American Laser Cutter: Your Precision Cutting Partner in Los Angeles

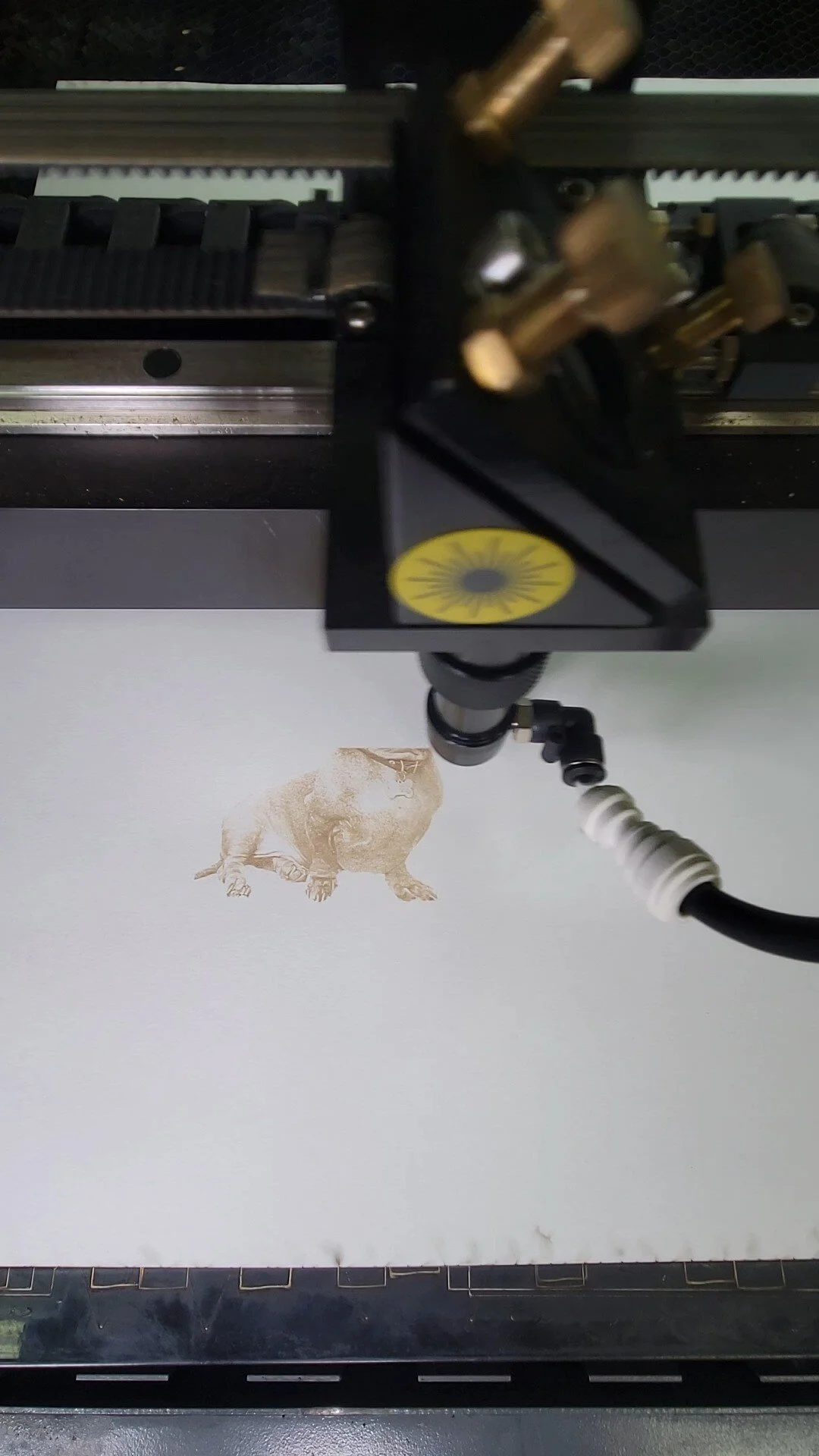

Located in the heart of Los Angeles, American Laser Cutter offers innovative CO2 laser cutting solutions to bring your creative and industrial projects to life. We specialize in transforming your ideas into reality with unmatched precision and efficiency.

Whether you're a seasoned maker, a burgeoning artist, or an established business, American Laser Cutter has the expertise and technology to empower your vision. We offer a range of services, from intricate artistic cutting to precise industrial applications, all delivered with exceptional quality and fast turnaround times.

Here's what sets American Laser Cutter apart:

Unmatched Precision: Our state-of-the-art CO2 laser cutting technology guarantees clean, sharp cuts on a vast array of materials.

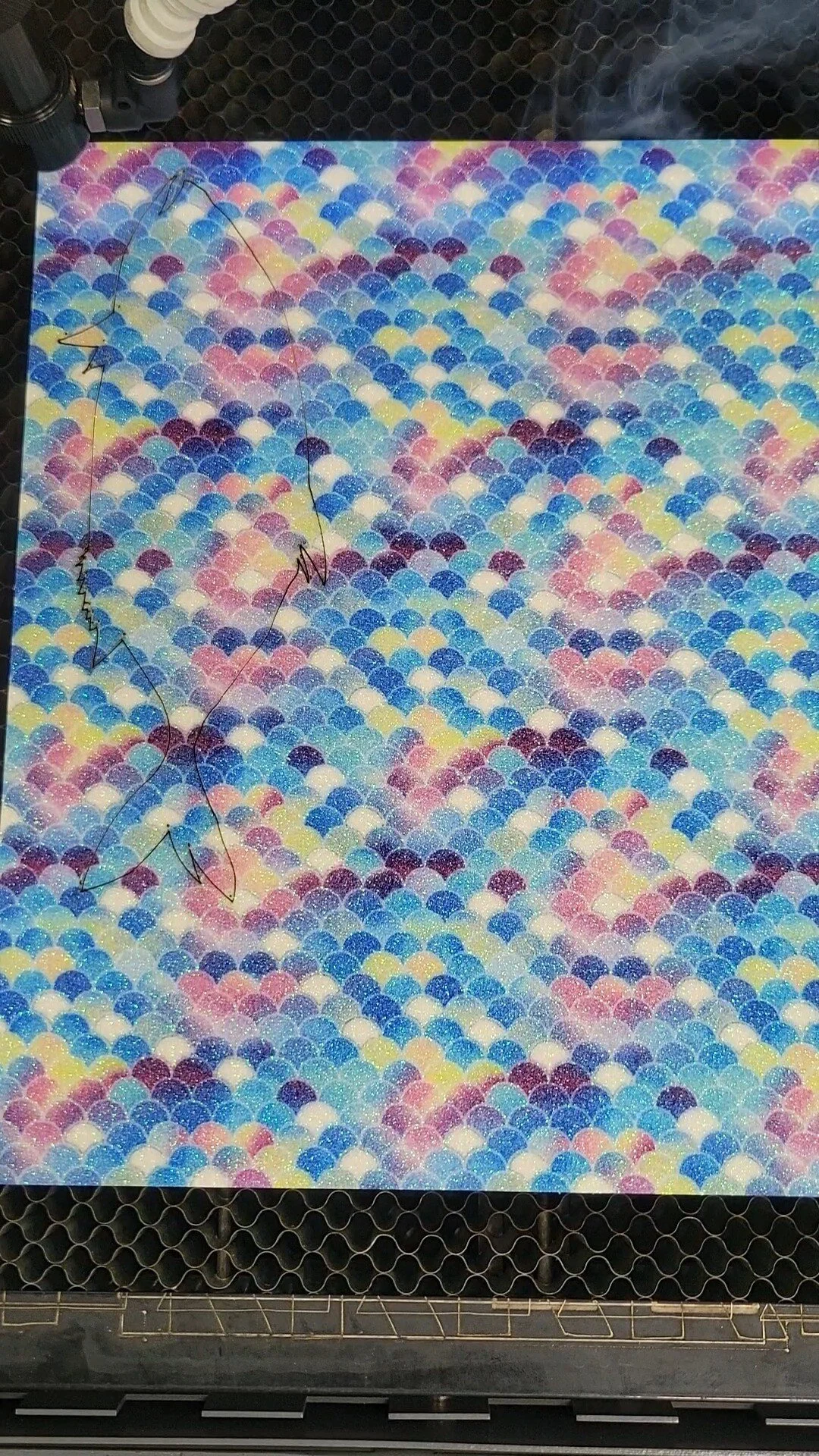

Material Versatility: We work with a wide range of materials, from wood and acrylic to paper and more, catering to diverse project needs.

Expertise at Your Fingertips: Our experienced technicians are passionate about laser cutting and dedicated to providing exceptional customer service.

Remote and On-Site Support: We offer both remote troubleshooting and on-site repair services for your convenience (Los Angeles area only).

Ready to experience the power of laser cutting?

American Laser Cutter is your one-stop shop in Los Angeles. Contact us today to discuss your project, learn more about our services, and unlock the limitless possibilities of laser cutting!

American Laser Cutter: A Leader in Precision Cutting Solutions

American Laser Cutter: A Leader in Precision Cutting Solutions

American Laser Cutter is a leading provider of advanced laser cutting technology, offering a wide range of solutions for various industries. With a focus on innovation and customer satisfaction, American Laser Cutter has established itself as a trusted partner for businesses seeking precise and efficient cutting processes.

Key Products and Services:

Laser Cutting Machines: American Laser Cutter offers a comprehensive range of laser cutting machines, including CO2 and fiber laser systems, to suit different applications and materials.Custom Cutting Services: The company provides custom laser cutting services, tailored to meet the specific needs of each customer, ensuring precise and high-quality results.Engineering and Design Support: American Laser Cutter offers engineering and design support to help customers optimize their projects and achieve the desired outcomes.Maintenance and Repair Services: The company provides comprehensive maintenance and repair services to ensure the longevity and performance of its laser cutting machines.

Industries Served:

American Laser Cutter serves a diverse range of industries, including:

Aerospace and Defense: Cutting components for aircraft, satellites, and military equipment.Automotive: Producing parts for cars, trucks, and other vehicles.Medical Devices: Manufacturing components for medical equipment and devices.Electronics: Cutting components for electronic devices and circuits.Metal Fabrication: Producing custom metal parts and structures.

Commitment to Quality and Innovation:

American Laser Cutter is committed to providing the highest quality laser cutting solutions and continuously invests in research and development to stay at the forefront of technological advancements. The company's focus on customer satisfaction and dedication to excellence have made it a trusted partner for businesses worldwide.

Conclusion:

American Laser Cutter is a leading provider of advanced laser cutting technology, offering a wide range of solutions for various industries. With a commitment to quality, innovation, and customer satisfaction, American Laser Cutter is well-positioned to continue its success and meet the evolving needs of its customers.

The Case for Offline Laser Cutters: Why Internet Connectivity Isn't Always a Necessity

The Case for Offline Laser Cutters: Why Internet Connectivity Isn't Always a Necessity

While internet-connected laser cutters offer certain conveniences, there are compelling reasons why offline models remain a valuable choice.

Reliability and Independence:

Uninterrupted Operation: Offline laser cutters are not reliant on internet connection, ensuring uninterrupted operation even during network outages or in areas with limited connectivity.Data Privacy: Offline models eliminate the risk of data breaches associated with cloud-based storage and transmission.

Control and Customization:

Full Autonomy: Offline laser cutters provide complete control over the cutting process, allowing for precise customization and adjustments without external interference.Offline Design Software: Many offline laser cutters come with integrated design software, enabling standalone operation and reducing reliance on internet-based tools.

Cost-Effectiveness and Accessibility:

Lower Entry Cost: Offline laser cutters often have lower upfront costs compared to internet-connected models, making them more accessible to individuals and small businesses.Reduced Operating Costs: Eliminating the need for internet connectivity and cloud-based services can lead to lower operating expenses over time.

Conclusion:

While internet-connected laser cutters offer certain benefits, offline models provide reliability, control, cost-effectiveness, and enhanced data privacy. For those who prioritize uninterrupted operation, customization, and reduced reliance on external factors, offline laser cutters remain a compelling choice.

Web-Based Laser Cutters: Advantages and Disadvantages

Web-Based Laser Cutters: Advantages and Disadvantages

Web-based laser cutters, also known as cloud-based or remote laser cutters, offer a convenient and accessible way to access laser cutting technology without the need for a physical machine. However, there are both advantages and disadvantages to consider before choosing this option.

Advantages:

Accessibility: Web-based laser cutters can be accessed from anywhere with an internet connection, making them convenient for those who don't have the space or resources to own a physical machine.Affordability: Web-based laser cutters can be more affordable than owning a physical machine, as the cost is typically based on usage rather than upfront investment.Variety of materials: Web-based laser cutter services often offer a wider range of materials to choose from than what might be available on a personal machine.Support and expertise: Many web-based laser cutter services provide technical support and expertise to help users get the most out of the technology.

Disadvantages:

Dependence on internet connection: Web-based laser cutters rely on a stable internet connection, which can be a limitation in areas with unreliable connectivity.File upload and download: Uploading and downloading files can take time, especially for large files.Limited control: Users may have less control over the laser cutting process compared to owning a physical machine, as they are relying on the service provider's settings and equipment.Security concerns: There may be concerns about data security when uploading files to a cloud-based service.

Overall, web-based laser cutters offer a convenient and accessible option for those who need laser cutting services without the investment of a physical machine. However, it is important to carefully consider the advantages and disadvantages before making a decision.

Leveraging Professional Laser Assistance: A Shortcut to Mastery

Leveraging Professional Laser Assistance: A Shortcut to Mastery

While owning a laser cutter offers unparalleled freedom, accessing professional laser cutting services can be an invaluable resource for learning and experimentation.

Benefits of Professional Laser Assistance

Access to High-End Equipment: Many professional services have industrial-grade laser cutters capable of handling a wider range of materials and complexities.

Expert Guidance: Professionals can offer valuable insights into material selection, design optimization, and laser settings.

Time Efficiency: Outsourcing the cutting process saves time for design, prototyping, and finishing.

Quality Assurance: Benefit from professional expertise to ensure consistent and high-quality results.

Safety: Avoid the risks associated with operating a laser cutter without proper training.

Tips for Working with Professional Services

Clear Communication: Provide detailed specifications about your project, including materials, dimensions, and desired finish.

File Preparation: Ensure your design files are in the correct format (e.g., SVG, DXF) and optimized for laser cutting.

Material Selection: Collaborate with the service provider to choose the best material for your project.

Proofing: Request proofs or samples before committing to a full production run.

Feedback: Provide constructive feedback to help the service provider improve their offerings.

By leveraging professional laser cutting assistance, you can accelerate your learning process, access advanced equipment, and focus on design and product development.

Spooktacular Laser Cut Halloween Projects to Haunt Your Halls (and Impress Your Guests)

Halloween is all about unleashing your creativity and transforming your home into a thrilling wonderland. This year, why not delve into the exciting world of laser cutting and craft some hauntingly beautiful decorations and spooky surprises? With a laser cutter and a touch of imagination, you can conjure up a variety of personalized Halloween projects that will leave your guests spellbound.

1. Wickedly Wonderful Wall Art:

Shadowy Silhouettes: Laser cut classic Halloween shapes like bats, witches, or haunted houses from black cardstock or acrylic. Arrange them on your walls for a hauntingly minimalist look.

Ghastly Greetings: Design a personalized Halloween sign or spooky welcome message in a creepy font. Intricately cut details like spiderwebs or bats can elevate the design.

2. Flickering Frights with Luminaries:

Terrific Tea Light Covers: Transform ordinary tea lights into extraordinary Halloween accents. Design and laser cut spooky faces, pumpkins, or spiderwebs from thin metal or wood to create flickering silhouettes when illuminated.

Eerie Etched Glassware: Add a touch of frightful flair to your drinkware. Laser etch spooky designs like ghosts, bats, or gravestones onto mason jars or glasses for a personalized touch to your Halloween table.

3. Boo-tiful Bat Brigade:

Flocking Bats: Laser cut a variety of bat shapes and sizes from black cardstock. String them together at different heights to create a hauntingly beautiful bat installation that flutters in the slightest breeze.

Batty Place Settings: Surprise your guests with personalized place settings. Laser cut bat silhouettes from black or orange cardstock and add a name or spooky message for a unique touch.

4. Bewitching Boxes and Bags:

Trick-or-Treat Treat Boxes: Ditch the store-bought treat bags and craft your own! Design and laser cut festive boxes from brightly colored cardstock. Personalize them with Halloween greetings or spooky silhouettes.

Frightful Favor Boxes: Laser cut small boxes from black or orange cardstock and fill them with Halloween candies or spooky trinkets. Decorate them with laser-cut spiderwebs, ghosts, or bats for an extra eerie touch.

5. Signs and Stencils That Spell Spooktacular

Door Signs that Dare: Welcome guests with a personalized door sign. Laser cut your name or a spooky message from wood, acrylic, or even painted MDF. Add a festive touch with cobweb or bat designs.

Spooktacular Stencils: Design and laser cut stencils with Halloween motifs like pumpkins, ghosts, or haunted houses. Use these stencils to paint spooky designs on walls, furniture, or even windows.

These are just a few ideas to spark your creativity. With a laser cutter and a willingness to experiment, the possibilities for hauntingly beautiful Halloween projects are endless. So, fire up your laser cutter, grab your favorite spooky design, and get ready to create a Halloween that will be remembered for years to come!

American Laser Cutter: Your Remote Laser Cutter and Engraver Diagnostic Expert

American Laser Cutter: Your Remote Laser Cutter and Engraver Diagnostic Expert

American Laser Cutter (ALC) is a pioneer in the field of remote diagnostics for laser cutters and engravers. Our advanced technology and experienced technicians enable us to provide expert support and troubleshooting services from anywhere in the United States.

The Benefits of Remote Diagnostics

Reduced Downtime: By addressing issues remotely, we can often resolve problems quickly, minimizing disruptions to your operations.Cost-Effective: Remote diagnostics can save you time and money by eliminating the need for on-site visits and potential travel expenses.Convenience: Our remote services allow you to access expert support from the comfort of your own facility.Proactive Maintenance: Regular remote monitoring can help identify potential issues before they escalate, preventing costly downtime.

Our Remote Diagnostic Process

1. Contact Us: Reach out to our customer support team to report the issue with your laser cutter or engraver.2. Remote Access: We will establish a secure remote connection to your machine.3. Diagnostics: Our technicians will use advanced diagnostic tools to analyze your equipment's performance and identify any problems.4. Troubleshooting: Based on the diagnostics, our technicians will provide troubleshooting steps or recommend specific repairs.5. Remote Updates: If necessary, we can remotely update your machine's software or firmware to address issues.

Common Issues We Can Address Remotely

Software Glitches: Our technicians can help you troubleshoot software issues, update firmware, and optimize your machine's settings.Hardware Malfunctions: We can diagnose problems with components such as lasers, lenses, and control systems.Connectivity Issues: We can troubleshoot network connectivity problems and ensure your machine is communicating effectively.Performance Optimization: Our experts can help you optimize your machine's performance for specific applications and materials.

Our Expertise and Technology

Our team of experienced technicians has a deep understanding of laser cutter and engraver technology. We utilize state-of-the-art remote diagnostic tools to accurately identify and resolve issues, even for complex problems.

Remote Diagnostics for OEM-Discontinued Equipment

If your laser cutter or engraver's original equipment manufacturer (OEM) has discontinued support, our remote diagnostic services can be invaluable. We have the expertise and resources to diagnose and repair a wide range of models, even if they are no longer supported by the original manufacturer.

Additional Support Services

In addition to remote diagnostics, ALC offers a range of other support services, including:

Preventive Maintenance: Regular maintenance can help prevent breakdowns and extend the life of your equipment.Spare Parts and Accessories: We offer a wide range of spare parts and accessories to keep your machine running smoothly.Training and Education: Our experts can provide training on machine operation, maintenance, and safety procedures.Custom Solutions: We can work with you to develop customized solutions tailored to your specific needs.

Why Choose ALC for Remote Diagnostics?

Expertise and Experience: Our technicians have years of experience working with various laser cutter and engraver models.Advanced Diagnostic Tools: We utilize state-of-the-art technology to accurately diagnose and resolve issues.Global Reach: Our services are available to customers worldwide, regardless of their location.Commitment to Customer Satisfaction: We are dedicated to providing exceptional customer service and ensuring the optimal performance of your equipment.

Contact Us

To schedule a remote diagnostic or learn more about our services, please contact our customer support team. We are committed to providing you with the highest level of support and ensuring the continued performance of your laser cutter or engraver.

American Laser Cutter: Your Trusted Partner for On-Site Laser Cutter Repair

American Laser Cutter: Your Trusted Partner for On-Site Laser Cutter Repair

American Laser Cutter (ALC) is dedicated to providing comprehensive laser cutter repair services to customers throughout the United States, including Southern California. Our team of experienced technicians is equipped with the latest tools and expertise to diagnose and repair a wide range of laser cutter issues, ensuring minimal downtime and optimal performance.

Why Choose ALC for On-Site Laser Cutter Repair?

Rapid Response: Our technicians are available to respond to your repair request promptly, minimizing downtime and disruptions to your operations.Experienced Technicians: Our team consists of highly skilled professionals with extensive experience in laser cutter repair and maintenance.Comprehensive Services: We offer a wide range of repair services, including component replacement, electrical troubleshooting, and software updates.Genuine Parts: We use only original manufacturer parts to ensure the highest quality repairs and maintain the integrity of your laser cutter.Preventive Maintenance: In addition to repairs, we offer preventive maintenance services to help prevent future breakdowns and extend the life of your equipment.

Our On-Site Repair Process

1. Contact Us: Reach out to our customer support team to report the issue with your laser cutter.2. Remote Diagnostics: In many cases, we can diagnose the problem remotely to save time and potentially avoid an on-site visit.3. On-Site Assessment: If necessary, one of our technicians will visit your location to conduct a thorough assessment of the issue.4. Repair and Maintenance: Our technicians will use their expertise to diagnose and repair the problem, ensuring that your laser cutter is restored to optimal working condition.5. Testing and Verification: After the repair is complete, we will test the laser cutter to ensure that it is functioning properly before leaving your facility.

Common Laser Cutter Repair Issues We Address

Mechanical Problems: Our technicians can diagnose and repair issues with mechanical components such as gears, motors, and bearings.Electrical Faults: We can troubleshoot electrical problems, including faulty wiring, circuit boards, and power supplies.Laser Tube Issues: We specialize in repairing and replacing laser tubes for various laser cutter models.Optical Alignment: Our technicians can ensure that the optical components of your laser cutter are properly aligned for optimal performance.Software Glitches: We can diagnose and resolve software issues, including programming errors and system crashes.

Preventive Maintenance Services

To help prevent breakdowns and extend the life of your laser cutter, we offer a range of preventive maintenance services, including:

Regular Inspections: Our technicians can conduct regular inspections to identify potential problems before they escalate.Cleaning and Lubrication: We can clean and lubricate critical components to ensure optimal performance.Software Updates: We can keep your laser cutter's software up-to-date with the latest patches and updates.Component Replacement: We can replace components that are nearing the end of their lifespan to prevent unexpected failures.

Why Choose ALC for Laser Cutter Repair in Southern California?

Local Expertise: Our team of technicians is based in Southern California, ensuring a rapid response time and a deep understanding of local regulations and requirements.Commitment to Customer Satisfaction: We are dedicated to providing exceptional customer service and ensuring that your laser cutter is repaired efficiently and effectively.Competitive Pricing: We offer competitive pricing for our on-site laser cutter repair services, without compromising on quality.

Contact Us

To schedule a laser cutter repair or learn more about our services, please contact our customer support team. We are committed to providing you with the highest level of service and ensuring the continued performance of your laser cutting equipment.

Laser Cutting Artists: Pioneers of Precision

Laser Cutting Artists: Pioneers of Precision

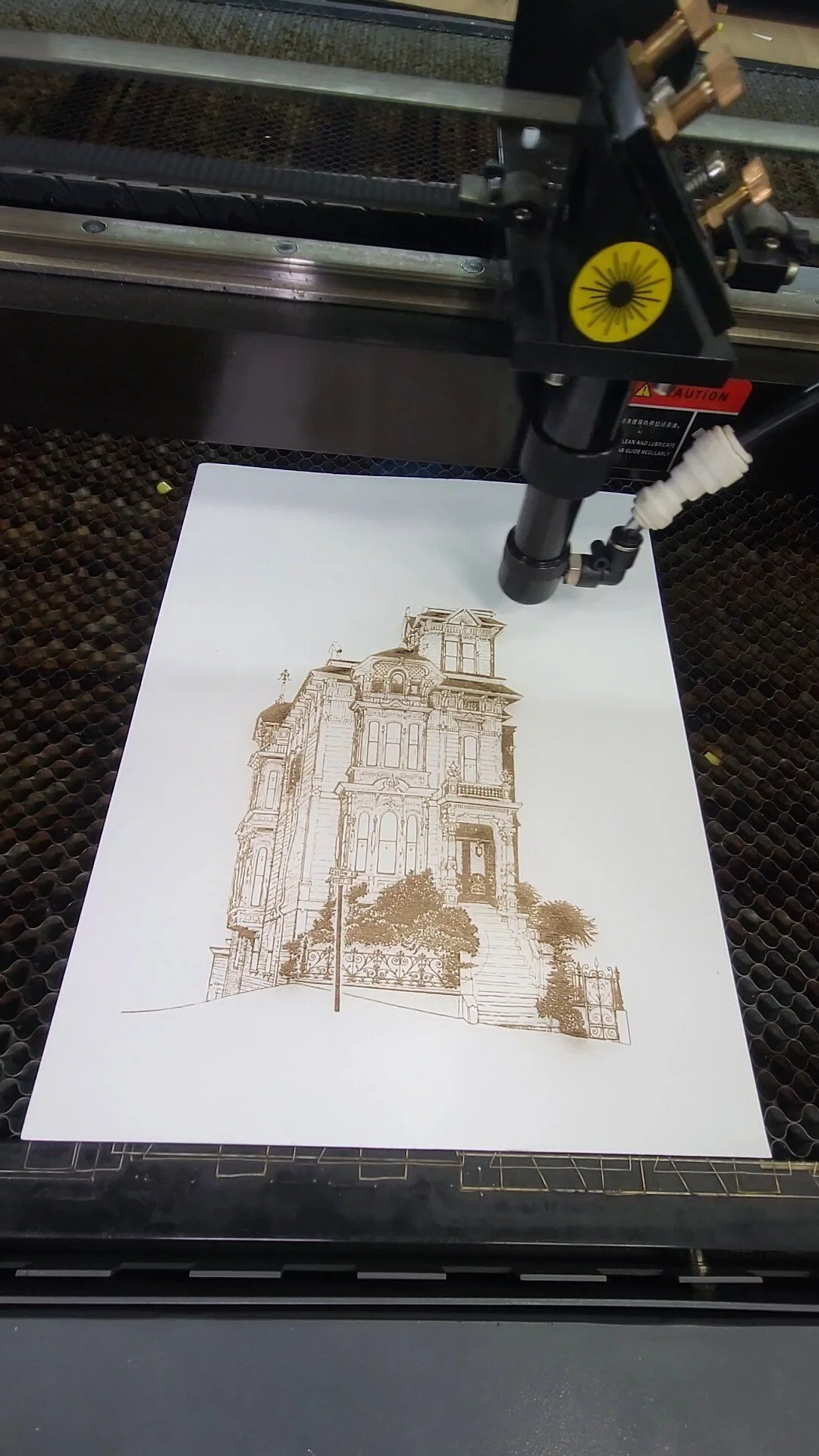

Laser cutting, once a tool for industrial manufacturing, has evolved into a powerful medium for artistic expression. Here are some of the leading artists pushing the boundaries of this innovative technique:

Anila Quayyum Agha: Known for her intricate geometric light installations, Agha uses laser-cut wood to create stunning, immersive spaces.Eric Standley: Standley's layered paper sculptures, inspired by religious art, are meticulously crafted using laser cutting technology.Sarah Pike: Pike combines traditional drawing techniques with laser cutting to create unique, sculptural pieces from various materials.Matt C. Ellis: Ellis's intricate, detailed laser-cut designs are often inspired by nature and mythology.

These artists, among many others, are demonstrating the versatility and potential of laser cutting as a tool for contemporary art.

How CO2 Laser Cutter Optics Work

How CO2 Laser Cutter Optics Work

A CO2 laser cutter is a complex system that relies on a series of optical components to deliver a focused beam of light capable of cutting and engraving materials.

The Laser Tube

The heart of the system, the laser tube, produces a beam of infrared light. This beam is typically quite large and divergent.

1. How Does A Laser Cutter Work? CO2 & Fiber Explained

The Collimator

The collimator is the first optical component that the beam encounters. Its job is to transform the divergent beam into a parallel beam, ensuring that the light rays travel in the same direction. This is crucial for maintaining focus at the cutting head.

1. Collimator | Optics, Light Measurement, Imaging - Britannica

Mirrors

A series of mirrors precisely direct the laser beam through the optical path. These mirrors are typically made of gold or silver to maximize reflectivity. The angles of these mirrors determine the path of the beam and the final position of the cutting head.

1. 1-5 How does laser cutting work? - FLUX Help Center

Focus Lens

The focus lens is the most critical component in the optical path. It concentrates the parallel beam into a tiny spot, creating the intense heat needed to cut or engrave materials. The focal length of the lens determines the size of the spot and the depth of focus.

Air Assist

While not strictly an optical component, air assist plays a crucial role in the cutting process. A jet of air is directed at the cutting point to remove molten material and prevent the formation of dross. This improves cut quality and extends the life of the focus lens.

1. Why Laser Air Assist is Essential for Laser Cutting

2. How Can Air Assist Improve Laser Cutting? — Monportlaser

The entire optical path is precisely aligned to ensure that the laser beam reaches the material with maximum intensity and focus. Any misalignment can result in poor cut quality, damage to the material, or even damage to the laser tube.

Opens in a new window dragondiamondcnc.en.made-in-china.com

CO2 laser cutter optics

Understanding how these components work together is essential for maintaining and troubleshooting a CO2 laser cutter. Regular cleaning and alignment of the optics are crucial for optimal performance.

Laser Cutting: The New Retail Revolution

Laser Cutting: The New Retail Revolution

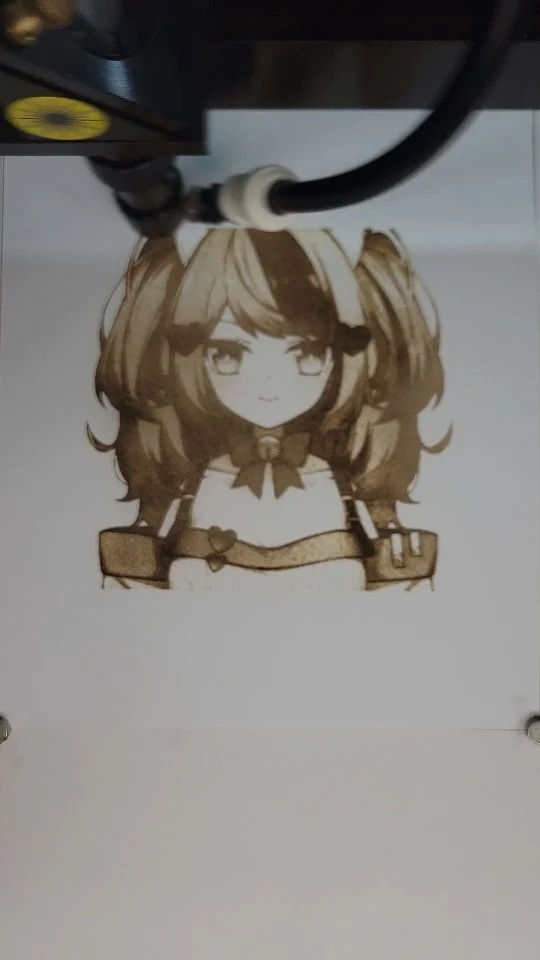

Laser cutting is no longer confined to industrial settings. It's making waves in retail, offering unique and personalized products that are capturing the attention of consumers. Let's explore some of the exciting ways businesses are incorporating laser cutting into their offerings.

Personalized Products on Demand

Custom Apparel: Laser cutting is being used to create intricate designs on t-shirts, hoodies, and jackets, offering a high level of customization.

Accessories: From keychains and phone cases to jewelry and eyewear, laser cutting enables mass customization with a personal touch.

Home Decor: Personalized wall art, clocks, and decorative items are becoming increasingly popular, thanks to laser cutting's ability to create intricate designs.

Unique Retail Experiences

In-Store Customization:

Some stores are offering on-the-spot laser cutting services for products like leather goods, wooden signs, or acrylic accessories.

Pop-Up Shops: Laser cutting can be used to create unique and eye-catching displays for pop-up shops.

Product Launches: Generate buzz around new product launches by incorporating laser-cut elements into promotional materials.

Challenges and Opportunities

Investment: Laser cutting equipment can be costly, but the potential return on investment is significant.

Skilled Labor: Hiring or training staff with laser cutting expertise is essential.

Material Selection: Choosing the right materials for laser cutting can impact product quality and cost.

Safety Regulations: Adhering to safety guidelines is crucial for protecting customers and employees.

Laser cutting is transforming the retail landscape by offering personalized, high-quality products. As technology continues to advance and become more accessible, we can expect to see even more innovative applications in the future.

The Maker Movement in 2024: Innovation, Education, and the Rise of the Prosumer

The Maker Movement in 2024: Innovation, Education, and the Rise of the Prosumer

The Maker Movement, once a fringe movement for hobbyists and tinkerers, has blossomed into a powerful force shaping the landscape of manufacturing, education, and entrepreneurship. In 2024, the movement continues to evolve, with a focus on empowering individuals, fostering innovation, and blurring the lines between hobbyists and professional creators.

From Passion Projects to Economic Engine:

A hallmark of the Maker Movement's growth is its impact on the economy. A study: [invalid URL removed] by Laura Wolf-Powers highlights the rise of "emerging place-based manufacturers" – small-scale makers who leverage laser cutters, 3D printers, and other digital fabrication tools to create innovative products. These makers contribute to local economies by creating jobs, stimulating supply chains, and fostering a culture of entrepreneurship.

Education Embraces the Maker Mindset:

The Maker Movement's emphasis on hands-on learning and problem-solving is resonating in educational institutions. Schools are increasingly incorporating maker spaces – workshops equipped with tools and technologies – to encourage creativity, critical thinking, and STEM skills development. This trend signifies a shift from rote learning to a more experiential approach to education, empowering students to become active participants in their learning journeys.

The Rise of the Prosumer:

The affordability and accessibility of digital fabrication tools have given rise to a new breed of creator: the prosumer. Prosumers are individuals who combine the characteristics of producers and consumers. They leverage technology to design, prototype, and even manufacture their own products, blurring the lines between hobbyists and professional makers. Online platforms like Etsy and Shopify allow prosumers to sell their creations directly to consumers, fostering a thriving marketplace for unique and innovative goods.

Challenges and the Road Ahead:

Despite its significant growth, the Maker Movement faces challenges. Ensuring equitable access to technology and maker spaces remains a concern. Additionally, safety training and fostering responsible use of potentially hazardous tools like laser cutters are crucial aspects to consider.

Looking ahead, the Maker Movement is poised for continued growth. As technologies like 3D printing and digital fabrication become even more affordable and user-friendly, we can expect to see a surge in innovation and entrepreneurship across various sectors. The movement's emphasis on collaboration, education, and empowering individuals to create will undoubtedly shape the future of manufacturing and design.

Proper Storage for Laser Cutting Materials

Proper Storage for Laser Cutting Materials

Proper storage of laser cutting materials is crucial for maintaining their quality and ensuring optimal performance when used. Here are some tips:

General Storage Guidelines

Cleanliness: Keep materials clean and free from dust, debris, or fingerprints.

Flat Storage: Store materials flat to prevent warping or bending.

Temperature and Humidity Control: Extreme temperature and humidity fluctuations can damage materials.

Protection from Light: Some materials, like acrylics, can degrade when exposed to prolonged sunlight.

1. Performance of Acrylic - Impact Solutions | PlastikCity News

Specific Material Storage

Wood: Store in a dry place to prevent warping. Consider using wood clamps or spacers for thicker pieces.

Acrylic: Protect from scratches and dust. Store flat or vertically to prevent warping.

Metal: Avoid contact with other metals to prevent corrosion. Store in a dry environment.

Paper and Cardstock: Keep in a cool, dry place away from direct sunlight.

Fabric: Store in a clean, dust-free environment. Avoid folding or creasing delicate fabrics.

Storage Solutions

Shelving: Use adjustable shelving to accommodate different material sizes.

Racks: Vertical racks can efficiently store sheets of material.

Storage Bins: Organize smaller pieces and scraps in labeled bins.

Vacuum-Sealed Bags: Protect sensitive materials from dust and moisture.

Additional Tips

Material Inventory: Keep track of your material stock to avoid running out of supplies.

Labeling: Clearly label materials with type, size, and date of purchase.

Regular Inspection: Check materials periodically for signs of damage or deterioration.

By following these guidelines, you can ensure that your laser cutting materials remain in optimal condition, ready for your next project.

RDWorks Learning Lab: Your One-Stop Shop for Mastering RDWorks Software

RDWorks Learning Lab: Your One-Stop Shop for Mastering RDWorks Software

The world of laser cutting unlocks incredible creative potential, but navigating the software that controls your laser cutter can feel like a hurdle. If you utilize a Ruida-controlled laser cutter, then RDWorks Learning Lab is an invaluable resource waiting to be explored https://rdworkslab.com/. This online haven, created by Russ Sadler, empowers you to conquer the intricacies of RDWorks software and elevate your laser cutting experience.

Understanding RDWorks and Its Importance

While your laser cutter is the workhorse, the RDWorks software acts as its brain. It allows you to import designs, configure cutting parameters, and ultimately control the laser cutting process. RDWorks specifically caters to Ruida control systems, ensuring optimal compatibility and functionality.

RDWorks Learning Lab: A Treasure Trove of Knowledge

Russ Sadler, the mastermind behind RDWorks Learning Lab, is a passionate laser enthusiast who shares his extensive knowledge through a comprehensive library of resources. Here's what you can expect to find on this treasure trove of laser cutting wisdom:

In-Depth Video Tutorials: The core of RDWorks Learning Lab lies in its exceptional video tutorials https://www.youtube.com/playlist?list=PLeKaKWOIPgi_XP6Nxzeapp-vUMCLQyVMB. These detailed walkthroughs cover a wide range of topics, from the fundamental aspects of importing files and setting basic parameters to advanced features like nesting and custom macros. Russ' clear explanations and engaging presentation style make even complex functionalities easy to understand.

RDWorksLab.com Website: Beyond the video tutorials, the RDWorksLab.com website offers additional resources https://rdworkslab.com/. Here you'll find downloadable resources, helpful articles, and a forum where you can connect with other RDWorks users and troubleshoot any challenges you encounter.

The "Concise RDWorks Learning Lab Menu": This downloadable PDF document acts as a roadmap, providing a categorized overview of all the video tutorials available https://laseruser.com/the-concise-rdworks-learning-lab-menu/. This allows you to quickly find the specific information you need, saving you valuable time searching through the video library.

The Benefits of Utilizing RDWorks Learning Lab

By immersing yourself in the resources offered by RDWorks Learning Lab, you'll reap a multitude of benefits:

Steeper Learning Curve: The clear and concise video tutorials make it easier to grasp the functionalities of RDWorks software, accelerating your learning curve and empowering you to start using your laser cutter effectively sooner.

Reduced Frustration: Having a comprehensive understanding of RDWorks features helps you avoid common pitfalls and troubleshoot any issues that may arise.

Unlocking Advanced Techniques: The tutorials delve into more advanced features of RDWorks, allowing you to explore new possibilities and push the boundaries of your laser cutting projects.

Building Confidence: As your proficiency with RDWorks software grows, so too will your confidence in operating your laser cutter. This newfound confidence allows you to tackle more complex projects and experiment with greater creativity.

Beyond RDWorks Learning Lab: Expanding Your Laser Cutting Knowledge

While RDWorks Learning Lab is an excellent resource for mastering RDWorks software, there's a whole world of laser cutting knowledge waiting to be explored. Here are some suggestions to complement your learning:

Online Forums and Communities: Engage with other laser cutting enthusiasts on online forums and communities to share experiences, ask questions, and discover new tips and tricks.

Laser Cutting YouTube Channels: Numerous YouTube channels cater to laser cutting enthusiasts, offering tutorials, project inspiration, and insights into various laser cutting techniques.

Books and Online Articles: Several books and online articles delve deeper into the science and art of laser cutting, providing valuable knowledge applicable to any laser cutter software.

With RDWorks Learning Lab as your guiding light and a willingness to explore further, you'll be well on your way to becoming a laser cutting master. So, fire up your RDWorks software, delve into the tutorials, and prepare to unleash the incredible creative potential of your laser cutter!

DSP Controllers: A Superior Choice for Laser Cutting

DSP Controllers: A Superior Choice for Laser Cutting

When it comes to laser cutting, the choice of controller can significantly impact the precision, speed, and overall performance of your machine. While G-code controllers have been the traditional standard, DSP (Digital Signal Processor) controllers are rapidly gaining popularity due to their numerous advantages.

Key Benefits of DSP Controllers:

Enhanced Precision and Accuracy: DSP controllers offer superior precision and accuracy compared to G-code controllers. Their dedicated hardware and specialized algorithms allow for finer control over laser power modulation, resulting in cleaner cuts and more detailed engravings.

Faster Processing Speeds: DSP controllers are designed to handle complex calculations and data processing at much higher speeds than G-code controllers. This translates to faster engraving and cutting times, increasing productivity.

Advanced Features: DSP controllers often come with built-in features like automatic focus adjustment, rotary axis support, and power ramping, which can significantly enhance the capabilities of your laser cutter.

Seamless Integration: DSP controllers are designed to work seamlessly with popular laser cutting software, making it easier to control and operate your machine.

Improved Reliability: DSP controllers are generally more reliable and less prone to errors compared to G-code controllers, leading to fewer downtime and maintenance issues.

In Conclusion:

While G-code controllers have been the standard for many years, DSP controllers offer a clear advantage in terms of precision, speed, features, and reliability. If you're looking to maximize the potential of your laser cutter and achieve the highest quality results, investing in a DSP controller is a worthwhile consideration.

Top 10 Laser-Cut Back-to-School Projects

Top 10 Laser-Cut Back-to-School Projects

Laser cutting technology offers a unique and creative way to personalize your back-to-school essentials. Here are 10 exciting project ideas to get you inspired:

1. Custom Laptop Decals: Add a personal touch to your laptop with laser-cut decals. Choose your favorite design, pattern, or quote and create a one-of-a-kind accessory.

2. Personalized Phone Cases: Protect your phone in style with a custom laser-cut phone case. You can incorporate your name, initials, or a favorite design for a unique and stylish look.

3. Decorative Notebooks: Elevate your note-taking experience with a custom laser-cut notebook cover. Add intricate patterns, quotes, or your name for a personalized touch.

4. Bookmark Holders: Keep your place in your favorite books with a stylish laser-cut bookmark holder. You can choose from a variety of designs or create your own.

5. Pen Holders: Organize your desk with a custom laser-cut pen holder. Add your name, initials, or a favorite quote for a personalized touch.

6. Name Tags: Make a statement with custom laser-cut name tags for your school supplies or backpack. Choose from a variety of materials and designs to create a unique and stylish accessory.

7. Keychain Charms: Add a touch of personality to your keys with custom laser-cut charms. You can create charms featuring your favorite characters, symbols, or quotes.

8. Desk Organizer: Keep your workspace tidy with a custom laser-cut desk organizer. You can design compartments for pens, pencils, scissors, and other essentials.

9. Laptop Sleeves: Protect your laptop in style with a custom laser-cut laptop sleeve. Choose from a variety of materials and designs to create a unique and functional accessory.

10. Tote Bags: Carry your books and supplies in a personalized laser-cut tote bag. You can add your name, initials, or a favorite design for a stylish and functional accessory.

These are just a few examples of the endless possibilities that laser cutting offers for back-to-school projects. With a little creativity and imagination, you can create unique and personalized items that will make your school year unforgettable.

American Laser Cutter: Your Public Access to Precision and Innovation

American Laser Cutter: Your Public Access to Precision and Innovation

American Laser Cutter is proud to be a public access laser cutting facility, offering our state-of-the-art equipment and expertise to individuals and businesses alike. Whether you're a hobbyist, entrepreneur, or student, our facility provides a welcoming and collaborative environment for all your laser cutting needs.

Why Choose American Laser Cutter?

Accessibility: Our facility is open to the public, providing affordable access to laser cutting technology for everyone.

State-of-the-Art Equipment: We have a range of high-quality laser cutters, including a powerful 100-watt machine with a spacious 4'x5' bed.

Expert Guidance: Our experienced staff is available to assist you with your projects and provide guidance on laser cutting techniques.

Creative Community: Connect with other makers and designers at our facility and collaborate on exciting projects.

Affordable Rates: Our pricing is competitive, making laser cutting accessible to a wide range of individuals and businesses.

Our Services:

DIY Laser Cutting: Unleash your creativity and bring your ideas to life with our DIY laser cutting options.

Professional Laser Cutting: Our experienced technicians can handle your projects from start to finish, ensuring precision and quality.

Training and Workshops: Learn the basics of laser cutting or enhance your skills with our training programs.

Material Cutting: We can cut a wide range of materials, including wood, acrylic, metal, fabric, and more.

Visit Us Today!

Come experience the power of laser cutting at American Laser Cutter.

Adam Savage: A Laser Cutter Enthusiast Unleashing Creativity

Adam Savage: A Laser Cutter Enthusiast Unleashing Creativity

Adam Savage, the beloved co-host of the Mythbusters television show and a renowned maker himself, is a big proponent of laser cutting https://m.youtube.com/watch?v=m9lFcduaZPU. His background in special effects for Industrial Light & Magic (ILM) heavily relied on this versatile technology, and his passion for it continues to this day.

Early Days and the "Laser Boy" Nickname

During his time at ILM, Adam extensively used laser cutters for model making https://www.youtube.com/watch?v=0eGiQzf6nac. The efficiency and precision offered by laser cutters made them an invaluable tool for crafting intricate details and components essential for movie props and special effects. His colleagues even bestowed upon him the playful nickname "Laser Boy" due to his frequent use of this technology.

Rekindling the Flame: Bringing Laser Cutting Back to the Workshop

After leaving ILM, Adam lacked access to a laser cutter for quite some time. However, his desire to experiment and create with this tool never faded. In a YouTube video titled "Inside Adam Savage's Cave: The New Laser Cutter!", he finally unveils his acquisition (or perhaps more accurately, loan) of a laser cutter for his workshop https://www.youtube.com/watch?v=0eGiQzf6nac. The excitement and nostalgia are evident in the video as Adam dives into the process of setting up the machine and rediscovering its capabilities.

Laser Cutting: A Perfect Fit for Adam's Creative Process

So, what makes laser cutting such a perfect fit for Adam Savage? Several factors contribute to his enthusiasm for this technology:

Precision and Control: Laser cutting allows for incredibly precise cuts, enabling Adam to create intricate details and complex shapes with unmatched accuracy.

Versatility: A wide range of materials can be laser cut, from wood and acrylic to cardboard and even some fabrics. This opens doors to a vast array of creative possibilities.

Efficiency: Laser cutting streamlines the process of creating multiple identical pieces, saving time and effort compared to traditional crafting methods.

Exploration and Experimentation: Adam's love for tinkering and exploring new techniques makes laser cutting a perfect tool. He can experiment with different materials, settings, and designs to bring his creative visions to life.

Laser Cutting: A Tool for Makers of All Levels

While Adam Savage utilizes laser cutting for complex projects, this technology is not limited to experienced makers. The growing accessibility of desktop laser cutters and user-friendly software makes it a valuable tool for anyone interested in crafting, prototyping, or personalizing everyday objects.

If you're looking for inspiration and want to see Adam Savage in action with his laser cutter, be sure to check out the aforementioned YouTube videos. His enthusiasm for this technology is contagious, and you might just discover your own inner "Laser Boy" or "Laser Girl" waiting to unleash their creativity.

Laser Cutting for Students: A Hands-On Learning Experience

Laser Cutting for Students: A Hands-On Learning Experience

Are you a student looking to enhance your projects with laser-cut precision? Renting a laser cutter can be a valuable tool for students in various fields, from design and engineering to art and architecture.

Benefits of Renting a Laser Cutter for Students:

Hands-On Learning: Renting a laser cutter provides a practical and hands-on way to learn about laser cutting technology. You can experiment with different materials, techniques, and designs to develop your skills.

Project Enhancement: Laser cutting can add a professional and polished touch to your student projects, making them stand out from the crowd.

Career Development: Proficiency in laser cutting technology can be a valuable asset on your resume and open doors to future career opportunities.

Creativity Unleashed: Laser cutters allow you to bring your creative ideas to life, exploring new design possibilities and pushing the boundaries of your imagination.

How to Rent a Laser Cutter as a Student:

Research Rental Options: Look for laser cutter rental companies or makerspaces in your area. Many of these facilities offer student discounts or special rates.

Consider Your Project Needs: Determine the type of laser cutter and materials you'll need for your projects.

Safety Training: Ensure you receive proper training on laser cutter safety and operation to prevent accidents.

Budgeting: Set a budget for your laser cutter rental to avoid unexpected costs.

Plan Ahead: Book your rental in advance, especially during peak times.

Tips for Students Using Laser Cutters:

Start Small: Begin with simpler projects to familiarize yourself with the laser cutter and its capabilities.

Experiment with Materials: Explore different materials to discover their unique properties and how they interact with the laser.

Design Carefully: Create detailed and accurate designs using design software to ensure precise cuts.

Safety First: Always follow safety guidelines and wear appropriate personal protective equipment (PPE).

Seek Guidance: Don't hesitate to ask for help from experienced users or facility staff if you encounter any difficulties.

Conclusion:

Renting a laser cutter can be a valuable experience for students looking to enhance their projects, develop new skills, and explore their creativity. By following these tips and taking advantage of the opportunities offered by laser cutting technology, you can take your student work to the next level.

Test the Waters: Renting a Laser Cutter to See If It's Right for You

Test the Waters: Renting a Laser Cutter to See If It's Right for You

Considering investing in a laser cutter but unsure if it's the right fit? Renting a laser cutter is an excellent way to explore its capabilities and determine if it aligns with your needs and goals. Here's why renting is a smart move:

1. Flexibility and No Commitment: Renting a laser cutter offers the freedom to try it out without the long-term commitment of purchasing one. This is ideal for those who are new to laser cutting or unsure about the frequency of their usage.

2. Access to Advanced Technology: Laser cutter rental companies often have the latest models, providing you with access to cutting-edge features and capabilities.

3. Cost-Effective Solution: Renting can be more economical than purchasing, especially for occasional or short-term use. It allows you to spread out the costs and avoid the overhead of owning your own machine.

4. Expert Support: Many rental companies offer technical support to assist you throughout your rental period, ensuring you get the most out of the laser cutter.

5. Explore Different Applications: Renting a laser cutter gives you the opportunity to experiment with various materials and projects to see what you can achieve.

6. Assess Your Workflow: Determine if laser cutting aligns with your workflow and production needs. Evaluate the efficiency and precision it brings to your projects.

7. Evaluate Return on Investment: If you're considering purchasing a laser cutter, renting one first can help you assess the potential return on investment.

Steps to Rent a Laser Cutter:

Research Rental Companies: Look for reputable laser cutter rental companies in your area.

Inquire About Options: Contact the companies to inquire about their available laser cutters, rental terms, and pricing.

Schedule a Rental: Once you've selected a suitable laser cutter, schedule your rental period.

Familiarize Yourself with the Machine: Take time to learn how to operate the laser cutter safely and effectively.

Start Experimenting: Use the rental period to explore different materials, projects, and techniques.

Conclusion:

Renting a laser cutter is a great way to test the waters and see if it's the right tool for your needs. By following these steps and taking advantage of the benefits it offers, you can make an informed decision about whether to invest in your own laser cutter.

Start Your Business with a Laser Cutter: A Guide to Renting at a Professional Facility

Start Your Business with a Laser Cutter: A Guide to Renting at a Professional Facility

Laser cutting technology has opened up new avenues for entrepreneurs and small businesses. If you're considering starting a business that involves precision cutting, renting a laser cutter at a professional facility can be a smart and cost-effective option.

Why Rent a Laser Cutter?

Flexibility and Scalability: Renting a laser cutter allows you to start your business without the significant upfront investment of purchasing your own equipment. As your business grows, you can adjust your rental needs accordingly.

Access to Advanced Technology: Professional facilities often have state-of-the-art laser cutters, providing you with access to the latest technology and capabilities.

Expert Support: Many facilities offer technical support and training to help you get the most out of the laser cutter and ensure your projects are successful.

Reduced Overhead: Renting a laser cutter eliminates the need for maintenance, insurance, and storage costs associated with owning your own equipment.

How to Get Started:

Research Facilities: Look for reputable laser cutting facilities in your area. Consider factors such as location, equipment availability, rental rates, and customer reviews.

Contact the Facility: Reach out to the facility to inquire about their rental options, pricing, and any required training or certifications.

Discuss Your Project: Explain your business idea and the types of materials you'll be working with. The facility can advise you on the best laser cutter for your needs.

Sign a Rental Agreement: Once you've agreed on the terms, sign a rental agreement outlining the rental period, fees, and any additional conditions.

Tips for Success:

Start Small: Begin with smaller projects to familiarize yourself with the laser cutting process and build your skills.

Network with Other Makers: Connect with other entrepreneurs and makers who use laser cutting to learn from their experiences and collaborate on projects.

Focus on Your Niche: Identify your target market and specialize in a particular area, such as custom signage, jewelry, or home decor.

Promote Your Business: Utilize social media, online marketplaces, and local events to promote your products and services.

Conclusion:

Renting a laser cutter at a professional facility can be a great way to start your own business and explore the possibilities of laser cutting technology. By following these steps and leveraging the resources available, you can turn your entrepreneurial dreams into a reality.

Forum coming soon

LASER CUTTING RESOURCES

This website is fantastic to pick up parts for your laser cutter.

This is a fantastic replacement software for laser cutters

https://lightburnsoftware.com/

This is a link to RdWorks software

https://www.ruidacontroller.com/download/

rescue files for RDworks and lightburn (still adding files)