of the channel, leverages his extensive experience to provide insightful videos on a range of topics. You'll find in-depth explorations of laser settings for various materials, project walkthroughs with detailed explanations, and discussions on advanced techniques like rotary attachments and fume extraction systems.

5. CNC Kitchen: Exploring the Intersection of CNC and Laser Cutting

CNC Kitchen [https://www.youtube.com/c/cnckitchen] takes a broader approach, venturing into the fascinating world of CNC (Computer Numerical Control) machines, which includes laser cutters. Their laser cutting content delves into topics like machine reviews, software comparisons, and project ideas that showcase the versatility of laser cutting. CNC Kitchen's in-depth explanations and engaging presentation style make them a valuable resource for those curious about the wider world of CNC technologies.

6. Laser Engraving Tips & Techniques with Steve Makes Everything

Steve Makes Everything https://m.youtube.com/c/SteveMakesEverything focuses on both laser engraving and laser cutting. This channel is a great resource for learning techniques to personalize your projects with text, logos, or intricate designs. Steve, the host, provides clear tutorials on engraving settings for various materials, design tips and tricks, and project ideas that showcase the creative potential of laser engraving.

Leveraging Cameras with LightBurn: A Precision Boost

Leveraging Cameras with LightBurn: A Precision Boost

LightBurn's camera integration has revolutionized the laser cutting process, offering increased accuracy, efficiency, and flexibility. By incorporating a camera into your setup, you can significantly enhance your projects.

Key Benefits of Using a Camera with LightBurn

Precise Alignment: Cameras eliminate the need for manual measurements and adjustments, ensuring accurate placement of materials.

1. The Power of a Built-In Camera in CO2 Laser Cutting for OmTech and Mon — Monportlaser

Material Recognition: LightBurn can automatically detect and outline materials, streamlining the design process.

Job Monitoring: Real-time camera feed allows you to monitor the cutting process and make adjustments if needed.

Image Tracing: Convert physical objects or images into vector graphics for cutting or engraving.

Camera Setup and Calibration

Camera Selection: Choose a camera compatible with LightBurn, considering factors like resolution, field of view, and mounting options.

Camera Placement: Mount the camera above the laser bed to capture a clear view of the workspace.

Calibration: Use LightBurn's calibration tools to accurately map the camera's image to the laser bed coordinates.

Practical Applications

Complex Designs: Accurately position intricate designs on materials of various sizes and shapes.

Material Optimization: Efficiently use materials by precisely aligning designs to minimize waste.

Batch Production: Quickly and accurately place multiple pieces for consistent results.

Image-Based Projects: Convert photos or drawings into physical objects using image tracing.

Tips for Optimal Results

Good Lighting: Ensure sufficient lighting for clear camera images.

Camera Focus: Maintain proper camera focus for accurate measurements.

Material Contrast: Use materials with good contrast for easier detection and tracing.

Experimentation: Test different camera settings and lighting conditions to optimize performance.

By incorporating a camera into your LightBurn setup, you can unlock new possibilities for precision and efficiency in your laser cutting projects.

LightBurn's Hidden Gems: Uncovering Obscure Features

LightBurn's Hidden Gems: Uncovering Obscure Features

LightBurn, a popular software for laser cutting and engraving, is packed with features. While many users are familiar with the core functionalities, there are several lesser-known features that can significantly enhance your design and production process. Let’s dive into some of LightBurn’s hidden gems.

Advanced Vector Editing

Node Editing: While most users are familiar with node editing, exploring advanced techniques like node smoothing, joining, and splitting can refine your designs.

Offsetting: Master the art of creating inner and outer shapes by offsetting paths, essential for creating box designs or intricate patterns.

Boolean Operations: Combine or subtract shapes using Boolean operations (union, difference, intersection) for complex designs.

Image Processing Magic

Halftone: Create unique textures and patterns by converting grayscale images into halftone patterns.

Dithering: Reduce color depth while preserving image detail using dithering techniques.

Color Separation: Separate color images into individual color channels for multi-layer cutting or engraving.

Laser Control Nuances

Variable Power: Experiment with gradual power changes during a cut to achieve interesting effects like fades or highlights.

Pulse Frequency Modulation (PFM): Control the laser's pulse frequency for specific materials and cutting styles.

Acceleration and Deceleration: Optimize cutting performance by adjusting acceleration and deceleration settings.

Workflow Efficiency Tips

Customizable Toolbars: Create personalized toolbars for quick access to frequently used functions.

Macros: Automate repetitive tasks by creating macros.

Keyboard Shortcuts: Learn and use keyboard shortcuts to speed up your workflow.

Other Useful Features

Customizable Grids and Guides: Create custom grids and guides to assist with alignment and precision.

Shape Libraries: Explore built-in shape libraries for quick access to common shapes.

Text Effects: Experiment with various text effects like arcs, paths, and outlines.

By delving into these often overlooked features, you can unlock new creative possibilities and streamline your laser cutting workflow. Remember, practice makes perfect, so experiment with different settings and techniques to discover your preferred methods.

Mastering Repetition: A Guide to Using Jigs for Flawless Laser Cutting

Mastering Repetition: A Guide to Using Jigs for Flawless Laser Cutting

Laser cutting empowers you to bring your creative visions to life, transforming digital designs into a tangible reality. But achieving consistent results, particularly when dealing with repetitive cuts, can be a challenge. Enter the humble jig – a game-changer in the world of laser cutting. Jigs, also known as laser cutting jigs, are templates that hold your material in place, ensuring precise positioning and streamlined production. This guide delves into the world of jigs, equipping you with the knowledge to elevate your laser cutting game.

Understanding Jigs and Their Benefits

A jig is a specially designed template, typically crafted from sturdy materials like wood, acrylic, or MDF. It acts as a guide for your laser cutter, holding your material in precise locations for consistent and accurate cutting. Here's why jigs deserve a spot in your laser cutting arsenal:

Precision Powerhouse: Jigs guarantee perfect alignment of your material every time, leading to flawlessly identical cuts across multiple pieces.

Material Efficiency Champion: By utilizing jigs, you can optimize material usage. Jigs allow for nesting, strategically placing multiple cutting areas close together, minimizing waste.

Speed Demon: Once your jig is set up, creating multiple identical pieces becomes a breeze, significantly boosting your production speed.

Reduced Error Risk: Jigs minimize the chance of human error during material placement, leading to cleaner and more professional-looking results.

Crafting Your Perfect Jig

Design Your Jig: Embrace your inner designer! Using your preferred design software (Inkscape, Illustrator, etc.), create a vector file representing the baseplate of your jig.

Mark Material Placement: Include designated slots or cutouts within the baseplate that perfectly match the shape and size of the material you intend to cut.

Factor in the Kerf: The kerf refers to the width of material removed by the laser beam. Don't forget to account for this by adjusting your cutout sizes slightly larger than your desired final dimensions to compensate for the kerf.

Choose Your Material Wisely: Jigs are typically crafted from sturdy materials that can withstand repeated laser cutting. Popular options include MDF, plywood, or even acrylic. Consider the intended number of uses for your jig and select a material compatible with your laser's cutting capabilities.

Laser Cut Your Jig: Once your design is finalized, send it to your laser cutter and breathe life into your jig by cutting it out from your chosen material.

Utilizing Your Jig for Flawless Cuts

Secure the Jig Wall: Place your freshly created jig wall securely within your laser cutter bed, ensuring it's level and properly positioned.

Align Your Material: Carefully position your material within the designated slots or cutouts on the jig wall, meticulously aligning it with the intended cutting areas.

Secure Your Material: Employ masking tape or other appropriate methods to hold your material firmly in place during the laser cutting process. This prevents accidental movement and ensures clean cuts.

Laser Settings Double-Check: Double-check your laser cutting settings for the specific material you're using and adjust them if necessary.

Initiate the Cut: Once everything is aligned, secured, and your settings are confirmed, proceed with the laser cutting process as you would normally with any other project.

Pro Tips for Jig Mastery

Test Cuts are Your Friend: Before diving headfirst into your final project, perform a test cut on scrap material using your jig. This allows you to verify proper alignment and refine your laser settings for optimal results.

Labeling is Key: If you plan on creating a collection of jigs for various projects, clearly label them for easy identification and organization.

Cleaning is Essential: Over time, debris and residue can accumulate on your jig. Regularly clean it with a soft brush or compressed air to maintain optimal performance and prevent cutting inconsistencies.

Advanced Jig Techniques: As you gain experience, explore more advanced jig techniques like layering jigs for creating 3D objects or incorporating registration marks for intricate projects involving multiple jigs and cuts.

By incorporating jigs into your laser cutting routine, you unlock a new level of precision, efficiency, and consistency. With a little planning and creativity, jigs can transform your laser cutting experience, empowering you to produce professional-looking results and elevate your projects to new heights. So, grab your design software, craft your jigs, and get ready to laser cut with confidence and precision!

Renting a Laser Cutter at American Laser Cutter: A Strategic Approach

Renting a Laser Cutter at American Laser Cutter: A Strategic Approach

Introduction

Laser cutting, a precision technology that uses a focused laser beam to cut through materials, has become an invaluable tool for businesses and individuals alike. For those considering entering the world of laser cutting, renting a laser cutter at American Laser Cutter offers several advantages.

Benefits of Renting a Laser Cutter at American Laser Cutter

Reduced Upfront Costs: Renting a laser cutter eliminates the need for a significant upfront investment, making it a more accessible option for those with limited budgets.

Flexibility and Scalability: Renting allows businesses to adjust their laser cutting capacity based on demand. If project volume increases, they can rent a more powerful machine or increase their rental time.

Access to Latest Technology: American Laser Cutter provides access to state-of-the-art laser cutting equipment, ensuring that users benefit from the latest advancements in the field.

Expert Support: The company's experienced staff is available to provide guidance, training, and technical support, helping users get the most out of their laser cutting projects.

Convenient Location: American Laser Cutter's facility is located in Los Angeles, making it easily accessible for many individuals and businesses.

DIY Option: Users have the option to operate the laser cutter themselves, providing hands-on experience and creative control.

Timeshare Program: For those who need frequent access to a laser cutter, American Laser Cutter offers a timeshare program, providing dedicated time slots on their machines.

Getting Started with American Laser Cutter

Contact: Reach out to American Laser Cutter to inquire about availability and pricing.

Schedule: Once you've determined your rental needs, schedule a time to use the laser cutter.

Training: If you're new to laser cutting, consider taking a training session provided by American Laser Cutter to ensure safe and effective operation.

Materials: You can bring your own materials or purchase them from American Laser Cutter.

Project Completion: Use the laser cutter to complete your project, following safety guidelines and best practices.

Conclusion

Renting a laser cutter at American Laser Cutter is a strategic approach for individuals and businesses looking to explore the world of laser cutting. By leveraging the benefits of reduced upfront costs, flexibility, access to advanced technology, and expert support, users can embark on their laser cutting journey with confidence.

3D Laser Engraving with CO2 Lasers: A New Dimension

3D Laser Engraving with CO2 Lasers: A New Dimension

While traditionally associated with 2D cutting and engraving, CO2 lasers are increasingly being used to create stunning 3D effects. This technique, often referred to as pseudo-3D or 2.5D engraving, involves varying the laser's power and focus to create depth and dimension in the engraved image.

How Does It Work?

Grayscale Image:

A grayscale image is used as the basis for the engraving. Lighter areas correspond to shallower depths, while darker areas create deeper engravings.

Laser Power Modulation: The laser's power is adjusted based on the grayscale values, creating variations in the material's removal depth.

Focus Control: In some cases, the laser's focus can be dynamically adjusted to achieve more pronounced depth effects.

Materials Suitable for 3D Laser Engraving

Wood: Offers excellent results due to its varied density and ability to absorb the laser beam.

Acrylic: Can produce impressive depth effects, but material selection is crucial for optimal results.

Leather: Creates unique textures and shadows, but requires careful parameter adjustments.

Challenges and Considerations

Material Consistency: Variations in material density can affect engraving depth, so material selection is vital.

Laser Power and Focus: Precise control over these parameters is essential for achieving desired results.

Software Capabilities: The engraving software should support grayscale image processing and power modulation.

Time Consumption: 3D laser engraving can be time-consuming due to multiple passes required for depth.

Applications of 3D Laser Engraving

Art and Decor: Creating unique and visually appealing pieces with depth and texture.

Product Personalization: Adding depth to engraved logos, names, or designs on products.

Industrial Applications: Creating textured surfaces or functional patterns on components.

While 3D laser engraving with CO2 lasers is still a developing field, it offers exciting possibilities for artists, designers, and manufacturers. As technology continues to advance, we can expect even more impressive results from this technique.

Laser Cutting for Business: A Profitable Venture

Laser Cutting for Business: A Profitable Venture

Laser cutting offers a vast array of opportunities for businesses to create unique and high-quality products. With its precision and versatility, this technology can be a game-changer for entrepreneurs.

1. Industry-Specific Applications of Laser Cutting - Koenig Machinery

2. How a CO2 Laser Cutter Can Launch Your Home-Based Business

Identifying Profitable Niches

Custom Products: Offering personalized items like jewelry, home decor, or corporate gifts can be a lucrative niche.

Prototyping: Many businesses require rapid prototyping, and laser cutting can provide quick and accurate prototypes.

Manufacturing Components: Producing small to medium-sized components for various industries can be a profitable venture.

Hobby and Craft Supplies: Selling laser-cut blanks or kits to hobbyists and crafters can generate steady income.

Building a Successful Laser Cutting Business

Market Research: Identify your target audience and their needs.

Investment: Consider the cost of laser cutter equipment, software, and materials.

Design Expertise: Develop strong design capabilities or partner with designers.

Marketing and Sales: Build a strong online presence and explore various sales channels.

Quality Control: Maintain consistent product quality to build a loyal customer base.

Safety Compliance: Adhere to all safety regulations to protect your business and employees.

Challenges and Opportunities

Competition: The laser cutting industry is competitive, so finding a unique niche is essential.

Technology: Staying updated with the latest laser cutting technology is crucial for staying ahead.

Material Costs: The cost of materials can impact profitability, so explore cost-effective options.

Scalability: As your business grows, consider expanding your production capacity.

Laser cutting offers immense potential for entrepreneurs. By carefully planning and executing your business strategy, you can turn this technology into a profitable venture.

Top Laser Cut Design Programs

Top Laser Cut Design Programs

Choosing the right design software is crucial for successful laser cutting projects. With numerous options available, it can be overwhelming to decide which one best suits your needs. Here's a breakdown of ten popular choices:

Professional-Grade Software

Adobe Illustrator: Industry standard for vector graphics, offering unparalleled precision and design tools.

CorelDRAW: Comprehensive software with powerful illustration and layout capabilities.

AutoCAD: Primarily for CAD applications, but offers robust 2D design tools for laser cutting.

User-Friendly Options

LightBurn: Specifically designed for laser cutting and engraving, offering a balance of features and ease of use.

Inkscape: Free, open-source software with a strong community and a wide range of capabilities.

SketchUp Make: Primarily a 3D modeling tool, but offers 2D drawing capabilities for laser cutting.

Laser Machine Specific Software

RDWorks: Commonly used for Ruida controller-based laser machines, offering machine control and design features.

LaserGRBL: Open-source software for controlling GRBL-based laser cutters, with basic design capabilities.

Online-Based Tools

Canva: While primarily for graphic design, it can be used for simple laser cut designs.

Online vector editors: Various online tools offer basic vector editing for quick designs.

Factors to Consider

Compatibility: Ensure the software is compatible with your laser cutter's controller.

Features: Consider the specific features you need, such as vector editing, image tracing, and laser control.

Cost: Evaluate the software's pricing and licensing options.

Learning Curve: Assess the software's complexity and the time required to learn it.

File Formats: Check if the software supports the file formats required by your laser cutter (e.g., SVG, DXF).

Ultimately, the best software depends on your specific needs, budget, and skill level. Experimenting with different options is often the best way to find the perfect fit for your laser cutting projects.

Top 10 Tools You Need for Your Laser Cutter: From Essential to Exploratory

Top 10 Tools You Need for Your Laser Cutter: From Essential to Exploratory

Your laser cutter is a powerful tool, but it doesn't operate in a vacuum. To unleash its full potential and ensure a smooth workflow, you'll need a companion set of tools to optimize the laser cutting process. This curated list explores the top 10 tools, ranging from essentials for every project to those that open doors for more adventurous laser cutting endeavors.

1. Essential Software: The Brains Behind the Beam

Your laser cutter is the muscle, but your design software is the brain. Having the right software allows you to create intricate vector designs, manipulate objects, and ultimately send cutting instructions to your laser cutter. Some popular options include:

Inkscape: A free and open-source vector design software perfect for beginners and experienced users alike.

Adobe Illustrator: The industry standard for vector design, offering a comprehensive toolset for creating complex designs (paid software).

RDWorks: While not for design creation itself, RDWorks is the software that comes bundled with many Ruida-controlled laser cutters. It allows you to import designs, set laser parameters, and control the cutting process.

2. Vector Graphics Files: The Language of Your Laser

Laser cutters understand a specific language – vector graphics. These file formats, like SVG (Scalable Vector Graphics) and DXF (Drawing Exchange Format), define the shapes and paths your laser will cut. Ensure you have access to or can create vector graphics files for your desired projects.

3. Safety Glasses: A Must-Have for Every Laser Session

Safety is paramount when working with a laser cutter. Laser beams can damage your eyes, so a good pair of laser safety glasses specifically designed for your laser's wavelength is an absolute necessity.

4. Honeycomb Cutting Bed: A Stable Foundation for Precise Cuts

The cutting bed plays a crucial role in achieving clean and precise cuts. A honeycomb cutting bed allows debris and fumes to fall through, preventing them from reflecting back up and scorching your project. It also provides a stable and supportive surface for your material.

5. Air Assist System: Keeping Things Cool and Clean

An air assist system helps keep your cutting area free of debris and fumes. A constant stream of compressed air directed at the cutting point removes smoke and molten material, minimizing scorching and improving cut quality.

6. Fume Extraction System: Breathing Easy During Laser Cutting

Laser cutting can generate fumes, especially when cutting certain materials. A fume extraction system helps remove these fumes from your workspace, ensuring a safe and healthy environment.

7. Masking Material: Protecting Your Project and Your Laser

Masking materials like painter's tape or application tape help protect your project material from unwanted laser marks or heat distortion on areas you don't intend to cut. It can also protect your laser lens from splatter or fumes from some materials.

8. Digital Caliper: Ensuring Measurement Precision

For projects requiring precise dimensions, a digital caliper is an invaluable tool. It allows you to accurately measure your material thickness and ensure your design elements fit perfectly.

9. Safety Vacuum and Brush: Keeping Your Workspace Clean

A small safety vacuum and brush are handy tools for keeping your laser cutter and workspace clean. Regularly cleaning debris and dust helps maintain optimal airflow and laser performance.

10. Optionalexploratory Tools: Expanding Your Laser Cutting Horizons

Once you've mastered the basics, these tools open doors for more advanced laser cutting techniques:

Rotary Attachment: This attachment allows you to laser cut cylindrical objects like mugs or tumblers.

Focus Lens Gauge: Ensuring proper laser focus is crucial for achieving clean cuts. A focus lens gauge helps you precisely set the focal length for different material thicknesses.

Offline Controller: An offline controller allows you to operate your laser cutter without a computer connection, ideal for situations where a dedicated computer might not be feasible.

With this arsenal of tools at your disposal, you're well-equipped to embark on your laser cutting journey and transform your creative visions into tangible realities. Remember, safety is always the top priority, so wear your safety glasses and consult your laser cutter's manual for specific instructions and safety protocols. Happy laser cutting!

Where to Find Free Laser Cut Files Online

Where to Find Free Laser Cut Files Online

The internet is a treasure trove of free laser cut files, offering a wealth of inspiration and ready-to-use designs.

Here are some of the best places to start your search:

1. Laser Cut Files, Download Templates, Designs & Patterns For Free - Ponoko

Dedicated Laser Cut File Websites

LaserFileFinder: A dedicated search engine for free laser cut files, aggregating results from various sources.

Online Communities and Forums

Reddit: Subreddits like r/lasercutting often have users sharing their designs and files.

Maker Spaces and Forums: Local maker spaces and online forums may have members sharing their creations.

Free Vector Graphics Websites

OpenClipart: Offers a vast collection of free vector graphics that can be adapted for laser cutting.

Vecteezy: Provides a wide range of free vector images, including many suitable for laser cutting projects.

Thingiverse and Other 3D Model Repositories

Thingiverse: While primarily for 3D printing, it also hosts a variety of 2D designs that can be used for laser cutting.

Important Considerations

File Format: Ensure the downloaded files are in a compatible format for your laser cutter software (e.g., SVG, DXF).

Design Quality: Not all free files are created equal. Check for design accuracy and completeness.

Copyright: Be aware of copyright restrictions and use files legally.

Customization: Most free files will require customization to fit your specific project.

By exploring these resources, you can find a wealth of free laser cut files to inspire your creativity and save time on design.

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)